Professional Documents

Culture Documents

Welding and Cutting Procedure

Welding and Cutting Procedure

Uploaded by

Ilham WidyasaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding and Cutting Procedure

Welding and Cutting Procedure

Uploaded by

Ilham WidyasaCopyright:

Available Formats

Nasrconsortium

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

POGC

ParsOilGasCompany

ONSHOREFACILITIES

DocNo.SP122Y1HSPP999012D0

PAGE1of13

WELDING

&

CUTTING

SAFETYPROCEDURE

D0

REV.

15Aug2009

DATE

ForReview/Comment

DESCRIPTION

S.Dadmehr

B.Hossiani

PREPARED

CHECKED

M.S.Vaziri

APPROVED

Sh.Tabibzadeh

AUTHORIZED

South Pars Gas Field Development Phase 12

Page1of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

POGC

ParsOilGasCompany

ONSHOREFACILITIES

DocNo.SP122Y1HSPP999012D0

PAGE2of13

Tableofcontents

Purpose

2.0 Responsibilities

3.0 Procedures

4.0 Training&qualification

1.0

13

South Pars Gas Field Development Phase 12

Page2of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE3of13

1. Purpose

Thepurposeofthisprocedureistoensureasafeandcontrolledworkingenvironmentandthe

protectionofpersonnel,plantandequipmentinthevicinityofweldingandburningoperations.

2. Responsibilities

21SiteManager

TheSiteManagerisresponsibleforassessingtheneedandgrantingpermissionforhotworktobe

carriedouton"live"linesandorinthevicinityofflammableliquids.

22SubcontractorShi Supervisor

TheSubcontractorShiftSupervisorisresponsibleforensuringthat:

AmainWorkPermit(Hot)israisedandissuedpriortothecommencementofwork(ifrequired).

AllappropriateprecautionsdetailedinthisprocedureareenteredontheworkPermit(Hot)and

areimplementedpriortocommencementofthetask.

23SafetyAuthority

TheSafetyAuthorityisresponsibleformonitoringthesafetyofallweldingpractices.

24TaskSupervisors

TheTaskSupervisorisresponsiblefor:

EnsuringthattherequirementsoftheWorkPermitarecarriedout.

Familiarizinghimselfandhisoperatorswiththedetailsoftheprocedures.

Ensuringthatduecareandattentionismaintainedthroughouttheoperation.

25PersonnelRaisingRequisitionorContract

Itistheresponsibilityofanypersonraisingarequisitionorcontractforanyweldingequipmentor

contractedworkrequestingweldingequipmenttobeusedtoensurethattheequipmentisin

accordancewiththerequirementofthepresentstandard,particularlyasfarastheworker

protectionagainstelectricalshocksisconcerned.

3Procedures

31GeneralRequirementApplicableToAnyWelding,BurningorCuttingOperations

311FumeHazards

Awelderinaconfinedspacemustbeaccompaniedbyapersonwhostaysoutsideandcangivethe

operatoranyassistanceasrequired.

South Pars Gas Field Development Phase 12

Page3of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE4of13

Ingeneralanupperexposurelimitforweldingfumesis5mg/m3.(ReferenceHSEguidancenote

EH40).Howeverforcertainelementse.g.Cadmium,whichmaybepresentinweldingfumeslower

limitsareset.Examplesofmethodsofcontrollingweldingfumesaregiveninpage12

Toxicgasesandfumes,producedinweldingoperations,createserioushazards:

Fumescanbeproducedfromtheweldingofmaterialsthataregreasy.Allsuchmaterials

mustbethoroughlydegreasedanddriedbeforewelding.

Harmfulleadfumesareproducedwhenweldingorcuttingmaterialcoatedwithleadbased

paint.

Theinhalationoffumesfromtheweldingorcuttingofzincgalvanizedmetal,mayresultin

"MetalFumeFever",whichischaracterizedbyaraisedtemperature,achingmuscles,

shiveringandsweating.Thesymptomsdevelopinafewhoursafterexposuretothefumes

andpersistforapproximately24hours.

Airlinemasks,orhighefficiencyrespiratorsshouldbeworninthosecaseswhere

galvanized,painted,leadorcadmiumcoatedmaterialsarebeingcutorwelded.

Nitrousfumesmaybeproducedonoccasionswhereanoxypropanefumesflameimpinges

onalargemassofmetalforlongperiods.Adeficiencyofairduringsuchworkmayalso

producecarbonmonoxide.

