Professional Documents

Culture Documents

4 6 0 Metallography: Fracture Grain Size For High-Hardness, Relatively Brittle Steels, The Prior-Austenite

4 6 0 Metallography: Fracture Grain Size For High-Hardness, Relatively Brittle Steels, The Prior-Austenite

Uploaded by

Prasanth SoundappanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 6 0 Metallography: Fracture Grain Size For High-Hardness, Relatively Brittle Steels, The Prior-Austenite

4 6 0 Metallography: Fracture Grain Size For High-Hardness, Relatively Brittle Steels, The Prior-Austenite

Uploaded by

Prasanth SoundappanCopyright:

Available Formats

4 6 0 METALLOGRAPHY

The above micrograph at I0O0X (nital) has two 5 in. long lines drawn diagonally to fit the picture size (ten

measurements on horizontal lines normally used.) A count of the number of grains intercepted reveals 12 plus

for one line and 13 plus 2UJ for the other for an average of 13.5 interceptions. Hence, the Snyder-Graff

intercept grain si/e number is 13.5. To convert to ASTM grain si/e. two procedures may be used.

Equation 6-42 can be used to estimate G,

G = [6.635 log(S-G)] + 2.66 = 10.16 (round to 10)

NI can be determined in two ways.

NL = 13.5/(5/1000) = 2700 in*1

or.

N,. = < 13.5) (200)= 2700 in '

The mean lineal intercept is \INL = 0.00037 in.

The ASTM grain si/e is:

G = [-6.6353 log(0.00037)] - 12.6 = 10.17 (round to 10)

Figure 6-15 Example of grain size measurement of M2 high speed steel using the Snyder-Graff

intercept method (reduced 25 percent in reproduction).

Fracture grain size For high-hardness, relatively brittle steels, the prior-austenite

grain size can be determined simply by comparing a fractured specimen to a set of

10 graded standard fractures numbered 1 to 10 to coincide with the ASTM grain

size scale. The technique, which is referred to as the Shepherd fracture grain size

method, was introduced by Arpi in 1931. His samples consisted of 5 graded

fractures which were expanded to 10 by Shepherd. Figure 6-16 shows the 10

specimens of the Shepherd fracture grain size standards along with scanning

electron microscope (SEM) views of the fractures at 50X. Note that intergranular

You might also like

- Numerical Method For Engineers-Chapter 17Document30 pagesNumerical Method For Engineers-Chapter 17Mrbudakbaek90% (10)

- Chapter14 Solutions 11eDocument43 pagesChapter14 Solutions 11e종운No ratings yet

- Torque Calculations For Rotary Shouldered ConnectionDocument7 pagesTorque Calculations For Rotary Shouldered ConnectionJohan Medina Tovar100% (3)

- Chapter - 13 - Solutions Shigley's Mechanical Engineering Design 9th Edition Solutions ManualDocument35 pagesChapter - 13 - Solutions Shigley's Mechanical Engineering Design 9th Edition Solutions ManualMahdi Majidniya100% (12)

- C37b3eab 459Document1 pageC37b3eab 459Prasanth SoundappanNo ratings yet

- 128ac5fc 446Document1 page128ac5fc 446Prasanth SoundappanNo ratings yet

- 2, Is Divided by The Test Grid Area Computed at The PhotographDocument1 page2, Is Divided by The Test Grid Area Computed at The PhotographPrasanth SoundappanNo ratings yet

- Shi20396 ch09Document23 pagesShi20396 ch09Luis Fernando YguaroNo ratings yet

- Shi20396 ch09Document23 pagesShi20396 ch09Kaiphy XuanNo ratings yet

- Engineering Drawing Prelim 1Document57 pagesEngineering Drawing Prelim 1chienikolaoNo ratings yet

- Corrected Solutions Manual Problems: 3.10 Reverse Polarity Marks On 3.12 by (3.17)Document7 pagesCorrected Solutions Manual Problems: 3.10 Reverse Polarity Marks On 3.12 by (3.17)Julian RGNo ratings yet

