Professional Documents

Culture Documents

Introduction To Unit Operations: Fundamental Concepts: 1.1 Process

Introduction To Unit Operations: Fundamental Concepts: 1.1 Process

Uploaded by

Janpol AldairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction To Unit Operations: Fundamental Concepts: 1.1 Process

Introduction To Unit Operations: Fundamental Concepts: 1.1 Process

Uploaded by

Janpol AldairCopyright:

Available Formats

TX69299 ch01 frame.

book Page 1 Wednesday, September 4, 2002 2:13 PM

1

Introduction to Unit Operations:

Fundamental Concepts

1.1

Process

Process is the set of activities or industrial operations that modify the properties of raw materials with the purpose of obtaining products to satisfy the

needs of a society. Such modifications of natural raw materials are directed

to obtain products with greater acceptance in the market, or with better

possibilities of storage and transport.

The primary needs of every human being, individually or as a society,

have not varied excessively throughout history; food, clothing, and housing

were needed for survival by prehistoric man as well as by modern man. The

satisfaction of these necessities is carried out by employing, transforming,

and consuming resources available in natural surroundings.

In the early stages of mankinds social development, natural products were

used directly or with only small physical modifications. This simple productive scheme changed as society developed, so that, at the present time, raw

materials are not used directly to satisfy necessities, but rather are subjected

to physical and chemical transformations that convert them into products

with different properties.

This way, not only do raw materials satisfy the necessities of consumers,

but also those products derived from the manipulation of such raw materials.

1.2

Food Process Engineering

By analogy with other engineering branches, different definitions of food

process engineering can be given. Thus, according to one definition, food

process engineering includes the part of human activity in which the knowledge of physical, natural, and economic sciences is applied to agricultural

products as related to their composition, energetic content, or physical state.

1

2003 by CRC Press LLC

TX69299 ch01 frame.book Page 2 Wednesday, September 4, 2002 2:13 PM

Unit Operations in Food Engineering

Food process engineering can also be defined as the science of conceiving,

calculating, designing, building, and running the facilities where the transformation processes of agricultural products, at the industrial level and as

economically as possible, are carried out.

Thus, an engineer in the food industry should know the basic principles

of process engineering and be able to develop new production techniques

for agricultural products. He should also be capable of designing the equipment to be used in a given process. The main objective of food process

engineering is to study the principles and laws governing the physical,

chemical, or biochemical stages of different processes, and the apparatus or

equipment by which such stages are industrially carried out. The studies

should be focused on the transformation processes of agricultural raw materials into final products, or on conservation of materials and products.

1.3

Transformation and Commercialization

of Agricultural Products

For efficient commercialization, agricultural products should be easy to handle and to place in the market. As a general rule, products obtained directly

from the harvest cannot be commercialized as they are, but must undergo

certain transformations. Products that can be directly used should be adequately packaged according to requirements of the market. These products

are generally used as food and should be conveniently prepared for use.

One problem during handling of agricultural products is their transport

from the fields to the consumer. Since many agricultural products have a

short shelf life, treatment and preservation methods that allow their later

use should be developed. As mentioned earlier, many of these products

cannot be directly used as food but can serve as raw material to obtain other

products. Developed countries tend to elaborate such products in the harvest

zone, avoiding perishable products that deteriorate during transport from

the production zone to the processing plant.

1.4

Flow Charts and Description of Some Food Processes

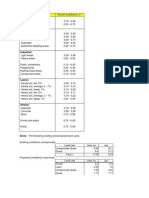

Food processes are usually schematized by means of flow charts. These are

diagrams of all processes that indicate different manufacturing steps, as well

as the flow of materials and energy in the process.

There are different types of flow charts; the most common use blocks or

rectangles. In these charts each stage of the process is represented by a

block or rectangle connected by arrows to indicate the way in which the

materials flow. The stage represented is written within the rectangle.

2003 by CRC Press LLC

TX69299 ch01 frame.book Page 3 Wednesday, September 4, 2002 2:13 PM

Introduction to Unit Operations: Fundamental Concepts

Olives

WASHING

PRESSING

Bagasse

Oil from

press

DRYING

CENTRIFUGATION

Exhausted

bagasse

Virgin oil

EXTRACTION

Bagasse oil

FIGURE 1.1

Extraction of olive oil.