Thearcweldingofiron,orsteel,isaccompaniedbytheevolutionofconsiderablequantities

offumesconsistingofveryfineparticlesofironoxide.Theweldingofbrass,bronzeand

manganesesteelgenerateslargequantitiesofCarbonMonoxideandCarbonDioxidegases

whichrequiretheprovisionofadequateventilationorthewearingofsuitableapparatusto

giveeffectivenasal/oralprotection.

Forthepurposeofweldingfumeextraction,aventilationsystemcouldbeconsideredas

adequateifprovidingaminimumof100airchangesperhouroftheconsideredenclosed

spacevolume.

Wherehardeneddepositsarefoundontheequipment,weldingorcuttingmustnotbe

starteduntilthegeneralnatureofthedepositsareestablished.

312Fire,Explosionandelectrocutionhazards

Noweldingorcuttingwithina"live"gasplantoratthevicinityofflammableliquidsmaybedone

withoutaWorkPermit(Hot)andtheconditionslaiddownonthatpermitmustbestrictlyobserved.

Inallwelding&cuttingoperations,aportablefireextinguishermustbereadilyaccessiblenearthe

work.

South Pars Gas Field Development Phase 12

Page4of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE5of13

Anex nguisherdesignatedforfirewatchmustbeused(8kgdrypowderminimum).Donotuse

extinguisherswhicharepermanentlypositionedforemergencyuse.

Theworkmustbesuitablyscreenedtopreventsparksandhotmetalfromflyingoutsidethe

immediateworkarea.

Fireblanketsaretobeusedtoscreenlocalorotherareasandequipment.Theuseof

flammablesubstancesasscreenisforbidden(plasticssheets).

Weldingboothsandscreensmust:

Benoncombustible.

Haveinteriorsurfacewhichminimizethereflectionofdangerousradiation.

Allowthoroughventilation.

THEWORKPIECEMUSTBEBONDEDTOEARTHBEFORESTARTINGANYWELDINGOPERATION.

Theearthcablesshouldbefixedattheworksite,orifitthisisnotpractical,within3mofthework

site.

Weldersmustnevercoilhosesorcablesaroundtheirbodywhenburningorwelding.

MerelyclosingthevalvesontheweldingtorchisNOTADISCONNECTION,gascylindervalvesshould

alsobeclosedandhosesdisconnectedatcylindershead.

Cuttingintoanycladdingcoveringpolyurethanefoaminsulationmustbeundertakenusingacold

cuttingmethod.

IfhotcuttingisunavoidablethentheSafetySuperintendent/Authorityconsultedpriorto

commencementofoperationssothatadditionalprecautions(i.e.BreathingApparatusorAirline

Equipment)areenteredontheWorkPermit.

313PreOperationChecks

CheckifaMainWorkPermit(Hot)isrequiredandifyeshasbeenraised.

Checkthatalltanks,vesselsandequipmentonwhichwelding,cutting,burning,brazingorsoldering

workistobecarriedout,arefreefromflammablegasesandvapors,oilandsludge.IFWELDINGIS

ONONESIDEOFAVESSEL,ETC.CHECKTHATTHEREARENOFLAMMABLEGASES(ORMIXTURES)

ONTHEOTHERSIDE.

Donotunderanycircumstancesusecompressedoxygenforventilation,ortoblowthrough

propanehoses.Explosionscanoccur.

South Pars Gas Field Development Phase 12

Page5of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE6of13

Inspectthespacebetweendoubleplates,orweirplates,whereflammablematerialmaybefound

beforeweldingorburningoperationsbegin.

Beforecuttingthebottomplatesofanytank,drilltestholesandtakegasteststoensurethat

conditionsaresafeunderthetankfloor.

314WorkSite

Ensurethatweldingandburningequipmentisproperlymaintainedandwelllocatedwithproper

lighting.

Checkthattheworkpieceisproperlyearthed.

Checkthatventilationisadequate.

Keeptheworkareatidythroughouttheoperation.

Donotuseoldbarrels,ordrumstosupportworktheymayexplodeandare

unstable.

315Ventilation/RespiratoryProtection

Whenvesselsandtanksarebeingweldedorburnedontheoutside,thereisadangeroftoxicor

flammablegasescollectingwithin.Theheatfromoutsideatankcanigniteanexplosivemixture

insidethetank.Particularcaremustbetakentoensureadequateventilationand/orrespirator

protection.Thiswillbeespeciallyrelevantinconfinedspaces,orwheretoxicornoxiousvaporsmay

resultfromcuttingorburningpipe,etc.,whichhasspecialcoating,e.g."skotcote".

