Professional Documents

Culture Documents

Lube Oil Purification PDF

Lube Oil Purification PDF

Uploaded by

jelena_bojovic1Copyright:

Available Formats

You might also like

- 7 High Quality Base Oil Production Via The HyLube TM Process - UOPDocument13 pages7 High Quality Base Oil Production Via The HyLube TM Process - UOPxinghustNo ratings yet

- Regeneration of Waste Lubricant Oil by Extraction-Flocculation PDFDocument8 pagesRegeneration of Waste Lubricant Oil by Extraction-Flocculation PDFsasanNo ratings yet

- Converting Waste Plastics Into Liquid Fuel by Pyrolysis Developments in China - Yuan XingzhongDocument27 pagesConverting Waste Plastics Into Liquid Fuel by Pyrolysis Developments in China - Yuan Xingzhongvuongcoi102No ratings yet

- Used Lube RecyclingDocument62 pagesUsed Lube RecyclingBharat SharmaNo ratings yet

- Waste Oil RefiningDocument6 pagesWaste Oil RefiningJohn simpson100% (1)

- Re-Refining of Used Lube OilsDocument23 pagesRe-Refining of Used Lube OilsJaydeep TayadeNo ratings yet

- Re-Refining of Used Lube Oil: Presented By-M.tech PLE BatchDocument30 pagesRe-Refining of Used Lube Oil: Presented By-M.tech PLE BatchKhageshwar RongkaliNo ratings yet

- Used Engine Oil RerefiningDocument31 pagesUsed Engine Oil RerefiningMasomese Henry Kikile100% (3)

- Lube RefineryDocument20 pagesLube RefineryRajNo ratings yet

- Lubricating OilDocument24 pagesLubricating OilShyam YadavNo ratings yet

- 1ton Used Oil Distillation To Base Oil Plant0402 PDFDocument3 pages1ton Used Oil Distillation To Base Oil Plant0402 PDFOmar Suárez JacayNo ratings yet

- Method of Re Refining Used Lubricating Oil & Salt Bath RefiningDocument35 pagesMethod of Re Refining Used Lubricating Oil & Salt Bath RefiningMacarthur B. MonsantoNo ratings yet

- Solvent Extraction Technology For Used Oil TreatmentDocument30 pagesSolvent Extraction Technology For Used Oil TreatmentGyra LuthmanaNo ratings yet

- Lube Oil ManufacturingDocument7 pagesLube Oil ManufacturingLakshya SaxenaNo ratings yet

- Recycling Used Lubricating Oil Using Untreated, Activated and Calcined Clay MethodsDocument6 pagesRecycling Used Lubricating Oil Using Untreated, Activated and Calcined Clay MethodsTuribio SunnyNo ratings yet

- Technology For Rerefining Used Lube Oils Applied in Europe: A ReviewDocument14 pagesTechnology For Rerefining Used Lube Oils Applied in Europe: A ReviewPaula Citelli100% (1)

- Waste Oil Re-Refining Syste..Document1 pageWaste Oil Re-Refining Syste..khandoo_amitNo ratings yet

- Refining of Used Oil POSTER (4489)Document1 pageRefining of Used Oil POSTER (4489)Movies EraNo ratings yet

- Thermal Cracking of Waste Engine Oil (Lubricant) at 430oc TemperatureDocument4 pagesThermal Cracking of Waste Engine Oil (Lubricant) at 430oc TemperatureAshok RathodNo ratings yet

- Waste Oil Distillation MachineDocument12 pagesWaste Oil Distillation Machinenazif100% (1)

- Solvent Extraction and DewaxingDocument21 pagesSolvent Extraction and DewaxingAnwesh SatapathyNo ratings yet

- Discuss The Pure Dry Waste Oil Recovery System On Board The ShipDocument3 pagesDiscuss The Pure Dry Waste Oil Recovery System On Board The ShipSwarg VibhaNo ratings yet

- Engineering Chemistry Unit 3 Notes RGPVDocument14 pagesEngineering Chemistry Unit 3 Notes RGPVMufaddal HamidNo ratings yet

- Understanding Calcium Sulfonate ThickenersDocument3 pagesUnderstanding Calcium Sulfonate ThickenersAlejandro José Poveda GuevaraNo ratings yet

- Team ThesisDocument71 pagesTeam ThesisChetan DebNo ratings yet

- Engine Oil RecoveryDocument36 pagesEngine Oil RecoveryAssif NisarNo ratings yet

- 6 Refining: 6.1 Fractional DistillationDocument10 pages6 Refining: 6.1 Fractional Distillationaldi gufroniNo ratings yet

- Lubricating Oil AdditivesDocument21 pagesLubricating Oil AdditivesTrần Thùy LinhNo ratings yet

- Processing of Grease With PDFDocument92 pagesProcessing of Grease With PDFahmet100% (1)

- Liquid Paraffin Sovyet Urea-DewaxingDocument6 pagesLiquid Paraffin Sovyet Urea-DewaxingAndrek QueckNo ratings yet

- Water Reduction and Reuse in The Petroleum IndustryNovemberDocument57 pagesWater Reduction and Reuse in The Petroleum IndustryNovemberwaheed2286No ratings yet

