Professional Documents

Culture Documents

Araldite Industrial Adhesive

Araldite Industrial Adhesive

Uploaded by

SatyamEngCopyright:

Available Formats

You might also like

- Improvised Munitions Handbook – Learn How to Make Explosive Devices & Weapons from Scratch (Warfare Skills Series): Illustrated & With Clear InstructionsFrom EverandImprovised Munitions Handbook – Learn How to Make Explosive Devices & Weapons from Scratch (Warfare Skills Series): Illustrated & With Clear InstructionsRating: 3.5 out of 5 stars3.5/5 (7)

- SK Fert F50ag-MsdsDocument6 pagesSK Fert F50ag-MsdsEmadNo ratings yet

- Loctite 594 1998Document5 pagesLoctite 594 1998Boss_enqNo ratings yet

- Araldite Epoxy Adhesive - 2Document4 pagesAraldite Epoxy Adhesive - 2SatyamEngNo ratings yet

- Araldite 2022Document6 pagesAraldite 20228612106535No ratings yet

- Araldite 2011Document2 pagesAraldite 2011nrd9771No ratings yet

- Ara 2012Document5 pagesAra 2012pavan_03No ratings yet

- Antox 71e Extra - GBDocument2 pagesAntox 71e Extra - GBmaatouguiabdelkader04No ratings yet

- LY556 Ar5021 XB3403 XB3471 EDocument6 pagesLY556 Ar5021 XB3403 XB3471 EJoão Korrodi SottomayorNo ratings yet

- 4090 F0931 MSDSDocument9 pages4090 F0931 MSDStoxicity230% (1)

- Araldite 2010Document6 pagesAraldite 2010nrd9771No ratings yet

- HU Araldite Standard Eur eDocument3 pagesHU Araldite Standard Eur eMauro S CabralNo ratings yet

- Araldite Standard-Data SheetDocument3 pagesAraldite Standard-Data SheetSuperCow FelizNo ratings yet

- Araldite Ly564 Aradur 2954.PDF ResinDocument5 pagesAraldite Ly564 Aradur 2954.PDF ResinAbdul Hakim Abdullah100% (1)

- Araldite Kit K134: Araldite Kit K134 Part A 100 PBW Araldite Kit K134 Part B 40 PBWDocument5 pagesAraldite Kit K134: Araldite Kit K134 Part A 100 PBW Araldite Kit K134 Part B 40 PBWVaibhav GuptaNo ratings yet

- PD - TemperKote 850 PrimerDocument2 pagesPD - TemperKote 850 PrimerJosé MoránNo ratings yet

- 71E Plus - GBDocument2 pages71E Plus - GBMahmoud TahaNo ratings yet

- MSDS AAC Hebel Blocks - 2002Document4 pagesMSDS AAC Hebel Blocks - 2002aditarian .pNo ratings yet

- Wattyl Colourthane Thinner Standard 6100-99 MSDS May13Document12 pagesWattyl Colourthane Thinner Standard 6100-99 MSDS May13Dil VasconcelosNo ratings yet

- 71EPDocument2 pages71EPYevhen OkhremchukNo ratings yet

- Antox 71 E Pickling Paste PDFDocument2 pagesAntox 71 E Pickling Paste PDFasaasd100% (1)

- Auer Stekla Borosilicate PDFDocument8 pagesAuer Stekla Borosilicate PDFrisbo12No ratings yet

- FDA 13007 (DALIC Selective Plating)Document6 pagesFDA 13007 (DALIC Selective Plating)Ugodilinwa Nnaemeka La SonNo ratings yet

- TDS - Uvitex® MSV LiqDocument6 pagesTDS - Uvitex® MSV LiqAlie ChirNo ratings yet

- 006B Product Data Sheet ESAB Stain Clean Picking Paste Sunday, Nov 22, 2020Document2 pages006B Product Data Sheet ESAB Stain Clean Picking Paste Sunday, Nov 22, 2020Habib RehmanNo ratings yet

- Perkenalan Produk Solvet BaseDocument10 pagesPerkenalan Produk Solvet BaseRenold DarmasyahNo ratings yet

- Gasket RTV Silicone 310 ML: Applications BenefitsDocument4 pagesGasket RTV Silicone 310 ML: Applications BenefitsNurcan BozkurtNo ratings yet