316PersonnelProtectiveEquipment

Goggles,screens,helmetsandprotectiveclothing,mustbeusedinforallwelding,cutting,chipping

andgrindingoperations.

Ensurethatanyonenearbywhomaybeexposedtotheradiationsandflashfromthistypeofwork

isalsoprotected.Useglovesorgauntletsmadeofleather,orsomeothernonignitablematerial,to

shieldthehandsandarmsfromtheradiationofthearcandfromsparks.Usesleevesofsimilar

materialinadditiontoglovesifgauntletsarenotworn.

Note:Leatherglovesandgauntletsgivelittleinsulationagainstelectricalhazards.

Thenecessityforwearingprotectiveclothing,asprotectionagainstsparksandpieces

South Pars Gas Field Development Phase 12

Page6of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE7of13

ofhotmetal,dependsuponthepositionofthearcwithreferencetothewelder'sbody.Forsome

weldingpostures,e.g.wherethewelderisstandingatabench,theheadscreenandgauntletsmay

wellprovidesufficientprotection.Athickapronofleather,orothersuitablematerial,maybe

neededifthewelderissittingathisworkpositionwheremoltenmetalmayfalluponhisthighsor

legs.Ifthearcisabovethelevelofhisshouldersoroverhead,completeprotectionforthehead,

armsandupperpartofthebodyisnecessary.

Acommoncauseofeyeinjuryisthechippingawayofslagwhichcoverstheweldwhencoated

electrodesareused.Inthesecircumstances,ahelmetwithadoublescreenshouldbeused;one

screenconsistsofaclearsafetyglasswindowwhiletheothercontainsaglasswhichabsorbsarc

radiations.Alternatively,clearglasssafetygogglesmaybeworninconjunctionwiththeuseofa

handscreen.

317Preheatingandheatingduringwelding

Forthickworkpieces,preheatingandheatingduringweldingmightberequiredtopreventcracks.

IFELECTRICALLYHEATEDCOILSAREUSED,THEYSHALLBESUPPLIEDTHROUGHLOWVOLTAGE

POWERSUPPLY(48VOR24VINWETATMOSPHERE).

Ifheatingisundertakenbygastorch,thetorchshallbekeptinhandbyadesignatedwelderhelper.

Alittorchshouldneverbesetdownuntilturnedoff.

32GasWeldingandBurning

321LightUpProcedure

Itisimportantthatanadequateflowoffuelgasisissuingfromthenozzleofthetorchorother

apparatusbeforelightingup.

Personnelmustusethefollowingprocedures:

Settheregulatorstotherecommendedworkingpressure.

Flashbackarrestorsmustbefi edclosetothetorchi.e.within0.5m.

Keepthetorchnozzleawayfromanysourceofignitionuntilthefuelgasisflowingfreelyfrothe

nozzle.flowingfreelyfromthenozzle.

Useasparklighterforignitingthetorch.

Ifthetorchflashesbackonlightingupitisbecausetheregulatorsarenotsettothecorrect

pressureoralighthasbeenappliedbeforetheflowoffuelgasisproperlyestablished.

Iftheflamesnapsoutwhenthetorchisinuse,itisbecause:

Regulatorpressureand/orgasflowareincorrect,eithertoohighortoolow.

South Pars Gas Field Development Phase 12

Page7of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE8of13

Thenozzlehasbeenobstructed.

Thenozzlehasbeenheldtooclosetothework.

Thenozzlehasbecomeoverheated.

Inthelastcase,completelyshutoffbothtorchvalves.Plungethenozzleandtorchheadintowater.

Makesurethatthenozzleistightbeforerelightingtorch.Checktheregulatorsettingandcylinder

pressuresthenrelightinaccordancewiththeaboveprocedure.

322VentilationandBreathingApparatusforGasWelding

Theapplicationofanoxypropaneflametosheetmetal,coatedwithmetalliclead,zinc,leadpaints

orotherinjurioussubstances,maygiverisetohighlytoxicvapors,particularlyincuttingworkwhere

anexcessofoxygenisrequired.Forsuchworksuitableairlinebreathingapparatus(NOTcanister

respiration)mustbeworn.

Unlessthereisgoodthroughventilation,anairlinebreathingapparatusmaskmustbewornwhen

carryingoutoxypropanecuttingorweldinginaconfinedspace.Ventilationisbettereffectedby

extractionfans/airmoversthanbyblowingfreshairintotheconfinedspace.Compressedoxygen

mustneverbeusedforventilatingpurposes,orbeblownthroughpropanepiping.

