Professional Documents

Culture Documents

Guide To Overhead Cranes

Guide To Overhead Cranes

Uploaded by

spacejuyCopyright:

Available Formats

You might also like

- Sugar Plant Specifications 5000 TCD-7500 TCDDocument104 pagesSugar Plant Specifications 5000 TCD-7500 TCDtsrinivasan508375% (4)

- SopManual HD255-5 PDFDocument975 pagesSopManual HD255-5 PDFQuy Le ThanhNo ratings yet

- TC5013A Manual 101208 PDFDocument108 pagesTC5013A Manual 101208 PDFThiyagarajan Murugesan100% (1)

- 11# EOT Crane Operation ManualDocument82 pages11# EOT Crane Operation Manualibnmessaoud10100% (5)

- Mathcad - Crane CalculationsDocument9 pagesMathcad - Crane Calculationsapi-232034744No ratings yet

- Crane ManualDocument91 pagesCrane ManualSuguna Devi100% (1)

- Gantry CraneDocument9 pagesGantry Craneyuza_maulana020% (1)

- Report On Gantry Crane and Overhead CraneDocument23 pagesReport On Gantry Crane and Overhead CraneAbhay UpadhyayNo ratings yet

- Asme B30.16, BS 3243, BS 4898Document2 pagesAsme B30.16, BS 3243, BS 4898engmuhmudNo ratings yet

- Lifting & Rigging ProceduresDocument32 pagesLifting & Rigging ProceduresBrunoro DantasNo ratings yet

- Design of CranesDocument24 pagesDesign of CranessourabhNo ratings yet

- Electric Overhead Traveling Nav GNFCDocument7 pagesElectric Overhead Traveling Nav GNFCkeyur1109No ratings yet

- Lifting MethodsDocument10 pagesLifting Methodsselva1965No ratings yet

- EN DEMAG PogledajDocument158 pagesEN DEMAG PogledajNenad TabandzelicNo ratings yet

- KBK SistemiDocument28 pagesKBK SistemiGogy100% (1)

- Operation Manual YALEDocument56 pagesOperation Manual YALEmarija1967No ratings yet

- Bridge and Gantry Crane Drivers Guide 0001Document72 pagesBridge and Gantry Crane Drivers Guide 0001John Henry SinuratNo ratings yet

- 2 Tonne Spark Resistant 220model Post Swing Jib Crane - 1Document1 page2 Tonne Spark Resistant 220model Post Swing Jib Crane - 1AnishNo ratings yet

- Non-Driven Wheel DIN15090 Series 223 enDocument1 pageNon-Driven Wheel DIN15090 Series 223 enayavuzbvsNo ratings yet

- Crane ManaulDocument18 pagesCrane ManaulfaisalnadimNo ratings yet

- TGN 08 Crane Rail Selection 2Document3 pagesTGN 08 Crane Rail Selection 2Prasad PatilNo ratings yet

- Demag DMR (Brochure)Document20 pagesDemag DMR (Brochure)MadhaneNo ratings yet

- Multiple Crane LiftingDocument11 pagesMultiple Crane LiftingAbdul Majid ZulkarnainNo ratings yet

- Guide For EOT Crane SelectionDocument15 pagesGuide For EOT Crane SelectionMaulik Patel100% (1)

- Gantry GirderDocument38 pagesGantry GirderPiyush Yadav75% (4)

- GantryDocument7 pagesGantrysatydevsinghnegiNo ratings yet

- Crane Solutions and ModelsDocument24 pagesCrane Solutions and ModelsAmandeep NandaNo ratings yet

- Specifications Goliath CranesDocument8 pagesSpecifications Goliath CranesarvindkaushikNo ratings yet

- Crane PDFDocument102 pagesCrane PDFBrook KingNo ratings yet

- Balok CraneDocument31 pagesBalok CraneEzekiel Ezhe Iwawo100% (1)

- Abacus HoistDocument22 pagesAbacus Hoistomiti Engineering systemsNo ratings yet

- Top Running, Double Girder Overhead Cranes: Engineering & Design DataDocument8 pagesTop Running, Double Girder Overhead Cranes: Engineering & Design DataSteven SebastianNo ratings yet

- Port Douglas 3 304Document1 pagePort Douglas 3 304Ngaire TaylorNo ratings yet

- EOT Crane Maintenance ManualDocument99 pagesEOT Crane Maintenance ManualAvishek DasNo ratings yet

