Professional Documents

Culture Documents

Abutment PDF

Abutment PDF

Uploaded by

IwanTiaraMotorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abutment PDF

Abutment PDF

Uploaded by

IwanTiaraMotorCopyright:

Available Formats

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

B.

Design of Substructure

1.0 Design Data:

1.1. Materials and its Properties:

Concrete:

Reinforcement:

M20

Fe415

Basic Permissible Stresses of Concrete as per IRC : 21-2000:

Permissible direct compressive stress, co

=

Permissible flexural compressive stress, c

=

Maximum Permissible shear stress, max

5.0 Mpa

6.67 Mpa

1.8 N/mm2

Basic Permissible Stresses of Reinforcing Bars as per IRC : 21-2000:

Permissible Flexural Tensile stress, st

=

200 N/mm2

Permissible direct compressive stress, co

170 N/mm2

Design of Data:

Modular Ratio

=

Neutral axis depth factor, n = (mc)/( mc+st) =

Lever arm factor, j = (1-n/3)

=

Moment of resistance coefficient, R = x n x j x c =

Unit weight of materials as per IRC : 6-2000:

Concrete (cement-Reinforced)

=

Macadam (binder premix)

=

Water

=

Backfill

=

1.2. Geometrical Properties:

Effective Span of Bridge Deck =

Total length of each Span =

Angle of internal friction of backfill

Approach slab

Length, L

Width, B

Depth, D

Size of bearing

Length

Width

Thickness

High Flood Level, HFL

Mean scour depth from HFL

Lowest Bed Level

Bottom level of abutment

Clearance above HFL

Top level of abutment

Depth of superstructure

Total height of abutment

h1 =

4.59 m

h2 =

0.26 m

Unique Engineering Consultancy (P) Ltd

10.98

0.268

0.911

0.814

2.4

t/m3

2.2

t/m4

1.0

t/m5

1.92

t/m6

18.0 m

18.60 m

29 degree

3.5 m

7m

0.26 m

400 mm

250 mm

50 mm

1002.15 m

3.28 m

997 m

999.600 m

0.9 m

1003.00 m

1.4 m

Fig.20

4.85 m

b1 =

b2 =

1m

0m

Page 1

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

h3 =

h4 =

h5 =

h6 =

b3 =

b4 =

b5 =

b6 =

b7 =

1.45 m

0.4 m

3.00 m

0.05 m

Cap overhang,

Min. length of cap =

Length of abutment shaft =

0.25 m

0.55 m

0.9 m

0.35 m

0.15 m

m

6.9 m

7.2

1.3. Calculation of weight and C.G. of the abutment stem

Elements Area, Ai

(m2)

P1

3.00

Weight (t)

Xi (m)

Yi (m)

AiXi

AiYi

49.68

0.5

1.50

1.50

4.50

P2

0.00

0.00

1.00

1.00

0.00

0.00

P3

P4

0.46

0.3625

3.82

7.95

6.00

63.63

0.58

0.125

3.20

4.12

0.26

0.05

1.47

1.50

7.47

C.G. from back of abutment, x =

e=

Moment about back face =

1.81

0.473

from bottom of abutment, y =

0.125 m

30.13 t-m

1.954

1.4. Calculation of Loads and Moments

Due to Dead Load

=

81.08 t

Dead load from superstructure,

=

4.05 t

Weight of bearings, expansion joint etc.

Total dead load from superstructure on each abutment, PDL =

85.14 t

=

0.6 m

Distance of bearing center from back of abutment

Eccentricity of DL & LL from superstructure acting through bearing,

e=

0.125 m

Moment due to DL of superstructure about CG of abutment =

10.64 t-m

Due to Live Load

Live load from superstructure:

Due to IRC Class A wheel load, in longitudinal direction,

11.4 t

11.4 t

6.8 t

6.8 t

6.8 t

6.8 t

Fig. 21

Max. LL on abutment from right side

impact factor

Max LL including Impact, PLL

= (11.4*18+11.4*16.8+6.8*12.5+6.8*9.5+6.8*6.5+6.8*3.5)/18

=

68.26 t

=

1.188

=

81.06 t

Moment due to eccentric load

10.13 t-m

In transverse direction, eccentricity of load

Moment due to live load

=

=

0.25 m

20.26 t-m

Unique Engineering Consultancy (P) Ltd

Page 2

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

Due to IRC Class AA Tracked Vehicle, in longitudinal direction,

70 t

Fig. 22

Max. LL on abutment from right side

impact factor

Max LL including Impact, PLL

= 70x(20-1.8)/20

=

=

=

63.70 t

1.10

70.07 t

Moment due to eccentric load

8.76 t-m

In transverse direction, eccentricity of load

Moment due to live load

=

=

0.35 m

24.52 t-m

Due to IRC Class AA Wheeled Vehicle, in longitudinal direction,

20 t

20 t

Fig. 23

Max. LL on abutment from right side

impact factor

Max LL including Impact, PLL

= 20+20x14.8/20

=

=

=

34.80 t

1.188

41.33 t

Moment due to eccentric load

5.17 t-m

In transverse direction, eccentricity of load

Moment due to live load

=

=

0.35 m

14.46 t-m

Due to Earth Pressure

= 0.5sh1

tan2(45o-/2)t

Horizontal force due to earth pressure

=

Which acts at a distance from abutment base = 0.42xh1 =

Magnitude of surcharge, q = 1.2xs

=

2

48.42 t

1.93 m

2.304 t/m2

Horizontal force due to surcharge = qxh1xtan (45-/2)xt =

25.32 t/m2

Which acts at a distance from abutment base = h1/2

2.295 m

Weight of backfill behind the abutment resting on foundation =

Moment due to earth pressure about abutment base

0.0 t

151.45 t-m

Due to Temperature Variation

Maximum temperature variation, T

=

25

Coefficient of thermal expansion,

=

1.17E-05

Max. Elongation ,

=

4.68

Shear Mdulus of bearing material, G

=

1.00

Depth of bearing

=

50.00

Longitudinal force / bearing

=

1.053

The total resistance offered by bearing =

=

3.159

Unbalanced force at the bearing

=

This force acts at the bearing level, i.e. at a distance from pier base =

Moment due to temperature variation

=

10.90

C

/m/oC

mm

Mpa

mm

t

t

3.16 t

3.45 m

t-m

Due to Braking Effect

Effect due to class A loading = 0.2x70

Unique Engineering Consultancy (P) Ltd

14 t

Page 3

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

This acts at distance above deck level

1.2 m

And at a distance from abutment base

6.05 m

Moment due to braking about abutment base

84.70 t-m

Due to Seismic force

Description

Total Load Seismic Lever arm (m)

(t)

Load (t)

Superstructure DL

85.14

8.51

4.15

Abutment shaft P1

49.68

4.97

1.50

Abutment shaft P2

0.00

0.00

1.00

Abutment shaft P3

7.95

0.79

3.00

Abutment shaft P4

6.00

0.60

4.12

Approach slab

15.288

1.53

4.72

Backfill

0

0.00

2.29

Total

164.06

16.41

Moment (t-m)

35.33

7.45

0.00

2.38

2.48

7.22

0.00

54.86

Summary of Loads and Moments

The summary of loads and moments are tabulated below. The transverse forces and moments are

not considered, since it would not be critical due to high moment of inertia of abutment. Therefore

stresses are checked in longitudinal direction only.

Description

Superstructure DL

LL including Impact

Self wt. of abutment

Braking effect

Temperature

Earth Pressure

Sub Total

Seismic Force

Total

Vertical load (t)

85.14

81.06

63.63

Horizontal force (t)

Moment (t-m)

10.64

10.13

0.00

84.70

10.90

151.45

267.83

54.86

322.69

14

3.16

73.74

90.90

16.41

107.31

229.82

229.82

As per standard design practice, design of abutment would be carried out for case A, and checked

for case B, as given below.

Case

Vertical load (t)

Horizontal force (t)

Moment (t-m)

A: (N+T)

229.82

90.90

267.83

B: (N+T+S)

229.82

107.31

322.69

Design of abutment stem section

Abutment section will be designed for case A and the section adequacy will be checked for case B.

Design vertical load

=

229.82 t

Design moment

=

267.83 t-m

Depth of section required =

M

Rb

Clear cover to reinforcement =

Effective depth provided =

691 mm

75

mm

910

mm

Unique Engineering Consultancy (P) Ltd

st

<

910

O.K.

M

=

j d

Page 4

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

Area of steel required for tension, Ast =

38

Provide

mm2 and spacing

nos. of

16

Provide

area of steel, Ast =

mm bars @

25

182

st

M

=

j d

16160 mm2

mm bars giving area of steel =

18653

mm c/c.

150

mm c/c at the front side of the abutment, giving

9651 mm2. Provided nos of bars =

90.90 t

Design horizontal force =

Corresponding shear stress, v =

0.14 N/mm2

0.30 %

Percentage area of tension steel, 100Ast/bd =

Shear strength increment factor = 1+5P/(Agxfck) = 1.083 < 1.5

> v

Design shear strength of concrete, c =

0.26

O.K.