- Polysulphide Sealant Technical Data.Document2 pagesPolysulphide Sealant Technical Data.stuart3962No ratings yet

- Material Safety Data Sheets: Rev.: 00 TSD/F/020 REV. 00 1. Manufacturer and Product InformationDocument5 pagesMaterial Safety Data Sheets: Rev.: 00 TSD/F/020 REV. 00 1. Manufacturer and Product InformationmartinacaisarferanandaNo ratings yet

- Material Safety Data Sheets: Rev.: 00 TSD/F/020 REV. 00Document5 pagesMaterial Safety Data Sheets: Rev.: 00 TSD/F/020 REV. 00martinacaisarferanandaNo ratings yet

- DEGASSING AGENT AF 100 - Ind1 - AngDocument1 pageDEGASSING AGENT AF 100 - Ind1 - AngFrench Corvette50% (2)

- Magnum 960 301-01438Document2 pagesMagnum 960 301-01438Yen Sebastian SantosNo ratings yet

- Solvalitt TDSDocument4 pagesSolvalitt TDSphillipskincaidNo ratings yet

- Instruction Manual Advanced Series: HotplatesDocument80 pagesInstruction Manual Advanced Series: HotplatesDaniel ZhunioNo ratings yet

- Care, Maintenance, and Testing OF Hot Line ToolsDocument20 pagesCare, Maintenance, and Testing OF Hot Line ToolsjosefmarqNo ratings yet

- Red Oxide PrimerDocument2 pagesRed Oxide Primermarsha.fsdNo ratings yet

- Paint SpecDocument2 pagesPaint Specjoydeep24088563No ratings yet

- Safe Use Instructions of Roving: Product IdentificationDocument10 pagesSafe Use Instructions of Roving: Product IdentificationAberth Ruben Jacinto CastilloNo ratings yet

- Allplastics - Samsung Staron Technical Data SheetDocument5 pagesAllplastics - Samsung Staron Technical Data Sheetanilbandi493No ratings yet

- SipxDocument5 pagesSipxIngenieria SuministroNo ratings yet

- S Weld CleanDocument3 pagesS Weld CleanRanjan AnchanNo ratings yet

- Jushi-Glass Fiber-MSDSDocument9 pagesJushi-Glass Fiber-MSDSTarek BenNo ratings yet

- Dow 3504Document2 pagesDow 3504khantoNo ratings yet

- Cold Mounting Brochure enDocument6 pagesCold Mounting Brochure enJames Harold Quiroz OjedaNo ratings yet

- S 54 D 59 U 000Document2 pagesS 54 D 59 U 000Joshua RomanNo ratings yet

- Nitoseal 130Document2 pagesNitoseal 130Venkata RaoNo ratings yet

- Manual de Operaciones PS-100200Document49 pagesManual de Operaciones PS-100200nairNo ratings yet

- Msds Rept LabsaDocument5 pagesMsds Rept Labsaamiller1987No ratings yet

- Imp MaterialsDocument37 pagesImp MaterialsPradeep SamuelNo ratings yet

- Penguard HBDocument4 pagesPenguard HBhedisanjayaNo ratings yet

- 54m-Line Dulux Weathershield Matt-Aus GHSDocument6 pages54m-Line Dulux Weathershield Matt-Aus GHSHồng PhongNo ratings yet

- Care Maintenance BookDocument18 pagesCare Maintenance BookFelipe FlorezNo ratings yet

- Denso Protal 7900HTDocument2 pagesDenso Protal 7900HTalbertojanetaNo ratings yet

- Acryl 60: Water-Based Acrylic Bonding and Modifying AdmixtureDocument4 pagesAcryl 60: Water-Based Acrylic Bonding and Modifying AdmixtureOgbedande Awo OrunmilaNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Stainless Steel Grade Comparision System Diagram of Stainless Steel - Corrosion &heat Resistance Strength, Machinability WiseDocument1 pageStainless Steel Grade Comparision System Diagram of Stainless Steel - Corrosion &heat Resistance Strength, Machinability WiseSatyamEngNo ratings yet