- Accurate and Efficient Evaluation of Modal Green's FunctionsDocument12 pagesAccurate and Efficient Evaluation of Modal Green's Functionsbelacqua2No ratings yet

- HW6 CEE275 UC BerkeleyDocument10 pagesHW6 CEE275 UC BerkeleyKurtWalterSonccoNo ratings yet

- Plane Trigonometry: OA Be The Initial Side OB Be The Terminal SideDocument14 pagesPlane Trigonometry: OA Be The Initial Side OB Be The Terminal SideJo HarNo ratings yet

- Solucion EMNM Papel 1 2006Document5 pagesSolucion EMNM Papel 1 2006JAVIER ALONSO MURILLO MURILLONo ratings yet

- AntennaDocument2 pagesAntennaDaniel BelachewNo ratings yet

- Approximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingDocument11 pagesApproximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingCan CemreNo ratings yet

- Figure 6-9 Example of Grain Size Determination by The Triple-Point Count Method and Comparison ToDocument1 pageFigure 6-9 Example of Grain Size Determination by The Triple-Point Count Method and Comparison ToPrasanth SoundappanNo ratings yet

- Closed-Form Formulas For The Electromagnetic Parameters of Inverted Microstrip LineDocument8 pagesClosed-Form Formulas For The Electromagnetic Parameters of Inverted Microstrip LineIJERDNo ratings yet

- Numero PiDocument23 pagesNumero PicrackenhNo ratings yet

- Arose Is AroseDocument15 pagesArose Is AroseFernandaNo ratings yet

- Instructions For The Use of A Slide RuleDocument20 pagesInstructions For The Use of A Slide RuleAcct999100% (1)

- Intro To Stereo Logy Grain SizeDocument64 pagesIntro To Stereo Logy Grain SizeRaistlin1No ratings yet

- Theory of Mechanics and Mechanisms 4th EditionDocument8 pagesTheory of Mechanics and Mechanisms 4th EditionTimothy's SpaceshipNo ratings yet

- Predicting The Average Lead Angle in Turning Using Non-Dimensional Parameters and Considering The Size EffectDocument23 pagesPredicting The Average Lead Angle in Turning Using Non-Dimensional Parameters and Considering The Size EffectgdelfinoNo ratings yet

- A Numerical Scheme For Unsteady Flow of A Viscous Fluid Between Elliptic PlatesDocument5 pagesA Numerical Scheme For Unsteady Flow of A Viscous Fluid Between Elliptic PlatesHamid MojiryNo ratings yet

- Chapter 13 Pipe NetworksDocument41 pagesChapter 13 Pipe NetworksNader AlaaNo ratings yet

- Bellman Ford ScreenDocument11 pagesBellman Ford ScreenThai Thi Hong LoanNo ratings yet

- Surface RoughnessDocument12 pagesSurface RoughnessMotaz Ahmad AmeenNo ratings yet

- Ch.10 SolDocument3 pagesCh.10 SolWatit HathaisirikulNo ratings yet

- A) Exp (2-Viri)Document5 pagesA) Exp (2-Viri)Mradul YadavNo ratings yet

- 4041-Article Text PDF-7799-1-10-20130718Document13 pages4041-Article Text PDF-7799-1-10-20130718Miloš BasarićNo ratings yet

- 2supp Supplemental Problem: Comparing Spreadsheet and CalculatorDocument4 pages2supp Supplemental Problem: Comparing Spreadsheet and CalculatorJORGENo ratings yet

- 78 - 5 - Gear BoxDocument9 pages78 - 5 - Gear Boxrip1111760% (1)

- Optimization of Biplanar Gradient Coils For Magnetic Resonance ImagingDocument5 pagesOptimization of Biplanar Gradient Coils For Magnetic Resonance ImagingmigislasNo ratings yet