Other types of flow charts are equipment and instrumentation.

Figures 1.1, 1.2, and 1.3 show some flow charts of food processes.

1.5

Steady and Unsteady States

A system is said to be under steady state when all the physical variables

remain constant and invariable along time, at any point of the system; however, they may be different from one point to another. On the other hand,

when the characteristic intensive variables of the operation vary through the

system at a given moment and the variables corresponding to each systems

point vary along time, the state is called unsteady. The physical variables to

consider may be mechanical or thermodynamic. Among the former are volume, velocity, etc., while the thermodynamic variables are viscosity, concentration, temperature, pressure, etc.

1.6

Discontinuous, Continuous, and

Semicontinuous Operations

The operations carried out in the industrial processes may be performed in

three different ways. In a discontinuous operation the raw material is loaded

2003 by CRC Press LLC

TX69299 ch01 frame.book Page 4 Wednesday, September 4, 2002 2:13 PM

Unit Operations in Food Engineering

Fruit

CRUSHING

PRESSING

Pulp

Juice 12 Brix

PRE-CONCENTRATION

Water and

aromas

Juice 15 Brix

ENZYMATIC

TREATMENT

CLARIFICATION

EVAPORATION

Water

Juice 70 Brix

COOLING

STORAGE

FIGURE 1.2

Production of fruit concentrated juices.

in the equipment; after performing the required transformation, the obtained

products are unloaded. These operations, also called batch or intermittent, are carried out in steps:

1.

2.

3.

4.

5.

Loading of equipment with raw materials

Preparation of conditions for transformation

Required transformation

Unloading products

Cleaning equipment

The batch operation takes place under an unsteady state, since its intensive

properties vary along time. An example of this batch process is the crushing

of oily seeds to obtain oil.

2003 by CRC Press LLC

TX69299 ch01 frame.book Page 5 Wednesday, September 4, 2002 2:13 PM

Introduction to Unit Operations: Fundamental Concepts

Roasted

coffee

GRINDING

Hot

water

EXTRACTION

Solid

waste

Coffee exhaust

(diluted solution)

EVAPORATION

Water

vapor

Coffee extract

(concentrated solution)

DRYING

Water

Soluble coffee

FIGURE 1.3

Elaboration of soluble coffee.

In continuous operations the loading, transformation, and unloading

stages are performed simultaneously. Equipment cleaning is carried out

every given time, depending on the nature of the process and the materials

used. To carry out the cleaning, production must be stopped. Continuous

operations take place under steady state, in such a way that the characteristic

intensive variables of the operation may vary at each point of the system

but do not vary along time. It is difficult to reach an absolute steady state,

since there may be some unavoidable fluctuations. An example of a continuous operation is the rectification of an alcoholwater mixture.

In some cases it is difficult to have a continuous operation; this type of

operation is called semicontinuous. A semicontinuous operation may occur

by loading some materials in the equipment that will remain there for a

given time in a discontinuous way, while other materials enter or exit continuously. Sometimes it is necessary to unload those accumulated materials.

For example, in the extraction of oil by solvents, flour is loaded and the

solvent is fed in a continuous way; after some time, the flour runs out of oil

and must be replaced.

2003 by CRC Press LLC

TX69299 ch01 frame.book Page 6 Wednesday, September 4, 2002 2:13 PM

Unit Operations in Food Engineering

These different ways of operation present advantages and disadvantages.

Advantages of continuous operation include:

1.

2.

3.

4.

Loading and unloading stages are eliminated.

It allows automation of the operation, thus reducing the work force.

Composition of products is more uniform.

There is better use of thermal energy.

Disadvantages of continuous operation are:

1. Raw materials should have a uniform composition to avoid operation fluctuations.

2. Is usually expensive to start the operation, so stops should be

avoided.

3. Fluctuations in product demand require availability of considerable quantities of raw materials and products in stock.

4. Due to automation of operation, equipment is more expensive and

delicate.