Cylindersofcompressedgasmustalwaysbekeptoutsideanyenclosedspacewhere

welding/cuttingistakingplace.

323Workinterruption

Torchesandhosesmustnotbeleftinvessels,orenclosedspaces,whentheyarenotinuse,e.g.

afteruse,duringalunchbreak,orovernight.Averysmallleakofanygas,particularlypropanefrom

atorchoversuchaperiod,canmaketheatmosphereinthevesseldangerous.Wherethiscannotbe

donetheoxygenandpropaneconnectionsMUSTBEDISCONNECTEDatthecylinderssituated

outsidethevessel(turningoffthevalvesisnotsufficient).

324RepairstoSmallContainers

Thisincludesthewelding,brazing,solderingorcuttingofdrums,orcontainers(e.g.40gallon

drums,fueltanksofvehicles)whichhavecontainedpetroleumproducts,flammableorother

combustiblematerials.

Beforeanysuchworkiscarriedout,thedrumorcontainermustbeuncappedanddrainedandthen

eitherthoroughlysteamedcleanedorsubmergedinboilingwater

South Pars Gas Field Development Phase 12

Page8of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE9of13

andkeptattheboilingpointforatleastonehour.

Afterthesteamingorboilingprocess,compressedairmustbeblownthroughthedrumcontainer

untilthevaporsareremoved(ensuringthattheairhasafreeexittopreventbuildupofpressure).

Beforecarryingoutthehotwork,thedrumorcontainermustbecertified"GasFree"andavalid

MainWorkPermit(Hot)mustbeissued.

Whenburningorweldingisinprogressonasmallvesselunburntgasescancollectinsideandan

explosivemixturecanbeformed.

Compressedairorsteammustbepassedthroughthevessel,carebeingtakentoensurefreeand

adequateexitfortheairorsteam.

Compressedoxygenmustnotbeusedforpurging.

ThefollowingmethodsareconsideredINADEQUATEbythemselvesforpreparingvesselsforrepair:

Washingoutwithhotorcoldwaterallowingwatertorunthrough.

Purgingwithcompressedair.

Cleaningbymeansofsolvents,suchastrichloroethylene.

Allvesselssenttotheworkshopforrepairmustbecertifiedfreeofgasandcorrosivechemicals.

33ElectricArcWeldingandBurning

331ElectricArcWeldingandBurning

Theinjuriouseffectsoftheradiation'sfromaweldingarcontheeyesandskinaresimilarwhether

DCorACcurrentisemployed.

Theeffectoflookingatanunscreenedarc,ataconsiderabledistanceandforafewsecondsonly,

cancauseatemporaryorpermanenteyeinjury,whichmaynotbecomeapparentuntilsomefourto

eighthourlater.

Weldersandanyhelpersmustprotecttheireyeswiththescreens,goggles,orspectaclesprovided.

Theworkmustalsobeeffectivelyscreenedfromotherworkersinthevicinity.

332ElectricalSupplyandConnectionsseepage11

South Pars Gas Field Development Phase 12

Page9of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE10of13

Allweldingsets,cables,connectorsandterminationsmustbemaintainedingoodcondition.

Electricalsupplyandearthingconnections,toweldingtransformersandgeneratorsets,mustbe

made,maintained(andcondemnedifnecessary)byacompetent

electrician.WELDINGTRANSFORMERSSHOULDBEPROVIDEDWITHAEARTHCONNECTION(casing

andneutralterminalofprimarywindings).Allsuppliesforweldingequipmentmustbemadewith

approvedcablesandapprovedplugboxesandmustbecontrolledfromacircuitwhichincludes

protectionsensitivetoearthfaultcurrents.

Wherestationarytransformersorgeneratorsetsarebeingused,asuitableswitchmustbemounted

adjacenttotheequipmenttoisolateitfromthesupplymain.

333WeldingLeads

Portabletransformersorgeneratorsetshavingtrailingleadsmustbeprovidedwithinterlocked

fusedswitchsocketsandplugs,protectingbothtrailingcableandequipment.

Allleadsmustbeproperlyterminatedandleadcablecouplersandterminationsmustbeof

adequatecurrentcarryingcapacity.

Toavoidlonglengthsofpowercables,themachinemustbesitedascloseaspossibletothepower

supplypoints.

AweldingreturnleadmustbeprovidedfromtheneutralterminalofeachphaseofanACwelding

transformerorfromthenegativeterminalofaDCgeneratortotheworkpiece.THISRETURNLEAD

ISNOTPROVIDINGANEARTHCONNECTION.

THISLEADISREQUIREDINADDITIONTOTHEEARTHBONDINGOFTHEWORKPIECE.Itshouldbe

locatedascloseaspossiblefromtheworkplace.

Theconnectionsattheworkpiecemustbemadebyboltingorclampingfirmly.

Wheremorethanoneoperatorisworkingfromthesameweldingmachine,thepolarityofeach

weldingleadandweldingreturnmustbethesame.

Wheretwoormoreleadsarebeingusedinaconfinedarea,thecorrespondingleadsmustbe

pairedand,asfaraspossible,thecrossingofpairswithoneanother,orwithanysinglelead,must

beavoided.

South Pars Gas Field Development Phase 12

Page10of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE11of13

Whereweldingleadstrailneartanksorsumpscontaininghydrocarbons,additionallengthsofcable

mustbeaddedtothecircuittoavoidthedangerarea.

334EarthingandBonding

ForallACweldingtransformers,thetransformerlowvoltagewindingmustNOTbeearthedbutthe

transformercasemustbeeffectivelybondedtotheearthconnectionloopoftheequipment.

ForallenginedrivenACandDCweldinggenerators,noearthconnectionmaybeappliedtoeither

poleoftheweldingoutput.

Themachineframemustbeeffectivelybondedtoearth.

THEWORKPIECEMUSTBEBONDEDTOEARTHBYMEANSOFAHEAVYSECTIONCONDUCTO

HAVINGSUITABLECLAMPEDORBOLTEDCONNECTIONS.

335StrayCurrents

Inallcaseswherebuttweldingoftwoitemshastobedoneandneitheritemispermanently

attachedtoanystructure,bothitemsmustbeconnectedtotheweldingreturnandindividually

bondedtoearth.

Bondingmaybeaffectedbytheuseofmechanicalclamps,orsecurelyattachedclips.

Thisrequirementisnecessarytopreventstrayelectricalcurrentscausingsparksatadistancefrom

theweldingpointwheretheremaybeflammableatmospheres.

335ElectrodeHolders

Electrodeholdersmustbeprovidedwithahandleoftoughinsulating,nonignitablematerialwitha

guarddiscofsimilarmaterialbetweenthehandoftheoperatorandtheweldingtool.

Anelectrodeholder,whenliveand/orcontainingarodmustbeplacedoninsulatingsupports,

whennotinuse.

South Pars Gas Field Development Phase 12

Page11of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

4.

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE12of13

Trainingandqualification

Allemployeesassignedtoperformwelding,gascutting,brazing,metalgrindingandburningshall

bequalifiedordemandcompetentbytheirsuperiortoperformthework

Allweldershouldreceivetrainingonthesafeuseofequipmentandprocess,safeworkpractice

andemergencyprocedure.

FIG1WELDINGCIRCUITCONNECTIONS

South Pars Gas Field Development Phase 12

Page12of13

NASRCONSORTIUM

SOUTHPARSGASFIELDDEVELOPMENT

(EPC1PHASE12)

PetroparsLTD

DocNo.SP122Y1HSPP999012D0

POGC

ParsOilGasCompany

ONSHOREFACILITIES

PAGE13of13

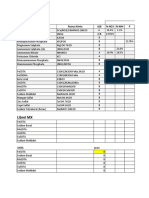

TABLE1METHODSOFCONTROLLINGWELDINGFUMES

Weldingprocess

Environment

Manualmetal

arc(stick)mild

steel

OpenAirWeldingshelter

WorkshopEnclosed

environmentConfined

Hazardous

Components

Fe,Fluoride

Fe,Fluoride

Fe,Fluoride

Fe,Fluoride

Fe,Fluoride

Recommendedminimum

Control

LEV

LEV

LEV+FFP

LEV+RPEorFFP

OpenAirWeldingshelter

Manualmetal

WorkshopEnclosed

arcstainlesssteel environmentConfinedspace

Cr,Ni

Cr,Ni

Cr,Ni

Cr,Ni

Cr,Ni

LEV

LEV

LEV

LEV+FFP

LEV+RPEfullface

TungstenInert

Gas(TIG)

OpenAirWeldingshelter

WorkshopEnclosed

EnvironmentConfinedspace

LEV=localexhaustventilation/fan

RPE=respiratoryprotectiveequipment

FFP=filteringfacepiecerespirator

Airline=compressedairlinebreathingapparatus.

South Pars Gas Field Development Phase 12

Weldgases

FFP

Airline+LEV

Page13of13

You might also like

- UPDATED SPDC MEPSS PRICED COMM SCHEDULE - Buckets - 2B.2 - 2B.3 - 2B.4 - 2BDocument240 pagesUPDATED SPDC MEPSS PRICED COMM SCHEDULE - Buckets - 2B.2 - 2B.3 - 2B.4 - 2BChristopher OjoNo ratings yet

- Maaden-JSA - Piping Erection 1Document1 pageMaaden-JSA - Piping Erection 1Santos RexNo ratings yet

- FX3000MD en PDFDocument2 pagesFX3000MD en PDFMuhammad Affan MaulanaNo ratings yet

- MS For The Audio Intercom SystemDocument11 pagesMS For The Audio Intercom Systemwaaji snapNo ratings yet

- Objective: The P&ID: Reading and Interpretation Course Is Designed ForDocument2 pagesObjective: The P&ID: Reading and Interpretation Course Is Designed ForAdnan RanaNo ratings yet

- ARO ChecklistDocument93 pagesARO Checklistmohammed_1401No ratings yet

- Ferrite Content MeasurementDocument5 pagesFerrite Content MeasurementFasil Paruvanath100% (1)

- Fire Insuranc E.: Done By: Sudeepta SabatDocument10 pagesFire Insuranc E.: Done By: Sudeepta SabatNicholas DavisNo ratings yet

- Larsen & Toubro Limited MSQ (Epcc 1) Up GradationDocument9 pagesLarsen & Toubro Limited MSQ (Epcc 1) Up GradationSaut Maruli Tua SamosirNo ratings yet

- Document Index: Hydrostatic Test ProcedureDocument7 pagesDocument Index: Hydrostatic Test ProcedureRupesh BhattacharyaNo ratings yet

- Procedure For Magnetic Particle ExaminationDocument2 pagesProcedure For Magnetic Particle ExaminationsrinivasansmNo ratings yet

- Test Booklet: Irrigation EngineeringDocument3 pagesTest Booklet: Irrigation EngineeringICE Group of Education BhopalNo ratings yet

- Installation, Testing & Flushing of Firefighting Piping System - Method Statement HQDocument20 pagesInstallation, Testing & Flushing of Firefighting Piping System - Method Statement HQvishwas salunkhe100% (1)

- LamelerDocument5 pagesLamelerPrasetyaOne NugraHantoeNo ratings yet

- Training ManualDocument69 pagesTraining ManualMudassarNo ratings yet

- MS-238-09 - Retaining Wall For PalaceDocument10 pagesMS-238-09 - Retaining Wall For PalaceJaime Manalili LandinginNo ratings yet

- Daily Report-31 (Su Jinlong)Document3 pagesDaily Report-31 (Su Jinlong)sujinlongNo ratings yet

- MethodeDocument24 pagesMethodemuhamadrafie1975No ratings yet

- Internal Cleaning of Piping System PDFDocument6 pagesInternal Cleaning of Piping System PDFNight WatchNo ratings yet

- Jazan Refinery & IGCC Industrial Support Facilities Jazan, Kingdom of Saudi ArabiaDocument5 pagesJazan Refinery & IGCC Industrial Support Facilities Jazan, Kingdom of Saudi Arabiamoytabura96No ratings yet

- QIPDocument9 pagesQIPzahid_497No ratings yet

- Rams CCTV, Cleaning, Cipp Uv Lining l5 Qat 273bDocument29 pagesRams CCTV, Cleaning, Cipp Uv Lining l5 Qat 273brajaNo ratings yet

- Rams Robotic Cutting l5 Qat 273cDocument25 pagesRams Robotic Cutting l5 Qat 273crajaNo ratings yet

- Minimum Automotive Quality Management System Requirements For Sub Tirev2Document9 pagesMinimum Automotive Quality Management System Requirements For Sub Tirev2Marco SilvaNo ratings yet

- Aluminium HVAC Duct Installation Method StatementDocument9 pagesAluminium HVAC Duct Installation Method Statementtumelo makgabutlaneNo ratings yet

- Draft Method Statement Decorative Tile Installation - RemovedDocument17 pagesDraft Method Statement Decorative Tile Installation - Removedyusuf anwerNo ratings yet

- KAK-AYT-REC-CMS-0002 Installation of Duct Bank Rev.A01Document10 pagesKAK-AYT-REC-CMS-0002 Installation of Duct Bank Rev.A01rickie7809No ratings yet