- Modular Waste Lube Oil PDFDocument19 pagesModular Waste Lube Oil PDFAdeel Ahmed100% (2)

- Upgrading The Bottom of The BarrelDocument7 pagesUpgrading The Bottom of The BarrelmmintakaNo ratings yet

- List of Commonly Encountered Petroleum and Petroleum ProductsDocument6 pagesList of Commonly Encountered Petroleum and Petroleum ProductsEddie MoeNo ratings yet

- Lube Oil Re-Refining TechnologyDocument25 pagesLube Oil Re-Refining TechnologySunil BhosaleNo ratings yet

- Hydraulic Oils PDFDocument3 pagesHydraulic Oils PDFdonyaNo ratings yet

- Oil Purification Plants REOIL Regeneration SystemsDocument35 pagesOil Purification Plants REOIL Regeneration SystemsFer PolNo ratings yet

- Vakuumdestillation eDocument2 pagesVakuumdestillation ejesusNo ratings yet

- GREASe Process ReportDocument110 pagesGREASe Process Reportrazamalik01No ratings yet

- Reprot On TrainingDocument36 pagesReprot On TrainingMd.Mahbub MorshedNo ratings yet

- Synthesis of Biolubricants From Non Edible OilsDocument5 pagesSynthesis of Biolubricants From Non Edible OilsAnonymous kw8Yrp0R5rNo ratings yet

- Angolan Oil Blends UpstreamDocument3 pagesAngolan Oil Blends UpstreamezioNo ratings yet

- Technology For Rerefining Used Lube Oils Applied in Europe A Review PDFDocument14 pagesTechnology For Rerefining Used Lube Oils Applied in Europe A Review PDFMASOMESE KIKILENo ratings yet

- Guideline For Establishment of Lube Plant and Application FormDocument11 pagesGuideline For Establishment of Lube Plant and Application FormEmmanuel OguaforNo ratings yet

- 2007 scWO PDFDocument10 pages2007 scWO PDFRodolfo Angulo OlaisNo ratings yet

- NaOH Untuk Used OilDocument9 pagesNaOH Untuk Used OilimronmasfruriNo ratings yet

- Mini Oil Refinery Plant PDFDocument3 pagesMini Oil Refinery Plant PDFrudiandriesNo ratings yet

- Base Oil and Wax ProductionDocument30 pagesBase Oil and Wax Productionphucdc095041100% (1)

- Heavy Oil HydrotreatingDocument15 pagesHeavy Oil HydrotreatingSIMON LIUNo ratings yet

- 2016 likozar Transesterification of oil to biodiesel in a continuous tubular reactor with static mixers- Modelling reaction kinetics, mass transfer, scale-up and optimization considering fatty acid composition.pdfDocument11 pages2016 likozar Transesterification of oil to biodiesel in a continuous tubular reactor with static mixers- Modelling reaction kinetics, mass transfer, scale-up and optimization considering fatty acid composition.pdfTlaltenco FC PonyNo ratings yet

- JZC Waste Oil Recycling Machine 2021Document15 pagesJZC Waste Oil Recycling Machine 2021multilinkaddisNo ratings yet

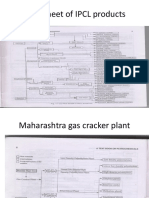

- Petrochemical Industry Flow SheetDocument51 pagesPetrochemical Industry Flow SheetDeekshith KodumuruNo ratings yet

- LUBRICANTING OilDocument18 pagesLUBRICANTING OilChetan AgroyaNo ratings yet

- Credit Analysis ProjectDocument7 pagesCredit Analysis ProjectSyed Muhammad Rafay AhmedNo ratings yet

- Waste Engine Oil Regeneration Machine1Document12 pagesWaste Engine Oil Regeneration Machine1Régis Ongollo100% (1)

- Lubricants and Its PropertiesDocument18 pagesLubricants and Its PropertiesAmogh SinghalNo ratings yet

- High Pressure Fluids Visualization CellsDocument4 pagesHigh Pressure Fluids Visualization Cellsapi-3703671No ratings yet

- Group I Base OilsDocument72 pagesGroup I Base OilsMustafa100% (1)

- Poliflock For Oil GeneralDocument7 pagesPoliflock For Oil GeneralSaad KhalidNo ratings yet

- Process Intensification in Industrial Wastewater Treatment FinalDocument10 pagesProcess Intensification in Industrial Wastewater Treatment FinalSantanu BiswasNo ratings yet

- The Ohsol PresentationDocument53 pagesThe Ohsol PresentationArsalan QadirNo ratings yet

- Chapter 5Document23 pagesChapter 5Jafe SulitNo ratings yet

- Mit PDFDocument197 pagesMit PDFgayathriNo ratings yet

- Activity #2.1Document3 pagesActivity #2.1Hanna Joy Mariñas OcampoNo ratings yet

- Environmental EngineeringDocument20 pagesEnvironmental EngineeringMeseret ShimelisNo ratings yet

- Collection Services of Solid WadteDocument5 pagesCollection Services of Solid WadteT chandanaNo ratings yet

- Recycled Concrete PavementsDocument9 pagesRecycled Concrete PavementsJitender SinghNo ratings yet

