Professional Documents

Culture Documents

Injection Molding: Part Cost Estimator

Injection Molding: Part Cost Estimator

Uploaded by

pchakkrapaniCopyright:

Available Formats

You might also like

- MMR - Weekly 29 Jan 2024Document20 pagesMMR - Weekly 29 Jan 2024dishukadam06100% (1)

- Blow Mould Component Cost EstimationDocument6 pagesBlow Mould Component Cost EstimationVenkateswaran venkateswaran50% (2)

- Lathe and VMC Cycle Time CalculatorDocument5 pagesLathe and VMC Cycle Time CalculatorDhanus KodiNo ratings yet

- Cost BreakupDocument6 pagesCost Breakuppiyush sharma100% (1)

- Die Design ChecklistDocument3 pagesDie Design ChecklistLương TuấnNo ratings yet

- SHT Metal EstimatorDocument7 pagesSHT Metal Estimatorkarthikkumarfeb6No ratings yet

- Tool Design Calculation: Cutting ForceDocument4 pagesTool Design Calculation: Cutting ForceRaja SathishNo ratings yet

- Tonnage CalculationDocument3 pagesTonnage CalculationEmba MadrasNo ratings yet

- Compression Molding Machine PriceDocument13 pagesCompression Molding Machine PriceSalma FarooqNo ratings yet

- Instructions For Completion of Piece Cost Breakdown WorksheetDocument9 pagesInstructions For Completion of Piece Cost Breakdown WorksheetfranciscoNo ratings yet

- Injctmld F03Document2 pagesInjctmld F03prasad_kcpNo ratings yet

- Injection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedDocument4 pagesInjection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedTiago CerqueiraNo ratings yet

- Form Tooling List Approval Tooling (002) Rev 4Document3 pagesForm Tooling List Approval Tooling (002) Rev 4Kalista BettiNo ratings yet

- The Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SDocument6 pagesThe Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SSanjay KumarNo ratings yet

- Inj Mold CalculateDocument9 pagesInj Mold CalculateGiap NguyenNo ratings yet

- CTM Mold Design Standards PDFDocument43 pagesCTM Mold Design Standards PDFDini ViruNo ratings yet

- Costing Format - Press ToolDocument6 pagesCosting Format - Press ToolVineet Pandey Vlogs67% (3)

- Injection Molding Part CostingDocument4 pagesInjection Molding Part Costingfantinno100% (1)

- 02injection Moulding MachineDocument31 pages02injection Moulding MachineS Karthick KeyanNo ratings yet

- Shot Area: Must Be 50% From Injection PressureDocument7 pagesShot Area: Must Be 50% From Injection PressureAri Wibowo NugrohoNo ratings yet

- Blanking Process Cost CalculationDocument3 pagesBlanking Process Cost CalculationVenkateswaran venkateswaran100% (1)

- Minsa Trial Report Molde SC194Document2 pagesMinsa Trial Report Molde SC194daniel ortiz fuentesNo ratings yet

- Stamping Blank and Tonnage CalculatorDocument10 pagesStamping Blank and Tonnage CalculatorDhanus KodiNo ratings yet

- PP - Injection Mould Component Cost EstimationDocument7 pagesPP - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Partcost With Freight Table Rev. 7Document3 pagesPartcost With Freight Table Rev. 7RJLockNo ratings yet

- D10369520ADocument4 pagesD10369520AQUALITY ControlNo ratings yet

- Mold Cost EstimationDocument5 pagesMold Cost EstimationPenjahit TedyNo ratings yet

- Tool Design - Chapter 3 (Part 3)Document48 pagesTool Design - Chapter 3 (Part 3)Fiq IFTNo ratings yet

- FES MTG Welding Fixture F7222910Document11 pagesFES MTG Welding Fixture F7222910Sekar NaikNo ratings yet

- Die CalculationsDocument13 pagesDie CalculationsDhinakaran R100% (1)

- Abs - Injection Mould Component Cost EstimationDocument7 pagesAbs - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Injection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Document1 pageInjection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Jake Floyd G. FabianNo ratings yet

- 20me702 - Process Planning and Cost Estimation Unit 5 2023-24Document65 pages20me702 - Process Planning and Cost Estimation Unit 5 2023-24CAD With RaoNo ratings yet

- How To Compute Tonnage RequirementsDocument5 pagesHow To Compute Tonnage RequirementsPrabhat SharmaNo ratings yet