- Eurobloc VT 9 10 11 12 GBDocument6 pagesEurobloc VT 9 10 11 12 GBToni RenedoNo ratings yet

- Spanco Freestanding Jib Cranes ManualDocument40 pagesSpanco Freestanding Jib Cranes ManualMarceloPolicastro100% (1)

- Tower Crane Cop 2006Document58 pagesTower Crane Cop 2006ooi100% (1)

- Crane Components: Technical CatalogueDocument30 pagesCrane Components: Technical CatalogueWissam JarmakNo ratings yet

- SC10876B - Hoist DrawingDocument1 pageSC10876B - Hoist DrawingMotlatjo RakgothoNo ratings yet

- Pm530-C Tower Crane Safety Monitoring System: Product Manual StatementDocument26 pagesPm530-C Tower Crane Safety Monitoring System: Product Manual StatementkabirmkjgfjNo ratings yet

- Hooks: Safety Standard For Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and SlingsDocument34 pagesHooks: Safety Standard For Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and SlingsRafaelMallquiAntialonNo ratings yet

- MHE-Demag Crane Rail Technology (H10 14-12EN)Document6 pagesMHE-Demag Crane Rail Technology (H10 14-12EN)Dimas Arya WicaksanaNo ratings yet

- Cmaa 70 Cmaa 70 Crane Classification: Aisc Crane Building Classification Class A (Scrap Yard) - 500000-2000000 RepDocument3 pagesCmaa 70 Cmaa 70 Crane Classification: Aisc Crane Building Classification Class A (Scrap Yard) - 500000-2000000 RepmrnicusNo ratings yet

- Crane CalculationDocument1 pageCrane Calculationhino_kaguNo ratings yet

- Certificate For Examination of Overhead CraneDocument2 pagesCertificate For Examination of Overhead CraneAnisha MayaNo ratings yet

- Stahl - SH Wire Rope Hoist BrochureDocument24 pagesStahl - SH Wire Rope Hoist BrochureNarayan PrasadNo ratings yet

- Owner'S Manual For End Carriage: ECN11-2562-A40996A0000-KEDocument10 pagesOwner'S Manual For End Carriage: ECN11-2562-A40996A0000-KEmanafNo ratings yet

- 1 Erection & Maint Manual CranesDocument19 pages1 Erection & Maint Manual Cranesadarsh_saxena2627No ratings yet

- Jib Cranes: Ree StandingDocument6 pagesJib Cranes: Ree StandingtintucinbNo ratings yet

- RTG Konecranes Booklet RTG Retrofits 2015 enDocument28 pagesRTG Konecranes Booklet RTG Retrofits 2015 enFendy KurniadiNo ratings yet

- Abus Cranes CatalogDocument28 pagesAbus Cranes CatalogGeorge JabbourNo ratings yet

- Katalog Stahlplus EngDocument254 pagesKatalog Stahlplus EngNilesh MahajanNo ratings yet

- 4ductor Engl PDFDocument8 pages4ductor Engl PDFNilesh MahajanNo ratings yet

- Designing of Cranes With StandardsDocument95 pagesDesigning of Cranes With Standardsank_mehraNo ratings yet

- Crane HookDocument55 pagesCrane HookEr Prabhakar100% (3)

- Spare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesDocument20 pagesSpare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesGuillermoNo ratings yet

- Goliath CraneDocument2 pagesGoliath CraneZankar R ParikhNo ratings yet

- Design Guide For Overhead CranesDocument3 pagesDesign Guide For Overhead CranesralluinNo ratings yet

- GM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBDocument1 pageGM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBEduardo Garcia SaraviaNo ratings yet

- Overview of Eclectric Overhead Traveling Cranes PDFDocument121 pagesOverview of Eclectric Overhead Traveling Cranes PDFSamik Mukherjee100% (1)

- EOT CraneDocument84 pagesEOT CraneSambhav Poddar80% (5)

- D06-003 - Overview of Electric Overhead Traveling (EOT) Cranes - USDocument121 pagesD06-003 - Overview of Electric Overhead Traveling (EOT) Cranes - USDiegO OliveiraNo ratings yet

- Electric Overhad Travelling CranesDocument84 pagesElectric Overhad Travelling CranesVinay KumarNo ratings yet

