Professional Documents

Culture Documents

Calcul Débit Convoyeur Cru Sur Débit Four Jour

Calcul Débit Convoyeur Cru Sur Débit Four Jour

Uploaded by

bulentbulutOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calcul Débit Convoyeur Cru Sur Débit Four Jour

Calcul Débit Convoyeur Cru Sur Débit Four Jour

Uploaded by

bulentbulutCopyright:

Available Formats

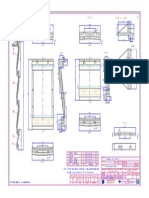

Annexe 1

½ time handling by G102 is

working for output Hopper 2

Capacity | Output exit | duration of filling

Limestone : 330 t | 47.6 t/h | 2.7 h + 0.33 h = 3 h

Shale : 245 t | 18.1 t/h | 1.7 h + 0.33 h = 2 h

Sand : 65 t | 2.3 t/h | 0.4 h + 0.33 h = 0.7 h

G102 conveyor = 170 t/h With output G102= 170 t/h

Time for the direction changing manual :

Material Hoppers time origine Material Hoppers time origine

Limestone Æ Raw mill 1 = 20’ x 2 Æ extractor C101 Limestone Æ Raw mill 2 = 20’ x 2 Æ extractor C101

Shale Æ Raw mill 1 = 20’ x 1 Æ D104 or F114 Shale Æ Raw mill 2 = 20’ x 1 Æ D104 or F114

Sand Æ Raw mill 1 = 20’ x 2 Æ D108 Sand Æ Raw mill 2 = 20’ x 2 Æ D108

Total per day = 200’ => the working conveyor time per day = 20.66 h/ 24.00 h

the time between handling and product = (14 %)

If the necessary time to fill the Hopper 2, 3486.5 / 20.66 = 168.8 t/h

with a simultaneous output is fixed at 4 3486.5 t/d (24h/24)

hours, the G102 conveyor output has to

be of:

Output hopper 2 G102

Limestone : 82% = 47.64 t/h= 151.2 t/h

[(330 + (47.64x4)))/4]x[24/20.6] The

Product

department

ask a ratio

between

Limestone Sand Shale

Shale Sand Limestone hopper hopper hopper

hopper hopper hopper filling and

output = capacity capacity capacity

capacity capacity capacity

+20 % 330 t 65 t 245 t

260 t 75 t 305 t

When the G102 conveyor is stopped,

the hopper 1 autonomy is of:

Limestone : 82% = 47.64 t/h= 6.4 h wet raw material 1394.6 t/d wet raw material 1394.6 t/d

Shale : 14 % = 8.13 t/h = 32 .0h 58.1 t/h 58.1 t/h

Sand : 4 % = 2.32 t/h = 32.3 h total wet raw

Total output = 58.1 t/h material When the G102 conveyor is stopped, the

humidity rate 2789.2 t/d hopper 2 autonomy is of:

10% 116.2 t/h Limestone : 82% = 47.64 t/h= 6.9 h

Shale : 14 % = 8.13 t/h = 30.10h

Sand : 4 % = 2.32 t/h = 28.0 h

dry raw Total output = 58.1 t/h

material

1255.2 t/d

52.3 t/h mill 1

raw

1092 t/d

dry raw Working’rate

material by day 87% Kiln 1

1255.2 t/d

52.3 t/h clinker

mill 2 raw Ratio 1.56 700 t/d

1092 t/d

total dry raw Kiln 2

material clinker

2510.4 t/d Total dry 700 t/d

104.6 t/h raw material

consumption

2184 t/d Total

clinker

production

by day

Please read the plan by going back up the page! = 1400 t/d

CONVOYEURS A COURROIE : Expertises – Conseils – Formations - Assistances techniques

n° de déclaration d’existence ‘’Entreprise de formation’’ 82 26 000610 26

n° SIRET : 398 454 389 00014 APE : 742C R.C.ROMANS 26 : 94 B 431

You might also like

- Regular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsDocument23 pagesRegular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsYogaAnandNo ratings yet

- Chapter 2 Slide BDocument104 pagesChapter 2 Slide Bgidey67% (3)

- Rab Tambang NikelDocument96 pagesRab Tambang NikelDevi Andri100% (2)

- Equipment ProductivityDocument10 pagesEquipment ProductivitySonya Karina RahelaniNo ratings yet

- Solucion MNE 407/507 HW #2 Production Requirements: 210,000 Tons Ore 420,000 Tons WasteDocument3 pagesSolucion MNE 407/507 HW #2 Production Requirements: 210,000 Tons Ore 420,000 Tons WasteJazamNo ratings yet

- Vietnam Pulp Project - VCX 400 - Process Steam and Condensate Return Scenario - No Grid Power - 1160 AdtpdDocument1 pageVietnam Pulp Project - VCX 400 - Process Steam and Condensate Return Scenario - No Grid Power - 1160 AdtpdHuu Nguyen DucNo ratings yet