- Cupola Melting CostDocument3 pagesCupola Melting CostnirevievNo ratings yet

- Mould Starndard Parts PDFDocument13 pagesMould Starndard Parts PDFMohd Nazri SalimNo ratings yet

- MHR Calculation 1Document13 pagesMHR Calculation 1RamNo ratings yet

- Investment Casting Cycle TimeDocument12 pagesInvestment Casting Cycle TimemaheshNo ratings yet

- Injection Molding Cost CalculatorDocument111 pagesInjection Molding Cost CalculatorvenkithankamNo ratings yet

- Rubber Component Cost Estimation SheetDocument1 pageRubber Component Cost Estimation SheetVenkateswaran venkateswaran100% (2)

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- Poly Carbonate - Injection Mould Component Cost EstimationDocument7 pagesPoly Carbonate - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Tool Life SheetDocument4 pagesTool Life SheetYam Udhai100% (1)

- Asa - Injection Mould Component Cost EstimationDocument7 pagesAsa - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Seminar On Split Cavity MouldDocument43 pagesSeminar On Split Cavity MouldasgrutuNo ratings yet

- Mold ChecklistDocument5 pagesMold ChecklistSelvaraj BalasundramNo ratings yet

- Body ModelDocument145 pagesBody ModelDipika PandaNo ratings yet

- Mold Design Fundamental Calculation BATTERY COVERDocument7 pagesMold Design Fundamental Calculation BATTERY COVERrgrao85No ratings yet

- Part/Material Inputs: Injection Molding Technical Cost Model MIT - Materials Systems LaboratoryDocument13 pagesPart/Material Inputs: Injection Molding Technical Cost Model MIT - Materials Systems LaboratoryEmba MadrasNo ratings yet

- Product or Service Technical Design Specifications, Including Unit of Measure (UOM)Document1 pageProduct or Service Technical Design Specifications, Including Unit of Measure (UOM)Priyaprasad PandaNo ratings yet

- Costing Sheet 500632403736Document6 pagesCosting Sheet 500632403736Sourabh PradhanNo ratings yet

- Methodology of Die Design For HPDCDocument8 pagesMethodology of Die Design For HPDCruben6286No ratings yet

- Fixtures Cost Break UpDocument23 pagesFixtures Cost Break UpAshok AroraNo ratings yet

- Internal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00Document2 pagesInternal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00ramabhplNo ratings yet

- Clutch HSG Casting CostingDocument18 pagesClutch HSG Casting CostingAjay DeshpandeNo ratings yet

- Lab10 Final Progressive Die PDFDocument7 pagesLab10 Final Progressive Die PDFSyed Asif Bukhari100% (1)

- Part Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailDocument2 pagesPart Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailramabhplNo ratings yet

- Injctmld F03Document3 pagesInjctmld F03Šetkić SemirNo ratings yet

- Answers MechanicalDocument3 pagesAnswers MechanicalLê Nguyễn Hoàng ThăngNo ratings yet

- File 10 Bab ViDocument20 pagesFile 10 Bab ViJoko TeloNo ratings yet

- Jumping Math!: Grade 1Document1 pageJumping Math!: Grade 1pchakkrapaniNo ratings yet

- Printer Compatibility List: Print Server Model Printer Manufacture Printer ModelDocument20 pagesPrinter Compatibility List: Print Server Model Printer Manufacture Printer ModelpchakkrapaniNo ratings yet

- Piping Material Selection TableDocument1 pagePiping Material Selection TablepchakkrapaniNo ratings yet

- Ash Land DetailsDocument1 pageAsh Land DetailspchakkrapaniNo ratings yet

- Obtaining Contents in DVDDocument1 pageObtaining Contents in DVDpchakkrapaniNo ratings yet

- Welding Terms & DefinitionsDocument42 pagesWelding Terms & DefinitionspchakkrapaniNo ratings yet

- Manuals Type3Document365 pagesManuals Type3pchakkrapani100% (1)

- Calibre User Manual, The - Kovid GoyalDocument2 pagesCalibre User Manual, The - Kovid GoyalpchakkrapaniNo ratings yet

- Design For Assembly WorksheetDocument1 pageDesign For Assembly WorksheetpchakkrapaniNo ratings yet

- Instrument Calibration ProcedureDocument7 pagesInstrument Calibration ProceduremullanjiNo ratings yet

- Hitachi CalibrationDocument3 pagesHitachi CalibrationpchakkrapaniNo ratings yet