- DOE-STD 1090-99 Hosting & RiggingDocument403 pagesDOE-STD 1090-99 Hosting & RiggingalphadingNo ratings yet

- Bridge CranesDocument83 pagesBridge Cranesflasnicug100% (1)

- CALDON LEFM 3xxci Ultrasonic Flowmeters With G3 Transmitters ManualDocument84 pagesCALDON LEFM 3xxci Ultrasonic Flowmeters With G3 Transmitters Manualangel uscangaNo ratings yet

- Tehnical Description Electropalan 2000kgDocument2 pagesTehnical Description Electropalan 2000kgIosif DURANo ratings yet

- Austlift Part-4.MaterialHandlingDocument18 pagesAustlift Part-4.MaterialHandlingNeil WayneNo ratings yet

- Chapter 06Document10 pagesChapter 06Kabil RajNo ratings yet

- Hydraulic Crawler Crane: Standard ConfigurationDocument12 pagesHydraulic Crawler Crane: Standard Configurationmail_mulyadi5151No ratings yet

- S76A AMM Chapter 07Document18 pagesS76A AMM Chapter 07Paulo BernardoNo ratings yet

- Drill Pipe Handler Operating ManualDocument48 pagesDrill Pipe Handler Operating ManualJose Luis Rodriguez FernandezNo ratings yet

- Inspection Checklist Overhead CraneDocument2 pagesInspection Checklist Overhead CraneMohammad Safdar SadatNo ratings yet

- 09a Weekly Safety AssessmentDocument4 pages09a Weekly Safety AssessmentMohammed MinhajNo ratings yet

- CS1000 - CatalogoDocument199 pagesCS1000 - CatalogoVinicius FelipeNo ratings yet

- Brochure S-Series Crane en 0Document5 pagesBrochure S-Series Crane en 0Aydin BighamNo ratings yet

- Verlinde Catalog PDFDocument44 pagesVerlinde Catalog PDFAgustinus Made Theo DwijayaNo ratings yet

- 29596-97 YSX40E en r0Document235 pages29596-97 YSX40E en r0darmaalikhwan7470% (1)

- P.DC Pro 1-20, DCM1-5Document68 pagesP.DC Pro 1-20, DCM1-5Andi KastrawanNo ratings yet

- LSA - Lifting & Hoisting - EN - ARDocument2 pagesLSA - Lifting & Hoisting - EN - ARmuatazNo ratings yet

- Emergency Braking Systems For Mine ElevatorsDocument19 pagesEmergency Braking Systems For Mine ElevatorsDhanraj PatilNo ratings yet

- Crane Safety Training CLP. 15.11.2016 .Pps PDFDocument117 pagesCrane Safety Training CLP. 15.11.2016 .Pps PDFJSW Bellary, Project100% (1)

- Osha Standard (Construction)Document9 pagesOsha Standard (Construction)Sameer PatilNo ratings yet

- Handling Loads Suspended From Rotorcraft: ASME B30.12-2006Document34 pagesHandling Loads Suspended From Rotorcraft: ASME B30.12-2006Mark D VillanuevaNo ratings yet

- General Safety Induction ProgrammeDocument39 pagesGeneral Safety Induction ProgrammePradeep Nair100% (1)

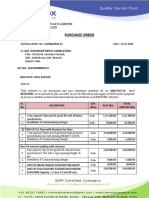

- Purchase Order: Chemox Pharma Private Limited GST NO: 24AAICC4574G1ZN Pan No: Aaicc4574GDocument7 pagesPurchase Order: Chemox Pharma Private Limited GST NO: 24AAICC4574G1ZN Pan No: Aaicc4574GVipul RathodNo ratings yet

- Product Presentation - Oct 2016Document143 pagesProduct Presentation - Oct 2016Dwi PutraNo ratings yet

- Specification Equipment For StringingDocument36 pagesSpecification Equipment For StringingedwardoNo ratings yet

- Freestanding Jib Crane: Spanco® Product Specifications 1Document10 pagesFreestanding Jib Crane: Spanco® Product Specifications 1behruzNo ratings yet

- CM Cady CatalogDocument67 pagesCM Cady Catalogsuperman3kNo ratings yet

Guide To Overhead Cranes

Guide To Overhead Cranes

Uploaded by

spacejuyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guide To Overhead Cranes

Guide To Overhead Cranes

Uploaded by

spacejuyCopyright:

Available Formats

Guide to Overhead

Cranes

Request for Quotation

Munck Cranes Inc.