48

O.K.

Check for shear at the bottom of the abutment cap.

17.16 t

Total horizontal force at the bottom of the cap =

=

1000

mm

Depth of abutment

=

893

mm

Effective depth, d

<

t

Corresponding shear stress, v =

0.03

O.K.

c

Tension reinforcement required at different level along the height of abutments.

At

1.93

m above base of abutment

Load Type

Lever arm (m)

Moment

Load (t)

DL of Superstructure

85.14

0.125

10.64

Live load (LL)

81.06

0.125

10.13

Breaking load

14

4.12

57.68

Temperature load

3.16

1.52

4.80

Earth Pressure

16.26

1.12

18.17

Surcharge

14.67

1.33

19.51

Total

120.94

Overall depth of abutment =

1000

mm

Effective depth of abutment =

893 mm

Area of tension reinforcement req. =

7436 mm2

Provide

23

numbers

25

mm bars and

0 numbers

11290

mm2

20

mm bars, giving area of steel =

Actual point of curtailment =

3.08

m from base of abutment.

NO CURTAILMENT IS DONE

Rear side Reinforcement

Provide 16 mm bars @ 150 mm c/c at rear side of the abutment.

Check for stresses for case B

Bending Moment =

322.69 t-m

Stress in steel =

208.75 N/mm2 <

300

O.K.

Horizontal force =

107.31 t

0.17

N/mm2 < 0.45

Corresponding shear stress =

O.K.

Design of abutment cap:

Vertical reaction due to

Unique Engineering Consultancy (P) Ltd

Page 5

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

Dead load, PDL/3

28.38 t

Live load including impact, PLL/3

=

27.02 t

=

55.40 t

Total vertical reaction

Providing minimum area of steel @ 1% assuming cap thickness 225 mm, area of steel required /m

of cap = 2250 mm2 (for both top and bottom layer).

Provide 16 mm bars @ 150 mm c/c, at both top and bottom layers in both ways, giving area of

steel, Ast = 2680 mm2.

As per IRC:78-2000, clause 710.10.4 the two layers of mesh reinforcement, one at 20 mm from

top and the other at 100 mm from top of abutment cap each consisting of 8 mm bars @ 100 mm

c/c in both directions, shall be provided directly under the bearings.

Check for bearing stresses

The allowable bearing pressure with nearly uniform distribution on the loaded area of a footing or

base under a bearing or column shall be given by following equation,

C=

A1

A2

C0 =

6.25 MPa, permissible direct compressive stress in concrete

0.52 m2, dispersed largest concentric area similar to A2

A1 =

0.1 m2, loaded area

A2 =

Therefore, 1/2 = 5.2

>2

8.84 Mpa

And, C =

Actual compressive stress =

5.54

< C

O.K.

Design of Backwall:

2

2

o

Horizontal force due to earth pressure = 0.5s(h3- h2) tan (45 -/2) =

0.4998 m

Which acts at a distance from backwall base =

Magnitude of surcharge, q =

2.304

t/m2

Horizontal force due to surcharge = q(h3-h2)tan2(45o-/2)

=

Which acts at a distance from backwall base = 0.595

m

Self weight of backwall /m width = 0.714

t/m

Live load on back wall considering class AA loading =

10

t

This acts at a distance from backwall toe =

0.125 m

0.47 t/m

0.95 t/m

Moment due to earth pressure about backwall base=

0.80 t-m/m

Moment due to self weight and LL

=

1.34 t-m/m

Total Moment =

2.14 t-m/m

Effective depth of backwall

=

194 mm

Area of steel required, Ast

=

606 mm2

Provide 12 mm bars @ 150 mm c/c, giving area of steel, Ast = 753 mm2. And provide 10 mm

bars @ 200 mm c/c as distribution bar.

Design of Return wall:

Return wall will be monolithic with the backwall. They are joined together through 30 cm x 30 cm fillets.

The load acting on the wing walls would be earth pressure and is designed to withstand a live load

equivalent to surcharge of 1.2 m height of earth fill according to IRC:78-2000.

Unique Engineering Consultancy (P) Ltd

Page 6

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

h1 =

h2 =

h3 =

h4 =

b1 =

1.65 m

1.2 m

1.30 m

0.4 m

2.25 m

Thickness of return wall assumed =

250 mm

Average value of earth pressure = 0.5s(h1/2+h2/2+1.2)

=

1.84 t

Acting at a distance from wing wall bottom

Moment due to earth pressure

Depth required

Effective depth provided

Area of steel required

tan (45 -/2)

=

=

=

0.7125 m

3.68 t-m/m

178 mm

194 mm

1369 mm2

<

Provided O.K.