- Energy and Environment BooksDocument6 pagesEnergy and Environment BooksFatima MirNo ratings yet

- RA 9003 Ecological Solid Waste Management Act of 2000 1 PDFDocument64 pagesRA 9003 Ecological Solid Waste Management Act of 2000 1 PDFAika Unica GabrielNo ratings yet

- Reduction of 7 WasteDocument20 pagesReduction of 7 WasteMititelu Liviu100% (1)

- Green Marketing: A Case Study On Green Products of Patanjali Ayurved LimitedDocument60 pagesGreen Marketing: A Case Study On Green Products of Patanjali Ayurved Limited224 G.RiteshNo ratings yet

- Leading Factor of Flooding in Tomas Del Rosatio College (Chapter 1-5)Document82 pagesLeading Factor of Flooding in Tomas Del Rosatio College (Chapter 1-5)Bryan MirandaNo ratings yet

- Graph WorksheetDocument21 pagesGraph WorksheetAndry MarpaungNo ratings yet

- CKC Guidance Manual Jan 10 2008 PDFDocument34 pagesCKC Guidance Manual Jan 10 2008 PDFamk2009No ratings yet

- Composting 2Document9 pagesComposting 2Jenny Lyn MasgongNo ratings yet

- Eia - Construction and Operation Period of Stationary Sea-Bohr PlattformDocument259 pagesEia - Construction and Operation Period of Stationary Sea-Bohr PlattformEzzadin BabanNo ratings yet

- Business From Waste PaperDocument5 pagesBusiness From Waste PaperSatish ShuklaNo ratings yet

- ResearchDocument2 pagesResearchAshley TalaveraNo ratings yet

- Glencorse WTW Case Study PDFDocument37 pagesGlencorse WTW Case Study PDFMarshall BravestarNo ratings yet

- WED 2020 Awareness: S.P. Singh EE (Env), Asset HSE CBM-ONGC, BokaroDocument21 pagesWED 2020 Awareness: S.P. Singh EE (Env), Asset HSE CBM-ONGC, BokaroSurendra Pratap SinghNo ratings yet

- Bottled Water Should Be BannedDocument8 pagesBottled Water Should Be BannedSafayet AzizNo ratings yet

- Composting - Benefits, How-To, and MoreDocument20 pagesComposting - Benefits, How-To, and MoreSachin AnandNo ratings yet

- English Activity (Fenis - Beryl)Document1 pageEnglish Activity (Fenis - Beryl)Austin Fenis100% (1)

- War On Waste: Implementation of Solid Waste Management (RA 9003) in The Municipality of RizalDocument14 pagesWar On Waste: Implementation of Solid Waste Management (RA 9003) in The Municipality of RizalIJELS Research JournalNo ratings yet

- Green Audit Report: Alphonsa CollegeDocument27 pagesGreen Audit Report: Alphonsa CollegevimalmailbookNo ratings yet

- 1.ordinance No. 1-SWM Ins. ClearanceDocument4 pages1.ordinance No. 1-SWM Ins. ClearanceRey AragonNo ratings yet

- Identifying Potential Solutions For Specific Reverse Logistics ProblemsDocument19 pagesIdentifying Potential Solutions For Specific Reverse Logistics Problemsparmeshwar mahatoNo ratings yet

- PME KSA en EnvStand17Document17 pagesPME KSA en EnvStand17Ali AlramulNo ratings yet

- SUPPORTIVE STUDY Nisha PDFDocument129 pagesSUPPORTIVE STUDY Nisha PDFrizwanNo ratings yet

- 6.-Organic-Resource-Agency-v4-170915-AH-food Waste in ScotlandDocument27 pages6.-Organic-Resource-Agency-v4-170915-AH-food Waste in ScotlandVita NurhikmahNo ratings yet

Lube Oil Purification PDF

Lube Oil Purification PDF

Uploaded by

jelena_bojovic1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lube Oil Purification PDF

Lube Oil Purification PDF

Uploaded by

jelena_bojovic1Copyright:

Available Formats

Everest .

Leaders in Vacuum Booster Technology

Lubricating oil is an important resource and a petroleum base product. The high price of oil

and objective of saving valuable foreign exchange has resulted in efforts for regeneration of

used lube oil.

Mismanagement of waste lube oil is a serious environmental problem. Almost all types of

waste oil have the potential to be recycled safely, saving a precious non-renewable source

and at the same time minimizing environmental pollution. Unfortunately, most of used oil is

handled improperly. Some is emptied in to sewers for going directly into water waste,

adversely affecting water treatment plants. Some is dumped directly on to the ground to kill

weeds or is poured on to dirty roads or is dumped in deserts, where it can contaminate

surface and ground water.

Disposal of used lubricating oil into the eco system creates environmental hazards. Toughlaws are being enacted throughout the world for the disposal of waste petroleum products and

every genuine effort should be made for its re-use. In most cases, used oil can be re-used

after reconditioning with or without the addition of any additives resulting in huge saving and

conservation of precious oil. Thus regeneration, reclamation or recycling of spent lubricating

oils has become an important process industry, adopting various techniques for oil

purification.