403 Dewitt Rd.

Stoney Creek, ON

L8E 4B9

Phone: (905) 561-2100

Toll Free: 1-800-461-4509

Fax: (905) 561-1238

sales@munckcranes.com

service@munckcranes.com

engineering@munckcranes.com

Company Name:

Address:

City, Province:

Contact Name:

Postal Code:

Phone:

Job Reference:

E-Mail Address:

Equipment Type:

T/R D/G Bridge Crane

T/R S/G Bridge Crane

U/R S/G Bridge Crane

Jib Crane

Fax:

D/G Trolley Hoist

S/G Trolley Hoist

Monorail Trolley Hoist

Radio Control Unit

D/G Gantry Crane

S/G Gantry Crane

Chain Hoist

Other:

Main Hoist

Auxiliary Hoist (if applicable)

Bridge (if applicable)

Lifting Capacity:

Lifting Capacity:

Capacity:

Lift Height:

Lift Height:

Span:

Lift Speeds:

Single Speed

Two Speed

VFD

Lift Speeds:

Single Speed

Two Speed

VFD

Trolley Speeds:

Single Speed

Two Speed

VFD

Trolley Speeds:

Single Speed

Two Speed

VFD

www.munckcranes.com

Travel speeds:

Single Speed

Two Speed

VFD

If there are two hoists on this equipment, are they to be on separate trolleys or one common trolley? Separate

Control

Other

Pendant on Track

Pendant from Hoist

Power Supply:

Radio Control with Pendant Back-Up

Enclosures:

Common

CEMA 1

CEMA 12

CEMA 4

Columns

Rail

Runway

Do you require a runway system for this equipment?

Yes

No

If yes, please check all the components you require.

Conductor

Beam

free standing

tied back to existing structure

What is the required length of the runway?

If new columns are required, will they be

What is or what will be the down shop center to center spacing between them?

Do you require installation of this equipment?

Yes

No

Do you require freight to the job site?

Yes

No

If yes, what is the location?

Your Overhead Crane Specialists

This pamphlet is intended to give a general understanding of the

terminology used in the overhead crane industry. The following

explanation of terms should provide you with the information you

will need to make an informed decision when purchasing material

handling equipment. On the reverse side of this pamphlet, you will

find an easy to use Request for Quotation form which can be

faxed to our office. If you have any questions regarding this

brochure or any of the products or services we provide, please

contact us.

Equipment Types

Under Running (U/R) - The crane bridge travels on the bottom

flange of the runway beam which is usually supported by the roof

structure. (See the third graphic on the front of this pamphlet.)

Standard Overhead, Jib and Gantry Cranes

Crane Components

Custom Cranes

Bridge - The main travelling structure of the crane which spans the

width of the bay. The bridge consists of two end trucks and one or

two bridge girders depending on the Equipment Type.

Heavy Duty Cranes

Runway Systems and Monorail Systems

Installations by Factory Trained Personnel

Rebuilds, Upgrades and Modifications of

Existing Systems

Parts for All Cranes and Related Equipment

for All Manufacturers

Service - Emergency 24 Hour Service

- Equipment Inspections

- Inspection Certificates (Ministry of

Labour Accepted)

Non-destructive Testing for All Types of

Lifting Attachments

Training Seminars in Crane Operation

End trucks - Located on either side of the span, the end trucks

house the wheels on which the entire crane travels. These wheels

ride on the runway beam allowing access to the entire length of the

bay.

Bridge Girder(s) - The principal horizontal beam of the crane

bridge which supports the trolley and is supported by the

endtrucks.

Trolley Hoist - The unit consisting of both the hoist and the trolley

frame. In situations where more than one hoist is required on one

crane, both hoists can be supplied on a single trolley or on

separate trolleys.

Trolley - The trolley carries the hoist across the bay along the

bridge girder(s) traversing the span.

Hoist - The hoist is mounted to the trolley and performs the actual

lifting function via a hook or lifting attachment. There are two basic

types of hoist. The Munck brand is a Wire Rope Hoist which is

very durable and will provide long term, reliable usage. The other

type of hoist is the Chain Hoist. These hoists are used for lower

capacity, lighter duty applications and for projects in which cost is

a primary deciding factor.

