Professional Documents

Culture Documents

A E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights Reserved

A E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights Reserved

Uploaded by

Miller Andres Ladino FernandezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights Reserved

A E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights Reserved

Uploaded by

Miller Andres Ladino FernandezCopyright:

Available Formats

3

4

A

10

85

125

30

20

85

250

30

318

R

C

L

Q Q

280

60

D

80

35

I

K

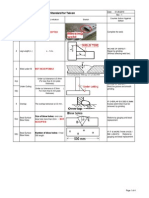

WELDING PROCESSES

1. SMAW--111

2. GTAW--141

3. GMAW--135

4. FCAW--136

380

E

F

INSTRUCTIONS

1.TACK WELDS CAN BE MADE IN ANY POSITION WITH ANY PROCESS IN THE MOST LOGICAL SEQUENCE

Test Project for the 42nd. WorldSkills

Competition in Leipzig, Germany 2013.

Copyright 2011 Worldskills International

All Rights Reserved.

FOR STRUCTURAL SQUARENESS AND JOINT ACCESS. ALL TACK WELDS ARE TO BE MADE NO LONGER

THAN 15 mm AND PLACED ON THE OUTSIDE OF THE VESSEL ONLY. ALL WELDS ARE TO BE MADE AS

INDICATED ON DRAWING.

Skill: 10. Welding, Schweissen, Soudage

2. ALL FILLET WELDS EXCEPT SPECIAL NOTES ARE TO BE 10 mm (+2mm/-0mm) IN LEG LENGTH.

Scale: N. T. S

3. GRINDING WILL BE LIMITED TO : TACK WELDS, STARTS, STOPS, ROOT PASS, FACE AND TOES.

Drawn/Designed by: Chih-Peng Chen TW / Kamyer Sadeghi IR

4. POST CLEANING : WIRE BRUSH ONLY AFTER SLAG REMOVAL, NO GRINDING.

ALL DIMENSION IN MILLIMETRES

OR

Date: 18. Dec. 2012 Paper: A3

Description: Pressure Vessel-Assembly

Drawing No: WSC2013_TP10_IR_PRESSURE VESSEL-ISO A

Rev. 2

Page: 4

10

10

WELDING PROCESSES

1. SMAW--111

2. GTAW--141

3. GMAW--135

4. FCAW--136

A

L

Q Q

280

60

B

80

35

I

K

380

250

INSTRUCTIONS

A

1.TACK WELDS CAN BE MADE IN ANY POSITION WITH ANY PROCESS IN THE

MOST LOGICAL SEQUENCE FOR STRUCTURAL SQUARENESS AND JOINT

ACCESS. ALL TACK WELDS ARE TO BE MADE NO LONGER THAN 15 mm AND

30

20

125

PLACED ON THE OUTSIDE OF THE VESSEL ONLY. ALL WELDS ARE TO BE

MADE AS INDICATED ON DRAWING.

85

2. ALL FILLET WELDS EXCEPT SPECIAL NOTES ARE TO BE 10 mm

(+2mm/-0mm) IN LEG LENGTH.

85

3. GRINDING WILL BE LIMITED TO : TACK WELDS, STARTS, STOPS, ROOT

PASS, FACE AND TOES.

4. POST CLEANING : WIRE BRUSH ONLY AFTER SLAG REMOVAL, NO

30

GRINDING.

Test Project for the 42nd. WorldSkills

Competition in Leipzig, Germany 2013.

Copyright 2011 Worldskills International

All Rights Reserved.