- Chapter13 Solutions 11eDocument41 pagesChapter13 Solutions 11e종운No ratings yet

- Solution To The Drill Problems of Chapter 05 (Engineering Electromagnetics, Hayt, A.Buck 7th Ed) BEE 4A, 4B & 4C D5.1 (A)Document1 pageSolution To The Drill Problems of Chapter 05 (Engineering Electromagnetics, Hayt, A.Buck 7th Ed) BEE 4A, 4B & 4C D5.1 (A)SHELPTSNo ratings yet

- Ijmet: ©iaemeDocument7 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- Journal of Cohiputaltonal PhysicsDocument5 pagesJournal of Cohiputaltonal PhysicsDimitrios Christos SarvanisNo ratings yet

- Geodesics On The EllipsoidDocument7 pagesGeodesics On The Ellipsoiddist2235No ratings yet

- Physics Diameter ExperimentDocument4 pagesPhysics Diameter ExperimentAryana TkaNo ratings yet

- Mple Question Paper Mathematics First TermDocument9 pagesMple Question Paper Mathematics First TermPrerna SharmaNo ratings yet

- Selective Harmonic Elimination Switching Strategy For Back To-Back Stacked Multicell ConverterDocument10 pagesSelective Harmonic Elimination Switching Strategy For Back To-Back Stacked Multicell ConverterIAEME PublicationNo ratings yet

- On The Base-B Expansion of The Number of Trailing Zeros of B !Document16 pagesOn The Base-B Expansion of The Number of Trailing Zeros of B !Risad ShahriarNo ratings yet

- Ncert Solutions For Class 10 Maths Chapter 12 Ex 2Document11 pagesNcert Solutions For Class 10 Maths Chapter 12 Ex 2Sora RoseNo ratings yet

- Polygon Area NewDocument4 pagesPolygon Area NewAYUSH KumarNo ratings yet

- Ncert Solutions For Class 10 Maths Chapter 12 PDFDocument30 pagesNcert Solutions For Class 10 Maths Chapter 12 PDFswapna allaNo ratings yet

- Kinematics of Selected Parts of Metal Cutting Machine: KeywordsDocument5 pagesKinematics of Selected Parts of Metal Cutting Machine: KeywordsRaviNo ratings yet

- CHPT 7Document51 pagesCHPT 7jimbob7410No ratings yet

- Western Australian Junior Mathematics Olympiad 2013Document15 pagesWestern Australian Junior Mathematics Olympiad 2013Hicham ElyassamiNo ratings yet

- Assignment From BookDocument7 pagesAssignment From Bookabdullah nokhaiz100% (1)

- 2019 Junior Third Round - Solutions: 25 July 2019Document6 pages2019 Junior Third Round - Solutions: 25 July 2019joshlancelemmetjiesNo ratings yet

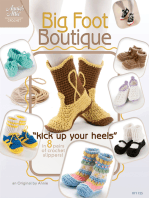

- Big Foot Boutique: "Kick Up Your Heels" in 8 Pairs of Crochet Slippers!From EverandBig Foot Boutique: "Kick Up Your Heels" in 8 Pairs of Crochet Slippers!Rating: 3 out of 5 stars3/5 (1)

- 2, Is Divided by The Test Grid Area Computed at The PhotographDocument1 page2, Is Divided by The Test Grid Area Computed at The PhotographPrasanth SoundappanNo ratings yet

- Jeffries Planimetric Method The Planimetric Method Developed by Jeffries HasDocument1 pageJeffries Planimetric Method The Planimetric Method Developed by Jeffries HasPrasanth SoundappanNo ratings yet

- 128ac5fc 446Document1 page128ac5fc 446Prasanth SoundappanNo ratings yet

- Table 6-8 Grain Size Analysis by The Saltykov Area Method:, D, and S (D) - All Methods Produced Higher NDocument1 pageTable 6-8 Grain Size Analysis by The Saltykov Area Method:, D, and S (D) - All Methods Produced Higher NPrasanth SoundappanNo ratings yet

- Quantitative Microscopy 4 6 7Document1 pageQuantitative Microscopy 4 6 7Prasanth SoundappanNo ratings yet