- BSR Sri LankaDocument4 pagesBSR Sri LankaPravee PereraNo ratings yet

- COSTDocument11 pagesCOSTJNo ratings yet

- Throughput CalcsDocument6 pagesThroughput Calcsharishkumar.ravichandranNo ratings yet

- Proses Fruktosa Dari SingkongDocument2 pagesProses Fruktosa Dari Singkongsuryo.pratama4002No ratings yet

- Solution MNE 407/507 in Class 2 Production RequirementsDocument4 pagesSolution MNE 407/507 in Class 2 Production RequirementsJazamNo ratings yet

- Load IdentificationDocument2 pagesLoad IdentificationerhansinattraNo ratings yet

- Process Flow For KRUNCH: Blender Blender Screw Feeder Screw FeederDocument13 pagesProcess Flow For KRUNCH: Blender Blender Screw Feeder Screw FeederbhenkakusNo ratings yet

- Mud Report Geotermal 11.04.2024Document1 pageMud Report Geotermal 11.04.2024cristianjugaruNo ratings yet

- Ball-Cement-Mill-Monitoring-Inspection-Evaluation PerformanceDocument7 pagesBall-Cement-Mill-Monitoring-Inspection-Evaluation PerformanceMin MCLNo ratings yet

- Realisasi Pengapalan - November 2018Document3 pagesRealisasi Pengapalan - November 2018Vhya WahyuniNo ratings yet

- Procurement of Materials & Equipment Management: Assignment Faculty: Dr. Babalu RajputDocument5 pagesProcurement of Materials & Equipment Management: Assignment Faculty: Dr. Babalu Rajputjobin.raj1989No ratings yet

- Name: Danial Afzal Malik Reg No: 17PWMIN0816Document6 pagesName: Danial Afzal Malik Reg No: 17PWMIN0816Danial AfzalNo ratings yet

- Ball Mill Inspection - Chap 3Document7 pagesBall Mill Inspection - Chap 3Min MCLNo ratings yet

- Lliquid Mass VelocityDocument2 pagesLliquid Mass VelocityMasrihanNo ratings yet

- Perhitungan BD & Jartest (Autosaved) BruDocument12 pagesPerhitungan BD & Jartest (Autosaved) BruDhimas PratomoNo ratings yet

- ProductivityDocument349 pagesProductivitydimar agusriawanNo ratings yet

- 03 Waste WaterDocument157 pages03 Waste WaterGarry Yan DiazNo ratings yet

- Fmip Summary Data On Agriculture Input Use: Name of Project: Bagmati Lift Irrigatin Project Location:Karmaiya, SarlahiDocument80 pagesFmip Summary Data On Agriculture Input Use: Name of Project: Bagmati Lift Irrigatin Project Location:Karmaiya, Sarlahirashmi bhailaNo ratings yet

- Rotary Drum FilterDocument13 pagesRotary Drum FilterGunasri SuryaNo ratings yet

- Sludge Dryer Payback Original FileDocument6 pagesSludge Dryer Payback Original FileumeshpatelNo ratings yet

- Seminar 04Document13 pagesSeminar 04Jayati GuptaNo ratings yet

- Improve PMR - S On - A - Fans PDFDocument44 pagesImprove PMR - S On - A - Fans PDFRushdan ZaimNo ratings yet

- Comet 5.0 Fiksasi RevisiDocument26 pagesComet 5.0 Fiksasi RevisiKhansa ArkhapNo ratings yet

- Name: Danial Afzal Malik Reg No: 17PWMIN0816Document5 pagesName: Danial Afzal Malik Reg No: 17PWMIN0816Danial AfzalNo ratings yet

- Assignment 5 (MRF)Document1 pageAssignment 5 (MRF)Nadiah DonNo ratings yet

- Calculation of Efficiency & Route DesignDocument5 pagesCalculation of Efficiency & Route DesignEmson ChitsungoNo ratings yet

- MORTH Data Book-Rate Analysis 23 JULY2008Document378 pagesMORTH Data Book-Rate Analysis 23 JULY2008surendraNo ratings yet

- Water CalculateDocument8 pagesWater CalculateLeon TanNo ratings yet

- Spinning Maths 3Document6 pagesSpinning Maths 3SantoshNo ratings yet

- BoG Recovery Study-Zero HP Gas Sending Out ModelDocument2 pagesBoG Recovery Study-Zero HP Gas Sending Out ModelNgọc Cường nguyễnNo ratings yet

- SDM Mill CalcsDocument6 pagesSDM Mill CalcsHoàng HùngNo ratings yet

- UTS PPK Styrene Butadiene Latex (Tubagus Luthfi F - 1141620040)Document10 pagesUTS PPK Styrene Butadiene Latex (Tubagus Luthfi F - 1141620040)TubagusNo ratings yet