Regeneration of used lubricating oils is based on the fact that, Petroleum lubricating oil are

almost indestructible. We can say, Lubricating oil never wears out. Lubricating oils are

impaired temporarily only because of accumulation during use or handling of contaminants

coming from extraneous impurities and products of oil deterioration, which can be separated

from the used oil by re-refining or re-conditioning. The treated oil, then, becomes almost

equivalent to fresh / virgin oil.

The major extraneous impurities in the waste oil are:

1.

2.

3.

4.

5.

6.

7.

Lube Oil Purification

2005.

Metallic Impurities

Non-metallic impurities

Water, moisture and untreated acid

Carboneous particles

Fuels, impaired additives and their by products.

Chemical contaminates

Polycyclic Aromatic hydrocarbons (PAHs)

Everest Transmission

January,

Everest . Leaders in Vacuum Booster Technology

In India, re-recycling waste oil industry is mainly an un-organized one. Although some

public service units (PSU) also doing re-recycling but most of the market demand is

furnished by the small scale industrial units (SSIs). Most of the SSI units, till now, were

adopting Acid Clay Process, which now has been dis-approved by the pollution control

boards, resulting in their closure until they adopt new certified process.

Acid clay process:

In the conventional acid clay process the used lubricating oil is settled or filtered after

collection and is dehydrated. The oil is then treated with concentrated sulphuric acid to

remove polymers, asphalts, degraded additives and other products of degradation. The

sludge formed is allowed to settle and removed. The oil is neutralized with activated clay, at

elevated temperatures. The clay also bleaches the oil and adsorbs certain impurities not

removed by acid treatment. The clay-oil slurry is filtered to remove clay and other solids. If

the raw material contains more than one grade of lube oil product further processing may be

required.

Process

Characteristics

Advantages

1. Simple process

2. Low initial investment

3. Low energy input

1.

2.

3.

4.

Disadvantages

Unacceptable process to Pollution

Control Boards.

Generates large quantity of pollutants.

Unable to treat modern Multi-Grade

oils

Difficult to remove Asphaltic

impurities

Spent oils, which have not deteriorated to great extent, are often clay contracted or treated

with adsorbents without any acid treatment. They are generally given a preliminary settling,

filtering, centrifuging or vacuum dehydrating treatment. Insulating oils and Transformer oils

are often treated in this way.

Environmentally Sound Technologies (EST)

Govt. of Indias legislation and amendments for waste oil re-cycling rules 1989 and as

amended, Central Pollution Control Board (CPCB) has been designated as the authority for

Lube Oil Purification

2005.

Everest Transmission

January,

Everest . Leaders in Vacuum Booster Technology

grant of registration to such re-cyclers, re-processors for re-processing of hazardous wastes

who comply with the norms of the Board.

Re-refiners and re-cyclers, now have to use only environmentally sound technologies (EST)

while re-cycling and refining waste oil. In case of oil re-refiners using acid clay process or

modified acid clay process have been advised to switch over to Environmentally Sound

Technologies only or close down.

The following processes have been approved as Environmentally Sound Processes,

1.

2.

3.

Vacuum distillation with clay treatment, fig.1

Thin Film evaporation process, fig.2

Vacuum distillation with hydro treating

VACUUM DISTILLATION PROCESS

VACUUM SYSTEM

RAW BASE OIL

WATER AND

EVEREST

BOOSTER

LIGHT OIL

GR.3

FUEL OIL FIRED

HEATER

Lube Oil Purification

2005.

FUEL OIL FIRED

HEATER

BASE OIL

VACUUM DISTILLATION

COLUMN

DEHYDRATOR

STORAGE

GR-4

GR.5

COLUMN NO-III

VACUUM DISTILLATION

VACUUM DISTILLATION

COLUMN -II

RBO

Raw Base Oil

VACUUM DISTILLATION

COLUMN -I

USED/WASTE

OIL

COLUMN NO-III

OPERATES AT

757mmHg + 330C

EVEREST

BOOSTER

PRODUCT

ROTARY

OIL PUMP

WATERING

PUMP

OIL FIRED

HEATER

RESIDUE TO STORAGE TANK

Everest Transmission

SPENT CLAY 2% TO 3%

January,

Everest . Leaders in Vacuum Booster Technology

THIN FILM EVAPORATION PROCESS

VACUUM SYSTEM

CLAY 2% TO 3%

Gr.2

Gr.3 STORAGE

HEATING JACKET

VACUUM DISTILLATION

COLUMN

Gr.1

BASE OIL

PRODUCT

EVEREST

BOOSTER

EVEREST

BOOSTER

FILTERS

SPENT CLAY 2% TO 3%

USED OIL

IN

RESIDUE 12 TO 15%

ROTARY

OIL PUMP

WATERING

PUMP

Selection of Vacuum pumping system:

In order to ensure satisfactory operation of any vacuum process it is essential that suitable

vacuum pump be used. There is generally no single pump that meets all the requirements of

the process. Combination of pumps is increasingly being used to optimize the process

performance. Process condensable and non-condensable loads, air leakage loads, out-gassing

loads and the working process pressures are the important parameters that influence the

pump selection. Various empirical load estimation charts, and leak tests must be referred for

the proper selection of the vacuum system. Some of the widely used pumps for vacuum

process are described below along with their limitations.