- 6-7.4 Summary: Grain Size Analysrs Saltykov Area MethodDocument1 page6-7.4 Summary: Grain Size Analysrs Saltykov Area MethodPrasanth SoundappanNo ratings yet

- Quantitative Microscopy 4 4 1Document1 pageQuantitative Microscopy 4 4 1Prasanth SoundappanNo ratings yet

- Max X: Quantitative Microscopy 4 6 9Document1 pageMax X: Quantitative Microscopy 4 6 9Prasanth SoundappanNo ratings yet

- 468 Metallography: Table 6-7 Basic Information For The Saltykov Area MethodDocument1 page468 Metallography: Table 6-7 Basic Information For The Saltykov Area MethodPrasanth SoundappanNo ratings yet

- Figure 6-11 Example of A Well-Dispersed Duplex Grain Structure in A Low-Carbon Steel (150 X, EtchedDocument1 pageFigure 6-11 Example of A Well-Dispersed Duplex Grain Structure in A Low-Carbon Steel (150 X, EtchedPrasanth SoundappanNo ratings yet

- 670c8c2c 463Document1 page670c8c2c 463Prasanth SoundappanNo ratings yet

- 6-6.6 Summary: Quantitative Microscopy 4 3 5Document1 page6-6.6 Summary: Quantitative Microscopy 4 3 5Prasanth SoundappanNo ratings yet

- Nonequiaxed Grains When The Grain Shape Is Noticeably Distorted, Grain SizeDocument1 pageNonequiaxed Grains When The Grain Shape Is Noticeably Distorted, Grain SizePrasanth SoundappanNo ratings yet

- Delineation of Grain Boundaries Methods To Reveal Austenite Grain Structures inDocument1 pageDelineation of Grain Boundaries Methods To Reveal Austenite Grain Structures inPrasanth SoundappanNo ratings yet

- Duplex Grain Structures It Is Not Uncommon To Observe Duplex Grain Structures inDocument1 pageDuplex Grain Structures It Is Not Uncommon To Observe Duplex Grain Structures inPrasanth SoundappanNo ratings yet

- Alkaline Sodium Picrate - Boiling 2% Nital: Quantitative Microscopy 4 3 9Document1 pageAlkaline Sodium Picrate - Boiling 2% Nital: Quantitative Microscopy 4 3 9Prasanth SoundappanNo ratings yet

- c6c7b65f 461Document1 pagec6c7b65f 461Prasanth SoundappanNo ratings yet

- C37b3eab 459Document1 pageC37b3eab 459Prasanth SoundappanNo ratings yet

- Snyder-Graff Intercept Method The Prior-Austenite Grain Size of High-Speed ToolDocument1 pageSnyder-Graff Intercept Method The Prior-Austenite Grain Size of High-Speed ToolPrasanth SoundappanNo ratings yet

- Figure 6-9 Example of Grain Size Determination by The Triple-Point Count Method and Comparison ToDocument1 pageFigure 6-9 Example of Grain Size Determination by The Triple-Point Count Method and Comparison ToPrasanth SoundappanNo ratings yet

- 6-7.2 Grain Size Measurement: 4 3 6 MetallographyDocument1 page6-7.2 Grain Size Measurement: 4 3 6 MetallographyPrasanth SoundappanNo ratings yet

- Standard Chart Methods The 1930 Revision of ASTM Specification E2 ContainedDocument1 pageStandard Chart Methods The 1930 Revision of ASTM Specification E2 ContainedPrasanth SoundappanNo ratings yet

- RM-H-R: Intercept Length Distribution-Duplex Grain StructureDocument1 pageRM-H-R: Intercept Length Distribution-Duplex Grain StructurePrasanth SoundappanNo ratings yet

- Material CharacterisationDocument1 pageMaterial CharacterisationPrasanth SoundappanNo ratings yet

- Advanced High Strength SteelsDocument24 pagesAdvanced High Strength SteelsPrasanth SoundappanNo ratings yet