Professional Documents

Culture Documents

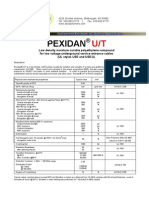

Injection Molding: Physical Properties Test Method Unit Value

Injection Molding: Physical Properties Test Method Unit Value

Uploaded by

IjhAr R'din H-iCopyright:

Available Formats

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Tds-Bi5 0gaDocument1 pageTds-Bi5 0gaFalecyaRedinaNo ratings yet

- Si6008 TDS PDFDocument2 pagesSi6008 TDS PDFBelalang NgantukNo ratings yet

- TDS PP 305 HF10TQ 02Document2 pagesTDS PP 305 HF10TQ 02Lungkoneng HRDNo ratings yet

- TDS PP 500 Bi5.0ga 02Document2 pagesTDS PP 500 Bi5.0ga 02Adrianto GNo ratings yet

- TDS PP 310 Hi50tn 01Document2 pagesTDS PP 310 Hi50tn 01Adrianto GNo ratings yet

- Hdpe H355jaDocument2 pagesHdpe H355janimonh100% (1)

- TDS-PE-102-UB5502H (Provisional) 2019Document2 pagesTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraNo ratings yet

- TDS PP 503 Bi5.0gn 02Document2 pagesTDS PP 503 Bi5.0gn 02Adrianto GNo ratings yet

- 00 6825 PDFDocument5 pages00 6825 PDFibrahim_mohamed3361100% (1)

- P840J Feb, 09Document2 pagesP840J Feb, 09Tan Chen TatNo ratings yet

- P640JDocument2 pagesP640JTan Chen TatNo ratings yet

- MasterFlow880 TDSDocument2 pagesMasterFlow880 TDSNdoro BeiNo ratings yet

- EL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingDocument2 pagesEL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingTan Chen TatNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- P740JDocument2 pagesP740JTan Chen TatNo ratings yet

- H5818J Feb, 09Document2 pagesH5818J Feb, 09Tan Chen TatNo ratings yet

- Polyethylene: For Blow Moulding & Blown Film GradeDocument1 pagePolyethylene: For Blow Moulding & Blown Film GradeRikinNo ratings yet

- Pe 45GP004Document2 pagesPe 45GP004Sumukha RNo ratings yet

- TDS Pe 100 Ub5206h 01 PDFDocument2 pagesTDS Pe 100 Ub5206h 01 PDFOktaviandri SaputraNo ratings yet

- Sikadur 752Document2 pagesSikadur 752Arlianty Arsyad LamusuNo ratings yet

- HF10TQ: IPP Film GradeDocument2 pagesHF10TQ: IPP Film GradeLaili AzkiyahNo ratings yet

- Sikagrout - 212 GPDocument2 pagesSikagrout - 212 GPKanapol KaewdangNo ratings yet

- SG610Document1 pageSG610Huynh Nam QuangNo ratings yet

- Masterflow 880Document2 pagesMasterflow 880api-283891975100% (1)

- 02 Bab IiDocument2 pages02 Bab IiariefNo ratings yet

- TDS Pe 200 SF5007Document2 pagesTDS Pe 200 SF5007Oktaviandri SaputraNo ratings yet

- SM66EDocument1 pageSM66EHuynh Nam QuangNo ratings yet

- SF580Document1 pageSF580Huynh Nam QuangNo ratings yet

- Sikadur 752 PdsDocument2 pagesSikadur 752 PdsTaufik FiklyNo ratings yet

- Pexidan Ut Saco 0510Document2 pagesPexidan Ut Saco 0510Eddy BrentonNo ratings yet

- Sigmazinc 109 HSDocument5 pagesSigmazinc 109 HSKrishna VachaNo ratings yet

- Lldpe Jl210: Application / Use CaseDocument2 pagesLldpe Jl210: Application / Use CaselyesNo ratings yet

- Nishant Molding TCDocument1 pageNishant Molding TCprabhunmayNo ratings yet

- Sigmacover 630 March 13Document6 pagesSigmacover 630 March 13leonciomavarezNo ratings yet