318

Skill: 10. Welding, Schweissen, Soudage

Scale: N. T. S

Drawn/Designed by: Chih-Peng Chen TW / Kamyer Sadeghi IR

ALL DIMENSION IN MILLIMETRES

OR

Date: 18. Dec. 2012 Paper: A3

Description: Pressure Vessel-Assembly

Drawing No: WSC2013_TP10_IR_PRESSURE VESSEL-ISO E

Rev. 2

Page: 1

10

10

TO SUIT THE ACTUAL OD. OF PIPE PROVIDED BY HOST WORKSHOP

R 44

.5 5

250

105

A

A

n2

95

190

n100

10

30BEVEL CUTTING

50

190

380

ALL DIMENSION IN MILLIMETRES

20

70

30BEVEL CUTTING

30

30BEVEL CUTTING

70

n2

60

30BEVEL CUTTING

30 BEVEL

6

140

190

MILD STEEL

NIPPLE AND DRAIN PLUG

MILD STEEL

MILD STEEL

O

N

M

L

K

J

I

1

1

1

1

1

1

1

MILD STEEL

MILD STEEL

MILD STEEL

MILD STEEL

MILD STEEL

MILD STEEL

MILD STEEL

PIPE, OD 60.5, SCH 40, 50

mm LONG

PIPE, OD 89.1, SCH 40, 140

mm LONG

PLATE, OD 52.7X6

PLATE, OD 78.1X6

PLATE, OD 100X10

PLATE, 70X70X10

PLATE, 170X77X10

PLATE, 170X160X10

PIPE, OD 89.1, SCH 40, 140

mm LONG

MILD STEEL

PLATE, 190X100X10

MILD STEEL

PLATE, 190X100X10

F

E

2

1

MILD STEEL

MILD STEEL

PLATE, 190X50.45X10

PLATE, 190X140X10

D

C

2

2

MILD STEEL

MILD STEEL

PLATE, 190X113X77x10

PLATE, 190X60X10

MILD STEEL

PLATE, 190X140X10

1

Q'TY

MILD STEEL

MATERIAL

PLATE, 380X250X10

DESCRIPTIONS

30 BEVEL

0

n2

160

n89.1

170

140

80

113

77

n20

n89.1

190

140

n2

100

95

n78.1

n52.7

50

190

85

30 BEVEL CUTTING

n60.5

3.9

77

140

E

30BEVEL CUTTING

A

ITEM

50

170

190

70

50.45

70

Scale: N. T. S

Description: Pressure Vessel-Parts list

OR

Date: 17. Dec. 2012 Paper: A3

Drawn/Designed by: Chih-Peng Chen TW / Kamyer Sadeghi IR

Skill: 10. Welding, Schweissen, Soudage

190

Test Project for the 42nd. WorldSkills

Competition in Leipzig, Germany 2013.

Copyright 2011 Worldskills International

All Rights Reserved.

R

L

ID 20 mm CENTER HOLE DRILLED

ONE END 30 DEGREE BEVEL

CUTTING AND ID 20 mm HOLE

DRILLED AS PER SKETCH

ONE END 30 DEGREE BEVEL

CUTTING

CUT TO SHAPE AND ONE END 30

DEGREE BEVEL CUTTING

ONE END 30 DEGREE BEVEL

CUTTING

CUT TO SHAPE, TRAPEZOID

ONE END 30 DEGREE BEVEL

CUTTING

ID 20mm CENTER HOLE DRILLED

AND ONE END 30 DEGREE BEVEL

CUTTING

CUT TO SHAPE

REMARKS

TO SUIT THE TESTING PUMP AT

WORKSHOP

ONE END 30 DEGREE BEVEL

CUTTING

ONE END 30 DEGREE BEVEL

CUTTING

ID 20 mm CENTER HOLE DRILLED

ID 20 mm CENTER HOLE DRILLED

ID 20 mm CENTER HOLE DRILLED

Drawing No: WSC2013_TP10_IR_PRESSURE VESSEL-ISO E

Rev. 2

Page: 2

10

135

WELDING PROCESSES

1. SMAW--111

2. GTAW--141

3. GMAW--135

4. FCAW--136

10

INSTRUCTIONS

135

111

1.TACK WELDS CAN BE MADE IN ANY POSITION WITH ANY PROCESS IN THE

MOST LOGICAL SEQUENCE FOR STRUCTURAL SQUARENESS AND JOINT

135

ACCESS. ALL TACK WELDS ARE TO BE MADE NO LONGER THAN 15 mm AND

PLACED ON THE OUTSIDE OF THE VESSEL ONLY. ALL WELDS ARE TO BE

135

MADE AS INDICATED ON DRAWING.

2. ALL FILLET WELDS EXCEPT SPECIAL NOTES ARE TO BE 10 mm

(+2mm/-0mm) IN LEG LENGTH.