Basic Terminology

Chain Hoists and Lifting Attachments

Capacity - The maximum weight the crane will be required to lift.

Span - The horizontal distance between the rails of the runway on

which the crane is to travel.

Lift or Hook Height - The required distance from the floor to the

crane hook. This dimension is critical in most applications as it

determines the height of the runway from the floor and is

dependent on the clear inside height of the building.

Bridge, Trolley and Lift Speeds - The rate at which the bridge

or trolley travels, or at which the hoist lifts, usually in feet per

minute or FPM. You may specify either Single Speed or Two

Speed travel/lift or a specific rate of speed, (i.e. 120 & 30 FPM

bridge travel). Another option as far a motion speeds are

concerned is a Variable Frequency Drive. See the Control

section for more information.

This section specifies the kind of equipment you require.

Overhead cranes come in four basic configurations;

Top Running (T/R) - The crane bridge travels on top of rails

mounted on a runway beam supported by either the building

columns or columns specifically engineered for the crane. (See

the first and second graphics on the front of this pamphlet.)

Single Girder (S/G) - The crane consists of two end trucks, a

single bridge girder and the trolley hoist unit. The trolley runs on the

bottom flange of the bridge girder. (See the second and third

graphics on the front of this pamphlet.)

Double Girder (D/G) - The crane consists of two end trucks, two

bridge girders and the trolley hoist unit. The trolley runs on rails on

top of the bridge girders. (See the first graphic on the front of this

pamphlet.)

A variation on these types of overhead crane are Gantry Cranes.

These cranes are essentially the same as the regular overhead

cranes, however, the bridge girder(s) are connected to legs on

either side of the span. These legs eliminate the supporting

runway and column system and connect to end trucks which run on

a rail either embedded in, or laid on top of, the floor.

For some applications only a Trolley Hoist is required. For

instance, in the case of a monorail system a Trolley Hoist unit

similar to the one used on single girder cranes is mounted on a

beam which might be used to service an assembly line within the

clients facility. Other clients may have an existing single or double

girder crane bridge and may just want to replace the hoisting unit.

In most of these situations, capacity permitting, we can provide

either a Wire Rope or Chain Hoist.

Another solution which may fit your needs is a Jib Crane. A Jib

Crane basically consists of a boom which is supported as a

cantilever on a column. A Trolley Hoist travels along the boom

which can rotate up to 360E.

Control

Pendant - The pendant gives the operator precise control over the

motions of the crane. There are many configurations of pendant

depending on the functions of the equipment being controlled.

Each pushbutton on the pendent controls an operating function of

the crane.

The pendant may be suspended from the Trolley Hoist, requiring

the operator to walk with and beside the load, or on a separate

sliding track system allowing the operator to move independently

of the load.

VFD - A pendant can also be used in conjunction with a Variable

Frequency Drive. A VFD is used to vary the frequency of the

motors controlling the motions allowing for smooth acceleration

and deceleration. The buttons on the pendant operate a VFD unit

operated in much the same way as Two Speed control. The first

step is held to maintain the current speed while the second step is

used for acceleration. Deceleration is achieved by releasing the

button entirely. Pressing the button back to the first step will

maintain the new slower speed. It should be noted that the

deceleration is not achieved through uncontrolled coasting but

through a programable dynamic braking system. The control

provided by a VFD allows for a high level of customization.

Radio Control - The radio control performs exactly like the

pendant but operates using a radio frequency. The radio control

incorporates numerous safety features and allows the operator a

greater range of operator motion than a pendant.

Power Supply - The electrical service available in the building for

which the crane is being designed (i.e. 575 Volt, 3 phase, 60

Hertz).

Enclosures - The enclosures house all of the electrical

components on the crane and are rated by the National Electrical

Manufacturers Association (NEMA) or the Canadian Electrical

Manufacturers Association as to the level of protection they

provide from the conditions in the surrounding environment. There

are three basic levels of protection.

CEMA/NEMA 1 - Provides protection against accidental contact

with, and electrical shock from, enclosed equipment.

CEMA/NEMA 12 - Provides indoor protection against falling dirt,

dust, oil and water.

CEMA/NEMA 4 - Provides indoor protection in hosed down, very

wet or outdoor environments, as well as falling dirt, dust, oil and

water.