Continuous operation is performed under an unsteady state during starts

and stops but, once adequately running, may be considered to be working

under steady state. This is not completely true, however, since there could

be fluctuations due to variations in the composition of the raw materials and

due to modifications of external agents.

When selecting a form of operation, the advantages and disadvantages of

each type should be considered. However, when low productions are

required, it is recommended to work under discontinuous conditions. When

high productions are required, it is more profitable to operate in a continuous

way.

1.7

Unit Operations: Classification

When analyzing the flow charts of different processes described in other

sections, it can be observed that some of the stages are found in all of them.

Each of these stages is called basic or unit operation, in common with many

industrial processes. The individual operations have common techniques

and are based on the same scientific principles, simplifying the study of these

operations and the treatment of these processes.

There are different types of unit operations depending on the nature of

the transformation performed; thus, physical, chemical, and biochemical

stages can be distinguished:

2003 by CRC Press LLC

TX69299 ch01 frame.book Page 7 Wednesday, September 4, 2002 2:13 PM

Introduction to Unit Operations: Fundamental Concepts

Physical stages: grinding, sieving, mixture, fluidization, sedimentation, flotation, filtration, rectification, absorption, extraction,

adsorption, heat exchange, evaporation, drying, etc.

Chemical stages: refining, chemical peeling

Biochemical stages: fermentation, sterilization, pasteurization,

enzymatic peeling

Hence, the group of physical, chemical, and biochemical stages that take

place in the transformation processes of agricultural products constitute the

so-called unit operations of the food industry, the purpose of which is the

separation of two or more substances present in a mixture, or the exchange

of a property due to a gradient. Separation is achieved by means of a separating agent that is different, depending on the transferred property.

Unit operations can be classified into different groups depending on the

transferred property, since the possible changes that a body may undergo

are defined by variations in either its mass, energy, or velocity. Thus, unit

operations are classified under mass transfer, heat transfer, or momentum

transfer.

Besides the unit operations considered in each mentioned group, there

exist those of simultaneous heat and mass transfer, as well as other operations that cannot be classified in any of these groups and are called complementary unit operations.

All the unit operations grouped in these sections are found in physical

processes; however, certain operations that include chemical reactions can

be included.

1.7.1

Momentum Transfer Unit Operations

These operations study the processes in which two phases at different velocities are in contact. The operations included in this section are generally

divided into three groups:

Internal circulation of fluids: study of the movement of fluids through

the interior of the tubing; also includes the study of equipment

used to impel the fluids (pumps, compressors, blowers, and fans)

and the mechanisms used to measure the properties of fluids

(diaphragms, venturi meters, rotameters, etc.).

External circulation of fluids: the fluid circulates through the external

part of a solid. This circulation includes the flow of fluids through

porous fixed beds, fluidized beds (fluidization), and pneumatic

transport.

Solids movement within fluids: the base for separation of solids within a fluid. This type of separation includes: sedimentation, filtration,

and ultrafiltration, among others.

2003 by CRC Press LLC

TX69299 ch01 frame.book Page 8 Wednesday, September 4, 2002 2:13 PM

Unit Operations in Food Engineering

1.7.2

Mass Transfer Unit Operations

These operations are controlled by the diffusion of a component within a

mixture. Some of the operations included in this group are:

Distillation: separation of one or more components by taking advantage of vapor pressure differences.

Absorption: a component of a gas mixture is absorbed by a liquid

according to the solubility of the gas in the liquid. Absorption may

occur with or without chemical reaction. The opposite process is

called desorption.

Extraction: based on the dissolution of a mixture (liquid or solid) in

a selective solvent, which can be liquidliquid or solidliquid. The

latter is also called washing, lixiviation, etc.

Adsorption: also called sorption, adsorption involves the elimination

of one or more components of a fluid (liquid or gas) by retention

on the surface of a solid.

Ionic exchange: substitution of one or more ions of a solution with

another exchange agent.

1.7.3

Heat Transfer Unit Operations

These operations are controlled by temperature gradients. They depend on

the mechanism by which heat is transferred:

Conduction: in continuous material media, heat flows in the direction

of temperature decrease and there is no macroscopic movement of

mass.

Convection: the enthalpy flow associated with a moving fluid is called

convective flow of heat. Convection can be natural or forced.