- PP Trilene Hi10hoDocument2 pagesPP Trilene Hi10hoLaili AzkiyahNo ratings yet

- SikaGrout 212 Product Data B25956Document2 pagesSikaGrout 212 Product Data B25956Guillermo Garcia50% (2)

- Plastiment RTD-01: Water Reducing and Set RetardingDocument2 pagesPlastiment RTD-01: Water Reducing and Set RetardingLuqmanuel Hugoz SavalovicNo ratings yet

- 7564 Sigmatherm 540Document2 pages7564 Sigmatherm 540Ibrahim MahranNo ratings yet

- PE Yellow Gas - WebDocument16 pagesPE Yellow Gas - WebGavin KwanNo ratings yet

- High Early Strength Cement - PdsDocument1 pageHigh Early Strength Cement - Pdsطه اللوذعيNo ratings yet

- DS Flex Rev7 0309 PDFDocument2 pagesDS Flex Rev7 0309 PDFDavid GonzaloNo ratings yet

- Sikagard-670 WMYDocument3 pagesSikagard-670 WMYNARUdaARCNo ratings yet

- SG580Document1 pageSG580Huynh Nam QuangNo ratings yet

- Shakun Polymers Limited: Spl-Afosr High Performance PVC CompoundDocument2 pagesShakun Polymers Limited: Spl-Afosr High Performance PVC CompoundquycoctuNo ratings yet

- PDS en-IN 20220126Document2 pagesPDS en-IN 20220126EMADNo ratings yet

- GAIL (India) LTD.: High Density Polyethylene For OFC DuctsDocument1 pageGAIL (India) LTD.: High Density Polyethylene For OFC DuctsMd MinhajNo ratings yet

- 7117 - Sigmarine 28Document0 pages7117 - Sigmarine 28eraswastaNo ratings yet

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- Pe HD50MA180Document1 pagePe HD50MA180Suraj DavdaNo ratings yet

- Alathon H5618Document2 pagesAlathon H5618Ing Ipn VbaNo ratings yet

- Isoplast Industrial ResinsDocument1 pageIsoplast Industrial ResinsJou0411No ratings yet

- Datasheet D880Document3 pagesDatasheet D880Lissette DomínguezNo ratings yet

- SigmaCover 280Document5 pagesSigmaCover 280ajuhaseenNo ratings yet

- ASA Material Specs Sheet LGDocument2 pagesASA Material Specs Sheet LGjitendertalwar1603No ratings yet

- Sigma PrimeDocument7 pagesSigma Primegstketut0% (1)

- TDS PP 306 Hi10ho 03Document2 pagesTDS PP 306 Hi10ho 03indahNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

Injection Molding: Physical Properties Test Method Unit Value

Injection Molding: Physical Properties Test Method Unit Value

Uploaded by

IjhAr R'din H-iOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Injection Molding: Physical Properties Test Method Unit Value

Injection Molding: Physical Properties Test Method Unit Value

Uploaded by

IjhAr R'din H-iCopyright:

Available Formats

LOW LINEAR DENSITY POLYETHYLENE

Injection Molding

UI2650

CHARACTERISTICS :

APPLICATIONS :

- Non-UV Stabilized

- High Flow Properties

- Excellent Moldability and Toughness

- Good ESCR

- Compliance with FDA Regulation 21 CFR177.1520

- Housewares

- Lids, Bottle Closures, and Toys

- Masterbatches and Powder Coatings

Physical Properties

Density

Test Method*

Unit

Value

3

ASTM D 1505

g/cm

ASTM D 1238

g/10 min.

50

Melt Index ( 190 C/21.6 kg )

ASTM D 1238

g/10 min.