Runway

The rails, beams and columns on which the crane operates. The

rail, on which the endtrucks run, is fastened to the runway beam.

This beam is then supported on columns (Top Running) or from

the roof structure (Under Running). The existing building columns

can be used or new ones can be supplied with the system. New

columns can either be completely Free Standing or Tied Back to

the existing building structure for additional lateral support. When

designing a runway system that is to use existing building columns,

it is important to provide the down shop center to center spacing

between them. Conductors supply power to the crane and are

mounted on the runway beam.

You might also like

- Sugar Plant Specifications 5000 TCD-7500 TCDDocument104 pagesSugar Plant Specifications 5000 TCD-7500 TCDtsrinivasan508375% (4)

- SopManual HD255-5 PDFDocument975 pagesSopManual HD255-5 PDFQuy Le ThanhNo ratings yet

- TC5013A Manual 101208 PDFDocument108 pagesTC5013A Manual 101208 PDFThiyagarajan Murugesan100% (1)

- 11# EOT Crane Operation ManualDocument82 pages11# EOT Crane Operation Manualibnmessaoud10100% (5)

- Mathcad - Crane CalculationsDocument9 pagesMathcad - Crane Calculationsapi-232034744No ratings yet

- Crane ManualDocument91 pagesCrane ManualSuguna Devi100% (1)

- Gantry CraneDocument9 pagesGantry Craneyuza_maulana020% (1)

- Report On Gantry Crane and Overhead CraneDocument23 pagesReport On Gantry Crane and Overhead CraneAbhay UpadhyayNo ratings yet

- Asme B30.16, BS 3243, BS 4898Document2 pagesAsme B30.16, BS 3243, BS 4898engmuhmudNo ratings yet

- Lifting & Rigging ProceduresDocument32 pagesLifting & Rigging ProceduresBrunoro DantasNo ratings yet

- Design of CranesDocument24 pagesDesign of CranessourabhNo ratings yet

- Electric Overhead Traveling Nav GNFCDocument7 pagesElectric Overhead Traveling Nav GNFCkeyur1109No ratings yet

- Lifting MethodsDocument10 pagesLifting Methodsselva1965No ratings yet

- EN DEMAG PogledajDocument158 pagesEN DEMAG PogledajNenad TabandzelicNo ratings yet

- KBK SistemiDocument28 pagesKBK SistemiGogy100% (1)

- Operation Manual YALEDocument56 pagesOperation Manual YALEmarija1967No ratings yet

- Bridge and Gantry Crane Drivers Guide 0001Document72 pagesBridge and Gantry Crane Drivers Guide 0001John Henry SinuratNo ratings yet

- 2 Tonne Spark Resistant 220model Post Swing Jib Crane - 1Document1 page2 Tonne Spark Resistant 220model Post Swing Jib Crane - 1AnishNo ratings yet

- Non-Driven Wheel DIN15090 Series 223 enDocument1 pageNon-Driven Wheel DIN15090 Series 223 enayavuzbvsNo ratings yet

- Crane ManaulDocument18 pagesCrane ManaulfaisalnadimNo ratings yet

- TGN 08 Crane Rail Selection 2Document3 pagesTGN 08 Crane Rail Selection 2Prasad PatilNo ratings yet

- Demag DMR (Brochure)Document20 pagesDemag DMR (Brochure)MadhaneNo ratings yet

- Multiple Crane LiftingDocument11 pagesMultiple Crane LiftingAbdul Majid ZulkarnainNo ratings yet

- Guide For EOT Crane SelectionDocument15 pagesGuide For EOT Crane SelectionMaulik Patel100% (1)

- Gantry GirderDocument38 pagesGantry GirderPiyush Yadav75% (4)

- GantryDocument7 pagesGantrysatydevsinghnegiNo ratings yet

- Crane Solutions and ModelsDocument24 pagesCrane Solutions and ModelsAmandeep NandaNo ratings yet

- Specifications Goliath CranesDocument8 pagesSpecifications Goliath CranesarvindkaushikNo ratings yet

- Crane PDFDocument102 pagesCrane PDFBrook KingNo ratings yet

- Balok CraneDocument31 pagesBalok CraneEzekiel Ezhe Iwawo100% (1)

- Abacus HoistDocument22 pagesAbacus Hoistomiti Engineering systemsNo ratings yet