- Parker O-Ring Material Guide-2008Document72 pagesParker O-Ring Material Guide-2008Ian Pillay50% (2)

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNo ratings yet

- Equivalencia de MaterialesDocument1 pageEquivalencia de MaterialesHelden Jasmani100% (1)

- Fittech Brochure Companion Flanges and FittingsDocument16 pagesFittech Brochure Companion Flanges and FittingsSatyamEngNo ratings yet

- Asco Direct Acting Solenoid Valve - 320Document6 pagesAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Hindstan Nylons - Ptfe CatalogueDocument11 pagesHindstan Nylons - Ptfe CatalogueSatyamEngNo ratings yet

- Weartech Electrode Stellite Cobalt NickleDocument1 pageWeartech Electrode Stellite Cobalt NickleSatyamEngNo ratings yet

- MechIndia Burnishing ToolsDocument4 pagesMechIndia Burnishing ToolsSatyamEngNo ratings yet

- Surface Roughness Tester Page 1Document1 pageSurface Roughness Tester Page 1SatyamEngNo ratings yet

- Equivalent Materials GradeDocument2 pagesEquivalent Materials GradeSatyamEng80% (5)

- Material Conversion TableDocument5 pagesMaterial Conversion TableMilin DesaiNo ratings yet

- ENERPAC 00682GB - LPwrenchDocument4 pagesENERPAC 00682GB - LPwrenchSatyamEngNo ratings yet

- GEE ElectrodeDocument17 pagesGEE ElectrodeSatyamEngNo ratings yet

- Enerpac NC E324Document1 pageEnerpac NC E324SatyamEngNo ratings yet

- TorcupDocument4 pagesTorcupSatyamEngNo ratings yet

- International Industrial SpringsDocument6 pagesInternational Industrial SpringsSatyamEngNo ratings yet

- Araldite Industrial AdhesiveDocument6 pagesAraldite Industrial AdhesiveSatyamEngNo ratings yet

- Araldite Epoxy Adhesive - 2Document4 pagesAraldite Epoxy Adhesive - 2SatyamEngNo ratings yet

- BAJAJ Industrial LightsDocument5 pagesBAJAJ Industrial LightsSatyamEngNo ratings yet

Araldite Industrial Adhesive

Araldite Industrial Adhesive

Uploaded by

SatyamEngCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Araldite Industrial Adhesive

Araldite Industrial Adhesive

Uploaded by

SatyamEngCopyright:

Available Formats

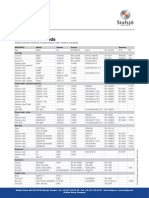

Araldite

Industrial Range

Product

Araldite 2000 designation

AW 2104/HW 2934

Araldite 2012

Features

Fast cure

Usable life < 20 minutes at 23C

Liquid general purpose

XD 4463/XD 4369

Liquid high peel strength

Araldite 2010

XD 4443/XD 4444

AW 2101/HW 2951

Thixotropic gap filling

XD 4662 A/B

Araldite 2022

XD 4664 A/B

Thixotropic gap filling very fast setting

XD 4661 A/B

Araldite 2021

XD 4490/XD 4491

Highly thixotropic gap filling

XD 4497/XB 5304

Putty

AV/HV 1580

Liquid easily spread

XB 5090-1/XB 5304

AY 105-1/HY 991

Liquid

Medium reactivity

Usable life 30-90 minutes at 23C

XB 5047/XB 5067

AW 136H/XB 5067

Liquid viscous

Araldite 2018

XD 4445/XD 4446

AW 136H/HY 991

Lightly thixotropic

AV 144-2/HY 4076

Easily spread paste

AV 121N/HY 991

Medium thixotropic

AW 136H/HV 997

AV 138M/HV 998

Thixotropic

AW 139/XB 5323

Araldite 2014

Thixotropic resilient

AV 144-2/HV 997

Araldite 2013

Thixotropic toughened

AV 4076-1/HY 4076

Highly thixotropic

XD 4510/XD 4511

Highly thixotropic toughened

AV 5308/HV 5309-1

Araldite 2015

Long usable life

90 minutes at 23C

AY 103/HY 991

Liquid easily spread low viscosity

XD 4467/XB 5304

Liquid general purpose

AW 106/HV 953U

Liquid easily spread medium viscosity

XD 4495/XB 5304

Araldite 2011

XB 5032 A/ XB 5319

Highly thixotropic

XD 4525/XD 4526

One

component

heat curing

XD 4436-1/XB 5304

Powder

AT 1-1

Liquid toughened

AV 118

Thixotropic toughened

AV 119

Thixotropic very high impact resistance

AV 4600

Heat resistance (Tg)