Water Ring Pump, Liquid Ring Pump

These pumps use water or low vapor pressure fluid as the pumping medium. For this reason,

the ultimate vacuum achieved gets limited to the vapor pressure of the pump fluid at the

working temperature. Owing to the above, water ring Pump would stall at around 60 Torr

abs. (700mm Hg) and their working range would be between 60 to 150 Torr (700-610mm

Hg). They have further disadvantage of being energy inefficient, because most of the power

is lost in friction losses of moving the pump fluid inside the pump. This restricts the water

ring pump to relatively modest volumetric pumping capacities. Another disadvantage of ring

pumps is that the working fluid often has to be treated before it can be discharged or reused

as it contains the carry over of condensed product.

Lube Oil Purification

2005.

Everest Transmission

January,

Everest . Leaders in Vacuum Booster Technology

Steam Ejectors (Single & Multistage)

Steam ejectors have relatively high volumetric speeds. However, they require the

maintenance of a complete high pressure steam generation facility confirming to IBAR

regulations and inspection. They are generally not available as stand alone installations but

are found where high pressure process steam is readily available.

Multistage steam ejectors demand inter stage condensing putting considerable load on the

cooling towers. Apart from the direct steam generation cost, large energy and maintenance

cost of secondary equipment such as circulation pumps, cooling tower, softening plant, DM

plant and boiler maintenance add to recurring expenses.

Rotary Vane and Piston Pumps:

These type of pumps have high power to capacity ratios and are therefore, not available in

large volumetric capacities. They are effective for pumping non-condensable loads but have

limitations of not being able to pump large and regular quantities of water vapor

(condensable loads) released in low pressure vacuum processes

MECHANICAL VACUUM BOOSTER

Mechanical Vacuum Boosters are being extensively used in chemical process industry to

boost the performance of vacuum pumps where conventional vacuum pumps have poor

volumetric efficiency. These boosters are capable of moving large quantity of gases at low

pressures with far smaller power consumption than for any other equipment now available.

The internals of the boosters are totally free of any sealant fluid and therefore the pumping

dry. Also because of vapor compression action by the booster the pressure at the inlet of

backing pump is relatively high resulting in higher volumetric efficiency and low back

streaming of sealing fluid.

FIG: Everest Mechanical Vacuum Booster Installation in an Oil Distillation Unit.

Lube Oil Purification

2005.

Everest Transmission

January,

Everest . Leaders in Vacuum Booster Technology

FIG: Everest Mechanical Vacuum Booster Installation in a Thin Film Evaporator.

The table 1, below gives the general range of Vacuum/Pressures different vacuum pumps are

designed for. The Ultimate/Blank-off may be slightly higher than the table values but is of

little importance since at the ultimate pressure, the pumps pumping speed is ZERO.

Table1

PRESSURE RANGE WITH

BOOSTER COMBINATION

VACUUM PUMP

PRESSURE RANGE

Single Stage Ejector

600 mmHg

710-720 mmHg

Water Ejector

680 mmHg

740 mmHg

Water Ring Pump

680-710 mmHg

750 mmHg

Liquid Ring Pump

710-730 mmHg

750-755mmHg

Piston Pumps

710-730 mmHg

750-755mmHg

Rotary Piston Pumps

0.1 Torr (abs)

0.01 Torr (abs)

Rotary Vane Pump

0.01 0.001 Torr(abs)

0.001 0.0001 Torr(abs)

The last column, table 1 gives the approximate pressure regime a single stage Booster-Pump

combination can easily achieve. Further lower pressures (better vacuum) can be achieved by

multi-staging of boosters. With suitable combinations pressures in the range of 0.001 Torr

can easily be achieved. However, it is strongly advised that the system should be designed

for the required pressure since lower pressures than the desired by the process would only

add to initial and working costs without much benefit.

The table 2 gives the general pressure range essentially necessary for the successful

operations generally involved during the oil refining process. These are guidelines only and

may differ design to design.

Lube Oil Purification

2005.

Everest Transmission

January,

Everest . Leaders in Vacuum Booster Technology

Table2

Process

Dehydration

Vacuum Range

650-680mmHg

Vacuum Pump Combination

Water Ring Pump

First cut of Light oils and

710-730 mmHg

volatiles

Water Ring Pump and Vacuum Booster

combination

Second cut of high Boilers

730-759 mmHg

Water Ring Pump and Vacuum Boosters

in series combination

Thin film distillation

0.1-0.005 Torr

Rotary Oil seal pump and Vacuum

Boosters in series combination

From the above table, it is evident that

Mechanical Vacuum Boosters are very

versatile and can be used with

practically any vacuum pump to

achieve higher efficiencies, which

otherwise would not be possible

economically.

Used motor oil can be re-refined to make to new lube oils. Re-refining is an efficient and

sophisticated process which removes contaminants and impurities producing premium grade

base oil. One gallon of used motor oil would yield about 0.7 gallons of re-refine oil. Lube

oils can be re-used indefinitely in an endless cycle from refinery to engine to refinery again.