- Top Running, Double Girder Overhead Cranes: Engineering & Design DataDocument8 pagesTop Running, Double Girder Overhead Cranes: Engineering & Design DataSteven SebastianNo ratings yet

- Port Douglas 3 304Document1 pagePort Douglas 3 304Ngaire TaylorNo ratings yet

- EOT Crane Maintenance ManualDocument99 pagesEOT Crane Maintenance ManualAvishek DasNo ratings yet

- Eurobloc VT 9 10 11 12 GBDocument6 pagesEurobloc VT 9 10 11 12 GBToni RenedoNo ratings yet

- Spanco Freestanding Jib Cranes ManualDocument40 pagesSpanco Freestanding Jib Cranes ManualMarceloPolicastro100% (1)

- Tower Crane Cop 2006Document58 pagesTower Crane Cop 2006ooi100% (1)

- Crane Components: Technical CatalogueDocument30 pagesCrane Components: Technical CatalogueWissam JarmakNo ratings yet

- SC10876B - Hoist DrawingDocument1 pageSC10876B - Hoist DrawingMotlatjo RakgothoNo ratings yet

- Pm530-C Tower Crane Safety Monitoring System: Product Manual StatementDocument26 pagesPm530-C Tower Crane Safety Monitoring System: Product Manual StatementkabirmkjgfjNo ratings yet

- Hooks: Safety Standard For Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and SlingsDocument34 pagesHooks: Safety Standard For Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and SlingsRafaelMallquiAntialonNo ratings yet

- MHE-Demag Crane Rail Technology (H10 14-12EN)Document6 pagesMHE-Demag Crane Rail Technology (H10 14-12EN)Dimas Arya WicaksanaNo ratings yet

- Cmaa 70 Cmaa 70 Crane Classification: Aisc Crane Building Classification Class A (Scrap Yard) - 500000-2000000 RepDocument3 pagesCmaa 70 Cmaa 70 Crane Classification: Aisc Crane Building Classification Class A (Scrap Yard) - 500000-2000000 RepmrnicusNo ratings yet

- Crane CalculationDocument1 pageCrane Calculationhino_kaguNo ratings yet

- Certificate For Examination of Overhead CraneDocument2 pagesCertificate For Examination of Overhead CraneAnisha MayaNo ratings yet

- Stahl - SH Wire Rope Hoist BrochureDocument24 pagesStahl - SH Wire Rope Hoist BrochureNarayan PrasadNo ratings yet

- Owner'S Manual For End Carriage: ECN11-2562-A40996A0000-KEDocument10 pagesOwner'S Manual For End Carriage: ECN11-2562-A40996A0000-KEmanafNo ratings yet

- 1 Erection & Maint Manual CranesDocument19 pages1 Erection & Maint Manual Cranesadarsh_saxena2627No ratings yet

- Jib Cranes: Ree StandingDocument6 pagesJib Cranes: Ree StandingtintucinbNo ratings yet

- RTG Konecranes Booklet RTG Retrofits 2015 enDocument28 pagesRTG Konecranes Booklet RTG Retrofits 2015 enFendy KurniadiNo ratings yet

- Abus Cranes CatalogDocument28 pagesAbus Cranes CatalogGeorge JabbourNo ratings yet

- Katalog Stahlplus EngDocument254 pagesKatalog Stahlplus EngNilesh MahajanNo ratings yet

- 4ductor Engl PDFDocument8 pages4ductor Engl PDFNilesh MahajanNo ratings yet

- Designing of Cranes With StandardsDocument95 pagesDesigning of Cranes With Standardsank_mehraNo ratings yet

- Crane HookDocument55 pagesCrane HookEr Prabhakar100% (3)

- Spare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesDocument20 pagesSpare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesGuillermoNo ratings yet

- Goliath CraneDocument2 pagesGoliath CraneZankar R ParikhNo ratings yet

- Design Guide For Overhead CranesDocument3 pagesDesign Guide For Overhead CranesralluinNo ratings yet

- GM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBDocument1 pageGM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBEduardo Garcia SaraviaNo ratings yet

- Overview of Eclectric Overhead Traveling Cranes PDFDocument121 pagesOverview of Eclectric Overhead Traveling Cranes PDFSamik Mukherjee100% (1)

- EOT CraneDocument84 pagesEOT CraneSambhav Poddar80% (5)

