Professional Documents

Culture Documents

VDR 717 Ag 9C: BS 1868 Trim Materials

VDR 717 Ag 9C: BS 1868 Trim Materials

Uploaded by

halim_kaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VDR 717 Ag 9C: BS 1868 Trim Materials

VDR 717 Ag 9C: BS 1868 Trim Materials

Uploaded by

halim_kaCopyright:

Available Formats

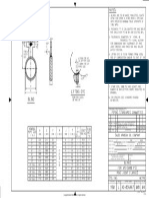

7.

Type :

NOZZLE CHECK VALVES

TRIM MATERIALS

BS 1868

CODE

VALVE ITEM VDR

717 AG 9C1

717 AG 9C2

MIN / MAX OPERATING TEMP. Deg. C:

-29 : +150

-29 : +150

NON SLAM TYPE

A 182 F316

A 182 F316

13% CR

13% CR

SERVICE:

DISC

TRIM

BODY SEAT

SEALING RING

INSERT

GUIDING ROD

WITH SPRING

SPRING

PTFE

PTFE

A 182 F316

A 182 F316

AISI 302

INCONEL

1) Valves shall comply with specification of this document and AGIP 15801.PIP.MEC.SDS.

NOTES:

2) A flow arrow shall be marked on each body valve.

RATING

M

O

D

.

M

E

C

.

V

L

I

.

bar

-29

255.3

38

50

100

255.3

250.4

231.9

150

226.1

bar

DIMENSIONS (mm) , WEIGHTS (kg)

3/4

10

12

14

16

18

20

24

RF

368

470

546

705

832

991

1130

1257

1384

1537

1664

1943

RJ

371

473

549

711

841

1000

1146

1276

1407

1559

1686

1972

3600

5500

26

28

30

32

34

36

FACE TO FACE

Tolerances

TEST

383.0

WRENCH

SEAT

281.0

OPERATOR

SEAT

+/- 3.2

Center to top

SHELL

AIR

+/- 1.6

BODY OUTSIDE DIA. (min.)

bar

bar

WEIGHT

5.5

(appr.)

Flanged

S

H

0

1

1/2

VALVE SIZE (inch)

HYDROSTATIC

0

0

8

/

1

CHECK VALVES

RATING

VALVE ENDS

BODY MATERIAL

:

:

1500 lb ASME B16.34

FLANGED

ASTM A 105 / ASTM A 216 WCB

50

95

130

275

500

800

1100

1500

2050

Agip

Sheet

1

2800

Prep'd

1

VDR 717 AG 9C

Internal Normalization

15.6.1996

Rev .

15404.PIP.MEC.STD

This document is Company property. The Company lawfully reserves all rights.

You might also like

- Ghidini p87 88 Navod ND enDocument31 pagesGhidini p87 88 Navod ND enjunkyjunk7116No ratings yet

- 13 - Copes-Vulcan ValvesDocument7 pages13 - Copes-Vulcan ValvesshalegpNo ratings yet

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- MPQT Alishar SPM 3 31.08.2013 To 02.09.2013Document68 pagesMPQT Alishar SPM 3 31.08.2013 To 02.09.2013mdsajidalamNo ratings yet

- Service Manual: Washing Machine Toploader AWT 2287/3Document14 pagesService Manual: Washing Machine Toploader AWT 2287/3panda3362No ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Complete Plumbing and Central Heating GuideDocument83 pagesComplete Plumbing and Central Heating GuideIan RizaNo ratings yet

- Cab Tilt, System DescriptionDocument7 pagesCab Tilt, System DescriptionBui Xuan Duc0% (1)

- 15414E01 - Valve Data SheetDocument1 page15414E01 - Valve Data Sheethalim_kaNo ratings yet

- 15413E01 - Valve Data SheetDocument1 page15413E01 - Valve Data Sheethalim_kaNo ratings yet

