Professional Documents

Culture Documents

Etching For Bulk Micromachining (Cavity/Cantilever Anisotropic)

Etching For Bulk Micromachining (Cavity/Cantilever Anisotropic)

Uploaded by

sasisCopyright:

Available Formats

You might also like

- Class MEMSDocument9 pagesClass MEMSTiruveedula RishendraNo ratings yet

- MEMS (Micro-Electro-Mechanical Systems) : Presented byDocument50 pagesMEMS (Micro-Electro-Mechanical Systems) : Presented byGaurav GuptaNo ratings yet

- Mechatronics Module 2-MemsDocument26 pagesMechatronics Module 2-MemsRahul DasNo ratings yet

- Mechanical Material2Document11 pagesMechanical Material2sasisNo ratings yet

- Unit-Ii: Micromachining Technologies (Microfabrications)Document15 pagesUnit-Ii: Micromachining Technologies (Microfabrications)Rayees AhmedNo ratings yet

- Isat 436 Micro-/Nanofabrication and Applications: Microelectromechanical Systems: MemsDocument18 pagesIsat 436 Micro-/Nanofabrication and Applications: Microelectromechanical Systems: MemsShweta GoyalNo ratings yet

- MEMS Design Chap 2-MEMS ProcessesDocument31 pagesMEMS Design Chap 2-MEMS ProcessesvuonglupNo ratings yet

- Rapid Manufacturing NotesDocument32 pagesRapid Manufacturing NotesFRANCIS THOMASNo ratings yet

- Micro MachiningDocument18 pagesMicro MachiningSUMEET SINGHNo ratings yet

- Micro Electro Mechanical Systems Full ReportDocument27 pagesMicro Electro Mechanical Systems Full ReportRohit Uma TiwariNo ratings yet

- PolyMUMPs ProcessDocument28 pagesPolyMUMPs ProcessMajid GhaffarNo ratings yet

- 5 LicaDocument26 pages5 LicaVantharAlaNo ratings yet

- How Semicon WorksDocument15 pagesHow Semicon WorkskrisNo ratings yet

- Smart Sensors 7 SEM Electronics & Instrumentation Engineering Open ElectiveDocument34 pagesSmart Sensors 7 SEM Electronics & Instrumentation Engineering Open ElectiveTanisha SinhaNo ratings yet

- Semester: VII: A. Theory PapersDocument4 pagesSemester: VII: A. Theory PapersAkhil KhandelwalNo ratings yet

- Unit-1: 1.7 Bulk Micromachining TechniqueDocument20 pagesUnit-1: 1.7 Bulk Micromachining TechniqueAdityaNo ratings yet

- PYL726 2022 Lecture 29Document16 pagesPYL726 2022 Lecture 29piyushNo ratings yet

- Infrared Microbolometer Sensors and Their Application in Automotive SafetyDocument15 pagesInfrared Microbolometer Sensors and Their Application in Automotive SafetyAnandraj004No ratings yet

- Microelectromechanical Systems Are Integrated Micro Devices or SystemsDocument13 pagesMicroelectromechanical Systems Are Integrated Micro Devices or SystemsAnush AruNo ratings yet

- Micro-Electro-Mechanical Systems: Presented by Vinayak HegdeDocument37 pagesMicro-Electro-Mechanical Systems: Presented by Vinayak HegdeAaron VillanuevaNo ratings yet

- Processes For Micro FabricationDocument55 pagesProcesses For Micro FabricationSumant GutheNo ratings yet

- CM - MEMS - TWO MARKS Five UNITSDocument7 pagesCM - MEMS - TWO MARKS Five UNITSSandhiyaNo ratings yet

- Project PPT by Devendra SainiDocument17 pagesProject PPT by Devendra SainiJK COTTONNo ratings yet

- Soimumps Design Handbook: A Mumps® ProcessDocument26 pagesSoimumps Design Handbook: A Mumps® ProcessFallon RiosNo ratings yet

- MicromachiningDocument51 pagesMicromachiningManoj MurthyNo ratings yet

- Mems Seminar 2Document24 pagesMems Seminar 2UPENDAR REDDY PULLAGURLANo ratings yet

- Visvesvaraya National Institute of Technology Nagpur Department of Mechanical EngineeringDocument24 pagesVisvesvaraya National Institute of Technology Nagpur Department of Mechanical EngineeringARUN KNo ratings yet