- D06-003 - Overview of Electric Overhead Traveling (EOT) Cranes - USDocument121 pagesD06-003 - Overview of Electric Overhead Traveling (EOT) Cranes - USDiegO OliveiraNo ratings yet

- Electric Overhad Travelling CranesDocument84 pagesElectric Overhad Travelling CranesVinay KumarNo ratings yet

- DOE-STD 1090-99 Hosting & RiggingDocument403 pagesDOE-STD 1090-99 Hosting & RiggingalphadingNo ratings yet

- Bridge CranesDocument83 pagesBridge Cranesflasnicug100% (1)

- CALDON LEFM 3xxci Ultrasonic Flowmeters With G3 Transmitters ManualDocument84 pagesCALDON LEFM 3xxci Ultrasonic Flowmeters With G3 Transmitters Manualangel uscangaNo ratings yet

- Tehnical Description Electropalan 2000kgDocument2 pagesTehnical Description Electropalan 2000kgIosif DURANo ratings yet

- Austlift Part-4.MaterialHandlingDocument18 pagesAustlift Part-4.MaterialHandlingNeil WayneNo ratings yet

- Chapter 06Document10 pagesChapter 06Kabil RajNo ratings yet

- Hydraulic Crawler Crane: Standard ConfigurationDocument12 pagesHydraulic Crawler Crane: Standard Configurationmail_mulyadi5151No ratings yet

- S76A AMM Chapter 07Document18 pagesS76A AMM Chapter 07Paulo BernardoNo ratings yet

- Drill Pipe Handler Operating ManualDocument48 pagesDrill Pipe Handler Operating ManualJose Luis Rodriguez FernandezNo ratings yet

- Inspection Checklist Overhead CraneDocument2 pagesInspection Checklist Overhead CraneMohammad Safdar SadatNo ratings yet

- 09a Weekly Safety AssessmentDocument4 pages09a Weekly Safety AssessmentMohammed MinhajNo ratings yet

- CS1000 - CatalogoDocument199 pagesCS1000 - CatalogoVinicius FelipeNo ratings yet

- Brochure S-Series Crane en 0Document5 pagesBrochure S-Series Crane en 0Aydin BighamNo ratings yet

- Verlinde Catalog PDFDocument44 pagesVerlinde Catalog PDFAgustinus Made Theo DwijayaNo ratings yet

- 29596-97 YSX40E en r0Document235 pages29596-97 YSX40E en r0darmaalikhwan7470% (1)

- P.DC Pro 1-20, DCM1-5Document68 pagesP.DC Pro 1-20, DCM1-5Andi KastrawanNo ratings yet

- LSA - Lifting & Hoisting - EN - ARDocument2 pagesLSA - Lifting & Hoisting - EN - ARmuatazNo ratings yet

- Emergency Braking Systems For Mine ElevatorsDocument19 pagesEmergency Braking Systems For Mine ElevatorsDhanraj PatilNo ratings yet

- Crane Safety Training CLP. 15.11.2016 .Pps PDFDocument117 pagesCrane Safety Training CLP. 15.11.2016 .Pps PDFJSW Bellary, Project100% (1)

- Osha Standard (Construction)Document9 pagesOsha Standard (Construction)Sameer PatilNo ratings yet

- Handling Loads Suspended From Rotorcraft: ASME B30.12-2006Document34 pagesHandling Loads Suspended From Rotorcraft: ASME B30.12-2006Mark D VillanuevaNo ratings yet

- General Safety Induction ProgrammeDocument39 pagesGeneral Safety Induction ProgrammePradeep Nair100% (1)

- Purchase Order: Chemox Pharma Private Limited GST NO: 24AAICC4574G1ZN Pan No: Aaicc4574GDocument7 pagesPurchase Order: Chemox Pharma Private Limited GST NO: 24AAICC4574G1ZN Pan No: Aaicc4574GVipul RathodNo ratings yet

- Product Presentation - Oct 2016Document143 pagesProduct Presentation - Oct 2016Dwi PutraNo ratings yet

- Specification Equipment For StringingDocument36 pagesSpecification Equipment For StringingedwardoNo ratings yet

- Freestanding Jib Crane: Spanco® Product Specifications 1Document10 pagesFreestanding Jib Crane: Spanco® Product Specifications 1behruzNo ratings yet

- CM Cady CatalogDocument67 pagesCM Cady Catalogsuperman3kNo ratings yet