- Calculating Electrical CostsDocument1 pageCalculating Electrical CostspchakkrapaniNo ratings yet

- Vendors 820Document28 pagesVendors 820pchakkrapaniNo ratings yet

- c006b QDocument54 pagesc006b QpchakkrapaniNo ratings yet

- Setting Rings: Total Solution For Thread GaugingDocument1 pageSetting Rings: Total Solution For Thread GaugingpchakkrapaniNo ratings yet

Injection Molding: Part Cost Estimator

Injection Molding: Part Cost Estimator

Uploaded by

pchakkrapaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Injection Molding: Part Cost Estimator

Injection Molding: Part Cost Estimator

Uploaded by

pchakkrapaniCopyright:

Available Formats

Injection Molding: Part Cost Estimator

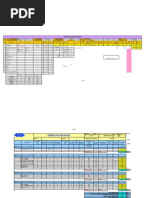

Copyright R. J. Eggert, Boise State University

Oct. 27, 2003

Injection Time

required shot size =

Reset Time

dry cycle time =

part depth =

stroke length =

rec. injection pressure =

rec. injection pressure =

rec. injection pressure =

machine power =

injection time =

Total Cycle Time =

31.7

0.0000317

1000

100

14.5

18.5

cm^3

m^3

Bars

MPa

ksi

kW

0.34 s

10.69 s

Clamping Force

net part area =

no. cavities =

runner %=

clamp area=

rec. injection pressure =

clamping force =

40

3

32

158.4

100

792

Mold Cost per part

no. cavities =

mold cost=

Production Qty=

mold cost=

mold cost/part=

mold cost/part=

3

5000

2.00E+04

10788.35

0.54

53.94

Total Cost/part

material=

mold=

machine=

2.53

53.94

3.3

cm^2

%

Mpa

kN

$

$

$/part

cents/part

Cooling Time

Recommended Temperatures

injection =

260 C

mold =

54 C

ejection =

82 C

Thermal difusivity =

max. wall thickness =

cooling time =

Part Material Cost

net part area =

thickness =

volume =

volume =

specific gravity =

mass =

mat'l cost=

mat'l cost=

mat'l cost=

0.13 mm^2/s

2 mm

6.97 s

40

2

8

8E-006

1.05

0.0084

3.01

0.03

2.53

cm^3

mm

cm^3

m^3

kg

$/kg

$/part

cents/part

reset time =

Processing Costs

machine rate =

no. cavities =

processing cost =

3.3 s

0.2 cm

32 cm

3.37 s

33 $/hr

3

0.03 $/part

3.3 cents/part

total=

59.74 cents/part

Injection Molding - Mold Cost Estimator

R. J. Eggert

(Copyright Boise State University - Follows B, D & K Chapter 8)

Mold Base Cost Estimate

Ac

cavity plate area =

hp

part depth =

hd

combined plate thickness =

Core/Cavity Cost Estimate

1 Area Dependent Costs

Mpo

primary core/cavity

Me

Ejection system

Ap

projected area =

Ne

number of ejectors =

2 Geometric Complexity

Nsp

Interior surface patches

Xi

Nsp

Exterior surface patches

Xo

Oct. 29, 2003

$5,473

2550 cm^2

15 cm

30 cm

21.0 hours

22.2 hours

$839

$886

3.0 hours

$122

0.0 hours

0.0 hours

0.0 hours

$0

$0

$0

11.5 hours

$462

0.0 hours

$0

0.0 hours

$0

0.0 hours

$0

78.5 cm^2

8.9

2

0.2

4

0.4

Undercuts

3

4

5

number of side pulls =

number of internal lifters =

number of unscrewing cores =

0

0

0

6 Surface finish / appearance

surface finish factor (T8.6) =

25 %

7 Tolerance Level

tolerance level factor (T8.7) =

0 %

8 Texture (Yor N)

9 Parting Plane Surface

parting plane surface factor (T8.8) =

Total Manufacturing Points =

Mold Machining Rate =

Core/Cavity Costs =

57.7 hours

$40 $/hr

$2,308

Total Mold Cost =

$7,781

You might also like

- MMR - Weekly 29 Jan 2024Document20 pagesMMR - Weekly 29 Jan 2024dishukadam06100% (1)

- Blow Mould Component Cost EstimationDocument6 pagesBlow Mould Component Cost EstimationVenkateswaran venkateswaran50% (2)