60C

80C

110C

Typical lap shear strength

at 23C

Typical usable life

100gms at 23C

Typical curing time at 23C

to handing strength*

Typical curing time at 23C

for near to full cure

(minutes)

*1 N/mm2 (minutes)

(hours)

(sandblasted aluminium )

(N/mm2)

ca. 30 (0-0,5mm)

20

48

19

100:76 (100:100)

ca. 65 (0-0,5mm)

20

35

48

26

100:100 (100:100)

ca. 80 (0-2mm)

30

48

23

100:100 (100:100)

Thixotropic (0-4mm)

25

48

20

100:94 (100:100)

ca. 60 (0-4mm)

10

20

12

23

100:12,5 (100:10)

ca. 150 (0-4mm)

15

12

12

100:90 (100:100)

ca. 45 (0-4mm)

12

22

100:104 (100:100)

Thixotropic (0-10mm)

100

48

13

100:40 (100:45)

Thixotropic (0-15mm)

80

24

20

100:100 (100:100)

Putty (1-20mm)

15

60

48

100:20 (100:25)

ca. 7 (0-0,4mm)

90

300

72

23

100:50 (100:60)

ca. 15 (0-0,4mm)

60

500

72

12

100:30 (100:45)

ca. 12 (0-0,4mm)

70

500

1h at 60C

22

100:29 (100:38)

ca. 15 (0-1mm)

90

300

48 (1h at 80C)

17

100:95 (100:100)

ca. 8 (0-2mm)

40

240

72

100:35 (100:45)

ca. 25 (0-0,5mm)

65

300

72

15

100:28 (100:40)

Thixotropic (0-2mm)

80

360

72

22

100:25 (100:40)

Thixotropic (0-2mm)

60

300

72

14

100:60 (100:80)

Thixotropic (0-3mm)

60

300

72

18

100:40 (100:40)

Thixotropic (0-3mm)

35

240

48

14

100:50 (100:50)

Thixotropic (0-4mm)

40

230

48

19

100:60 (100:100)

Thixotropic (0-4mm)

65

240

48

18

100:44 (100:50)

Thixotropic (0-4mm)

60

300

72

28

100:50 (100:50)

Thixotropic (0-6mm)

90

15 at 60C

2 at 100C

17

100:100 (100:100)

Thixotropic (0-10mm)

40

240

48

18

100:40 (100:50)

ca. 3 (0-0,3mm)

90

900

150

14

100:20 (100:26)

ca. 2 (0-0,4mm)

120

240

72

100:80 (100:100)

ca. 35 (0-1mm)

120

420

100

27

100:25 (100:30)

ca. 10 (0-1mm)

90

265

72

20

100:55 (100:70)

Thixotropic (0-6mm)

120

300

72

22

100:45 (100:50)

Thixotropic (0-10mm)

120

300

72

16

100:20 (100:27)

Thixotropic (0-25mm)

90

300

72

14

Solid (0-0.5mm)

2 years (shelf life)

Minimum 120C

1 at 180C

33

ca. 100 (0-0.5mm)

6 months (shelf life)

Minimum 110C

1/2 at 150C

30

Thixotropic (0-4mm)

6 months (shelf life)

Minimum 110C

1/2 at 150C

30

Thixotropic (0-3mm)

6 months (shelf life)

Minimum 160C

1/2 at 175C

25

Mix ratio by weight

(volume)

Product viscosity Pas

(gap filling capacity)

100:100 (100:100)

Typical peel strength

at 23C

(chromated aluminium)

(N/mm)

Typical Tg value/max.

temperature giving

LSS of 5N/mm2

Flexibility/toughness

Chemical

resistance

Water/humidity

resistance

Apperance of resin/hardener (mixed)

Data sheet ref No.

5.5

40/80

Rigid

Good

Good

Translucent/yellow (yellow)

A231

45/60

Rigid

Good

Good

Beige/brown (beige)

A411

7.8

40/80

Impact resistant

Good

Good

Translucent/yellow (yellow)

A279

4.5

45/80

Rigid

Good

Good

White/grey (grey)

A312

45/100

Impact resistant

Limited

Limited

Translucent/yellow (yellow)

A298

20/80

Impact resistant

Limited

Good

Yellow/white (yellow)

A300

11

65/110

Impact resistant

Good

Good

Translucent/yellow (yellow)

A297

2.4

55/80

Rigid

Excellent

Excellent

White/black (grey)

A412

3.3

50/80

Rigid

Good

Good

Beige/brown (beige)

A413

65/90

Rigid

Good

Good

Yellow/blue (green)

A54

3.4

30/70

Flexible

Limited

Limited

Beige/brown (beige)

A286

100/130

Rigid

Excellent

Excellent

Translucent/brown (brown)

A123

100/120

Rigid

Excellent

Excellent

White/brown (blanc)

A291

80/120

Rigid

Excellent

Excellent

Grey/brown (grey)

A414

0 (flexible)/40

Flexible

Limited

Limited

Opaque/opaque (opaque)

A280

80/100

Rigid

Excellent

Excellent

Grey/brown (grey)

A186

45/100

Impact resistant

Good

Good

Grey/brown (grey)

A294

55/90

Rigid

Good

Good

Black/brown (black)

A49

60/80

Rigid

Good

Excellent

Grey/beige (grey)

A315

95/140

Rigid

Excellent

Excellent

Beige/grey (grey)

A63

85/140

Rigid

Excellent

Excellent

Beige/grey (grey)

A233

45/70

Rigid

Good

Good

Grey/beige (grey)

A232

7.5

55/70

Impact resistant

Limited

Good

Opaque/opaque (opaque)

A72

1.5

130/180

Rigid

Excellent

Excellent

White/black (grey)

A393

4.5

65/100

Impact resistant

Good

Good

Beige/beige (beige)

A234

<1

55/80

Rigid

Good

Excellent

Brown/transparent (brown)

A281

10 (flexible)/50

Flexible

Limited

Good

Beige/ brown (brown)

A305

45/80

Rigid

Good

Good

Yellow/translucent (yellow)

A230

40/60

Rigid

Good

Good

Beige/brown (brown)

A404

2.2

58/85

Rigid

Good

Good

Yellow/red (brown)

A415

80/125

Rigid

Excellent

Excellent

White/grey (grey)

A416

20/50

Impact resistant

Limited

Good

Beige/brown (brown)

A273

100/130

Rigid

Excellent

Good

White

A405

100/130

Impact resistant

Good

Good

Beige

A313

100/130

Impact resistant

Good

Good

Beige

A314

110/130

Impact resistant

Excellent

Excellent

Orange

A417

*Tg is the maximum temperature at which full strength and E-modulus will be maintained

Metals

Composites

(SMC, GRE, GRP)

Engineering

thermoplastics

(glass reinforced

PPS, PEI)

Metal to composite/

Engineering

thermoplastics

Polyamide,

ABS, PVC, PC

Metal to flexible

plastics

Metal to

thermoset laminates

Ceramics, glass

Americas:

Asia / Pacific:

Europe / Middle East / Africa:

Huntsman Advanced Materials

Americas Inc.

10003 Woodloch Forest Drive

The Woodlands

Texas 77380

USA

Huntsman Advanced Materials

(Hong Kong) Ltd

Suites 2303-2306, Tower 1

The Gateway, 25 Canton Road

Tsimshatsui, Kowloon

Hong Kong

Huntsman Advanced Materials

(UK) Ltd

Ickleton Road

Duxford

Cambridge, CB2 4QA

U.K.

Tel:

Fax:

Tel:

Fax:

Tel:

Fax:

+1 818 265 7312

+1 818 507 0167

Huntsman Advanced Materials

Qumica Brasil Ltda

Avenida Professor Vincente Ro 90

04706-900 So Paulo, SP

Brazil

Tel:

Fax:

+55 11 5532 7369

+55 11 5543 6386

+852 2148 8835

+852 2418 0994

+44 1223 493 010

+44 1223 493 156

Huntsman Advanced Materials

(Australia) Pty Ltd

Gate 3, Ballarat Road

Deer Park, Vic 3023

Private Bag 2

St Albans DC Vic 3021

Australia

Tel:

Fax:

+61 3 9361 6088

+61 3 9361 6077

Handling Precautions

Distributed by:

Caution

Huntsman Advanced Materials products are generally quite harmless to handle provided that certain

precautions normally taken when handling chemicals are observed. The uncured materials must not,

for instance, be allowed to come in contact with foodstuffs or food utensils, and measures should also

be taken to prevent the uncured materials from coming in contact with the skin, since people with

particularly sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will

normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed at

the end of each working period by washing with soap and warm water. The use of solvents is to be

avoided. Disposable paper towels not cloth towels should be used to dry the skin. The work area

should be well ventilated. Mandatory and recommended industrial hygiene procedures should be

followed whenever our products are being handled and processed. For additional information, please

consult the corresponding material safety data sheet.

Produced by:

Huntsman Advanced Materials

(Switzerland) GmbH

Klybeckstrasse 200

CH-4057 Basel

Switzerland

Tel: +41 61 966 33 33

Fax: +41 61 966 35 19

www.araldite.com

While all the information and recommendations in this publication are to the best of our knowledge, information and belief accurate at the date of

publication, NOTHING HEREIN IS TO BE CONSTRUED AS A WARRANTY, EXPRESS OR OTHERWISE.

IN ALL CASES, IT IS THE RESPONSIBILITY OF THE USER TO DETERMINE THE APPLICABILITY OF SUCH INFORMATION AND

RECOMMENDATIONS AND THE SUITABILITY OF ANY PRODUCT FOR ITS OWN PARTICULAR PURPOSE. The sale of products referred to in this

publication is subject to the general terms and conditions of sale of Huntsman Advanced Materials (Europe) BVBA or of its affiliated companies.

Publication no. A418f-GB/1000/06/05/ Printed in Great Britain.

Araldite is a registered trademark of Huntsman LLC or an affiliate thereof in one or more, but not all, countries.

Copyright 2005 Huntsman Advanced Materials (Switzerland) GmbH

You might also like

- Improvised Munitions Handbook – Learn How to Make Explosive Devices & Weapons from Scratch (Warfare Skills Series): Illustrated & With Clear InstructionsFrom EverandImprovised Munitions Handbook – Learn How to Make Explosive Devices & Weapons from Scratch (Warfare Skills Series): Illustrated & With Clear InstructionsRating: 3.5 out of 5 stars3.5/5 (7)

- SK Fert F50ag-MsdsDocument6 pagesSK Fert F50ag-MsdsEmadNo ratings yet

- Loctite 594 1998Document5 pagesLoctite 594 1998Boss_enqNo ratings yet

- Araldite Epoxy Adhesive - 2Document4 pagesAraldite Epoxy Adhesive - 2SatyamEngNo ratings yet

- Araldite 2022Document6 pagesAraldite 20228612106535No ratings yet

- Araldite 2011Document2 pagesAraldite 2011nrd9771No ratings yet

- Ara 2012Document5 pagesAra 2012pavan_03No ratings yet

- Antox 71e Extra - GBDocument2 pagesAntox 71e Extra - GBmaatouguiabdelkader04No ratings yet

- LY556 Ar5021 XB3403 XB3471 EDocument6 pagesLY556 Ar5021 XB3403 XB3471 EJoão Korrodi SottomayorNo ratings yet

- 4090 F0931 MSDSDocument9 pages4090 F0931 MSDStoxicity230% (1)

- Araldite 2010Document6 pagesAraldite 2010nrd9771No ratings yet

- HU Araldite Standard Eur eDocument3 pagesHU Araldite Standard Eur eMauro S CabralNo ratings yet

- Araldite Standard-Data SheetDocument3 pagesAraldite Standard-Data SheetSuperCow FelizNo ratings yet

- Araldite Ly564 Aradur 2954.PDF ResinDocument5 pagesAraldite Ly564 Aradur 2954.PDF ResinAbdul Hakim Abdullah100% (1)