- Micro-Electro-Mechanical Systems: Manufacturing Engineering Technology in SI Units, 6 EditionDocument36 pagesMicro-Electro-Mechanical Systems: Manufacturing Engineering Technology in SI Units, 6 EditionBarrathan Tamil SelvanNo ratings yet

- 219 - EE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With AnswersDocument8 pages219 - EE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With AnswersBALAKRISHNANNo ratings yet

- Introducing MemsDocument49 pagesIntroducing MemsRajendra ParmanikNo ratings yet

- Module 5 PDFDocument16 pagesModule 5 PDFManjunath Alagundi50% (2)

- CH 3 - SILICON LAYER & LIGA PROCESSES (2022.02) - DR - BaoDocument34 pagesCH 3 - SILICON LAYER & LIGA PROCESSES (2022.02) - DR - BaoTrần Minh KhôiNo ratings yet

- 1 Online PDFDocument5 pages1 Online PDFSang HoNo ratings yet

- Introduction To Microelectromechanical Systems (MEMS) Materials, Fabrication Processes and Failure AnalysisDocument59 pagesIntroduction To Microelectromechanical Systems (MEMS) Materials, Fabrication Processes and Failure AnalysisyohannesNo ratings yet

- EE2254 LIC 2marks 2013Document16 pagesEE2254 LIC 2marks 2013sivagamiNo ratings yet

- Microelectromechanical Systems (MEMS) (Also Written As Micro-Electro-MechanicalDocument10 pagesMicroelectromechanical Systems (MEMS) (Also Written As Micro-Electro-MechanicalManu MohanNo ratings yet

- Overview of MEMSDocument152 pagesOverview of MEMSDr. Sampatrao L PinjareNo ratings yet

- Silicon Optical Bench - Micralyne MEMS FoundryDocument2 pagesSilicon Optical Bench - Micralyne MEMS FoundryMicralyneNo ratings yet

- Che384t Jykim Mems v2 SubmitDocument24 pagesChe384t Jykim Mems v2 SubmitBhuvnesh BhambooNo ratings yet

- Micro Electromechanical SystemDocument22 pagesMicro Electromechanical SystemLandi KhaibuNo ratings yet

- Steps For IC Manufacturing - VLSI Tutorials - MepitsDocument6 pagesSteps For IC Manufacturing - VLSI Tutorials - MepitsAbhiNo ratings yet

- Materials For MEMS ManufacturingDocument7 pagesMaterials For MEMS ManufacturingGajanan BirajdarNo ratings yet

- 1.5.1 Intro To MicromachiningDocument24 pages1.5.1 Intro To MicromachiningAshish MishraNo ratings yet

- Ic FabricationDocument7 pagesIc FabricationphooolNo ratings yet

- NSE - 847 Essentials of NEMS/MEMS: in The Name of ALLAH, The Most Gracious, The Most MercifulDocument37 pagesNSE - 847 Essentials of NEMS/MEMS: in The Name of ALLAH, The Most Gracious, The Most MercifulBahroz RashidNo ratings yet

- Lecture 6 Integration PDFDocument21 pagesLecture 6 Integration PDFAmit GoyalNo ratings yet

- NSE - 847 Essentials of NEMS/MEMS: in The Name of ALLAH, The Most Gracious, The Most MercifulDocument21 pagesNSE - 847 Essentials of NEMS/MEMS: in The Name of ALLAH, The Most Gracious, The Most MercifulBahroz RashidNo ratings yet

- Micro MachiningDocument18 pagesMicro MachiningChandana KotaNo ratings yet

- Bulk Micromachining For MicrosystemsDocument44 pagesBulk Micromachining For MicrosystemsSai Lavanya VedhanabhatlaNo ratings yet

- Lecture MEMS Materials and Fabrication - Part1Document28 pagesLecture MEMS Materials and Fabrication - Part1Deepak kumar singhNo ratings yet

- Chapter 15Document39 pagesChapter 15Priya VenkadachalamNo ratings yet

- Microfabrication: Fields of UseDocument4 pagesMicrofabrication: Fields of UseannbennNo ratings yet

- Micro Electro Mechanical Systems (Mems)Document12 pagesMicro Electro Mechanical Systems (Mems)S Bharadwaj ReddyNo ratings yet

- 03 Microsystems Fabrication ProcessesDocument3 pages03 Microsystems Fabrication ProcessesiangarvinsNo ratings yet

- M. Sahith Chandan Roll. No: 05P71A0438 B.TECH 4/4 E.C.E Ph. No: 9985066696Document27 pagesM. Sahith Chandan Roll. No: 05P71A0438 B.TECH 4/4 E.C.E Ph. No: 9985066696D S RaoNo ratings yet

- 18ECE302T-U1-L8 Thin Film DepositionDocument20 pages18ECE302T-U1-L8 Thin Film Depositionamitava2010No ratings yet

- Introduction To Integrated Circuit TechnologyDocument45 pagesIntroduction To Integrated Circuit TechnologyShrikant JagtapNo ratings yet

- Optical Engineering of DiamondFrom EverandOptical Engineering of DiamondRich MildrenRating: 4 out of 5 stars4/5 (11)

- New Sensors and Processing ChainFrom EverandNew Sensors and Processing ChainJean-Hugh ThomasNo ratings yet

- Activated SludgeDocument4 pagesActivated SludgesasisNo ratings yet

- Main UASB ReactorDocument23 pagesMain UASB ReactorsasisNo ratings yet

- Primary Treatment of Sewage 3Document17 pagesPrimary Treatment of Sewage 3sasisNo ratings yet

- Mechanical Material2Document11 pagesMechanical Material2sasisNo ratings yet

- Production Planning and Control13Document10 pagesProduction Planning and Control13sasisNo ratings yet

- Cavitation Corrosion9Document38 pagesCavitation Corrosion9sasisNo ratings yet

- Single Crystal Silicon For MEMSDocument10 pagesSingle Crystal Silicon For MEMSsasisNo ratings yet

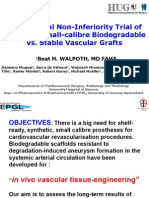

- Experimental Non-Inferiority Trial of Synthetic Small-Calibre Biodegradable vs. Stable Vascular GraftsDocument12 pagesExperimental Non-Inferiority Trial of Synthetic Small-Calibre Biodegradable vs. Stable Vascular GraftssasisNo ratings yet

- Production Planning and Control12Document9 pagesProduction Planning and Control12sasisNo ratings yet

- Hydrogen Attack7Document10 pagesHydrogen Attack7sasisNo ratings yet

- NDT 1Document14 pagesNDT 1sasisNo ratings yet

- Graphitic Corrosion8Document18 pagesGraphitic Corrosion8sasisNo ratings yet

- Galvanic Corrosion3Document15 pagesGalvanic Corrosion3sasisNo ratings yet

- Cavitation Corrosion6Document12 pagesCavitation Corrosion6sasisNo ratings yet

- Pitting Corrosion2Document15 pagesPitting Corrosion2sasisNo ratings yet

- Corrosion Fatigue5Document12 pagesCorrosion Fatigue5sasisNo ratings yet

- Forms of Deterioration: Rusting, Season Cracking, Waterline Attack, Crazing, Checking, ChalkingDocument15 pagesForms of Deterioration: Rusting, Season Cracking, Waterline Attack, Crazing, Checking, ChalkingsasisNo ratings yet

- Environmental Science and EngineeringDocument19 pagesEnvironmental Science and EngineeringsasisNo ratings yet

- S.I. Engine Mixture Preparation: CarburetionDocument31 pagesS.I. Engine Mixture Preparation: CarburetionsasisNo ratings yet

- Environmental DegradationDocument10 pagesEnvironmental DegradationsasisNo ratings yet

- The Greenhouse Effect On EarthDocument43 pagesThe Greenhouse Effect On EarthsasisNo ratings yet

- Types of PlasticsDocument13 pagesTypes of PlasticssasisNo ratings yet

- Unit 4 Gear & Gear TrainsDocument17 pagesUnit 4 Gear & Gear TrainssasisNo ratings yet

Etching For Bulk Micromachining (Cavity/Cantilever Anisotropic)

Etching For Bulk Micromachining (Cavity/Cantilever Anisotropic)

Uploaded by

sasisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Etching For Bulk Micromachining (Cavity/Cantilever Anisotropic)

Etching For Bulk Micromachining (Cavity/Cantilever Anisotropic)

Uploaded by

sasisCopyright:

Available Formats

ETCHING for BULK

MICROMACHINING

(Cavity/Cantilever Anisotropic)

DRY (Plasma) ETCHING

Deep Reactive Ion Etch

(DRIE)

Single Crystal Silicon for

MEMS

Single Crystal Silicon for

MEMS

Single Crystal Silicon for

MEMS

What is MICRO-MACHINING?

h What can Micromachined Parts/Systems do for

us?

Be a Conduit to Microscopic

Domain:

1. Sensing (Information)

2. Information Processing

3. Communication

4. Manipulation (Actuation

and Control)

Why / Why not

SILICON?

Semiconductor:

Active Devices + Sensors

(Photo-Magneto-Strain Sensing)

Insulator:

SiO2 , Si3N4 , Glass

Thin Film Conductor:

Aluminum, Gold, Silicides

PhotoLithography: Planar control (+ & -)

Mechanical Material

SILICON?

Stiff => Thinning is required for appreciable strain

Micromachining of

SILICON?

Additive Processes:

Chemical and Physical Deposition

(Thin Layers only) (Single/Poly)

Removal Processes: Chemical and Physical Etching

(Wet/Dry/Plasma/Inert/Reactive)

(Bulk/Film) (Anisotropic/Isotropic)

MICROMACHINING of SILICON =>

(a) BULK (substrate)

(b) SURFACE (films)

You might also like

- Class MEMSDocument9 pagesClass MEMSTiruveedula RishendraNo ratings yet

- MEMS (Micro-Electro-Mechanical Systems) : Presented byDocument50 pagesMEMS (Micro-Electro-Mechanical Systems) : Presented byGaurav GuptaNo ratings yet

- Mechatronics Module 2-MemsDocument26 pagesMechatronics Module 2-MemsRahul DasNo ratings yet

- Mechanical Material2Document11 pagesMechanical Material2sasisNo ratings yet

- Unit-Ii: Micromachining Technologies (Microfabrications)Document15 pagesUnit-Ii: Micromachining Technologies (Microfabrications)Rayees AhmedNo ratings yet

- Isat 436 Micro-/Nanofabrication and Applications: Microelectromechanical Systems: MemsDocument18 pagesIsat 436 Micro-/Nanofabrication and Applications: Microelectromechanical Systems: MemsShweta GoyalNo ratings yet

- MEMS Design Chap 2-MEMS ProcessesDocument31 pagesMEMS Design Chap 2-MEMS ProcessesvuonglupNo ratings yet

- Rapid Manufacturing NotesDocument32 pagesRapid Manufacturing NotesFRANCIS THOMASNo ratings yet

- Micro MachiningDocument18 pagesMicro MachiningSUMEET SINGHNo ratings yet

- Micro Electro Mechanical Systems Full ReportDocument27 pagesMicro Electro Mechanical Systems Full ReportRohit Uma TiwariNo ratings yet

- PolyMUMPs ProcessDocument28 pagesPolyMUMPs ProcessMajid GhaffarNo ratings yet

- 5 LicaDocument26 pages5 LicaVantharAlaNo ratings yet

- How Semicon WorksDocument15 pagesHow Semicon WorkskrisNo ratings yet

- Smart Sensors 7 SEM Electronics & Instrumentation Engineering Open ElectiveDocument34 pagesSmart Sensors 7 SEM Electronics & Instrumentation Engineering Open ElectiveTanisha SinhaNo ratings yet

- Semester: VII: A. Theory PapersDocument4 pagesSemester: VII: A. Theory PapersAkhil KhandelwalNo ratings yet

- Unit-1: 1.7 Bulk Micromachining TechniqueDocument20 pagesUnit-1: 1.7 Bulk Micromachining TechniqueAdityaNo ratings yet

- PYL726 2022 Lecture 29Document16 pagesPYL726 2022 Lecture 29piyushNo ratings yet

- Infrared Microbolometer Sensors and Their Application in Automotive SafetyDocument15 pagesInfrared Microbolometer Sensors and Their Application in Automotive SafetyAnandraj004No ratings yet

- Microelectromechanical Systems Are Integrated Micro Devices or SystemsDocument13 pagesMicroelectromechanical Systems Are Integrated Micro Devices or SystemsAnush AruNo ratings yet

- Micro-Electro-Mechanical Systems: Presented by Vinayak HegdeDocument37 pagesMicro-Electro-Mechanical Systems: Presented by Vinayak HegdeAaron VillanuevaNo ratings yet

- Processes For Micro FabricationDocument55 pagesProcesses For Micro FabricationSumant GutheNo ratings yet

- CM - MEMS - TWO MARKS Five UNITSDocument7 pagesCM - MEMS - TWO MARKS Five UNITSSandhiyaNo ratings yet

- Project PPT by Devendra SainiDocument17 pagesProject PPT by Devendra SainiJK COTTONNo ratings yet

- Soimumps Design Handbook: A Mumps® ProcessDocument26 pagesSoimumps Design Handbook: A Mumps® ProcessFallon RiosNo ratings yet

- MicromachiningDocument51 pagesMicromachiningManoj MurthyNo ratings yet

- Mems Seminar 2Document24 pagesMems Seminar 2UPENDAR REDDY PULLAGURLANo ratings yet

- Visvesvaraya National Institute of Technology Nagpur Department of Mechanical EngineeringDocument24 pagesVisvesvaraya National Institute of Technology Nagpur Department of Mechanical EngineeringARUN KNo ratings yet

- Micro-Electro-Mechanical Systems: Manufacturing Engineering Technology in SI Units, 6 EditionDocument36 pagesMicro-Electro-Mechanical Systems: Manufacturing Engineering Technology in SI Units, 6 EditionBarrathan Tamil SelvanNo ratings yet

- 219 - EE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With AnswersDocument8 pages219 - EE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With AnswersBALAKRISHNANNo ratings yet

- Introducing MemsDocument49 pagesIntroducing MemsRajendra ParmanikNo ratings yet

- Module 5 PDFDocument16 pagesModule 5 PDFManjunath Alagundi50% (2)

- CH 3 - SILICON LAYER & LIGA PROCESSES (2022.02) - DR - BaoDocument34 pagesCH 3 - SILICON LAYER & LIGA PROCESSES (2022.02) - DR - BaoTrần Minh KhôiNo ratings yet

- 1 Online PDFDocument5 pages1 Online PDFSang HoNo ratings yet

- Introduction To Microelectromechanical Systems (MEMS) Materials, Fabrication Processes and Failure AnalysisDocument59 pagesIntroduction To Microelectromechanical Systems (MEMS) Materials, Fabrication Processes and Failure AnalysisyohannesNo ratings yet

- EE2254 LIC 2marks 2013Document16 pagesEE2254 LIC 2marks 2013sivagamiNo ratings yet

- Microelectromechanical Systems (MEMS) (Also Written As Micro-Electro-MechanicalDocument10 pagesMicroelectromechanical Systems (MEMS) (Also Written As Micro-Electro-MechanicalManu MohanNo ratings yet

- Overview of MEMSDocument152 pagesOverview of MEMSDr. Sampatrao L PinjareNo ratings yet

- Silicon Optical Bench - Micralyne MEMS FoundryDocument2 pagesSilicon Optical Bench - Micralyne MEMS FoundryMicralyneNo ratings yet

- Che384t Jykim Mems v2 SubmitDocument24 pagesChe384t Jykim Mems v2 SubmitBhuvnesh BhambooNo ratings yet

- Micro Electromechanical SystemDocument22 pagesMicro Electromechanical SystemLandi KhaibuNo ratings yet

- Steps For IC Manufacturing - VLSI Tutorials - MepitsDocument6 pagesSteps For IC Manufacturing - VLSI Tutorials - MepitsAbhiNo ratings yet

- Materials For MEMS ManufacturingDocument7 pagesMaterials For MEMS ManufacturingGajanan BirajdarNo ratings yet

- 1.5.1 Intro To MicromachiningDocument24 pages1.5.1 Intro To MicromachiningAshish MishraNo ratings yet

- Ic FabricationDocument7 pagesIc FabricationphooolNo ratings yet

- NSE - 847 Essentials of NEMS/MEMS: in The Name of ALLAH, The Most Gracious, The Most MercifulDocument37 pagesNSE - 847 Essentials of NEMS/MEMS: in The Name of ALLAH, The Most Gracious, The Most MercifulBahroz RashidNo ratings yet

- Lecture 6 Integration PDFDocument21 pagesLecture 6 Integration PDFAmit GoyalNo ratings yet

- NSE - 847 Essentials of NEMS/MEMS: in The Name of ALLAH, The Most Gracious, The Most MercifulDocument21 pagesNSE - 847 Essentials of NEMS/MEMS: in The Name of ALLAH, The Most Gracious, The Most MercifulBahroz RashidNo ratings yet

- Micro MachiningDocument18 pagesMicro MachiningChandana KotaNo ratings yet

- Bulk Micromachining For MicrosystemsDocument44 pagesBulk Micromachining For MicrosystemsSai Lavanya VedhanabhatlaNo ratings yet

- Lecture MEMS Materials and Fabrication - Part1Document28 pagesLecture MEMS Materials and Fabrication - Part1Deepak kumar singhNo ratings yet

- Chapter 15Document39 pagesChapter 15Priya VenkadachalamNo ratings yet

- Microfabrication: Fields of UseDocument4 pagesMicrofabrication: Fields of UseannbennNo ratings yet

- Micro Electro Mechanical Systems (Mems)Document12 pagesMicro Electro Mechanical Systems (Mems)S Bharadwaj ReddyNo ratings yet

- 03 Microsystems Fabrication ProcessesDocument3 pages03 Microsystems Fabrication ProcessesiangarvinsNo ratings yet

- M. Sahith Chandan Roll. No: 05P71A0438 B.TECH 4/4 E.C.E Ph. No: 9985066696Document27 pagesM. Sahith Chandan Roll. No: 05P71A0438 B.TECH 4/4 E.C.E Ph. No: 9985066696D S RaoNo ratings yet

- 18ECE302T-U1-L8 Thin Film DepositionDocument20 pages18ECE302T-U1-L8 Thin Film Depositionamitava2010No ratings yet

- Introduction To Integrated Circuit TechnologyDocument45 pagesIntroduction To Integrated Circuit TechnologyShrikant JagtapNo ratings yet

- Optical Engineering of DiamondFrom EverandOptical Engineering of DiamondRich MildrenRating: 4 out of 5 stars4/5 (11)

- New Sensors and Processing ChainFrom EverandNew Sensors and Processing ChainJean-Hugh ThomasNo ratings yet

- Activated SludgeDocument4 pagesActivated SludgesasisNo ratings yet

- Main UASB ReactorDocument23 pagesMain UASB ReactorsasisNo ratings yet

- Primary Treatment of Sewage 3Document17 pagesPrimary Treatment of Sewage 3sasisNo ratings yet

- Mechanical Material2Document11 pagesMechanical Material2sasisNo ratings yet

- Production Planning and Control13Document10 pagesProduction Planning and Control13sasisNo ratings yet

- Cavitation Corrosion9Document38 pagesCavitation Corrosion9sasisNo ratings yet

- Single Crystal Silicon For MEMSDocument10 pagesSingle Crystal Silicon For MEMSsasisNo ratings yet

- Experimental Non-Inferiority Trial of Synthetic Small-Calibre Biodegradable vs. Stable Vascular GraftsDocument12 pagesExperimental Non-Inferiority Trial of Synthetic Small-Calibre Biodegradable vs. Stable Vascular GraftssasisNo ratings yet

- Production Planning and Control12Document9 pagesProduction Planning and Control12sasisNo ratings yet

- Hydrogen Attack7Document10 pagesHydrogen Attack7sasisNo ratings yet

- NDT 1Document14 pagesNDT 1sasisNo ratings yet

- Graphitic Corrosion8Document18 pagesGraphitic Corrosion8sasisNo ratings yet

- Galvanic Corrosion3Document15 pagesGalvanic Corrosion3sasisNo ratings yet

- Cavitation Corrosion6Document12 pagesCavitation Corrosion6sasisNo ratings yet

- Pitting Corrosion2Document15 pagesPitting Corrosion2sasisNo ratings yet

- Corrosion Fatigue5Document12 pagesCorrosion Fatigue5sasisNo ratings yet

- Forms of Deterioration: Rusting, Season Cracking, Waterline Attack, Crazing, Checking, ChalkingDocument15 pagesForms of Deterioration: Rusting, Season Cracking, Waterline Attack, Crazing, Checking, ChalkingsasisNo ratings yet

- Environmental Science and EngineeringDocument19 pagesEnvironmental Science and EngineeringsasisNo ratings yet

- S.I. Engine Mixture Preparation: CarburetionDocument31 pagesS.I. Engine Mixture Preparation: CarburetionsasisNo ratings yet

- Environmental DegradationDocument10 pagesEnvironmental DegradationsasisNo ratings yet

- The Greenhouse Effect On EarthDocument43 pagesThe Greenhouse Effect On EarthsasisNo ratings yet

- Types of PlasticsDocument13 pagesTypes of PlasticssasisNo ratings yet

- Unit 4 Gear & Gear TrainsDocument17 pagesUnit 4 Gear & Gear TrainssasisNo ratings yet