Provide

16

mm f bars @

150

mm c/c, giving area of steel, Ast =

1910

mm bars @ 150

mm2. And provide

12

mm c/c as distribution bar in vertical

direction. In the fillet at the joint provide nominal reinforcement of 10 mm bars @ 200 mm c/c.

The wing wall would be properly anchored to the abutment, backwall and cap.

Design of Approach Slab:

The approach slab is resting over the abutment and the other end supported by the soil underneath.

It should be designed on the basis of elastic base theory, which is complicated. Hence the

dimensions and reinforcement is provided as per the standard design practice.

Self weight /m width

0.624

=

t/m

Weight of pavement

0.176

=

t/m

Maximum live load

11.44

=

t/m2

Total udl

t/m

=

12.24

Assuming maximum cavitation of 1.2m behind the abutment,

Maximum bending moment =

22.03 kN-m/m

Effective depth of slab required =

164 mm

Effective depth provided =

212 mm

Area of steel required =

751 mm2

mm bars @

Provide

16

150

mm c/c both top and bottom, in both direction

Provided area of steel, Ast =

1340

mm2.

Maximum shear force =

73.4 kN/m

Shear stress

0.35

=

N/mm2

Percentage area of steel =

0.63

%

Permissible shear stress =

N/mm2 > actual shear stress O.K.

0.365

Design of RCC Stoppers:

Base width of sttoper, b1 =

Top width of sttoper, b2 =

Height above abutment cap, h1 =

Length of sttoper, l =

0.4

0.3

0.45

0.8

m

m

m

m

Horizontal force acting on the stopper above pier cap @ 10% of vertical load= 7.94 t

11.92

Friction resistance

=

t

However as additional factor of safety, assuming an extra lateral force in excess of frictional

resistance taking R = 0.20 in worst case, Fs =

15.89 t

3.97 t

Difference

=

Unique Engineering Consultancy (P) Ltd

Page 7

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

Moment at the base of stopper =

1.79 t-m

166 mm

Effective depth required =

342 mm

Effective depth provided =

287 mm2

Area of steel required =

Provide 12 mm f bars @ 150 mm c/c. Area of steel provided = 716 mm2

=

N/mm2

Max. Shear stress, tv

0.15

%

Percentage area of steel provided, p = 0.26

N/mm2 >

tv

Permissible minimum shear strength of concrete =0.226

Provide nominal shear reinforcement of 8 mm bars @ 100 mm c/c.

Design of abutment footing (Piles)

4.2 Geometrical Properties:

High Flood Level, HFL =

Maximum depth of scour from HFL =

Elevation of maximum scour level (MSL) =

Max. Water depth in the river =

Water depth near the abutment =

Proportionate scour depth near the abutment

Elevation of MSL near abutment =

Lowest Bed Level =

Elevation of top of foundation base =

Bottom level of foundation =

h1

h2

h3

h4

h5

=

=

=

=

=

4.59

0.26

1.45

0.4

3.00

O.K.

1002.2 m

3.28 m

998.87 m

3.28 m

3.280 m

3.280 m

998.87 m

997 m

999.600 m

998.500 m

m

m

m

m

m

CL of Bearing

HFL

MSL

2

LBL

h6 =

HFL above MSL, h7 =

HFL above min. bed level h8 =

0.05 m

3.28 m

5.15 m

MSL below min. bed level, h9 =

Top of foundation base below MSL, h10 =

Depth of pile cap, h11 =

-1.87 m

-0.73 m

1.1 m

Unique Engineering Consultancy (P) Ltd

Page 8

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

b1 =

b3 =

1.0 m

0.25 m

b4 =

0.55 m

b5 =

0.9 m

b6 =

0.35 m

b7

b8

b9

b10

b11

b12

=

=

=

=

=

=

Foundation base length, b13 =

0.15

0.4

3.5

3.1

1

3.1

m

m

m

m

m

m

7.2 m

Abutment base length

Foundation projection beyond abutment stem

Total width of foundation

Angle of internal friction of soil

Safe bearing capacity of soil

Load bearing capacity of pile

=

Numbers of piles along longitudinal dirrection =

Numbers of piles along transverse dirrection =

Total numbers of piles

=

Diameter of piles

=

Length of piles

=

Soil Type :

Clayey Silt

Determination of depth of fixity of piles:

Unconfined compressive strength, S =

Modulus of subgrade reaction, K =

Lf/d

Therefore,

and, depth of fixity,

Lf

6.9

0.15

7.2

29

0

m

m

m

degree

t/m2

40 t

4

4

m

m

16

700 mm

16 m

0.46 kg/cm2

13.2 kg/cm2

=

4.9

from figure 1 and 2.