- Araldite Kit K134: Araldite Kit K134 Part A 100 PBW Araldite Kit K134 Part B 40 PBWDocument5 pagesAraldite Kit K134: Araldite Kit K134 Part A 100 PBW Araldite Kit K134 Part B 40 PBWVaibhav GuptaNo ratings yet

- PD - TemperKote 850 PrimerDocument2 pagesPD - TemperKote 850 PrimerJosé MoránNo ratings yet

- 71E Plus - GBDocument2 pages71E Plus - GBMahmoud TahaNo ratings yet

- MSDS AAC Hebel Blocks - 2002Document4 pagesMSDS AAC Hebel Blocks - 2002aditarian .pNo ratings yet

- Wattyl Colourthane Thinner Standard 6100-99 MSDS May13Document12 pagesWattyl Colourthane Thinner Standard 6100-99 MSDS May13Dil VasconcelosNo ratings yet

- 71EPDocument2 pages71EPYevhen OkhremchukNo ratings yet

- Antox 71 E Pickling Paste PDFDocument2 pagesAntox 71 E Pickling Paste PDFasaasd100% (1)

- Auer Stekla Borosilicate PDFDocument8 pagesAuer Stekla Borosilicate PDFrisbo12No ratings yet

- FDA 13007 (DALIC Selective Plating)Document6 pagesFDA 13007 (DALIC Selective Plating)Ugodilinwa Nnaemeka La SonNo ratings yet

- TDS - Uvitex® MSV LiqDocument6 pagesTDS - Uvitex® MSV LiqAlie ChirNo ratings yet

- 006B Product Data Sheet ESAB Stain Clean Picking Paste Sunday, Nov 22, 2020Document2 pages006B Product Data Sheet ESAB Stain Clean Picking Paste Sunday, Nov 22, 2020Habib RehmanNo ratings yet

- Perkenalan Produk Solvet BaseDocument10 pagesPerkenalan Produk Solvet BaseRenold DarmasyahNo ratings yet

- Gasket RTV Silicone 310 ML: Applications BenefitsDocument4 pagesGasket RTV Silicone 310 ML: Applications BenefitsNurcan BozkurtNo ratings yet

- Polysulphide Sealant Technical Data.Document2 pagesPolysulphide Sealant Technical Data.stuart3962No ratings yet

- Material Safety Data Sheets: Rev.: 00 TSD/F/020 REV. 00 1. Manufacturer and Product InformationDocument5 pagesMaterial Safety Data Sheets: Rev.: 00 TSD/F/020 REV. 00 1. Manufacturer and Product InformationmartinacaisarferanandaNo ratings yet

- Material Safety Data Sheets: Rev.: 00 TSD/F/020 REV. 00Document5 pagesMaterial Safety Data Sheets: Rev.: 00 TSD/F/020 REV. 00martinacaisarferanandaNo ratings yet

- DEGASSING AGENT AF 100 - Ind1 - AngDocument1 pageDEGASSING AGENT AF 100 - Ind1 - AngFrench Corvette50% (2)

- Magnum 960 301-01438Document2 pagesMagnum 960 301-01438Yen Sebastian SantosNo ratings yet

- Solvalitt TDSDocument4 pagesSolvalitt TDSphillipskincaidNo ratings yet

- Instruction Manual Advanced Series: HotplatesDocument80 pagesInstruction Manual Advanced Series: HotplatesDaniel ZhunioNo ratings yet

- Care, Maintenance, and Testing OF Hot Line ToolsDocument20 pagesCare, Maintenance, and Testing OF Hot Line ToolsjosefmarqNo ratings yet

- Red Oxide PrimerDocument2 pagesRed Oxide Primermarsha.fsdNo ratings yet

- Paint SpecDocument2 pagesPaint Specjoydeep24088563No ratings yet

- Safe Use Instructions of Roving: Product IdentificationDocument10 pagesSafe Use Instructions of Roving: Product IdentificationAberth Ruben Jacinto CastilloNo ratings yet

- Allplastics - Samsung Staron Technical Data SheetDocument5 pagesAllplastics - Samsung Staron Technical Data Sheetanilbandi493No ratings yet