- Fire Fighting Facilities Checklist PDFDocument8 pagesFire Fighting Facilities Checklist PDFMarcio BritoNo ratings yet

- SBA2021 04 Elevated Water Storage Tower Project COMPLETE REPORTDocument171 pagesSBA2021 04 Elevated Water Storage Tower Project COMPLETE REPORTsamkelo shongweNo ratings yet

- Supervision Procedure: Oml100 (Fso Unity)Document8 pagesSupervision Procedure: Oml100 (Fso Unity)Ezemeh Nigeria100% (1)

- JMS - Snuffing Pipe Installation Rev 1Document17 pagesJMS - Snuffing Pipe Installation Rev 1mohd as shahiddin jafriNo ratings yet

- Old Hot InsulationDocument9 pagesOld Hot InsulationNehal VaghelaNo ratings yet

- Asbestos Management ProcedureDocument23 pagesAsbestos Management ProcedureSANTHOSH Gopinathan pillaiNo ratings yet

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- How To Read Welding Gauges PDFDocument5 pagesHow To Read Welding Gauges PDFjimbox88No ratings yet

- Procedure For Testing & Commissioning of Water Booster Jockey PumpsDocument3 pagesProcedure For Testing & Commissioning of Water Booster Jockey Pumpsvin ssNo ratings yet

- PMPT Itp 010Document3 pagesPMPT Itp 010hz135874No ratings yet

- Groundwater Management Sub PlanDocument16 pagesGroundwater Management Sub PlanibrahimNo ratings yet

- Fire Fighting CodesDocument7 pagesFire Fighting Codesanuavi93No ratings yet

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuNo ratings yet

- Standard Demolition ProceduresDocument3 pagesStandard Demolition ProceduresBillyNo ratings yet

- Hydrotest JHADocument29 pagesHydrotest JHABenjamin EmmanuelNo ratings yet

- AE-QA-09 - Master List of Instrument Cum Calibration PlanDocument3 pagesAE-QA-09 - Master List of Instrument Cum Calibration PlanKarthi ThiyagarajanNo ratings yet

- Project Handover ChecklistDocument4 pagesProject Handover Checklistsolarera.invoiceNo ratings yet

- Yanbu Ii Power & Water Project: Method Statement For U/G Lamination Repair ProcedureDocument2 pagesYanbu Ii Power & Water Project: Method Statement For U/G Lamination Repair Proceduresethu1091No ratings yet

- IQWQ-FT-BSPDS-00-120111 - 0 Packing SpecDocument27 pagesIQWQ-FT-BSPDS-00-120111 - 0 Packing Specjacksonbello34No ratings yet

- MS - Retention Basin Leak TestingDocument4 pagesMS - Retention Basin Leak Testingmoytabura96No ratings yet

- 002-Quality PlanningDocument5 pages002-Quality PlanningDanOtahNo ratings yet

- Released: Company Document No: Document ClassDocument32 pagesReleased: Company Document No: Document ClassShajahan AsanarNo ratings yet

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- KSI Project Charter Outline and InstructionsDocument11 pagesKSI Project Charter Outline and InstructionsValentyne KwambokaNo ratings yet

- Procedures and Training ManualDocument69 pagesProcedures and Training ManualCrystal MurrayNo ratings yet

- D. Specs For Field & Shop PaintingDocument10 pagesD. Specs For Field & Shop PaintingrajeshNo ratings yet

- Quality Assurance/Quality Control Plan: ASARCO - Encycle Facility Asbestos Abatement, Waste Removal, and DemolitionDocument20 pagesQuality Assurance/Quality Control Plan: ASARCO - Encycle Facility Asbestos Abatement, Waste Removal, and DemolitionRen SalazarNo ratings yet

- 025-Pro For Sewer & Drainage PDFDocument25 pages025-Pro For Sewer & Drainage PDFKöksal PatanNo ratings yet

- MZ-000-CCX-HS-PRO-00011 Control of Hazardous Energy Procedure Rev 0Document63 pagesMZ-000-CCX-HS-PRO-00011 Control of Hazardous Energy Procedure Rev 0Abílio Júnior MubaiNo ratings yet

- 11 SpecificationDocument199 pages11 SpecificationAshish DevreNo ratings yet

- Method Statement For DraughtingDocument6 pagesMethod Statement For DraughtingMichaelChiwuezeNo ratings yet

