Professional Documents

Culture Documents

FM492 CheckValves DS CraneFS

FM492 CheckValves DS CraneFS

Uploaded by

Arman Maniago0 ratings0% found this document useful (0 votes)

21 views1 pageThe document provides information on cast iron check valves made by General Valves, including:

- Check valves allow flow in one direction and close if flow reverses.

- They operate automatically based on pressure and flow within the line.

- The valves have a swing pattern with bronze trim or metal faced disc.

- Materials include cast iron, bronze, and stainless steel.

- Dimensions, weights, pressure and temperature ratings are provided for various valve sizes.

Original Description:

FM492 CheckValves

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides information on cast iron check valves made by General Valves, including:

- Check valves allow flow in one direction and close if flow reverses.

- They operate automatically based on pressure and flow within the line.

- The valves have a swing pattern with bronze trim or metal faced disc.

- Materials include cast iron, bronze, and stainless steel.

- Dimensions, weights, pressure and temperature ratings are provided for various valve sizes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

21 views1 pageFM492 CheckValves DS CraneFS

FM492 CheckValves DS CraneFS

Uploaded by

Arman ManiagoThe document provides information on cast iron check valves made by General Valves, including:

- Check valves allow flow in one direction and close if flow reverses.

- They operate automatically based on pressure and flow within the line.

- The valves have a swing pattern with bronze trim or metal faced disc.

- Materials include cast iron, bronze, and stainless steel.

- Dimensions, weights, pressure and temperature ratings are provided for various valve sizes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

34276 CRANE PD 2014_genvalves_BS021214.

qxp_Layout 1 04/12/2014 09:50 Page 89

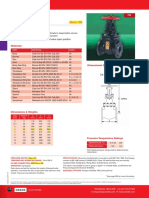

CHECK VALVES

FM492

FM492

Cast Iron Check Valve

GENERAL VALVES

PN16

Features & Benefits

Check valves permit flow in one direction only and close automatically

if flow reverses

Entirely automatic in action, depending upon pressure and velocity

of flow within the line to perform their functions of opening and closing

Swing pattern, bronze trim, resilient seated

Swing pattern, metal faced disc

Materials

PART

MATERIAL

SIZES

Body

Cast Iron BS EN 1561 GJL-250

All

Cap

Cast Iron BS EN 1561 GJL-250

All

Disc

Cast Iron BS EN 1561 GJL-250

All

Body Seat Ring

Bronze BS EN 1982 CC491K

All

Disc Ring

Bronze BS EN 1982 CC491K

All

Hinge Pin Bush

Bronze BS EN 1982 CC491K

All

Hinge Pin Plug

Bronze BS EN 1982 CC491K

All

Hinge Pin

Stainless Steel Type 304

50 - 100

Hinge Pin

13% Cr.Steel AISI Type 410

125 - 300

Cap Bolts

Steel BS 3692 Gr.8.8

All

Cap Bolt Nuts

Steel BS 3692 Gr.8

All

Gasket

Asbestos Free

All

Body Plate

Aluminium

All

Dimensional Drawing

Dimensions & Weights

SIZE

(mm)

WEIGHT

(kg)

A

(mm)

E

(mm)

50

65

11.3

15.6

203

216

113

126

80

19.3

241

136

100

26.6

292

153

125

44

330

186

150

55.5

356

207

200

119

495

250

250

175

622

352

300

263

698

397

Pressure/Temperature Ratings

TEMPERATURE (C)

-10 to 100

220

16

12.1

PRESSURE (BAR)

Intermediate pressure ratings shall be determined by

interpolation.

Valid as of 010412

PRESSURE RATING: PN16

TEMPERATURE OPERATING RANGE: -10 to 220C

SPECIFICATION: Valves are manufactured in accordance with BS EN 12334: 2001.

End flanges conform to BS EN 1092-2 with raised face and are normally supplied drilled.

UK END CONNECTION: Flanged BS EN 1092-2

This valve is not suitable for use on Group 1 gases or unstable fluids,

OPERATOR: Swing Type Check Valve

as defined by the Pressure Equipment Directive 97/23/EC.*

* See page 230 for more information

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Crane Ltd assumes no responsibility or liability for typographical errors or

omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

TECHNICAL HELPLINE: +44 (0)1473 277400

E: enquiries@cranefs.com W: www.cranefs.com

89

You might also like

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Valve Procurement SpecsDocument39 pagesValve Procurement Specsjoseph.maquez24100% (2)

- Samson Globe Control ValveDocument12 pagesSamson Globe Control ValveShishir DwivediNo ratings yet

- Method Statement For Installation of Electrical Water Heaters PDFDocument2 pagesMethod Statement For Installation of Electrical Water Heaters PDFArman ManiagoNo ratings yet

- F58 GateValves DS CraneFSDocument1 pageF58 GateValves DS CraneFSNaeem KhanNo ratings yet

- Wafer Check Valve 2Document1 pageWafer Check Valve 2Kristin AndrewsNo ratings yet

- Valvula de Globo CRANE D 14Document1 pageValvula de Globo CRANE D 14CARLOSNo ratings yet

- V9271 Fivalco 2902eDocument6 pagesV9271 Fivalco 2902eharenas7No ratings yet

- DCV Spirax PDFDocument2 pagesDCV Spirax PDFVaitheeswaran PalaniNo ratings yet

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- Allpex Bi-Metallic Flanges 0707Document4 pagesAllpex Bi-Metallic Flanges 0707Santhosh KumarNo ratings yet

- CVC Steel Valvulas LunkenheimerDocument28 pagesCVC Steel Valvulas LunkenheimerAlex WilmerNo ratings yet