m

Calculation of vertical load on foundation base

Due to Dead Load

Superstructure

85.14 t

=

Backwall

6.00 t

=

Abutment cap

7.95 t

=

Abutment shaft

49.68 t

=

Soil behind abutment

196.70 t

=

Approach slab

15.29 t

=

Soil in front of abutment =

0.00 t

Total =

360.76 t

Due to Live Load

Maximum live load including impact =

81.06 t

Due to self weight of foundation base =

Loss in weight due to Buoyancy

Depth of abutment shaft below HFL

Abutment width at HFL

Loss in weight of abutment shaft

Loss in weight of soil behind abutment

Loss in weight of soil in front of abutment

Unique Engineering Consultancy (P) Ltd

136.86 t

2.55 m

1.000 m

17.59 t

56.92 t

0.00 t

Page 9

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

Total buoyant force on abutment

78.06 t

Buoyant force on foundation base

57.02 t

166.19 t

Calculation of Moments at Foundation Base Level

Due to superstructure DL+LL

Total superstructure DL+LL

Eccentricity of load about pile cap transverse axis

Corresponding moment

Superstructure DL

Moment at foundation toe due to DL

=

=

=

=

0m

0.00 t-m

85.14 t

0.00 t-m

Due to Abutment + Soil filling DL

A. Maximum Load Condition

i) Due to abutment body

=

63.63 t

Load

=

-0.13 m

Lever arm

=

-7.95 t-m

Moment

ii) Due to Backfill and approach slab

=

196.70 t

Load

=

-2.1 m

Lever arm

=

-413.07 t-m

Moment

iii) Due to soil fill in front of abutment

=

0.00 t

Load

=

2m

Lever arm

=

0.00 t-m

Moment

Total moment due to abutment + soil filling DL =

-421.03

t-m

B. No LL + Buoyancy Condition

i) Due to abutment body

=

85.14 t

Load

=

-0.13 m

Lever arm

=

-10.64 t-m

Moment

ii) Due to Backfill and approach slab

=

133.93 t

Load

=

-2.1 m

Lever arm

Moment

=

-281.25 t-m

iii) Due to soil fill in front of abutment

=

0.00

Load

=

1.55

Lever arm

=

0.00

Moment

Total moment due to abutment + soil filling DL =

-291.89

t-m

Due to Earth Pressure

Earth pressure

Lever arm

Surcharge

Lever arm

Total Moment

Unique Engineering Consultancy (P) Ltd

=

=

=

48.42 t

3.03 m

25.32 t

3.395 m

232.57 t-m

Page 10

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

Due to Longitudinal forces:

a) Due to tractive effort or braking

Which acts at a distance above foundation bottom

Moment due to tractive effort or braking about foundation base

b) Force due to resistance in bearings due to temperature

Which acts at a distance above foundation bottom

Moment due to tractive effort or braking about foundation base

=

=

=

=

=

=

14

6.05

84.70

3.16

3.4

10.90

Due to Seismic Forces:

A. Along longitudinal direction for maximum load condition

Load (t)

Description

Seismic Load (t) Lever arm

85.14 8.51

4.15

Superstructure DL

Abutment shaft P1

49.68 4.97

1.50

Abutment shaft P2

0.00 0.00

1.00

Abutment shaft P3

7.95 0.79

3.00

Abutment shaft P4

6.00 0.60

4.12

Approach slab

15.29 1.53

4.72

Backfill

196.70

19.67

2.1

Total

360.76

36.08

B. Case of buoyancy and no live load

t

m

t-m

t

m

t-m

Moment (t-m)

35.33

7.45

0.00

2.38

2.48

7.22

41.31

96.17

The seismic load will be lesser than that for N+T case due to submerged part of the sub structure which

will be under buoyancy.

Description

Superstructure DL

Abutment shaft P1 above HFL

Abutment shaft P1 below HFL

Abutment shaft P2 above HFL

Abutment shaft P2 below HFL

Abutment Cap P3

Abutment backwall P4

Approach slab

Backfill above HFL

Backfill below HFL

Total

Load (t)

85.14

7.45

24.63

3.73

0.00

7.95

6.26

15.29

109.28

79.68

339.41

Seismic Load (t)

8.51

0.75

2.46

0.37

0.00

0.79

0.63

1.53

10.93

7.97

33.94

Lever arm (m)

4.15

3.875

2.375

3.80

#DIV/0!