- SipxDocument5 pagesSipxIngenieria SuministroNo ratings yet

- S Weld CleanDocument3 pagesS Weld CleanRanjan AnchanNo ratings yet

- Jushi-Glass Fiber-MSDSDocument9 pagesJushi-Glass Fiber-MSDSTarek BenNo ratings yet

- Dow 3504Document2 pagesDow 3504khantoNo ratings yet

- Cold Mounting Brochure enDocument6 pagesCold Mounting Brochure enJames Harold Quiroz OjedaNo ratings yet

- S 54 D 59 U 000Document2 pagesS 54 D 59 U 000Joshua RomanNo ratings yet

- Nitoseal 130Document2 pagesNitoseal 130Venkata RaoNo ratings yet

- Manual de Operaciones PS-100200Document49 pagesManual de Operaciones PS-100200nairNo ratings yet

- Msds Rept LabsaDocument5 pagesMsds Rept Labsaamiller1987No ratings yet

- Imp MaterialsDocument37 pagesImp MaterialsPradeep SamuelNo ratings yet

- Penguard HBDocument4 pagesPenguard HBhedisanjayaNo ratings yet

- 54m-Line Dulux Weathershield Matt-Aus GHSDocument6 pages54m-Line Dulux Weathershield Matt-Aus GHSHồng PhongNo ratings yet

- Care Maintenance BookDocument18 pagesCare Maintenance BookFelipe FlorezNo ratings yet

- Denso Protal 7900HTDocument2 pagesDenso Protal 7900HTalbertojanetaNo ratings yet

- Acryl 60: Water-Based Acrylic Bonding and Modifying AdmixtureDocument4 pagesAcryl 60: Water-Based Acrylic Bonding and Modifying AdmixtureOgbedande Awo OrunmilaNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Stainless Steel Grade Comparision System Diagram of Stainless Steel - Corrosion &heat Resistance Strength, Machinability WiseDocument1 pageStainless Steel Grade Comparision System Diagram of Stainless Steel - Corrosion &heat Resistance Strength, Machinability WiseSatyamEngNo ratings yet

- Parker O-Ring Material Guide-2008Document72 pagesParker O-Ring Material Guide-2008Ian Pillay50% (2)

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNo ratings yet

- Equivalencia de MaterialesDocument1 pageEquivalencia de MaterialesHelden Jasmani100% (1)

- Fittech Brochure Companion Flanges and FittingsDocument16 pagesFittech Brochure Companion Flanges and FittingsSatyamEngNo ratings yet

- Asco Direct Acting Solenoid Valve - 320Document6 pagesAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Hindstan Nylons - Ptfe CatalogueDocument11 pagesHindstan Nylons - Ptfe CatalogueSatyamEngNo ratings yet

- Weartech Electrode Stellite Cobalt NickleDocument1 pageWeartech Electrode Stellite Cobalt NickleSatyamEngNo ratings yet

- MechIndia Burnishing ToolsDocument4 pagesMechIndia Burnishing ToolsSatyamEngNo ratings yet

- Surface Roughness Tester Page 1Document1 pageSurface Roughness Tester Page 1SatyamEngNo ratings yet

- Equivalent Materials GradeDocument2 pagesEquivalent Materials GradeSatyamEng80% (5)

- Material Conversion TableDocument5 pagesMaterial Conversion TableMilin DesaiNo ratings yet

- ENERPAC 00682GB - LPwrenchDocument4 pagesENERPAC 00682GB - LPwrenchSatyamEngNo ratings yet

- GEE ElectrodeDocument17 pagesGEE ElectrodeSatyamEngNo ratings yet

- Enerpac NC E324Document1 pageEnerpac NC E324SatyamEngNo ratings yet

- TorcupDocument4 pagesTorcupSatyamEngNo ratings yet

- International Industrial SpringsDocument6 pagesInternational Industrial SpringsSatyamEngNo ratings yet

- Araldite Industrial AdhesiveDocument6 pagesAraldite Industrial AdhesiveSatyamEngNo ratings yet

- Araldite Epoxy Adhesive - 2Document4 pagesAraldite Epoxy Adhesive - 2SatyamEngNo ratings yet

- BAJAJ Industrial LightsDocument5 pagesBAJAJ Industrial LightsSatyamEngNo ratings yet