- Company Organizational Chart: Carl GaussDocument1 pageCompany Organizational Chart: Carl Gauss"zaqiNo ratings yet

- Lockstop SDS GreenstreakDocument8 pagesLockstop SDS Greenstreakrobox514No ratings yet

- SprinklersDocument2 pagesSprinklersMohamed El MorsyNo ratings yet

- Consumer Electronics Servicing Learning Module 130610203451 Phpapp02Document145 pagesConsumer Electronics Servicing Learning Module 130610203451 Phpapp02Maureen Pusing80% (10)

- Fichas Tecnicas Tyco Amd-2Document4 pagesFichas Tecnicas Tyco Amd-2Isaac Yull AguilarNo ratings yet

- TXP® BTC: GeometryDocument2 pagesTXP® BTC: GeometryLeonardo BarriosNo ratings yet

- Remote Sensing For Wind EnergyDocument310 pagesRemote Sensing For Wind EnergyNithin KannanNo ratings yet

- E Puck Based TestingDocument8 pagesE Puck Based TestingMuhammad SalmanNo ratings yet

- Exp3 DissolutionstudiesofparacetamolDocument5 pagesExp3 DissolutionstudiesofparacetamolTHARSHINI MURUGAIAHNo ratings yet

- I Rod Nu Bolt Product OverviewDocument6 pagesI Rod Nu Bolt Product Overviewjamehome85No ratings yet

- OTS Optical Tool Setter: Installation GuideDocument52 pagesOTS Optical Tool Setter: Installation GuideIrina BesliuNo ratings yet

- Far Trek Continue VoyagesDocument148 pagesFar Trek Continue Voyageswintermute57100% (2)

- Solve System of Equations Using GraphingDocument42 pagesSolve System of Equations Using Graphingapi-265481804No ratings yet

- JSW New Final ProjetDocument48 pagesJSW New Final ProjetRajender SinghNo ratings yet

- 10 Most Powerful Greek GodsDocument4 pages10 Most Powerful Greek GodsIris Milagro MembreñoNo ratings yet

- Sony KV 13TR27 Chasis.P 3BDocument29 pagesSony KV 13TR27 Chasis.P 3BTereza Yamileth Coto ENo ratings yet

- Yr1 Mid-Year Assessment - Model Test - AnswersDocument2 pagesYr1 Mid-Year Assessment - Model Test - AnswersNieda NorNo ratings yet

- Hows The Soil? Maniyar Village Has Red Soil and Black Soil For Its Villages. (Document4 pagesHows The Soil? Maniyar Village Has Red Soil and Black Soil For Its Villages. (Chinmay KaranNo ratings yet

- Liston The Lure of Learning in TeachingDocument28 pagesListon The Lure of Learning in TeachingDaniel NunnehNo ratings yet

- ACT Math Formulas To MemorizeDocument1 pageACT Math Formulas To MemorizeRack OsMaNo ratings yet

- Cheng 2021Document13 pagesCheng 2021Karen GarzónNo ratings yet

- Wire Nails Manufacturing Business. How To Start Nail Factory. Profitable Small Business Ideas in India-887813Document63 pagesWire Nails Manufacturing Business. How To Start Nail Factory. Profitable Small Business Ideas in India-887813MuazNo ratings yet

- Sabbaba MenuDocument8 pagesSabbaba Menuaresha6881No ratings yet

- 'RAUP IOM-Aug06Document35 pages'RAUP IOM-Aug06Ngô Khắc ToảnNo ratings yet

- PROGRAMA DE INGLES 11°jeDocument14 pagesPROGRAMA DE INGLES 11°jeJoséNo ratings yet

- Excel Meracik Nutrisi Bandung 11 Feb 2018Document30 pagesExcel Meracik Nutrisi Bandung 11 Feb 2018Ariev WahyuNo ratings yet

- Lab Report 7Document7 pagesLab Report 7Iena KasimNo ratings yet

- DIS 4.1 ExcavationDocument29 pagesDIS 4.1 ExcavationAshraf Ismail HassenNo ratings yet

- Project Proposal - BSMA 1202 byDocument19 pagesProject Proposal - BSMA 1202 byFabbi FababairNo ratings yet

- Commercial Block GIFT City - MEP-DBR-R0 PDFDocument142 pagesCommercial Block GIFT City - MEP-DBR-R0 PDFRamakrishnan SitaramanNo ratings yet

- Table of Fundamental Constants in Theoretical PhysicsDocument1 pageTable of Fundamental Constants in Theoretical PhysicsTunarisNo ratings yet