- Mud ThinnerDocument12 pagesMud Thinnerabdilrhman sulimanNo ratings yet

- Desain Perkerasan JalanDocument16 pagesDesain Perkerasan JalanArif Rahman PutrantoNo ratings yet

- Chapter 2 Examples & Reading AssignmentDocument23 pagesChapter 2 Examples & Reading AssignmentTsegaye TsegayeNo ratings yet

- TK Neraca Massa Cement Mill 4z1 & 4z2Document16 pagesTK Neraca Massa Cement Mill 4z1 & 4z2fatihaNo ratings yet

- POW Breakdown of QuantitiesDocument10 pagesPOW Breakdown of QuantitieselmerNo ratings yet

- B+G+20 Residential Building, Kolkata PlumbingDocument4 pagesB+G+20 Residential Building, Kolkata Plumbingvignesh msNo ratings yet

- Quantity Surveying and Contract Management: Module 3: Unit2Document25 pagesQuantity Surveying and Contract Management: Module 3: Unit2Shamana SureshNo ratings yet

- Alat UpdateDocument5 pagesAlat UpdatetommyNo ratings yet

- Air Oven MethodDocument2 pagesAir Oven MethodMark Kenneth BaldoqueNo ratings yet

- ME PenangkalPetirDocument36 pagesME PenangkalPetirElisrayNo ratings yet

- Flatbed Dryer Design2Document3 pagesFlatbed Dryer Design2api-19753598100% (3)

- Devil Creek Metal ProjectDocument15 pagesDevil Creek Metal Projectzhen zhangNo ratings yet

- Bridge DesignDocument28 pagesBridge DesignAnabelle Olimba SantillanNo ratings yet

- Basic Design of Bna PlantDocument11 pagesBasic Design of Bna Plantmasprie2010100% (1)

- Load & Haul - 2 - Production & CostDocument39 pagesLoad & Haul - 2 - Production & CostBenito Lionel ZoboNo ratings yet

- ExpPlan Filtration 13Document9 pagesExpPlan Filtration 13Castiel161No ratings yet

- Experiment Plan: Prepared and Submitted byDocument9 pagesExperiment Plan: Prepared and Submitted byCastiel161No ratings yet

- ASh Silo Sizing CalculationDocument7 pagesASh Silo Sizing CalculationBimal Dey100% (1)

- Productivity Chart SampleDocument4 pagesProductivity Chart SamplehasanNo ratings yet

- KP - RDry (For Report)Document10 pagesKP - RDry (For Report)Alfian YudhaNo ratings yet

- Bu Coalpsa en v011Document2 pagesBu Coalpsa en v011bulentbulutNo ratings yet

- Open Gears: Lubrication + Maintenance + ServiceDocument16 pagesOpen Gears: Lubrication + Maintenance + ServicebulentbulutNo ratings yet

- Nansulate For Energy Efficient WindowsDocument5 pagesNansulate For Energy Efficient WindowsbulentbulutNo ratings yet

- Flo Way PresentationDocument33 pagesFlo Way PresentationbbulutmmNo ratings yet

- SUPERTHERM To Replace HouseWrapDocument1 pageSUPERTHERM To Replace HouseWrapbulentbulutNo ratings yet

- High-Pressure Grinding 2MB PDFDocument0 pagesHigh-Pressure Grinding 2MB PDFbulentbulutNo ratings yet

- Loesche Classifiers Modification Report at MCLDocument42 pagesLoesche Classifiers Modification Report at MCLnsprasad88No ratings yet

- EN21004243A Roller StationsDocument51 pagesEN21004243A Roller StationsbulentbulutNo ratings yet

- WEBBH009 - Baghouse Maintenance GuideDocument1 pageWEBBH009 - Baghouse Maintenance GuidebulentbulutNo ratings yet

- Without ATEX Permission: LED-cap Lamp With 2-Step Illumination (Emergency Light, Main Light)Document29 pagesWithout ATEX Permission: LED-cap Lamp With 2-Step Illumination (Emergency Light, Main Light)bulentbulutNo ratings yet

- Çap3668 X L 1777-ModelDocument1 pageÇap3668 X L 1777-ModelbulentbulutNo ratings yet

- Dustex Overview For DustexTurkey TrainingDocument69 pagesDustex Overview For DustexTurkey TrainingbulentbulutNo ratings yet

- CompAir L23 - 26A 50Hz Compressor Performance Data PDFDocument1 pageCompAir L23 - 26A 50Hz Compressor Performance Data PDFbulentbulut100% (1)

- SUPERTHERM Over Tanks JapanDocument2 pagesSUPERTHERM Over Tanks JapanbulentbulutNo ratings yet

- Dustex Turkey - Power Industry 12-16-13Document37 pagesDustex Turkey - Power Industry 12-16-13bulentbulutNo ratings yet