The one main thing which is common in all three environmentally sound technologies (EST)

is that the vacuum requirement in each process, as per the specification furnished by Govt. of

India, is about 758mmHg (2 Torr) or better 2mm HG at the final distillation with temperature

of about 320 340 degree C. Whatever the process may be, the process vacuum demands a

combination of vacuum pumps.

Lube Oil Purification

2005.

Everest Transmission

January,

Everest . Leaders in Vacuum Booster Technology

GENERAL MYTHS ABOUT RE-REFINED OIL

MYTH

REALITY

What is used oil?

The term used oil applies to any oil that is no longer

useful to the original purchaser as a consequence of

extended storage, spillage or contamination with nonhazardous impurities such as dirt and water.

What is re-refined oil?

Re-refined waste oil is the end product of a long process

involving used oils. These are oils first cleansed of their

contaminants through vacuum distillation. Finally base

oil is combined with a fresh additive package by the

blender to bring it up to industry performance level.

Does re-refined oil cost more?

Not usually often costs less.

How many can oil be reOver and over.

refined?

Why should we buy re-refined To save our planet from various kind of pollution and to

oil?

maintain eco balance.

Is it a new development with

NO! ITS NOT NEW. Re-refined oil is being used in

insufficient information to

developed countries for decades.

support?

(Article written by technical team of Everest Transmission The only successful

manufacturer of Mechanical Vacuum Boosters in India)

EVEREST TRANSMISSION

B-44, Mayapuri Industrial Area, Phase-1, New Delhi-110064, India.

Telefax: 91-11-28114944, 28114955, 28116307, 28117469

Email: info@everestblowers.com

Web: www.everestblowers.com

Lube Oil Purification

2005.

Everest Transmission

January,

You might also like

- 7 High Quality Base Oil Production Via The HyLube TM Process - UOPDocument13 pages7 High Quality Base Oil Production Via The HyLube TM Process - UOPxinghustNo ratings yet

- Regeneration of Waste Lubricant Oil by Extraction-Flocculation PDFDocument8 pagesRegeneration of Waste Lubricant Oil by Extraction-Flocculation PDFsasanNo ratings yet

- Converting Waste Plastics Into Liquid Fuel by Pyrolysis Developments in China - Yuan XingzhongDocument27 pagesConverting Waste Plastics Into Liquid Fuel by Pyrolysis Developments in China - Yuan Xingzhongvuongcoi102No ratings yet

- Used Lube RecyclingDocument62 pagesUsed Lube RecyclingBharat SharmaNo ratings yet

- Waste Oil RefiningDocument6 pagesWaste Oil RefiningJohn simpson100% (1)

- Re-Refining of Used Lube OilsDocument23 pagesRe-Refining of Used Lube OilsJaydeep TayadeNo ratings yet

- Re-Refining of Used Lube Oil: Presented By-M.tech PLE BatchDocument30 pagesRe-Refining of Used Lube Oil: Presented By-M.tech PLE BatchKhageshwar RongkaliNo ratings yet

- Used Engine Oil RerefiningDocument31 pagesUsed Engine Oil RerefiningMasomese Henry Kikile100% (3)

- Lube RefineryDocument20 pagesLube RefineryRajNo ratings yet

- Lubricating OilDocument24 pagesLubricating OilShyam YadavNo ratings yet

- 1ton Used Oil Distillation To Base Oil Plant0402 PDFDocument3 pages1ton Used Oil Distillation To Base Oil Plant0402 PDFOmar Suárez JacayNo ratings yet

- Method of Re Refining Used Lubricating Oil & Salt Bath RefiningDocument35 pagesMethod of Re Refining Used Lubricating Oil & Salt Bath RefiningMacarthur B. MonsantoNo ratings yet

- Solvent Extraction Technology For Used Oil TreatmentDocument30 pagesSolvent Extraction Technology For Used Oil TreatmentGyra LuthmanaNo ratings yet

- Lube Oil ManufacturingDocument7 pagesLube Oil ManufacturingLakshya SaxenaNo ratings yet

- Recycling Used Lubricating Oil Using Untreated, Activated and Calcined Clay MethodsDocument6 pagesRecycling Used Lubricating Oil Using Untreated, Activated and Calcined Clay MethodsTuribio SunnyNo ratings yet

- Technology For Rerefining Used Lube Oils Applied in Europe: A ReviewDocument14 pagesTechnology For Rerefining Used Lube Oils Applied in Europe: A ReviewPaula Citelli100% (1)

- Waste Oil Re-Refining Syste..Document1 pageWaste Oil Re-Refining Syste..khandoo_amitNo ratings yet

- Refining of Used Oil POSTER (4489)Document1 pageRefining of Used Oil POSTER (4489)Movies EraNo ratings yet

- Thermal Cracking of Waste Engine Oil (Lubricant) at 430oc TemperatureDocument4 pagesThermal Cracking of Waste Engine Oil (Lubricant) at 430oc TemperatureAshok RathodNo ratings yet

- Waste Oil Distillation MachineDocument12 pagesWaste Oil Distillation Machinenazif100% (1)

- Solvent Extraction and DewaxingDocument21 pagesSolvent Extraction and DewaxingAnwesh SatapathyNo ratings yet