3

4.125

4.72

4.67

2.375

Moment

(t-m)

35.33

2.89

5.85

1.42

#DIV/0!

2.38

2.58

7.22

51.03

18.92

#DIV/0!

Summary of Moments and Forces

Vertical Loads

Case I

Case II

Case III

Max.

Buoyancy+No LL

Case I + Seismicity

Load

360.76

DL from superstructure + abutment

282.70

360.76

136.86

DL of foundation base

79.83

136.86

81.06 Live load

81.06

578.67

Total

362.53

578.67

Horizontal Forces

Description

Description

Earth Pressure

Tractive effort or braking

Unique Engineering Consultancy (P) Ltd

Case I

Case II

Case III

Max.

Buoyancy+No LL

Case I + Seismicity

Load

73.74

73.74

73.74

14

14

Page 11

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

3.16

90.90

Temperature effect

Seismic Force

Total

3.16

3.16

40.41

131.31

76.90

Resulting Moments

Description

Superstructure DL+LL

Abutment +Soil filling DL

Earth pressure

Tractive effort or braking

Temperature effect

Seismic force

Total

Case I

Max.

-291.89

-421.03

232.57

84.70

10.90

-384.75

Case II

Buoyancy+No LL

0.00

-291.89

232.57

-59.32

Case III

Case I + Seismicity

-291.89

-421.03

232.57

84.70

10.90

171.28

-213.47

Summary of loads

Cases

Unit

T

T

t-m

Vertical

Horizontal

Moment

Case I

Case II

Max. Load

Buoyancy+No LL

80.37

50.35

12.62

10.68

-53.44

-8.24

Case III

Case I + Seismicity

80.37

18.24

-29.65

Case: I

Deducting the bearing capacity of pile cap as a open footing, vertical loads to be taken by piles

=

80.37 t

Loads on each pile due to vertical load

=

=

5.02 t

12.62 t

Axial load on extreme pile due to moment

Axial load on second row of pile due to moment =

=

Resultant compressive force on extreme pile

Resultant tensile force on extreme pile

=

Resultant compressive force on second row of pile=

Coefficient of friction between concrete and clay =

=

Friction resistance of cap

Horizontal force on each pile

=

Moment on each piles =

4.02 t

21.67 t

<

40.00

t O.K.

0.00 t

<

40.00

t O.K.

17.34 t

0.20

0.00 t

11.17 t

54.72 t-m

Design of piles:

Length of pile, L

=

16 m

Diameter of pile, D =

0.7 m

L/D

=

22.86 > 12 Hence the pile is designed as long column.

Least radious of gyration, r

=

17.5 cm

Reduction coefficient for reduction of stress values is given as,

cr

= (1.25-L/48B) =

Safe stress are,

Permissible direct compressive stress, co =

Permissible flexural compressive stress, co =

Permissible Flexural Tensile stress, st =

Maximum compressive stress in concrete =

Unique Engineering Consultancy (P) Ltd

0.774

3.87

5.16

154.76

1.50

N/mm2

N/mm2

Mpa

(in steel)

N/mm2 <

3.869

N/mm2

Page 12

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

Provide minimum area of compression steel @

Asc

4811

15

nos. of

Provide

Check for combined stress:

Percentage area of steel provided, pt

p/fck

d'/D

25

1.25

2.400

0.120

0.091

0.088

Pu/fckD2

Mu/fckD3

Mu

82.32 t-m

M

=

Working moment,

Shear stress due to horizontal force =

Permissible shear strength of concrete =

54.88 t-m

From chart,

and

>

54.72

t-m O.K.

0.29 N/mm2

0.45 N/mm2 O.K.

27.49 t

65.07 t <

90.00 t O.K.

0.00 t <

90.00 t O.K.

=

6.18 t

30.27 t-m

Pu/fckD2

0.100

Mu/fckD3

0.106

Mu

72.72 t-m

M

=

Working moment,

Shear stress due to horizontal force =

Permissible shear strength of concrete =

48.48 t-m

and

7363

0.12

Case: C

Axial load on extreme pile due to moment

Resultant compressive force

Resultant tensile force

Horizontal force on each piles =

Moment on each piles =

From chart,

%.

mm2

mm bars, giving area of steel =

>

30.27

t-m O.K.

0.16 N/mm2

0.56 N/mm2

O.K.

Lateral Reinforcement:

Lateral reinforcement should be 0.2% of the gross volume. Using dia. 10 mm ties,

145577 mm3

we have the volume of one tie =

If p be the pitch of the ties in mm, then

Volume of pile per pitch length =

384845 p

Hence equating, we get, p

Hence provide dia

10

=

mm ties at

189 mm

160

mm c/c in the main body of the pile.