Radiation: energy transmission by electromagnetic waves. No material media are needed for its transmission.

Thermal treatments (sterilization and pasteurization), evaporation, heat

exchangers, ovens, solar plates, etc. are studied based on these heat transfer

mechanisms.

1.7.4

Simultaneous MassHeat Transfer Unit Operations

In these operations a concentration and a temperature gradient exist at the

same time:

Humidification and dehumidification: include the objectives of humidification and dehumidification of a gas and cooling of a liquid.

Crystallization: formation of solid glassy particles within a homogeneous liquid phase.

2003 by CRC Press LLC

TX69299 ch01 frame.book Page 9 Wednesday, September 4, 2002 2:13 PM

Introduction to Unit Operations: Fundamental Concepts

Dehydration: elimination of a liquid contained within a solid. The

application of heat changes the liquid, contained in a solid, into a

vapor phase. In freeze-drying, the liquid in solid phase is removed

by sublimation, i.e., by changing it into a vapor phase.

1.7.5

Complementary Unit Operations

One series of operations is not included in this classification because these

are not based on any of the transport phenomena cited previously. These

operations include grinding, milling, sieving, mixing of solids and pastes, etc.

1.8

Mathematical Setup of the Problems

The problems set up in the study of unit operations are very diverse,

although in all of them the conservation laws (mass, energy, momentum,

and stochiometric) of chemical reactions apply. Applying these laws to a

given problem is done to perform a balance of the property studied in

such a problem. In a general way, the expression of the mass, energy, and

momentum balances related to the unit time can be expressed as:

(Property entering the system) = (Property exiting the system)

+ ( Property that accumulates )

This is, that which enters into the system of the considered property is

equal to that which leaves what is accumulated. In a schematic way:

E =S+A

In cases where a chemical reaction exists, when carrying out a balance for

a component, an additional generation term may appear. In these cases the

balance expression will be:

E+G =S+A

When solving a given problem, a certain number of unknown quantities

or variables (V) are present, and a set of relationships or equations (R) is

obtained from the balances. According to values of V and R, the following

cases can arise:

If V < R, the problem is established incorrectly, or one equation is

repeated.

If V = R, the problem has only one solution.

If V > R, different solutions can be obtained; the best solution is

found by optimizing the process.

2003 by CRC Press LLC

TX69299 ch01 frame.book Page 10 Wednesday, September 4, 2002 2:13 PM

10

Unit Operations in Food Engineering

There are

F = V R

design variables. The different types of problems presented depend on the

type of equation obtained when performing the corresponding balances.

Thus,

Algebraic equations have an easy mathematical solution obtained

by analytical methods.

Differential equations are usually obtained for unsteady continuous processes. The solution of the mathematical model established

with the balances can be carried out through analytical or approximate methods. In some cases, differential equations may have an

analytical solution; however, when it is not possible to analytically

solve the mathematical model, it is necessary to appeal to approximate methods of numerical integration (digital calculus) or

graphic (analogic calculus).

Equations in finite differences are solved by means of analogic

computers which give the result in a graphic form. In some cases

the exact solution can be obtained by numerical methods.

2003 by CRC Press LLC

You might also like

- Mechanical Unit Operations 2015Document111 pagesMechanical Unit Operations 2015RebkaNo ratings yet

- 2.2. Step 1-Batch Versus Continuous ProcessDocument3 pages2.2. Step 1-Batch Versus Continuous ProcessAlejandro ReyesNo ratings yet

- PGD Project ProposalDocument4 pagesPGD Project Proposalenyi kennethNo ratings yet

- LectureDocument5 pagesLectureMahesh KumarNo ratings yet

- Some Innovative Drying Technologies For Dehydration of Foods PDFDocument11 pagesSome Innovative Drying Technologies For Dehydration of Foods PDFhari.suryanto8417100% (1)

- Introduction To Unit Operations and ProcessesDocument6 pagesIntroduction To Unit Operations and ProcessessosoNo ratings yet

- Dorado Assingment #1Document2 pagesDorado Assingment #1MARISSE LYN DORADONo ratings yet