- VDR 715 Ag Ac: BS 5352 Trim MaterialsDocument1 pageVDR 715 Ag Ac: BS 5352 Trim Materialshalim_kaNo ratings yet

- Valvula Borboleta Lug z614 ADocument6 pagesValvula Borboleta Lug z614 AWellington S. FrançaNo ratings yet

- bl01 Aa0104 4Document6 pagesbl01 Aa0104 4chris110No ratings yet

- Ac PDFDocument95 pagesAc PDFCarlos TorresNo ratings yet

- Uniworld: Series Pneumatic ValvesDocument2 pagesUniworld: Series Pneumatic ValvesSyarif Mutsaqqif100% (1)

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- Ss01014 SmithDocument6 pagesSs01014 SmithAchmad TabaNo ratings yet

- Automatic Valve Gemue DB - 512 - GBDocument6 pagesAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Sp-210-E-103 Rev 0Document7 pagesSp-210-E-103 Rev 0Natarajan RavisankarNo ratings yet

- IsometricsDocument4 pagesIsometricsMuhammedHafisNo ratings yet

- VDR 717 Ag Ac: BS 5352 Trim MaterialsDocument1 pageVDR 717 Ag Ac: BS 5352 Trim Materialshalim_kaNo ratings yet

- SDM 102 eDocument24 pagesSDM 102 eseaqu3stNo ratings yet

- Flow MeterDocument6 pagesFlow MeterYvoSteentjes100% (1)

- APNEA-J-DSH-0002 Rev. 1Document3 pagesAPNEA-J-DSH-0002 Rev. 1Michelle MartinezNo ratings yet

- PROGEF Standard PolypropyleneDocument74 pagesPROGEF Standard PolypropyleneoctavioNo ratings yet

- Piping Line List: Ventech Engineers, Inc. Pasadena, Texas, P.O.Box 4261Document7 pagesPiping Line List: Ventech Engineers, Inc. Pasadena, Texas, P.O.Box 4261samer8saifNo ratings yet

- Data Sheet Tag 180-Pu-011eDocument8 pagesData Sheet Tag 180-Pu-011eSarah PerezNo ratings yet

- B3 16M175Document2 pagesB3 16M175ecovarrubias1No ratings yet

- SDM 080 eDocument28 pagesSDM 080 eseaqu3stNo ratings yet

- Full Bore Ball Valve - T12 Series - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsDocument2 pagesFull Bore Ball Valve - T12 Series - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsjonnyhelluzNo ratings yet

- Ipr RegDocument34 pagesIpr RegNicolae PopNo ratings yet

- SDM 141 eDocument28 pagesSDM 141 eseaqu3stNo ratings yet

- Ta38107 1 PDFDocument20 pagesTa38107 1 PDFVyasaraj KumarNo ratings yet

- Flyer Rotar FMR Rev3Document2 pagesFlyer Rotar FMR Rev3Catarino FloresNo ratings yet

- TD SAD SAF03 E-45 PDFDocument2 pagesTD SAD SAF03 E-45 PDFSupolNo ratings yet

- Brand FC51-12SAE DrawingDocument1 pageBrand FC51-12SAE DrawingJustinNo ratings yet

- Data SheetDocument2 pagesData SheetBrijesh SharmaNo ratings yet

- Butterfly Valve Lug TypeDocument6 pagesButterfly Valve Lug TypeMr. ANo ratings yet

- L028 Me Dat 01 00122 001 00Document8 pagesL028 Me Dat 01 00122 001 00sivasan10006098No ratings yet

- SMC Neumatic CatalogDocument98 pagesSMC Neumatic Cataloganderssonpc100% (1)

- PSV - Folha de DadosDocument1 pagePSV - Folha de DadosInspetor SoldagemNo ratings yet

- Maintenance Arpex enDocument39 pagesMaintenance Arpex enPatrick BaridonNo ratings yet