Design of Pile Cap:

Maximum bending moment in the pile cap due to vertical load,

At center of cap

=

312.91 t-m

375.77 t-m

At face of abutment =

=

233.3 t-m

Bending moment due to moment on steam

609.0 t-m

Maximum bending moment =

The effective depth required is given by,

dreq =

999

mm

Adopt

1030

mm effective depth and overall depth =

1100 mm

32466 mm2

Area of steel required along width of cap =

Using

25

mm dia. bars, spacing would be

113 mm

Provede

25

mm dia bars @

120

mm c/c, provided area =

33469 mm2

at both top and bottom.

Distribution reinforcement @ 0.12% =

9900 mm2

20

mm dia bars @

150

mm c/c, giving area of stee = 15708 mm2.

Provide

Unique Engineering Consultancy (P) Ltd

Page 13

Generated by Foxit PDF Creator Foxit Software

http://www.foxitsoftware.com Design

For evaluation

Detailed Engineering Design of Chargahawa River Bridge

Calculation only.

VOLUMN-III

413.23 t

Shear force =

Shear stress, tv =

0.53 N/mm2

Percentage area of steel, pt

=

Permissible shear strength of concrete, tc =

Shear reinforement is required.

Assuming

10

mm dia

20

And spacing of stirrups, S =

163

mm

Maximum spacing of stirrups,

Provide

10

mm dia

189 mm

legged vertical tirrups @

=

4

0.43

0.28

N/mm2

<

tv

legged vertical tirrups, then Asv =

160

1571 mm2

mm c/c.

Check for punching shear along pier,

269.49 t

Shear force =

20.32 m

bo =

tv =

0.13 N/mm2

Punching shear strength, tc =

0.716

Check for punching shear along pile,

57.69 t

Shear force =

bo =

5435.0 m

tv =

N/mm2

>

tv

Safe.

N/mm2

>

tv

Safe.

0.10 N/mm2

Punching shear strength, tc =

Unique Engineering Consultancy (P) Ltd

0.72

Page 14

You might also like

- Bridge Abutment Pier Design As Per IRCDocument41 pagesBridge Abutment Pier Design As Per IRCjibendra mishra89% (44)

- Design of Abutment Excel SheetDocument33 pagesDesign of Abutment Excel Sheetbkvs12340% (5)

- Design of Box CulvertDocument17 pagesDesign of Box CulvertSanket Diwate100% (14)

- Design of Bridge PierDocument12 pagesDesign of Bridge PierSunita Chaurasia88% (8)

- Design of Abutment For BridgeDocument28 pagesDesign of Abutment For BridgeMuhammad Wazim Akram100% (1)

- Design of U Type Return Wall - 10.9mDocument15 pagesDesign of U Type Return Wall - 10.9mdipoksinghaNo ratings yet

- Abutment DesignDocument49 pagesAbutment Designhemantkle2u100% (1)

- Box Culvert Limit StateDocument45 pagesBox Culvert Limit StateMahadev Sastry0% (2)

- StaircaseDocument2 pagesStaircaseMAGED MOHMMED AHMED QASEMNo ratings yet

- Design Example PierDocument53 pagesDesign Example PierKasun Shidesh100% (11)

- DESIGN AqueductDocument37 pagesDESIGN AqueductGarg Tj71% (7)

- Fundamentals of Rock Joint DeformationDocument20 pagesFundamentals of Rock Joint DeformationIgnasi AliguerNo ratings yet

- 4.0 Design of PierDocument9 pages4.0 Design of PierDeepak Kr GuptaNo ratings yet

- TCDSCo Bridge SampleDocument79 pagesTCDSCo Bridge SampleEngineeri TadiyosNo ratings yet

- Design of Abutment-ROBDocument10 pagesDesign of Abutment-ROBNandeesha Ramesh100% (1)

- Design of PierDocument11 pagesDesign of PierNaveen Yadav100% (6)

- Design of BridgeDocument59 pagesDesign of BridgeMohd Aftab80% (5)

- Cantilever Retaining Wall - RameswaramDocument23 pagesCantilever Retaining Wall - RameswaramD.V.Srinivasa RaoNo ratings yet

- Abutment DesignDocument10 pagesAbutment DesigndsureshcivilNo ratings yet

- Wing Wall Design With CFDocument3 pagesWing Wall Design With CFTanvir Shahrier MahmudNo ratings yet

- Design of RCC PierDocument10 pagesDesign of RCC Piervijayunity40% (5)