- Unitops CH 1Document13 pagesUnitops CH 1Arturo TorresNo ratings yet

- Basic Consideration in Process Equipment DesignDocument65 pagesBasic Consideration in Process Equipment DesignAshish Sharma50% (4)

- Dehydration in Food Processing and Preservation: M. Shafiur RahmanDocument11 pagesDehydration in Food Processing and Preservation: M. Shafiur RahmanMaria MadanNo ratings yet

- Introduction To Plant DesignDocument9 pagesIntroduction To Plant DesignChimple MaanNo ratings yet

- Exergetic Assessment in Dairy IndustryDocument27 pagesExergetic Assessment in Dairy IndustrySanja SimicNo ratings yet

- Exergetic Assessment in Dairy IndustryDocument27 pagesExergetic Assessment in Dairy IndustrySanja SimicNo ratings yet

- Project - Theorical Framework and State of ArtDocument8 pagesProject - Theorical Framework and State of ArtRene AguilarNo ratings yet

- Lesson 1 PuppDocument35 pagesLesson 1 PuppMegan PakpahanNo ratings yet

- Heat Pump Assisted Drying of AgriculturalDocument19 pagesHeat Pump Assisted Drying of AgriculturalHang NguyenNo ratings yet

- Processes 08 00354 PDFDocument23 pagesProcesses 08 00354 PDFKNTNo ratings yet

- Scale-Up, Upstream and Downstream ProcessingDocument106 pagesScale-Up, Upstream and Downstream ProcessingAlbert KuufamNo ratings yet

- Report First DraftDocument31 pagesReport First DraftPrakash KhadkaNo ratings yet

- Blanching of Foods: Washington State University, Pullman, Washington, U.S.ADocument5 pagesBlanching of Foods: Washington State University, Pullman, Washington, U.S.ARizwan AhmedNo ratings yet

- CHE 410 Chemcal Process Industries Rev (Part 1)Document32 pagesCHE 410 Chemcal Process Industries Rev (Part 1)Benedick Jayson MartiNo ratings yet

- Processes: Ffect of Freeze-Drying On Quality and GrindingDocument23 pagesProcesses: Ffect of Freeze-Drying On Quality and GrindingBrexa ManagementNo ratings yet

- DE511 - 1084 - Lesson 5 - PPTDocument17 pagesDE511 - 1084 - Lesson 5 - PPTKumarNo ratings yet

- CHE 410 Unit Process and Operations Part2Document20 pagesCHE 410 Unit Process and Operations Part2Eilyza AballaNo ratings yet

- Skimmed Milk PlantDocument92 pagesSkimmed Milk PlantNSIKANABASI PETER AKPANNo ratings yet

- Unesco - Eolss Sample Chapters: Solar Drying - A Technology For Sustainable Agriculture and Food ProductionDocument9 pagesUnesco - Eolss Sample Chapters: Solar Drying - A Technology For Sustainable Agriculture and Food ProductionKhloud MadihNo ratings yet

- Elements of Food ProcessingDocument75 pagesElements of Food ProcessingEd Casas0% (1)

- Pharmaceutical ManufacturingDocument4 pagesPharmaceutical Manufacturingnevelle4667No ratings yet

- Group 6 (Recovered)Document21 pagesGroup 6 (Recovered)oluwasegunnathaniel0No ratings yet

- Some Recent Advances in Drying Technologies To Produce Particulate SolidsDocument15 pagesSome Recent Advances in Drying Technologies To Produce Particulate Solidsconker4No ratings yet

- Food Processing Plant Design LayoutDocument129 pagesFood Processing Plant Design LayoutAzizrahman AbubakarNo ratings yet

- Fermentation For DummiesDocument12 pagesFermentation For DummiesShahfaraNo ratings yet

- 228 PDFDocument11 pages228 PDFnauliNo ratings yet

- My Part in ProcessDocument8 pagesMy Part in ProcessSyafiyatulMunawarahNo ratings yet

- Fundamentals and Applications of High-Pressure Processing TechnologyDocument15 pagesFundamentals and Applications of High-Pressure Processing TechnologyLuca GarzilliNo ratings yet

- Whitepaper - Cleaning ProccessDocument15 pagesWhitepaper - Cleaning ProccessEddie Ajalcriña BocangelNo ratings yet