- Cimenterie Nationale PDFDocument2 pagesCimenterie Nationale PDFbulentbulutNo ratings yet

- Pre Alignment PDFDocument38 pagesPre Alignment PDFbulentbulutNo ratings yet

- PSP Kırma Eleme Genel Katalog PDFDocument40 pagesPSP Kırma Eleme Genel Katalog PDFbulentbulutNo ratings yet

- CompAir L23 - L29 - RS Compressor Brochure PDFDocument8 pagesCompAir L23 - L29 - RS Compressor Brochure PDFbulentbulutNo ratings yet

- Fuel and Combustion (Viva)Document7 pagesFuel and Combustion (Viva)Saad AhmedNo ratings yet

- Cutting Tools in Industrial AutomationDocument22 pagesCutting Tools in Industrial AutomationShazeenNo ratings yet

- GrrtyhvhDocument20 pagesGrrtyhvhDebolina DasNo ratings yet

- Bolt Connections Vs Welded JointsDocument2 pagesBolt Connections Vs Welded Jointslalkrishna123No ratings yet

- Bathnagar Et Al 2016Document13 pagesBathnagar Et Al 2016Marcelo CifuentesNo ratings yet

- Karakterisasi Material (S3) ENMT802007Document19 pagesKarakterisasi Material (S3) ENMT802007fikri wahyu pratamaNo ratings yet

- Rotary KilnDocument47 pagesRotary KilnPrabhakar Reddy PeramNo ratings yet

- Thermodynamics - Example Problems Problems and Solutions: 1 Examining A Power PlantDocument7 pagesThermodynamics - Example Problems Problems and Solutions: 1 Examining A Power PlantUmangtarangNo ratings yet

- BMTDSL Corrosion Resistant Ship WhitepaperDocument30 pagesBMTDSL Corrosion Resistant Ship WhitepaperDino PedutoNo ratings yet

- VGB S 021 04 2018 07 - ENDocument48 pagesVGB S 021 04 2018 07 - ENPeter Mangaluki100% (1)

- Cement KilnDocument2 pagesCement Kilnamir100% (2)

- Oriental Carbon and Chemicals LTD.: Page 1 of 6Document6 pagesOriental Carbon and Chemicals LTD.: Page 1 of 6Bharat ChatrathNo ratings yet

- Hsslive XII Chemistry Amines NoteDocument4 pagesHsslive XII Chemistry Amines Notetrendzz youtuberNo ratings yet

- General Chemistry 2: Quarter 3 - WEEK 2Document21 pagesGeneral Chemistry 2: Quarter 3 - WEEK 2RODEL AZARES100% (1)

- N2 Reference SheetDocument2 pagesN2 Reference SheetsthrzrNo ratings yet

- Schmidt Rebound Hammer TestDocument3 pagesSchmidt Rebound Hammer Testh4m0n4ng4nNo ratings yet

- Investigate of Parameter Setting in Plastic Injection MoldingDocument28 pagesInvestigate of Parameter Setting in Plastic Injection MoldingKristine de ClaroNo ratings yet

- prEN 12390-11 - DRAFTDocument32 pagesprEN 12390-11 - DRAFTCarlos GilNo ratings yet

- Investigation On 3-D-Printing Technologies For Millimeter-Wave and Terahertz ApplicationsDocument14 pagesInvestigation On 3-D-Printing Technologies For Millimeter-Wave and Terahertz ApplicationsAnuj SharmaNo ratings yet

- BuffersDocument4 pagesBuffersMarione Thea RodriguezNo ratings yet

- Advances in Aseptic ProcessingDocument12 pagesAdvances in Aseptic ProcessingTasneem VahoraNo ratings yet

- Crystallization Mechanisms in Solution: Crmc2 09Document17 pagesCrystallization Mechanisms in Solution: Crmc2 09Jesús BuenoNo ratings yet

- 12 20 (24) KV HXLP DSTA - Pdic01114Document2 pages12 20 (24) KV HXLP DSTA - Pdic01114Luis MurilloNo ratings yet

- Humboldt ASTM Asphalt SpecsDocument56 pagesHumboldt ASTM Asphalt Specsard_caballero100% (1)

- Limestone CalcinationDocument11 pagesLimestone Calcinationfaizah_ismail0308No ratings yet

- Textile Journal ListDocument2 pagesTextile Journal ListNat RajaNo ratings yet

- CPVC Spears CatalogueDocument11 pagesCPVC Spears Catalogue129935No ratings yet

- Paper BatteryDocument20 pagesPaper BatteryRajashekar ReddyNo ratings yet

- Elkem ProfileDocument1 pageElkem ProfilejitendraNo ratings yet

- New Fibers From JapanDocument48 pagesNew Fibers From JapanARUN PATILNo ratings yet