3. GRINDING WILL BE LIMITED TO : TACK WELDS, STARTS, STOPS, ROOT

PASS, FACE AND TOES.

136

4. POST CLEANING : WIRE BRUSH ONLY AFTER SLAG REMOVAL, NO

GRINDING.

136

136

141 4(+2/-0)

136

141

141 4(+2/-0)

141

111

141

111

135

141

136

D

136

135

135

136

135

136

135

136

135

136

135

111

6(+2/-0)

141

136

111

Test Project for the 42nd. WorldSkills

Competition in Leipzig, Germany 2013.

Copyright 2011 Worldskills International

All Rights Reserved.

Skill: 10. Welding, Schweissen, Soudage

Scale: N. T. S

OR

Date: 18. Dec. 2012 Paper: A3

Drawn/Designed by: Chih-Peng Chen TW / Kamyer Sadeghi IR

Drawing No: WSC2013_TP10_IR_PRESSURE VESSEL-ISO A

ALL DIMENSION IN MILLIMETRES

Description: Pressure Vessel-Welding Symbols

Rev. 2

Page: 5

10

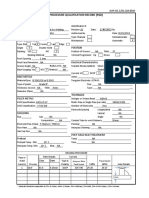

ITEM

A

B

C

D

E

F

G

H

I

J

K

L

45

n9

78

A

39

90

A

n8

Q'TY

1

2

4

1

1

1

1

1

1

1

1

1

MATERIAL

AISI 304

AISI 304

AISI 304

AISI 304

AISI 304

AISI 304

AISI 304

AISI 304

AISI 304

AISI 304

AISI 304

AISI 304

CUT TO SHAPE

CUT TO SHAPE

CUT TO SHAPE

ID 9 mm CENTER HOLE DRILLED

TACKED ON PLATE K

H

E

REMARKS

1. ALL TACK WELDS GTAW (TIG) (141) IN ANY POSITION.

2. ALL BUTTS & CORNER WELDS TO HAVE FULL PENETRATIONS.

3. ALL THE WELDING MUST BE CARRIED OUT WITH BASE PLATE "A" IN THE FLAT POSITION.

4. ALL FILLET LEG SIZES: 3.0 mm WITH TOLERANCE (+1.0 mm/-0.0 mm).

5. OUTSIDE CORNER WELD RADII: 2.0mm WITH TOLERANCE (+1.0 mm/-0.0 mm).

--TACKWELD ONLY FOR PURGING

--TO BE REMOVED FOR EXAMINATION

10

DESCRIPTIONS

PLATE, 120X110X2

PLATE, 80X50X2

PLATE, 90X80X2 TRIANGLE

PLATE, 100X80X2

PLATE, 60X50X2 TRIANGLE

PLATE, 100X60X2

PLATE, 90X48X2

PLATE, 150X60x100X2 TRAPEZOID

PLATE, 90X60X2

PLATE, 100X90X2

PLATE, 90X78X2 PURGING PLATE

TUBE, OD 8X50X2

INSTRUCTIONS TO COMPETITORS

50

C

B

20

20

20

90

50

50

100

80

60

60

Test Project for the 42nd. WorldSkills

Competition in Leipzig, Germany 2013.

Copyright 2011 Worldskills International

All Rights Reserved.

C

Skill: 10. Welding, Schweissen, Soudage

Scale: N. T. S

50

150

90

Drawn/Designed by: Chih-Peng Chen TW / K. S. Lee KR

ALL DIMENSION IN MILLIMETRES

OR

Date: 18. Dec. 2012 Paper: A3

Description: Stainless Steel/ Rostfrei Stahl/Inoxable L'acier

Drawing No: WSC2013_TP10_KR_SS-ISO A-R1

Rev. 2

Page: 2

10

1

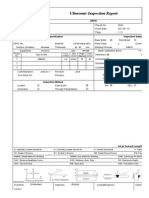

PIPE TEST COUPON 1A:

MATERIAL: CARBON STEEL PIPE

2 PCS n114.3 X 8.56 WALL X 115 LONG

NOTE:

THE NUMBER OF TACKS IS TO BE

LIMITED WITH A MAXIMUM 4 TACKS.