- Mini Project Reaction Stage1 (Student 4)Document5 pagesMini Project Reaction Stage1 (Student 4)M Asrar SidonNo ratings yet

- Chapter 1: General Information of Engineering and Its ApplicationDocument3 pagesChapter 1: General Information of Engineering and Its ApplicationSOm KAntaNo ratings yet

- Introduction Freeze DryingDocument82 pagesIntroduction Freeze DryingFabio Alexander Cortes RodriguezNo ratings yet

- Magarine PlantDocument99 pagesMagarine PlantNSIKANABASI PETER AKPANNo ratings yet

- Bios Era Part Ion 2Document10 pagesBios Era Part Ion 2Pooja Singh JainNo ratings yet

- Production Line Instant NoodleDocument13 pagesProduction Line Instant NoodleAnisah Aniz100% (1)

- List The Different Processes and Their Sequence Use in ManufacturingDocument3 pagesList The Different Processes and Their Sequence Use in ManufacturingTanvi ZakardeNo ratings yet

- Effect of Preservation Technologies On Microbial Inactivation in FoodsDocument4 pagesEffect of Preservation Technologies On Microbial Inactivation in FoodsTrysh IoanaNo ratings yet

- Material Balance With Out RXN Example Unit3-RSDocument129 pagesMaterial Balance With Out RXN Example Unit3-RSGodolias WoldemariamNo ratings yet

- AquaFit4Use - Water Quality Demands in Paper-Chemical-Food-Textile Industry PDFDocument125 pagesAquaFit4Use - Water Quality Demands in Paper-Chemical-Food-Textile Industry PDFVania Putri SenitaNo ratings yet

- A Review of Thin Layer Drying of Foods: Theory, Modeling, and Experimental ResultsDocument25 pagesA Review of Thin Layer Drying of Foods: Theory, Modeling, and Experimental ResultsFarelio JovanNo ratings yet

- Extrusion Technology For Novel Food PdtsDocument7 pagesExtrusion Technology For Novel Food Pdts9567592146No ratings yet

- Lecture No 1 PDLDocument4 pagesLecture No 1 PDLGoummeli6 SocratesNo ratings yet

- Enzymes As Industrial WorkhorseDocument69 pagesEnzymes As Industrial WorkhorseAlbert KuufamNo ratings yet

- Inorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyDocument37 pagesInorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyMohamed AbdelaalNo ratings yet

- Adigrat UniversityDocument41 pagesAdigrat Universityaregawi selemonNo ratings yet

- Reflection TabilogDocument2 pagesReflection TabilogSheila PalacayNo ratings yet

- Solar DrayerDocument12 pagesSolar Drayerfiras aliNo ratings yet

- Lecture 1Document12 pagesLecture 1TaytoNo ratings yet

- Food Processing EquipmentDocument6 pagesFood Processing EquipmentDevidas R AnantwarNo ratings yet

- Statistical Process ControlDocument6 pagesStatistical Process Controlmia farrowNo ratings yet

- Advances in Dairy ProductsFrom EverandAdvances in Dairy ProductsFrancesco ContoNo ratings yet

- Christian MathDocument3 pagesChristian MathGina MarmolNo ratings yet

- Final ExamDocument6 pagesFinal ExamAlber MartinsNo ratings yet

- Day 4Document9 pagesDay 4api-584365435No ratings yet

- Graphs and Transformations - HomeworkDocument3 pagesGraphs and Transformations - HomeworkHwi Jun AnNo ratings yet

- BM in The Simultaneous Equations Ax by Candmx Ny D, Then: Self Test: Mathematics (Part - 1) Std. X (Chapter 1) 1Document3 pagesBM in The Simultaneous Equations Ax by Candmx Ny D, Then: Self Test: Mathematics (Part - 1) Std. X (Chapter 1) 1UmarNo ratings yet

- Week 1Document3 pagesWeek 1giophilipNo ratings yet

- Week 14 - Frobenius MethodDocument20 pagesWeek 14 - Frobenius MethodHanee Farzana HizaddinNo ratings yet