- Discuss The Pure Dry Waste Oil Recovery System On Board The ShipDocument3 pagesDiscuss The Pure Dry Waste Oil Recovery System On Board The ShipSwarg VibhaNo ratings yet

- Engineering Chemistry Unit 3 Notes RGPVDocument14 pagesEngineering Chemistry Unit 3 Notes RGPVMufaddal HamidNo ratings yet

- Understanding Calcium Sulfonate ThickenersDocument3 pagesUnderstanding Calcium Sulfonate ThickenersAlejandro José Poveda GuevaraNo ratings yet

- Team ThesisDocument71 pagesTeam ThesisChetan DebNo ratings yet

- Engine Oil RecoveryDocument36 pagesEngine Oil RecoveryAssif NisarNo ratings yet

- 6 Refining: 6.1 Fractional DistillationDocument10 pages6 Refining: 6.1 Fractional Distillationaldi gufroniNo ratings yet

- Lubricating Oil AdditivesDocument21 pagesLubricating Oil AdditivesTrần Thùy LinhNo ratings yet

- Processing of Grease With PDFDocument92 pagesProcessing of Grease With PDFahmet100% (1)

- Liquid Paraffin Sovyet Urea-DewaxingDocument6 pagesLiquid Paraffin Sovyet Urea-DewaxingAndrek QueckNo ratings yet

- Water Reduction and Reuse in The Petroleum IndustryNovemberDocument57 pagesWater Reduction and Reuse in The Petroleum IndustryNovemberwaheed2286No ratings yet

- Modular Waste Lube Oil PDFDocument19 pagesModular Waste Lube Oil PDFAdeel Ahmed100% (2)

- Upgrading The Bottom of The BarrelDocument7 pagesUpgrading The Bottom of The BarrelmmintakaNo ratings yet

- List of Commonly Encountered Petroleum and Petroleum ProductsDocument6 pagesList of Commonly Encountered Petroleum and Petroleum ProductsEddie MoeNo ratings yet

- Lube Oil Re-Refining TechnologyDocument25 pagesLube Oil Re-Refining TechnologySunil BhosaleNo ratings yet

- Hydraulic Oils PDFDocument3 pagesHydraulic Oils PDFdonyaNo ratings yet

- Oil Purification Plants REOIL Regeneration SystemsDocument35 pagesOil Purification Plants REOIL Regeneration SystemsFer PolNo ratings yet

- Vakuumdestillation eDocument2 pagesVakuumdestillation ejesusNo ratings yet

- GREASe Process ReportDocument110 pagesGREASe Process Reportrazamalik01No ratings yet

- Reprot On TrainingDocument36 pagesReprot On TrainingMd.Mahbub MorshedNo ratings yet

- Synthesis of Biolubricants From Non Edible OilsDocument5 pagesSynthesis of Biolubricants From Non Edible OilsAnonymous kw8Yrp0R5rNo ratings yet

- Angolan Oil Blends UpstreamDocument3 pagesAngolan Oil Blends UpstreamezioNo ratings yet

- Technology For Rerefining Used Lube Oils Applied in Europe A Review PDFDocument14 pagesTechnology For Rerefining Used Lube Oils Applied in Europe A Review PDFMASOMESE KIKILENo ratings yet

- Guideline For Establishment of Lube Plant and Application FormDocument11 pagesGuideline For Establishment of Lube Plant and Application FormEmmanuel OguaforNo ratings yet

- 2007 scWO PDFDocument10 pages2007 scWO PDFRodolfo Angulo OlaisNo ratings yet

- NaOH Untuk Used OilDocument9 pagesNaOH Untuk Used OilimronmasfruriNo ratings yet

- Mini Oil Refinery Plant PDFDocument3 pagesMini Oil Refinery Plant PDFrudiandriesNo ratings yet

- Base Oil and Wax ProductionDocument30 pagesBase Oil and Wax Productionphucdc095041100% (1)

- Heavy Oil HydrotreatingDocument15 pagesHeavy Oil HydrotreatingSIMON LIUNo ratings yet

- 2016 likozar Transesterification of oil to biodiesel in a continuous tubular reactor with static mixers- Modelling reaction kinetics, mass transfer, scale-up and optimization considering fatty acid composition.pdfDocument11 pages2016 likozar Transesterification of oil to biodiesel in a continuous tubular reactor with static mixers- Modelling reaction kinetics, mass transfer, scale-up and optimization considering fatty acid composition.pdfTlaltenco FC PonyNo ratings yet

- JZC Waste Oil Recycling Machine 2021Document15 pagesJZC Waste Oil Recycling Machine 2021multilinkaddisNo ratings yet

- Petrochemical Industry Flow SheetDocument51 pagesPetrochemical Industry Flow SheetDeekshith KodumuruNo ratings yet

- LUBRICANTING OilDocument18 pagesLUBRICANTING OilChetan AgroyaNo ratings yet

- Credit Analysis ProjectDocument7 pagesCredit Analysis ProjectSyed Muhammad Rafay AhmedNo ratings yet

- Waste Engine Oil Regeneration Machine1Document12 pagesWaste Engine Oil Regeneration Machine1Régis Ongollo100% (1)