TEST PLATE COUPON 1B:

MATERIAL: CARBON STEEL PLATE

THICKNESS: 10 mm.

10

TEST PLATE COUPON 1C:

MATERIAL: CARBON STEEL PLATE

THICKNESS: 16 mm.

HOLD 12:00

HOLD POINT

AREA OF STOP AND

RESTART IN FINAL CAP

PASS

X

B

X = YOUR CHOICE

XX

XX

B

70

XX

XX

XX

WELDING POSITION:

ROOT PASS:_______________

FILL & CAP:________________

TACK IN CENTRE

(25 mm LENGTH MAXIMUM)

NOTE:

1. DEPOSIT A FILLET WELD ON THE FRONT SIDE OF THE

JOINT WITH A 10 mm (+2.0/-0) mm LEG LENGTH.

2. WELD TO BE DEPOSITED WITH A MINIMUM OF 2 RUNS

AND A MAXIMUM OF 3 RUNS.

3. EDGE PREPARATION MUST REMAIN AT 90 TO THE

PLATE FACE. NO CHAMFER AND GAP ALLOWED.

BAC

ID E

X

XXX

8.56 (A)

TACK EACH END

ROOT FACE YOUR CHOICE

115(A)

100 (B)

50

10

75

STOP/RESTART OF

ROOT PASS IN THIS

AREA

CARBON STEEL

PLATE 250 X 100 X 12

CARBON STEEL

PLATE 250 X 125 X 12

CARBON STEEL

PLATE 250 X 125 X 16

30 deg. MILLED BEVEL

CARBON STEEL

PLATE 250 X 100 X 10

30 deg. MILLED BEVEL

CARBON STEEL

PIPE OD 114.3 X 8.56 WALL X 115 LONG

30 deg. TURNED BEVEL

Q'TY

25

DETAIL OF MILLED BEVEL

25

ALL DIMENSIONS IN MILLIMETRES

BUT DO NOT SCALE DRAWING

DESCRIPTIONS

Skill: 10. Welding, Schweissen, Soudage

125

MATERIAL

REMARKS

Test Project for the 42nd. WorldSkills

Competition in Leipzig, Germany 2013

Copyright 2011 Worldskills International

All Rights Reserved.

Scale: N. T. S

25

NTS = NOT TO SCALE

ITEM

12

Ref.

NOTE

125 (C)

50

FRONT SIDE

DISCARD

100

KS

1. ANY PROCESS AND ANY POSITION MAY BE USED FOR TACKWELDING.

2. ALL TACK WELDS EXCEPT CENTRE OF FILLET WELDS ARE TO BE NOT LONGER THAN 15 mm. A MAXIMUM OF 4 TACKS ARE TO BE MADE FOR TEST PIPE COUPON.

3. ALL PLATE OR PIPE COUPONS ARE TO BE TACKWELDED BEFORE ANY WELDING COMMENCES.

4. PROCESS INDICATED FOR ROOT WELD TO BE USED ONLY FOR ONE RUN, NOT FOR SECOND AND SUBSEQUENT PASSES.

5. ALL PLATE OR PIPE COUPONS MUST BE WELDED IN THE POSITION AS INDICATED FOR EACH TEST.

6. GRINDING IS NOT ALLOWED FOR THE CLEANING OF THE FINAL SURFACES OF BOTH CAP AND ROOT WELDS.

7. XXXX= COMPETITOR'S I.D.

30

12

EVALUATION:

1. VISUAL

2. X-RAY ENTIRE WELD JOINT

NOTE:

FILLET WELD COUPON 1D:

MATERIAL: CARBON STEEL PLATE

THICKNESS: 12 mm

WELDING PROCESS:_______________

WELDING POSITION:_______________

C

C

WELDING POSITION:

ROOT PASS:_____________

FILL & CAP:______________

EVALUATION:

1. VISUAL

2. X-RAY ENTIRE WELD JOINT

10(B)

EVALUATION:

1. VISUAL

2. X-RAY ENTIRE WELD JOINT

16 (C)

WELDING POSITION:

ROOT PASS:_________________

FILL & CAP:__________________

DISCARD

XX

Designed/Drawn by: Chih-Peng Chen TW

Description: Module I--Test Coupons (Plates/Pipe/Fillet)

OR

Date: 19. Dec. 2012 Paper: A3

Drawing No: TP10_42DE_DAY1_GENERIC

Rev. 2

Page: 1 of 1

10

4

C

ITEM

A

B

C

D

E

F

G

H

I

J

I

A

12

12

12

12

C

E

7

Q'TY

1

2

2

1

2

1

2

1

1

1

MATERIAL

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

9

DESCRIPTIONS

PLATE, 190X90X3

PLATE, 110X103.92X3

PLATE, 177.74X80X3

PLATE, 160X110X3

PLATE, 120X120X3

PLATE, 160X57X3

PLATE, 120X103.92X3

PLATE, 190X120X3

PLATE, 160X120X3

TUBE, OD 60X25X3

10

REMARKS

CUT TO SHAPE

A

CUT TO SHAPE

95

G

60

D

F

Det. A

D

B

REVERSE ELEVATION

ELEVATION

Detail A

50

110

103.92

60

28.87

103.92

120

ITEM G

ITEM B

ALL DIMENSION IN MILLIMETRES

Test Project for the 42nd. WorldSkills

Competition in Leipzig, Germany 2013.

Copyright 2011 Worldskills International

All Rights Reserved.

INSTRUCTIONS TO COMPETITORS

1. WELDING PROCESS: GTAW (TIG) (141).

2. WELDING POSITIONS: ALL EXCEPT VERTICAL DOWN..

3. ALL THE WELDING MUST BE CARRIED OUT WITH BASE PLATE "A" IN THE FLAT POSITION.

4. ALL FILLET LEG SIZES: 4.0 mm WITH TOLERANCE (+2.0 mm/-0.0 mm).

5. OUTSIDE CORNER WELD RADII: 3.0mm WITH TOLERANCE (+2.0 mm/-0.0 mm).

Skill: 10. Welding, Schweissen, Soudage

Scale: N. T. S

Drawn/Designed by: Chih-Peng Chen TW

Description: Aluminium Alloy

OR

Date: 17. Dec. 2012 Paper: A3

Drawing No: WSC2013_TP10_TW_ALUMINIUM-ISO A

Rev. 2

Page: 2

10

10

95

G

60

Det. A

ELEVATION

B

REVERSE ELEVATION

Detail A

ALL DIMENSION IN MILLIMETRES

12

J

I

H

G

F

E

D

C

B

A

ITEM

12

12

12

E

60

1

1

1

2

1

2

1

2

2

1

Q'TY

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

AA 5052

MATERIAL

TUBE, OD 60X25X3

PLATE, 160X120X3

PLATE, 190X120X3

PLATE, 120X103.92X3

PLATE, 160X57X3

PLATE, 120X120X3

PLATE, 160X110X3

PLATE, 177.74X80X3

PLATE, 110X103.92X3

PLATE, 190X90X3

DESCRIPTIONS

CUT TO SHAPE

CUT TO SHAPE

REMARKS

50

103.92

110

28.87

103.92

120

ITEM B

ITEM G

Test Project for the 42nd. WorldSkills

Competition in Leipzig, Germany 2013.

Copyright 2011 Worldskills International

All Rights Reserved.

INSTRUCTIONS TO COMPETITORS

1. WELDING PROCESS: GTAW (TIG) (141).

2. WELDING POSITIONS: ALL EXCEPT VERTICAL DOWN..

3. ALL THE WELDING MUST BE CARRIED OUT WITH BASE PLATE "A" IN THE FLAT POSITION.

4. ALL FILLET LEG SIZES: 4.0 mm WITH TOLERANCE (+2.0 mm/-0.0 mm).

5. OUTSIDE CORNER WELD RADII: 3.0mm WITH TOLERANCE (+2.0 mm/-0.0 mm).

Skill: 10. Welding, Schweissen, Soudage

Scale: N. T. S

Drawn/Designed by: Chih-Peng Chen TW

Description: Aluminium Alloy

OR

Date: 17. Dec. 2012 Paper: A3

Drawing No: WSC2013_TP10_TW_ALUMINIUM-ISO E

Rev. 2

Page: 1

10

You might also like

- Data Fasilitas Peralatan Mekanikal (DPS) 2021Document69 pagesData Fasilitas Peralatan Mekanikal (DPS) 2021Dewa ayu putu laksmi putri wijayaNo ratings yet

- Gas Law Packet AnswersDocument6 pagesGas Law Packet Answersjerm655No ratings yet

- Welder Qualification ReportDocument2 pagesWelder Qualification ReportSyed Mahmud Habibur RahmanNo ratings yet

- CSWIP Module Re-ExamDocument2 pagesCSWIP Module Re-ExamAhmad Khalimi Ilmawan100% (1)

- TC VerificationDocument33 pagesTC VerificationmaheshNo ratings yet

- Asme Section Ix-Welding - Practice Quest PDFDocument3 pagesAsme Section Ix-Welding - Practice Quest PDFRajesh KumarNo ratings yet

- WeldingDocument23 pagesWeldingBilal TayyabNo ratings yet

- 1.2 Resistance and Special WeldingDocument14 pages1.2 Resistance and Special WeldingnikhilbathamNo ratings yet

- ASME B31.1 2018 (Inspection-Academy)Document31 pagesASME B31.1 2018 (Inspection-Academy)royal0% (1)

- IPBD Instruction Manual PDFDocument41 pagesIPBD Instruction Manual PDFrobinknit2009No ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- Porosity in WeldingDocument13 pagesPorosity in Weldingbn pandeyNo ratings yet

- Ut PQRDocument10 pagesUt PQRArvind Sahani100% (1)

- Aramco Questions-1Document22 pagesAramco Questions-1शैलेश सिंह तोमर - स्वयंसेवकNo ratings yet

- Spec Sheet - Handler 187Document4 pagesSpec Sheet - Handler 187Hobart Welding ProductsNo ratings yet

- Welding Standard Ver1Document4 pagesWelding Standard Ver1Sowmen ChakrobortyNo ratings yet

- NDT AcceptanceDocument62 pagesNDT Acceptancebommakanti srinivas100% (1)

- PT - Asme Sec Viii Div. 1 2004 EditionDocument2 pagesPT - Asme Sec Viii Div. 1 2004 EditiondhasdjNo ratings yet

- Submerged Arc WeldingDocument4 pagesSubmerged Arc WeldingshifaNo ratings yet

- 38 MM DAC Block - Master SUDHANDocument5 pages38 MM DAC Block - Master SUDHANmaxpan maxNo ratings yet

- Magnetic Flux Leakage (MFL) TechnologyDocument4 pagesMagnetic Flux Leakage (MFL) TechnologyShakirNo ratings yet

- Candidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)Document4 pagesCandidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)Ahmed Hassan100% (1)

- Selected Questions From General MechanicalDocument5 pagesSelected Questions From General MechanicalEhab Harb100% (1)

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Gmaw Guide PDFDocument54 pagesGmaw Guide PDFJorge perezNo ratings yet

- Question Paper For Snr. WeldingDocument3 pagesQuestion Paper For Snr. WeldingThulasi Ram100% (1)

- Table 5 - Wire Type IQI Selection Table 5 - Wire Type IQI SelectionDocument3 pagesTable 5 - Wire Type IQI Selection Table 5 - Wire Type IQI SelectionBhanu Pratap ChoudhuryNo ratings yet

- Weld TestingDocument51 pagesWeld TestingYuki FongNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEDocument18 pagesAcceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEEngineersEDGE CoimbatoreNo ratings yet

- Procedure For Magnetic Particle Testing: Ramachal NDT ServicesDocument3 pagesProcedure For Magnetic Particle Testing: Ramachal NDT ServicesAman SarfarazNo ratings yet

- Asnt Certification Scheme Radiography Method Level - Ii Home Work - Interpretation, Standards & Codes Name: DateDocument3 pagesAsnt Certification Scheme Radiography Method Level - Ii Home Work - Interpretation, Standards & Codes Name: DateMahade Hasan DipuNo ratings yet

- Welding FormDocument4 pagesWelding FormAnand SomanNo ratings yet

- Magnetic Particle Testing. Presentation Krishnamoorthi. VDocument50 pagesMagnetic Particle Testing. Presentation Krishnamoorthi. VThe Engineers EDGE, CoimbatoreNo ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- Ri - 2Document139 pagesRi - 2Benjamin BrownNo ratings yet

- Radiography TestingDocument4 pagesRadiography TestingTridib DeyNo ratings yet

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocument10 pagesProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNo ratings yet

- What Is Arc Blow and How Do You Prevent It?Document2 pagesWhat Is Arc Blow and How Do You Prevent It?amalhaj2013No ratings yet

- LPT As Per Asme & IsoDocument2 pagesLPT As Per Asme & Isosbmmla100% (1)

- Question 1 of 25Document7 pagesQuestion 1 of 25antonio larotta100% (1)

- Sae Ams-W-6858Document46 pagesSae Ams-W-6858Luis HernandezNo ratings yet

- Belt Drive AllignmentDocument3 pagesBelt Drive AllignmentMichaelNo ratings yet

- User Guide: API 653 Inspectors ToolboxDocument4 pagesUser Guide: API 653 Inspectors ToolboxBùi Văn HợpNo ratings yet

- Is 5082 1998 PDFDocument11 pagesIs 5082 1998 PDFRa Hul0% (1)

- Twi Training & Certification (S.E. Asia) SDN - BHDDocument1 pageTwi Training & Certification (S.E. Asia) SDN - BHDjasminneeNo ratings yet

- V+ 4.magnetic Particle ExaminationDocument12 pagesV+ 4.magnetic Particle ExaminationAMAL VISHNUNo ratings yet

- RI Appendix 1 Part 5c Radiographic Inspector 1st Edition April 2018Document12 pagesRI Appendix 1 Part 5c Radiographic Inspector 1st Edition April 2018Watsharawee LimpiputtipongNo ratings yet

- Coil MagDocument1 pageCoil MagABC Any Body Can RelaxNo ratings yet

- Saw Weld ProcedureDocument21 pagesSaw Weld ProcedurePhani KumarNo ratings yet

- A General Review of Geometric Shape ImperfectionsDocument12 pagesA General Review of Geometric Shape Imperfectionsbipete69No ratings yet

- Field Practice SpecificationDocument20 pagesField Practice SpecificationRichart SembiringNo ratings yet

- NDT-Basic-FormulaeDocument3 pagesNDT-Basic-FormulaeJayeshNo ratings yet

- G S Earth WireDocument10 pagesG S Earth WiresaratNo ratings yet

- Hashemite University - NDT Overview PDFDocument7 pagesHashemite University - NDT Overview PDFgeorgescribd1103No ratings yet

- Model 770 Ordering GuideDocument2 pagesModel 770 Ordering GuideSkiFy AlexNo ratings yet

- r1Document3 pagesr1naseema1No ratings yet

- Notes: Apply Two Layer of Anti Corrosion Paint Then Apply Third Layer of Semi Glossy Paint. Check Height of Base Assembly For AdjustmentDocument1 pageNotes: Apply Two Layer of Anti Corrosion Paint Then Apply Third Layer of Semi Glossy Paint. Check Height of Base Assembly For AdjustmentkhalidcosmosNo ratings yet

- Model 770: Incremental EncoderDocument2 pagesModel 770: Incremental EncoderwintermacNo ratings yet

- EIC B 1018 0 HPV Double Vane Pump RTR Tyytry RD T Rdtyrt DHGFHJGF Jtyhutr Hrdfty RGD Htrghyrdftyrgd Rtyudr Rtyudr Ur Rty Esetyrdy Yetyrtyyr Etyr5sdey Et Esytyrtdgyhrtd Styr RTSSTDGHR RytuhtrsDocument17 pagesEIC B 1018 0 HPV Double Vane Pump RTR Tyytry RD T Rdtyrt DHGFHJGF Jtyhutr Hrdfty RGD Htrghyrdftyrgd Rtyudr Rtyudr Ur Rty Esetyrdy Yetyrtyyr Etyr5sdey Et Esytyrtdgyhrtd Styr RTSSTDGHR RytuhtrsPravinPMKoolNo ratings yet