Vicat Softening Temperature

ASTM D 1525

90

Brittleness Temperature

ASTM D 746

< -70

ECSR [F50 ]

ASTM D 1693

Hrs

30

Tensile Strength @ Yield

ASTM D 638

MPa

18

Elongation @ Break

ASTM D 638

100

Tensile Impact Strength

ASTM D 1822

kJ/m

Flexural Modulus

ASTM D 790

MPa

Izod Impact Strength

ASTM D 256

kJ/m

Melt Index ( 190 C/2.16 kg )

*) Polyethylene tested per ASTM D 1928

0.927

600

Conversion :

40

1 MPa

= 10.2 kgf/cm 2

1 kJ/m 2 = 0.01 kgf.cm/mm 2

Recommended Processing Conditions :

Melt Temperature 175 - 225 deg. C

This material complies with recommendations and statutory regulations in the USA, Japan and most European

countries regarding packaging materials intended to come in contact with foodstuff.

The nominal properties reported herein are typical on the product of CAPC

but do not reflect normal testing variance and therefore should not to be

construed as specifications.

CAPC reserves the right to make any improvement or amendments to the

composition of any grade or product without alteration to the product code.

This document reports accurate and reliable information to the best of our

knowledge on the products manufactured by CAPC. Since CAPC can not anticipate

or control the conditions under which this information and its product may be used,

each user should review the information in the specific context of the intended

a p p l i c a t i o n . C A P C wi l l n o t b e r e s p o n s i b l e f o r da m a g es of a n y n a tu r e

resulting from the use of or reliance upon the information.

This technical datasheet is effective as from January 2013 and supersedes all previously published data.

PT. Chandra Asri Petrochemical Tbk

Wisma Barito Pacific Tower A, 7 th Floor

Jl. Let. Jend. S. Parman Kav. 62-63

Jakarta 11410, Indonesia

T +6221-530 7950, F +6221-530 8930

www.chandra-asri.com

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Tds-Bi5 0gaDocument1 pageTds-Bi5 0gaFalecyaRedinaNo ratings yet

- Si6008 TDS PDFDocument2 pagesSi6008 TDS PDFBelalang NgantukNo ratings yet

- TDS PP 305 HF10TQ 02Document2 pagesTDS PP 305 HF10TQ 02Lungkoneng HRDNo ratings yet

- TDS PP 500 Bi5.0ga 02Document2 pagesTDS PP 500 Bi5.0ga 02Adrianto GNo ratings yet

- TDS PP 310 Hi50tn 01Document2 pagesTDS PP 310 Hi50tn 01Adrianto GNo ratings yet

- Hdpe H355jaDocument2 pagesHdpe H355janimonh100% (1)

- TDS-PE-102-UB5502H (Provisional) 2019Document2 pagesTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraNo ratings yet

- TDS PP 503 Bi5.0gn 02Document2 pagesTDS PP 503 Bi5.0gn 02Adrianto GNo ratings yet

- 00 6825 PDFDocument5 pages00 6825 PDFibrahim_mohamed3361100% (1)

- P840J Feb, 09Document2 pagesP840J Feb, 09Tan Chen TatNo ratings yet

- P640JDocument2 pagesP640JTan Chen TatNo ratings yet

- MasterFlow880 TDSDocument2 pagesMasterFlow880 TDSNdoro BeiNo ratings yet

- EL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingDocument2 pagesEL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingTan Chen TatNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- P740JDocument2 pagesP740JTan Chen TatNo ratings yet

- H5818J Feb, 09Document2 pagesH5818J Feb, 09Tan Chen TatNo ratings yet

- Polyethylene: For Blow Moulding & Blown Film GradeDocument1 pagePolyethylene: For Blow Moulding & Blown Film GradeRikinNo ratings yet

- Pe 45GP004Document2 pagesPe 45GP004Sumukha RNo ratings yet

- TDS Pe 100 Ub5206h 01 PDFDocument2 pagesTDS Pe 100 Ub5206h 01 PDFOktaviandri SaputraNo ratings yet

- Sikadur 752Document2 pagesSikadur 752Arlianty Arsyad LamusuNo ratings yet

- HF10TQ: IPP Film GradeDocument2 pagesHF10TQ: IPP Film GradeLaili AzkiyahNo ratings yet