- Lathe and VMC Cycle Time CalculatorDocument5 pagesLathe and VMC Cycle Time CalculatorDhanus KodiNo ratings yet

- Cost BreakupDocument6 pagesCost Breakuppiyush sharma100% (1)

- Die Design ChecklistDocument3 pagesDie Design ChecklistLương TuấnNo ratings yet

- SHT Metal EstimatorDocument7 pagesSHT Metal Estimatorkarthikkumarfeb6No ratings yet

- Tool Design Calculation: Cutting ForceDocument4 pagesTool Design Calculation: Cutting ForceRaja SathishNo ratings yet

- Tonnage CalculationDocument3 pagesTonnage CalculationEmba MadrasNo ratings yet

- Compression Molding Machine PriceDocument13 pagesCompression Molding Machine PriceSalma FarooqNo ratings yet

- Instructions For Completion of Piece Cost Breakdown WorksheetDocument9 pagesInstructions For Completion of Piece Cost Breakdown WorksheetfranciscoNo ratings yet

- Injctmld F03Document2 pagesInjctmld F03prasad_kcpNo ratings yet

- Injection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedDocument4 pagesInjection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedTiago CerqueiraNo ratings yet

- Form Tooling List Approval Tooling (002) Rev 4Document3 pagesForm Tooling List Approval Tooling (002) Rev 4Kalista BettiNo ratings yet

- The Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SDocument6 pagesThe Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SSanjay KumarNo ratings yet

- Inj Mold CalculateDocument9 pagesInj Mold CalculateGiap NguyenNo ratings yet

- CTM Mold Design Standards PDFDocument43 pagesCTM Mold Design Standards PDFDini ViruNo ratings yet

- Costing Format - Press ToolDocument6 pagesCosting Format - Press ToolVineet Pandey Vlogs67% (3)

- Injection Molding Part CostingDocument4 pagesInjection Molding Part Costingfantinno100% (1)

- 02injection Moulding MachineDocument31 pages02injection Moulding MachineS Karthick KeyanNo ratings yet

- Shot Area: Must Be 50% From Injection PressureDocument7 pagesShot Area: Must Be 50% From Injection PressureAri Wibowo NugrohoNo ratings yet

- Blanking Process Cost CalculationDocument3 pagesBlanking Process Cost CalculationVenkateswaran venkateswaran100% (1)

- Minsa Trial Report Molde SC194Document2 pagesMinsa Trial Report Molde SC194daniel ortiz fuentesNo ratings yet

- Stamping Blank and Tonnage CalculatorDocument10 pagesStamping Blank and Tonnage CalculatorDhanus KodiNo ratings yet

- PP - Injection Mould Component Cost EstimationDocument7 pagesPP - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Partcost With Freight Table Rev. 7Document3 pagesPartcost With Freight Table Rev. 7RJLockNo ratings yet

- D10369520ADocument4 pagesD10369520AQUALITY ControlNo ratings yet

- Mold Cost EstimationDocument5 pagesMold Cost EstimationPenjahit TedyNo ratings yet

- Tool Design - Chapter 3 (Part 3)Document48 pagesTool Design - Chapter 3 (Part 3)Fiq IFTNo ratings yet

- FES MTG Welding Fixture F7222910Document11 pagesFES MTG Welding Fixture F7222910Sekar NaikNo ratings yet

- Die CalculationsDocument13 pagesDie CalculationsDhinakaran R100% (1)

- Abs - Injection Mould Component Cost EstimationDocument7 pagesAbs - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Injection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Document1 pageInjection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Jake Floyd G. FabianNo ratings yet

- 20me702 - Process Planning and Cost Estimation Unit 5 2023-24Document65 pages20me702 - Process Planning and Cost Estimation Unit 5 2023-24CAD With RaoNo ratings yet

- How To Compute Tonnage RequirementsDocument5 pagesHow To Compute Tonnage RequirementsPrabhat SharmaNo ratings yet

- Cupola Melting CostDocument3 pagesCupola Melting CostnirevievNo ratings yet

- Mould Starndard Parts PDFDocument13 pagesMould Starndard Parts PDFMohd Nazri SalimNo ratings yet

- MHR Calculation 1Document13 pagesMHR Calculation 1RamNo ratings yet

- Investment Casting Cycle TimeDocument12 pagesInvestment Casting Cycle TimemaheshNo ratings yet