- 15398E02 Valve Data SheetDocument1 page15398E02 Valve Data Sheethalim_kaNo ratings yet

- Full Bore Ball Valve - Types T14 - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsDocument2 pagesFull Bore Ball Valve - Types T14 - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsCarlos Gallardo Sanchez100% (1)

- Characteristics Series CE, CP, C: 2 Way Slip-In Cartridge ValvesDocument17 pagesCharacteristics Series CE, CP, C: 2 Way Slip-In Cartridge Valvess_waqarNo ratings yet

- Complressor R134aDocument2 pagesComplressor R134aHikmat KtkNo ratings yet

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter SpecificationsMechanicalMarwanNo ratings yet

- t-10 SensusDocument7 pagest-10 SensusAlam Garcia RodriguezNo ratings yet

- Yuken EC 1302 PilotDocument7 pagesYuken EC 1302 PilotAli RamosNo ratings yet

- Imo Ace PumpsDocument12 pagesImo Ace Pumpsrentz76No ratings yet

- Bolt Length TableDocument16 pagesBolt Length TablePrasanta Kumar BeheraNo ratings yet

- Brooks Rotameter Variable AreaDocument22 pagesBrooks Rotameter Variable Areamhidayat108No ratings yet

- Lifting Eye Blind: NotesDocument1 pageLifting Eye Blind: Notesnarutothunderjet216No ratings yet

- Ignis Awv 510-2 (ET)Document9 pagesIgnis Awv 510-2 (ET)Attila SzilvásiNo ratings yet

- VDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With SpringDocument1 pageVDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With Springhalim_kaNo ratings yet

- Re 15228 Radial Piston Hydraulic Motor With A Fixed DisplacementDocument36 pagesRe 15228 Radial Piston Hydraulic Motor With A Fixed Displacementraj8378100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- DGS-CU-016-R2 Testing LaboratoryDocument17 pagesDGS-CU-016-R2 Testing Laboratoryhalim_kaNo ratings yet

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaNo ratings yet

- 15413E01 - Valve Data SheetDocument1 page15413E01 - Valve Data Sheethalim_kaNo ratings yet

- 15413E01 - Valve Data SheetDocument1 page15413E01 - Valve Data Sheethalim_kaNo ratings yet

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaNo ratings yet

- 15414E01 - Valve Data SheetDocument1 page15414E01 - Valve Data Sheethalim_kaNo ratings yet

- Appendix B. Sample Problem: Chevron Corporation B-1 March 1991Document2 pagesAppendix B. Sample Problem: Chevron Corporation B-1 March 1991halim_kaNo ratings yet

- 15414E01 - Valve Data SheetDocument1 page15414E01 - Valve Data Sheethalim_kaNo ratings yet

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaNo ratings yet

- VDR 717 Ag Ac: BS 5352 Trim MaterialsDocument1 pageVDR 717 Ag Ac: BS 5352 Trim Materialshalim_kaNo ratings yet

- VDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With SpringDocument1 pageVDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With Springhalim_kaNo ratings yet

- VDR 731 Ag 1U: BS 1868 Trim MaterialsDocument1 pageVDR 731 Ag 1U: BS 1868 Trim Materialshalim_kaNo ratings yet

- 15398E02 Valve Data SheetDocument1 page15398E02 Valve Data Sheethalim_kaNo ratings yet

- 15391E01 Valve Data SheetDocument1 page15391E01 Valve Data Sheethalim_kaNo ratings yet

- 15396E01 Valve Data SheetDocument1 page15396E01 Valve Data Sheethalim_kaNo ratings yet

- 15397E01 Valve Data SheetDocument1 page15397E01 Valve Data Sheethalim_kaNo ratings yet

- VDR 715 Ag Ac: BS 5352 Trim MaterialsDocument1 pageVDR 715 Ag Ac: BS 5352 Trim Materialshalim_kaNo ratings yet