- Water SystemDocument9 pagesWater SystemArun GuptaNo ratings yet

- HYD VLV, Fire Hose, HR & Breeching - Export2014Document7 pagesHYD VLV, Fire Hose, HR & Breeching - Export2014Jonathan MartinezNo ratings yet

- Cil ValveDocument8 pagesCil ValveGarimaSinghNo ratings yet

- Kineva enDocument12 pagesKineva enRamazan YaşarNo ratings yet

- Actuator SpecificationDocument12 pagesActuator SpecificationFactory FactoryNo ratings yet

- MIV Product OverviewDocument13 pagesMIV Product OverviewAmir_skorpionNo ratings yet

- 21 50-002-006 AVK015 Eng v1-0Document2 pages21 50-002-006 AVK015 Eng v1-0Hani SaadeNo ratings yet

- PRV C 101 Data SheetDocument1 pagePRV C 101 Data SheetDevit FitriyantoNo ratings yet

- Wescol SS-N-10-2GDocument12 pagesWescol SS-N-10-2Gpuccio78No ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- Piston ValveDocument28 pagesPiston ValveDamien BouticourtNo ratings yet

- Water Supplies Department: M-02-01 June 2016Document11 pagesWater Supplies Department: M-02-01 June 2016seeralan_1986No ratings yet

- Rotex Solenoid ValveDocument16 pagesRotex Solenoid Valvemanmohansingh1999100% (1)

- 3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2Document16 pages3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2zampacaanasNo ratings yet

- D.O. 111, S 2017Document8 pagesD.O. 111, S 2017ZA TarraNo ratings yet

- Flow Conditioners: Plug-In Version BLN and Clamped Joint Version KDocument4 pagesFlow Conditioners: Plug-In Version BLN and Clamped Joint Version KmohamedwalyNo ratings yet

- Butterfly Valves For General Purposes (: Indian StandardDocument12 pagesButterfly Valves For General Purposes (: Indian Standardrahul caddNo ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- As 1301 en F Series Manifolds and Multi Way CocksDocument20 pagesAs 1301 en F Series Manifolds and Multi Way CocksTache MihaiNo ratings yet

- Oventrop DRVDocument15 pagesOventrop DRVblindjaxxNo ratings yet

- Self-Operated Pressure Regulators Pressure Reducing Valve Type 41-23Document6 pagesSelf-Operated Pressure Regulators Pressure Reducing Valve Type 41-23ehtisham khanNo ratings yet

- Double Reg Valves PDFDocument15 pagesDouble Reg Valves PDFNoushad P HamsaNo ratings yet

- Price ListDocument68 pagesPrice ListZuberYousufNo ratings yet

- Is 13095 1991Document15 pagesIs 13095 1991Surendra MalasaneNo ratings yet

- DS LT Lugged Type Butterfly ValveDocument5 pagesDS LT Lugged Type Butterfly ValvecvfNo ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveCatalina NutaNo ratings yet

- ValvesDocument6 pagesValvesstevegazeleyNo ratings yet

- Valvulas de Control FisherDocument16 pagesValvulas de Control FisherAnonymous GKTRypNo ratings yet

- VCA03 FH2 CE Fire HydrantDocument2 pagesVCA03 FH2 CE Fire HydrantSenghy MaoNo ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

- Broen Butterfly Valves v9Document13 pagesBroen Butterfly Valves v9bojanmileticNo ratings yet

- Saint Gobain Sluice ValvesDocument2 pagesSaint Gobain Sluice ValveskibzeamNo ratings yet

- Allweiler SN SeriesDocument12 pagesAllweiler SN SeriesAlexis Ernesto Cardenas BeltranNo ratings yet

- Ball Valve Flange TypeDocument7 pagesBall Valve Flange TypeperoooNo ratings yet

- Neojv 0040 enDocument0 pagesNeojv 0040 enLuis GuevaraNo ratings yet

- Screw Pumps Series SPF: Application Shaft SealingDocument16 pagesScrew Pumps Series SPF: Application Shaft Sealingmsh16000No ratings yet

- Datový List - Smyčkové Regulační Ventily - PřírubovéDocument16 pagesDatový List - Smyčkové Regulační Ventily - PřírubovéMoe KimoNo ratings yet

- 540 Split Flow - GBDocument0 pages540 Split Flow - GBMauroZJNo ratings yet

- Datasheet Clorius M3F 3 Way Control Valve DN80 DN150Document2 pagesDatasheet Clorius M3F 3 Way Control Valve DN80 DN150Javier Conesa OutedaNo ratings yet

- Valvula Check SwingDocument1 pageValvula Check SwingDenis Huamani QuispeNo ratings yet

- Ptfe Lined Valves CatalogueDocument6 pagesPtfe Lined Valves CatalogueBhavesh Panchal ParmarNo ratings yet

- Nim NamDocument20 pagesNim NamMohamad JammalNo ratings yet

- B1-Screw Hose CouplingsDocument10 pagesB1-Screw Hose Couplingskresimir.mikoc9765No ratings yet

- 止回阀Document27 pages止回阀聂林涛No ratings yet

- Crane Katalog-RS AngDocument29 pagesCrane Katalog-RS AngNNNo ratings yet

- Isovolt 160 Mobile Brochure English 0Document8 pagesIsovolt 160 Mobile Brochure English 0Arman ManiagoNo ratings yet

- ROCA - Acrylic Shower Tray (276080xx0)Document1 pageROCA - Acrylic Shower Tray (276080xx0)Arman ManiagoNo ratings yet

- Product Program SVMCDocument28 pagesProduct Program SVMCArman ManiagoNo ratings yet

- Self-Aligning Ball Bearings, Cylindrical and Tapered Bore - 2313 KDocument1 pageSelf-Aligning Ball Bearings, Cylindrical and Tapered Bore - 2313 KArman ManiagoNo ratings yet