- Lubricants and Its PropertiesDocument18 pagesLubricants and Its PropertiesAmogh SinghalNo ratings yet

- High Pressure Fluids Visualization CellsDocument4 pagesHigh Pressure Fluids Visualization Cellsapi-3703671No ratings yet

- Group I Base OilsDocument72 pagesGroup I Base OilsMustafa100% (1)

- Poliflock For Oil GeneralDocument7 pagesPoliflock For Oil GeneralSaad KhalidNo ratings yet

- Process Intensification in Industrial Wastewater Treatment FinalDocument10 pagesProcess Intensification in Industrial Wastewater Treatment FinalSantanu BiswasNo ratings yet

- The Ohsol PresentationDocument53 pagesThe Ohsol PresentationArsalan QadirNo ratings yet

- Chapter 5Document23 pagesChapter 5Jafe SulitNo ratings yet

- Mit PDFDocument197 pagesMit PDFgayathriNo ratings yet

- Activity #2.1Document3 pagesActivity #2.1Hanna Joy Mariñas OcampoNo ratings yet

- Environmental EngineeringDocument20 pagesEnvironmental EngineeringMeseret ShimelisNo ratings yet

- Collection Services of Solid WadteDocument5 pagesCollection Services of Solid WadteT chandanaNo ratings yet

- Recycled Concrete PavementsDocument9 pagesRecycled Concrete PavementsJitender SinghNo ratings yet

- Energy and Environment BooksDocument6 pagesEnergy and Environment BooksFatima MirNo ratings yet

- RA 9003 Ecological Solid Waste Management Act of 2000 1 PDFDocument64 pagesRA 9003 Ecological Solid Waste Management Act of 2000 1 PDFAika Unica GabrielNo ratings yet

- Reduction of 7 WasteDocument20 pagesReduction of 7 WasteMititelu Liviu100% (1)

- Green Marketing: A Case Study On Green Products of Patanjali Ayurved LimitedDocument60 pagesGreen Marketing: A Case Study On Green Products of Patanjali Ayurved Limited224 G.RiteshNo ratings yet

- Leading Factor of Flooding in Tomas Del Rosatio College (Chapter 1-5)Document82 pagesLeading Factor of Flooding in Tomas Del Rosatio College (Chapter 1-5)Bryan MirandaNo ratings yet

- Graph WorksheetDocument21 pagesGraph WorksheetAndry MarpaungNo ratings yet

- CKC Guidance Manual Jan 10 2008 PDFDocument34 pagesCKC Guidance Manual Jan 10 2008 PDFamk2009No ratings yet

- Composting 2Document9 pagesComposting 2Jenny Lyn MasgongNo ratings yet

- Eia - Construction and Operation Period of Stationary Sea-Bohr PlattformDocument259 pagesEia - Construction and Operation Period of Stationary Sea-Bohr PlattformEzzadin BabanNo ratings yet

- Business From Waste PaperDocument5 pagesBusiness From Waste PaperSatish ShuklaNo ratings yet

- ResearchDocument2 pagesResearchAshley TalaveraNo ratings yet

- Glencorse WTW Case Study PDFDocument37 pagesGlencorse WTW Case Study PDFMarshall BravestarNo ratings yet

- WED 2020 Awareness: S.P. Singh EE (Env), Asset HSE CBM-ONGC, BokaroDocument21 pagesWED 2020 Awareness: S.P. Singh EE (Env), Asset HSE CBM-ONGC, BokaroSurendra Pratap SinghNo ratings yet

- Bottled Water Should Be BannedDocument8 pagesBottled Water Should Be BannedSafayet AzizNo ratings yet

- Composting - Benefits, How-To, and MoreDocument20 pagesComposting - Benefits, How-To, and MoreSachin AnandNo ratings yet

- English Activity (Fenis - Beryl)Document1 pageEnglish Activity (Fenis - Beryl)Austin Fenis100% (1)

- War On Waste: Implementation of Solid Waste Management (RA 9003) in The Municipality of RizalDocument14 pagesWar On Waste: Implementation of Solid Waste Management (RA 9003) in The Municipality of RizalIJELS Research JournalNo ratings yet

- Green Audit Report: Alphonsa CollegeDocument27 pagesGreen Audit Report: Alphonsa CollegevimalmailbookNo ratings yet

- 1.ordinance No. 1-SWM Ins. ClearanceDocument4 pages1.ordinance No. 1-SWM Ins. ClearanceRey AragonNo ratings yet

- Identifying Potential Solutions For Specific Reverse Logistics ProblemsDocument19 pagesIdentifying Potential Solutions For Specific Reverse Logistics Problemsparmeshwar mahatoNo ratings yet

- PME KSA en EnvStand17Document17 pagesPME KSA en EnvStand17Ali AlramulNo ratings yet

- SUPPORTIVE STUDY Nisha PDFDocument129 pagesSUPPORTIVE STUDY Nisha PDFrizwanNo ratings yet

- 6.-Organic-Resource-Agency-v4-170915-AH-food Waste in ScotlandDocument27 pages6.-Organic-Resource-Agency-v4-170915-AH-food Waste in ScotlandVita NurhikmahNo ratings yet