- 8 Position Dip SwitchDocument2 pages8 Position Dip SwitchChai SilwanusNo ratings yet

- Wps Vosl-Pl-1 Pipeline Rev.2 XDocument11 pagesWps Vosl-Pl-1 Pipeline Rev.2 XVijo Jose100% (1)

- Super Porcelain Ex 3Document40 pagesSuper Porcelain Ex 3icepascuNo ratings yet

- Leespring EngguideDocument27 pagesLeespring EngguideAnonymous h6qnMVb8eNo ratings yet

- Fischer Tropsch Process PresentationDocument16 pagesFischer Tropsch Process Presentationmaz zlsNo ratings yet

- Cost EstimateDocument3 pagesCost Estimatemichael jan de celisNo ratings yet

- Energy Efficient Buildings Cooling Towers: HOT Water IN HOT Water INDocument17 pagesEnergy Efficient Buildings Cooling Towers: HOT Water IN HOT Water INAnup Maurya100% (1)

- Corrosion Engineering Lecture 1Document12 pagesCorrosion Engineering Lecture 1ABNo ratings yet

- Static Excitation SystemDocument36 pagesStatic Excitation Systemlrpatra100% (1)

- Belleville SpringsDocument26 pagesBelleville SpringsMuthu Kumar RNo ratings yet

- Week12 JIT TPS Kanban LeanDocument36 pagesWeek12 JIT TPS Kanban LeanDrake AdamNo ratings yet

- Abro TapeDocument2 pagesAbro TapeDhanish AhsenNo ratings yet

- Differential Pipe Sticking: Oleh: Ernindyas Himawasti 113120051 Bahasa Inggris Teknik PerminyakanDocument11 pagesDifferential Pipe Sticking: Oleh: Ernindyas Himawasti 113120051 Bahasa Inggris Teknik PerminyakanErnindyas100% (1)

- Show PubDocument8 pagesShow PubTanmay MajhiNo ratings yet

- BMW 8 Us Brake Booster RebuildDocument14 pagesBMW 8 Us Brake Booster RebuildJohn M. SmithNo ratings yet

- Composite Materials and StructuresDocument64 pagesComposite Materials and Structuresbabin tNo ratings yet

- Knife Gate Valve: Product DescriptionDocument2 pagesKnife Gate Valve: Product DescriptionTamil SelvanNo ratings yet

- RENAULT Quality PlanningDocument20 pagesRENAULT Quality PlanningEhsan ArbabtaftiNo ratings yet

- TM9 710 1944Document360 pagesTM9 710 1944Joseph MetrzNo ratings yet

- ImerCarb® 1T - ImerysDocument2 pagesImerCarb® 1T - Imerysumair912147No ratings yet

- Lec23 NptelDocument14 pagesLec23 NptelSajid IqbalNo ratings yet

- 7b Zinc Tape For TransportDocument2 pages7b Zinc Tape For TransportKen SidhartaNo ratings yet

- GDU Doc ListDocument29 pagesGDU Doc Listdeepak_1861987No ratings yet

- PVC Pipes Manufacturing ProcessDocument3 pagesPVC Pipes Manufacturing ProcessFabii Olave100% (2)

- Holex 2017-2018Document8 pagesHolex 2017-2018Krakovchi LorandNo ratings yet

- Temperature-Resistance Characteristics of Thermistors: Ambient Temperature (C) Ambient Temperature (C)Document1 pageTemperature-Resistance Characteristics of Thermistors: Ambient Temperature (C) Ambient Temperature (C)c_lucian2004No ratings yet

- MAXSpan DrawingDocument6 pagesMAXSpan DrawingLubangakene BrianNo ratings yet

- How To Confirm The Best PVB Thickness For Your ProjectDocument3 pagesHow To Confirm The Best PVB Thickness For Your ProjectHAN HANNo ratings yet

- Kaufmann HT20Document5 pagesKaufmann HT20Eduardo FiorentinoNo ratings yet

- Test ReportDocument1 pageTest ReportPiyush GuptaNo ratings yet