- 19 GCE A Level Pure Maths Modelling QuestionsDocument64 pages19 GCE A Level Pure Maths Modelling QuestionsafivealeNo ratings yet

- 03 EquilibriumDocument15 pages03 EquilibriumAndy BayuNo ratings yet

- Algebraic Geometry PDFDocument133 pagesAlgebraic Geometry PDFgsitciaNo ratings yet

- Math DLL 2nd ObservationDocument4 pagesMath DLL 2nd ObservationLeonora Lamarca AranconNo ratings yet

- Assignment On Assertion and Reason Class 9 NcertDocument3 pagesAssignment On Assertion and Reason Class 9 NcertPihu SrivastavaNo ratings yet

- Math 10 - Equation of A Circle Lesson PLDocument5 pagesMath 10 - Equation of A Circle Lesson PLJoyce anne ilumba100% (1)

- 3 Math 10 - Q2 - Week 6Document20 pages3 Math 10 - Q2 - Week 6Ralph Marcus ValdezNo ratings yet

- Business:: Area, Ha (Ac) 8.95 22.1 8.6 21.2 17.55 43.3 Area, Ha (Ac) 2.2 5.4 0.66 1.6 7.52 18.6 7.17 17.7Document5 pagesBusiness:: Area, Ha (Ac) 8.95 22.1 8.6 21.2 17.55 43.3 Area, Ha (Ac) 2.2 5.4 0.66 1.6 7.52 18.6 7.17 17.7Basuki RahardjoNo ratings yet

- Nova Scotia Department of Education Public School Programs Update: High School Mathematics 2006-2007Document16 pagesNova Scotia Department of Education Public School Programs Update: High School Mathematics 2006-2007Nisfir SyahrilNo ratings yet

- Noniterative Design of Multiple Effect Evaporators Using Excel Add InsDocument10 pagesNoniterative Design of Multiple Effect Evaporators Using Excel Add InsGalang Hanif AbdulahNo ratings yet

- Note On Numerical Solutions For Gas Lubricated Journal BearingsDocument3 pagesNote On Numerical Solutions For Gas Lubricated Journal Bearingsmanjunath k sNo ratings yet

- Syllabus 1st YearDocument18 pagesSyllabus 1st YearVedant GawandeNo ratings yet

- BCA Syllabus 2019 Batch Onwards I VI Semesters Passed in BOS 2020Document74 pagesBCA Syllabus 2019 Batch Onwards I VI Semesters Passed in BOS 2020Anon writNo ratings yet

- Some Methods of Evaluating Imperfect Gas Effects in Aerodynamic ProblemsDocument36 pagesSome Methods of Evaluating Imperfect Gas Effects in Aerodynamic ProblemsJames PsrNo ratings yet

- Differential Eqns 3.0Document52 pagesDifferential Eqns 3.0Cosmic BrilliantNo ratings yet

- Polar Coordinates Exam QuestionsDocument59 pagesPolar Coordinates Exam QuestionsJUNIOR RAID YEBARA GUTIERREZNo ratings yet

- Veer Surendra Sai University of Technology: Burla NoticeDocument4 pagesVeer Surendra Sai University of Technology: Burla NoticeSiddharth MNo ratings yet

- M2 Unit 3 QBDocument5 pagesM2 Unit 3 QBArun AntonyNo ratings yet

- Numerical Methodology of Mesh-Based Simulation TechniqueDocument5 pagesNumerical Methodology of Mesh-Based Simulation TechniqueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Part-A: CLASS: CC (Advanced) Worksheet-26 M.M.: 69 Time: 60 MinDocument2 pagesPart-A: CLASS: CC (Advanced) Worksheet-26 M.M.: 69 Time: 60 Minkartik gargNo ratings yet

- 2003 HSC Notes From The Marking Centre Mathematics Extension 2Document28 pages2003 HSC Notes From The Marking Centre Mathematics Extension 2Ye ZhangNo ratings yet

- Engineering Jobs in Indian Air ForceDocument13 pagesEngineering Jobs in Indian Air ForcePoonam ShallyNo ratings yet

- Ordinary Differential Equations 17 JDocument2 pagesOrdinary Differential Equations 17 JrapsjadeNo ratings yet