- Sikagrout - 212 GPDocument2 pagesSikagrout - 212 GPKanapol KaewdangNo ratings yet

- SG610Document1 pageSG610Huynh Nam QuangNo ratings yet

- Masterflow 880Document2 pagesMasterflow 880api-283891975100% (1)

- 02 Bab IiDocument2 pages02 Bab IiariefNo ratings yet

- TDS Pe 200 SF5007Document2 pagesTDS Pe 200 SF5007Oktaviandri SaputraNo ratings yet

- SM66EDocument1 pageSM66EHuynh Nam QuangNo ratings yet

- SF580Document1 pageSF580Huynh Nam QuangNo ratings yet

- Sikadur 752 PdsDocument2 pagesSikadur 752 PdsTaufik FiklyNo ratings yet

- Pexidan Ut Saco 0510Document2 pagesPexidan Ut Saco 0510Eddy BrentonNo ratings yet

- Sigmazinc 109 HSDocument5 pagesSigmazinc 109 HSKrishna VachaNo ratings yet

- Lldpe Jl210: Application / Use CaseDocument2 pagesLldpe Jl210: Application / Use CaselyesNo ratings yet

- Nishant Molding TCDocument1 pageNishant Molding TCprabhunmayNo ratings yet

- Sigmacover 630 March 13Document6 pagesSigmacover 630 March 13leonciomavarezNo ratings yet

- PP Trilene Hi10hoDocument2 pagesPP Trilene Hi10hoLaili AzkiyahNo ratings yet

- SikaGrout 212 Product Data B25956Document2 pagesSikaGrout 212 Product Data B25956Guillermo Garcia50% (2)

- Plastiment RTD-01: Water Reducing and Set RetardingDocument2 pagesPlastiment RTD-01: Water Reducing and Set RetardingLuqmanuel Hugoz SavalovicNo ratings yet

- 7564 Sigmatherm 540Document2 pages7564 Sigmatherm 540Ibrahim MahranNo ratings yet

- PE Yellow Gas - WebDocument16 pagesPE Yellow Gas - WebGavin KwanNo ratings yet

- High Early Strength Cement - PdsDocument1 pageHigh Early Strength Cement - Pdsطه اللوذعيNo ratings yet

- DS Flex Rev7 0309 PDFDocument2 pagesDS Flex Rev7 0309 PDFDavid GonzaloNo ratings yet

- Sikagard-670 WMYDocument3 pagesSikagard-670 WMYNARUdaARCNo ratings yet

- SG580Document1 pageSG580Huynh Nam QuangNo ratings yet

- Shakun Polymers Limited: Spl-Afosr High Performance PVC CompoundDocument2 pagesShakun Polymers Limited: Spl-Afosr High Performance PVC CompoundquycoctuNo ratings yet

- PDS en-IN 20220126Document2 pagesPDS en-IN 20220126EMADNo ratings yet

- GAIL (India) LTD.: High Density Polyethylene For OFC DuctsDocument1 pageGAIL (India) LTD.: High Density Polyethylene For OFC DuctsMd MinhajNo ratings yet

- 7117 - Sigmarine 28Document0 pages7117 - Sigmarine 28eraswastaNo ratings yet

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- Pe HD50MA180Document1 pagePe HD50MA180Suraj DavdaNo ratings yet

- Alathon H5618Document2 pagesAlathon H5618Ing Ipn VbaNo ratings yet

- Isoplast Industrial ResinsDocument1 pageIsoplast Industrial ResinsJou0411No ratings yet

- Datasheet D880Document3 pagesDatasheet D880Lissette DomínguezNo ratings yet

- SigmaCover 280Document5 pagesSigmaCover 280ajuhaseenNo ratings yet

- ASA Material Specs Sheet LGDocument2 pagesASA Material Specs Sheet LGjitendertalwar1603No ratings yet

- Sigma PrimeDocument7 pagesSigma Primegstketut0% (1)

- TDS PP 306 Hi10ho 03Document2 pagesTDS PP 306 Hi10ho 03indahNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet