Professional Documents

Culture Documents

F3 PQR

F3 PQR

Uploaded by

Slim KanounOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F3 PQR

F3 PQR

Uploaded by

Slim KanounCopyright:

Available Formats

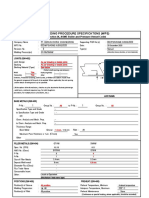

AWS B2.1/B2.

1M:2009

SAMPLE PROCEDURE QUALIFICATION RECORD (PQR)

for SAW, SMAW, GMAW, GTAW, FCAW

Company_____________________________________

Approved by _____________________________________

Approved by (Signature Required)

Date ___________________________________________

Type(s) _________________________________________

PQR No. _____________________________________

Welding Process(es) ____________________________

(Manual, Semiautomatic, Automatic, Robotic, Mechanized)

Joints (see 4.14.1)

Joint Type ____________________________________

Backing ______________________________________

Backing Material (Type)__________________________

Groove Angle _________________________________

Root Opening Radius: U

J

Root Face ____________________________________

Backgouging: Yes

No

Backgouging Method ___________________________

Joint Details

Sketches, production drawings, welding symbols, or written

description should show the general arrangement of

the parts to be welded. Where applicable, the root

details of the weld groove may be specified.

Base Metals (see 4.14.2)

M-No. _________________ Group No. ____________

or to M-No. _____________ Group No. _______________

Specification Type and Grade _____________________

to Specification Type and Grade ______________________

Thickness Range of Base Metal:

Groove___________________________

Fillet___________________________

Pipe Diameter Range:

Groove___________________________

Fillet___________________________

Other ___________________________________________________________________________________________

_______________________________________________________________________________________________

Filler Metals (see 4.14.3)

Filler Metal F-No._______________________________

AWS Classification _____________________________

Weld Metal Analysis A-No. _______________________

Filler Metal Size________________________________

Weld Metal Thickness ___________________________

Consumable Insert _____________________________

Other ___________________________________________

AWS Specification_________________________________

Other ___________________________________________

Electrode Flux (Class)______________________________

Flux Trade Name__________________________________

Other ___________________________________________

Positions (see 4.14.4)

Preheat (see 4.14.5)

Position(s) of Groove____________________________

Position(s) of Fillet______________________________

Weld Progression ______________________________

Preheat Temperature (Min.) _________________________

Temperature (Max.)________________________________

PWHT (see 4.14.6)

Temperature __________________________________

Time ___________________________________________

Shielding (see 4.14.7)

Torch Shielding

Root Shielding

Trailing

Environmental Shielding

Gas(es)

Composition

Flow Rate

Figure F.3Example of a Procedure Qualification Record

269

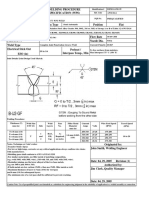

AWS B2.1/B2.1M:2009

Electrical Characteristics and Welding Parameters

(see 4.13.8)

Other Variables (see 4.14.9)

Current Type/Polarity____________________________

Pulsing: Yes

No

Current (Range) _______________________________

Voltage (Range) _______________________________

Wire Feed Speed (Range) _______________________

Travel Speed (Range) ___________________________

Tungsten Electrode Size/Type_____________________

Transfer Mode _________________________________

Pulsing Parameters _____________________________

Heat Input ____________________________________

Other ________________________________________

Cup or Nozzle Size ________________________________

Collet Body

or Glass Lens

Cleaning Method__________________________________

Technique: Stringer

or Weave Bead

Number of Electrodes ______________________________

Number of Passes per Side _________________________

Other ___________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

_______________________________________________

Test Results

Visual Test Results ________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

Tensile Results

Specimen

No.

Width

Thickness

Area

Yield

Load

Results

Yield

Tensile

Strength

Load

Tensile

Strength

Failure Type

and Location

Guided Bend Tests

Type and Figure Number

Qualification Results for Toughness Application

Type and Figure Number

Results

Results

Fillet Weld Tests

Type and Figure Number

Other Tests

Type and Figure Number

Results

Results

We, the undersigned, certify that the statements in this record are correct and the test welds were prepared, welded,

and tested in accordance with the requirements of AWS B2.1/B2.1M, ( __________), Specification for Welding Procedure

and Performance Qualification.

(year)

Manufacturer or Contractor __________________________________________________________________________

Date ________________________

By ____________________________

______________________________

Please Print

Signature Required

Permission to reproduce granted by the American Welding Society.

Figure F.3 (Continued)Example of a Procedure Qualification Record

270

You might also like

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocument2 pagesAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineer0% (1)

- Physics Project On Kirchhoff's Law: Submitted By: D.ishvarya XiiDocument21 pagesPhysics Project On Kirchhoff's Law: Submitted By: D.ishvarya Xiiish varya91% (22)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Smaw Fillet Aws d1.1Document1 pageSmaw Fillet Aws d1.1fallalovaldes100% (1)

- Signature RBC Rewards Visa: Previous Account Balance $2,646.15Document5 pagesSignature RBC Rewards Visa: Previous Account Balance $2,646.15Hoang DucNo ratings yet

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline SungahidNo ratings yet

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- AWS N-9 Stud Welding Procedure Specification (WPS) FormDocument1 pageAWS N-9 Stud Welding Procedure Specification (WPS) FormNatalia StarkNo ratings yet

- ISO 1579-1 (Part Only)Document5 pagesISO 1579-1 (Part Only)sn200709100% (1)

- Sample - Customer Churn Prediction Python DocumentationDocument33 pagesSample - Customer Churn Prediction Python Documentationchandrakanth BNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNavanitheeshwaran SivasubramaniyamNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Visual Inspection Report - During WeldingDocument1 pageVisual Inspection Report - During WeldingsurwaneNo ratings yet

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- PQR Form (Welding)Document2 pagesPQR Form (Welding)jasmineammaNo ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Preliminary Welding Procedure Specification (PWPS)Document1 pagePreliminary Welding Procedure Specification (PWPS)AzriNo ratings yet

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Body Flanges On Shells: (Name and Address of Manufacturer)Document3 pagesBody Flanges On Shells: (Name and Address of Manufacturer)David SantosNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocument4 pages170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- Welding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Document1 pageWelding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Lipika GayenNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- WPQDocument1 pageWPQChava TejaNo ratings yet

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Silvia CardenasNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- WQT - WPS 01Document71 pagesWQT - WPS 01Gururaj P Kundapur100% (1)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyNo ratings yet

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding TracebillityDocument15 pagesWelding TracebillityDeby Agung PratamaNo ratings yet

- Sample Welder ID As Per ASME Section IXDocument99 pagesSample Welder ID As Per ASME Section IXVivek Jadhav100% (1)

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- J 1 PQR GMAW FCAW D1.1 2020 FormDocument2 pagesJ 1 PQR GMAW FCAW D1.1 2020 FormCristian Narro100% (1)

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Document2 pagesSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzNo ratings yet

- B2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFDocument2 pagesB2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFNavanitheeshwaran SivasubramaniyamNo ratings yet

- D1.3 D1.3M 2018 Annexb1 PQR FormDocument1 pageD1.3 D1.3M 2018 Annexb1 PQR FormAkihiko TakagiNo ratings yet

- F4-WPS PQR Stud WeldingDocument1 pageF4-WPS PQR Stud WeldingBernardo LeorNo ratings yet

- B2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormDocument1 pageB2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormtuanNo ratings yet

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocument1 pageAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNo ratings yet

- Procedure Qualification Record (PQR) NoDocument3 pagesProcedure Qualification Record (PQR) NoMohamed elrefaeyNo ratings yet

- Rolled Steel Beams Indian StandardDocument5 pagesRolled Steel Beams Indian StandardudaysrpNo ratings yet

- CatalogueDocument52 pagesCatalogueudaysrpNo ratings yet

- IACS June 2013 Shipbuilding and Repair StandardDocument63 pagesIACS June 2013 Shipbuilding and Repair StandardudaysrpNo ratings yet

- WPS SampleDocument2 pagesWPS Sampleeetua100% (1)

- IACS Survey and CertificationDocument745 pagesIACS Survey and Certificationudaysrp100% (5)

- Rolled Steel Beams Indian StandardDocument5 pagesRolled Steel Beams Indian StandardudaysrpNo ratings yet

- IACSDocument247 pagesIACSsiakeehoNo ratings yet

- Throat THKDocument1 pageThroat THKudaysrpNo ratings yet

- WPQ FormDocument1 pageWPQ Formudaysrp100% (1)

- IACS-UR-W - Materials & Welding PDFDocument245 pagesIACS-UR-W - Materials & Welding PDFSerggie TabanaoNo ratings yet

- Water Rocket Launch: Lesson FocusDocument18 pagesWater Rocket Launch: Lesson FocusShahood AqilNo ratings yet

- Updated Accomplishment ReportDocument6 pagesUpdated Accomplishment ReportJessel YaraNo ratings yet

- Oil Specs Silver State BrandDocument1 pageOil Specs Silver State BrandAllen WilburNo ratings yet

- Impact Bre 3 Unit3Document18 pagesImpact Bre 3 Unit3Karhen Ximena NogueraNo ratings yet

- White Paper A I Ops Use Cases 1563909601853Document4 pagesWhite Paper A I Ops Use Cases 1563909601853Janer GraciaNo ratings yet

- Honeywell 4100sm Installion ManualDocument4 pagesHoneywell 4100sm Installion ManualVictor AamNo ratings yet

- Dbms Model Question PapersDocument5 pagesDbms Model Question PapersJaswanth PadigalaNo ratings yet

- Competitive DynamicsDocument42 pagesCompetitive DynamicsS. Ramgopal Rao100% (1)

- Bankers AlgorithmDocument49 pagesBankers AlgorithmRamagopal VemuriNo ratings yet

- NoneDocument18 pagesNoneSino KaNo ratings yet

- Gadamer, H-G - Truth and Method, 2d Edn. (Continuum, 2004) 01Document635 pagesGadamer, H-G - Truth and Method, 2d Edn. (Continuum, 2004) 01lam lamNo ratings yet

- Planning Essays and Presentations BDocument45 pagesPlanning Essays and Presentations BkylaNo ratings yet

- Specific and Non Specific DimersDocument6 pagesSpecific and Non Specific DimersDattu AbhiNo ratings yet

- Media and Information LiteracyDocument4 pagesMedia and Information LiteracyAnna Marie AgravanteNo ratings yet

- CE304 Design of Concrete Structures - II PDFDocument2 pagesCE304 Design of Concrete Structures - II PDFVineeth BavaNo ratings yet

- My Final Research PaperDocument23 pagesMy Final Research PaperyenpalerNo ratings yet

- Python SetsDocument4 pagesPython Setsmgyekum124No ratings yet

- Iesco Tariff 2015Document19 pagesIesco Tariff 2015sam vaidNo ratings yet

- Monitoring Measurement and Self-AssessmentDocument3 pagesMonitoring Measurement and Self-AssessmentVijaya Seharan NairNo ratings yet

- Resolution Systems Sample HandlingDocument38 pagesResolution Systems Sample HandlingResolution Systems, Inc.No ratings yet

- Dave Lawton Kit Instructions 1Document9 pagesDave Lawton Kit Instructions 1Ecancanvas100% (1)

- Selection SheetDocument6 pagesSelection Sheethussam_98No ratings yet

- RPM 8Document3 pagesRPM 8pinku_thakkarNo ratings yet

- Reflection - A Key To Professional Growth: Two Types of ReflectionDocument10 pagesReflection - A Key To Professional Growth: Two Types of ReflectionQuerobin GampayonNo ratings yet

- Intro-IGCSE Biology Y - 10 Term 1Document15 pagesIntro-IGCSE Biology Y - 10 Term 1Mohamed AlyNo ratings yet

- IAF Core CompetenciesDocument4 pagesIAF Core CompetenciesDavid SeowNo ratings yet

- Human Trafficking by The Numbers, 2016Document110 pagesHuman Trafficking by The Numbers, 2016Houston Chronicle100% (2)