- Injection Molding Cost CalculatorDocument111 pagesInjection Molding Cost CalculatorvenkithankamNo ratings yet

- Rubber Component Cost Estimation SheetDocument1 pageRubber Component Cost Estimation SheetVenkateswaran venkateswaran100% (2)

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- Poly Carbonate - Injection Mould Component Cost EstimationDocument7 pagesPoly Carbonate - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Tool Life SheetDocument4 pagesTool Life SheetYam Udhai100% (1)

- Asa - Injection Mould Component Cost EstimationDocument7 pagesAsa - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Seminar On Split Cavity MouldDocument43 pagesSeminar On Split Cavity MouldasgrutuNo ratings yet

- Mold ChecklistDocument5 pagesMold ChecklistSelvaraj BalasundramNo ratings yet

- Body ModelDocument145 pagesBody ModelDipika PandaNo ratings yet

- Mold Design Fundamental Calculation BATTERY COVERDocument7 pagesMold Design Fundamental Calculation BATTERY COVERrgrao85No ratings yet

- Part/Material Inputs: Injection Molding Technical Cost Model MIT - Materials Systems LaboratoryDocument13 pagesPart/Material Inputs: Injection Molding Technical Cost Model MIT - Materials Systems LaboratoryEmba MadrasNo ratings yet

- Product or Service Technical Design Specifications, Including Unit of Measure (UOM)Document1 pageProduct or Service Technical Design Specifications, Including Unit of Measure (UOM)Priyaprasad PandaNo ratings yet

- Costing Sheet 500632403736Document6 pagesCosting Sheet 500632403736Sourabh PradhanNo ratings yet

- Methodology of Die Design For HPDCDocument8 pagesMethodology of Die Design For HPDCruben6286No ratings yet

- Fixtures Cost Break UpDocument23 pagesFixtures Cost Break UpAshok AroraNo ratings yet

- Internal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00Document2 pagesInternal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00ramabhplNo ratings yet

- Clutch HSG Casting CostingDocument18 pagesClutch HSG Casting CostingAjay DeshpandeNo ratings yet

- Lab10 Final Progressive Die PDFDocument7 pagesLab10 Final Progressive Die PDFSyed Asif Bukhari100% (1)

- Part Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailDocument2 pagesPart Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailramabhplNo ratings yet

- Injctmld F03Document3 pagesInjctmld F03Šetkić SemirNo ratings yet

- Answers MechanicalDocument3 pagesAnswers MechanicalLê Nguyễn Hoàng ThăngNo ratings yet

- File 10 Bab ViDocument20 pagesFile 10 Bab ViJoko TeloNo ratings yet

- Jumping Math!: Grade 1Document1 pageJumping Math!: Grade 1pchakkrapaniNo ratings yet

- Printer Compatibility List: Print Server Model Printer Manufacture Printer ModelDocument20 pagesPrinter Compatibility List: Print Server Model Printer Manufacture Printer ModelpchakkrapaniNo ratings yet

- Piping Material Selection TableDocument1 pagePiping Material Selection TablepchakkrapaniNo ratings yet

- Ash Land DetailsDocument1 pageAsh Land DetailspchakkrapaniNo ratings yet

- Obtaining Contents in DVDDocument1 pageObtaining Contents in DVDpchakkrapaniNo ratings yet

- Welding Terms & DefinitionsDocument42 pagesWelding Terms & DefinitionspchakkrapaniNo ratings yet

- Manuals Type3Document365 pagesManuals Type3pchakkrapani100% (1)

- Calibre User Manual, The - Kovid GoyalDocument2 pagesCalibre User Manual, The - Kovid GoyalpchakkrapaniNo ratings yet

- Design For Assembly WorksheetDocument1 pageDesign For Assembly WorksheetpchakkrapaniNo ratings yet

- Instrument Calibration ProcedureDocument7 pagesInstrument Calibration ProceduremullanjiNo ratings yet

- Hitachi CalibrationDocument3 pagesHitachi CalibrationpchakkrapaniNo ratings yet

- Calculating Electrical CostsDocument1 pageCalculating Electrical CostspchakkrapaniNo ratings yet

- Vendors 820Document28 pagesVendors 820pchakkrapaniNo ratings yet

- c006b QDocument54 pagesc006b QpchakkrapaniNo ratings yet

- Setting Rings: Total Solution For Thread GaugingDocument1 pageSetting Rings: Total Solution For Thread GaugingpchakkrapaniNo ratings yet