- Sheet - 1-2022Document6 pagesSheet - 1-2022Ismail SakrNo ratings yet

- Sunflo P2500 Poster 042418Document1 pageSunflo P2500 Poster 042418galu100% (1)

- 01Document1 page01Derkung BenowatNo ratings yet

- Check List For Installation and Incoming Materials For Pipe Sleeves (Sanitary & Plumbing Works)Document2 pagesCheck List For Installation and Incoming Materials For Pipe Sleeves (Sanitary & Plumbing Works)Imho Tep100% (1)

- Module 01 Definition of Terms ArTY 1Document14 pagesModule 01 Definition of Terms ArTY 1JOSE RAFAEL COLUMNANo ratings yet

- A320 CB-PanelsDocument95 pagesA320 CB-Panelsyazan999No ratings yet

- PHQC 3036 - Pull Part Manual 2016 1010Document9 pagesPHQC 3036 - Pull Part Manual 2016 1010VladimirNo ratings yet

- 62-3078 3-Way ValveDocument4 pages62-3078 3-Way Valvesantosh yadavNo ratings yet

- Tohme Engineering: Total Demand Water Pipe Sizing Fixtures FU Qty. TFUDocument18 pagesTohme Engineering: Total Demand Water Pipe Sizing Fixtures FU Qty. TFUrodijammoulNo ratings yet

- PumpsDocument57 pagesPumpsJai Acharya100% (1)

- Normalizing NPSHDocument5 pagesNormalizing NPSHorchids28No ratings yet

- Disclosure To Promote The Right To InformationDocument22 pagesDisclosure To Promote The Right To Informationgeo_gabe_galan5473No ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Mohamed Harb100% (1)

- Me 605CDocument4 pagesMe 605CmkbNo ratings yet

- Bomba Neumatica Al Flo 13966-A100-P-1Document24 pagesBomba Neumatica Al Flo 13966-A100-P-1ToCaronteNo ratings yet

- Pipe Schedule ImperialDocument1 pagePipe Schedule ImperialDan ClarkeNo ratings yet

- Bucher Hydraulics hds11 - 200-P-991210-EnDocument39 pagesBucher Hydraulics hds11 - 200-P-991210-EnJustin100% (1)

- Section 12Document44 pagesSection 12sofiane tfhNo ratings yet

- DestrebutionDocument4 pagesDestrebutionYosef AbebeNo ratings yet

- Estimation of Power and Efficiency of Hydraulic Ram Pump With Re-Circulation SystemDocument13 pagesEstimation of Power and Efficiency of Hydraulic Ram Pump With Re-Circulation SystemAnand M VNo ratings yet

- Sanitary Drainage SystemsDocument19 pagesSanitary Drainage SystemsTaha Morad100% (1)

- Welcome To Jntu Kakinada: Subject Registerd For F0 CollegeDocument9 pagesWelcome To Jntu Kakinada: Subject Registerd For F0 CollegesivaenotesNo ratings yet

- Weil Pump Flow and Basin Sizing Calculator (EDocFind - Com)Document15 pagesWeil Pump Flow and Basin Sizing Calculator (EDocFind - Com)mohdnazirNo ratings yet

- TFP1315 07 2014Document16 pagesTFP1315 07 2014brockNo ratings yet

- II B.tech I Sem Resulsts Nove 2016Document215 pagesII B.tech I Sem Resulsts Nove 2016maheshNo ratings yet

- Experiment 5: Pressure Drop Through Orifice Plates: Group FDocument13 pagesExperiment 5: Pressure Drop Through Orifice Plates: Group FAslamNo ratings yet

- Water Hammer in Piping System-Part 1Document14 pagesWater Hammer in Piping System-Part 1Việt Đặng XuânNo ratings yet

- Method Statement For Leakage Testing of Gravity Sewer LineDocument3 pagesMethod Statement For Leakage Testing of Gravity Sewer LineGerlie DimayugaNo ratings yet