- Bridge Substructure With Pile Foundation at The State of JharkhandDocument82 pagesBridge Substructure With Pile Foundation at The State of JharkhandSree NivasNo ratings yet

- ROB Pier DesignDocument18 pagesROB Pier DesignTransportation Dept. SatyaVaniNo ratings yet

- Return Wall 10mDocument23 pagesReturn Wall 10mAkhil Singhal100% (2)

- Shambhavi Techno Solutions, Patna: Project: Subject: Design of Cantilever Type AbutmentDocument22 pagesShambhavi Techno Solutions, Patna: Project: Subject: Design of Cantilever Type AbutmentRohit Prakash100% (5)

- Design of Abutment BridgeDocument51 pagesDesign of Abutment BridgePrakash Singh Rawal92% (13)

- Gravity Retaining Wall - VakapalliDocument10 pagesGravity Retaining Wall - VakapalliD.V.Srinivasa RaoNo ratings yet

- RCC Detail Design of Abutment and PierDocument20 pagesRCC Detail Design of Abutment and Piershashibhushan singh100% (1)

- Design of RCC Retaining Wall at RelangiDocument18 pagesDesign of RCC Retaining Wall at RelangiD.V.Srinivasa RaoNo ratings yet

- Design of Box CulvertDocument66 pagesDesign of Box CulvertMd Ghani HaiderNo ratings yet

- Design of 10m Span RCC Slab CulvertDocument105 pagesDesign of 10m Span RCC Slab CulvertD.V.Srinivasa Rao100% (4)

- Design of RC AbutmentDocument15 pagesDesign of RC AbutmentSuman NakarmiNo ratings yet

- Design of Super StructureDocument30 pagesDesign of Super StructureHemraj Raj100% (16)

- Final Bridge Design Report (Berhampur AniDocument98 pagesFinal Bridge Design Report (Berhampur AniYogesh Indolia100% (6)

- DESIGN AqueductDocument89 pagesDESIGN AqueductmukhleshNo ratings yet

- Project: Date: Location: Designed By: Title: Checked By:: C C C R T C BDocument6 pagesProject: Date: Location: Designed By: Title: Checked By:: C C C R T C BDev LamichhaneNo ratings yet

- Cantilever Retaining Wall - RameswaramDocument23 pagesCantilever Retaining Wall - RameswaramD.V.Srinivasa RaoNo ratings yet

- Design of Well FoundationDocument39 pagesDesign of Well FoundationvasuNo ratings yet

- Design of 10m Clear Span Slab BridgeDocument53 pagesDesign of 10m Clear Span Slab BridgeD.V.Srinivasa Rao100% (4)

- Counter Fort Reatining WAll With HORZONTAL Bach FillDocument52 pagesCounter Fort Reatining WAll With HORZONTAL Bach FillRajib Chowdhury100% (1)

- Box Culvert by B.C.punmia Example 30.2Document39 pagesBox Culvert by B.C.punmia Example 30.2Yasika199078% (9)

- Effective WidhDocument17 pagesEffective WidhHimal KafleNo ratings yet

- Retaining Wall Design Final - From 12 To 8M Height Stone Mesonary - 24!12!18Document21 pagesRetaining Wall Design Final - From 12 To 8M Height Stone Mesonary - 24!12!18Shashank Srivastava100% (1)

- PSC Girder 23.75Document49 pagesPSC Girder 23.75ras_deep67% (3)

- Computation of Wind Force On Superstructure For PierDocument2 pagesComputation of Wind Force On Superstructure For Piervasu7900No ratings yet

- Design of Abutment PDFDocument4 pagesDesign of Abutment PDFChManikumarNo ratings yet

- L Shaped Reatining WAll With HORZONTAL Bach FillDocument29 pagesL Shaped Reatining WAll With HORZONTAL Bach Fillsarveshfdk48100% (2)

- RCC Detail Design of Bridge No.-422Document6 pagesRCC Detail Design of Bridge No.-422shashibhushan singhNo ratings yet

- East WallDocument8 pagesEast WallKumar Atray100% (1)

- Pile Reaction and Pile Cap (4PG) - P142Document147 pagesPile Reaction and Pile Cap (4PG) - P142Subir KundaNo ratings yet

- Design of RCC Wing WallDocument6 pagesDesign of RCC Wing WallAnkit Singla100% (1)

- Retaining Wall DesignDocument6 pagesRetaining Wall DesignshashiNo ratings yet

- Gravity Wall DesignDocument32 pagesGravity Wall DesignkanishkaNo ratings yet

- Elevated Storage Reservoir Design PDF FreeDocument47 pagesElevated Storage Reservoir Design PDF Freemirzakamranbaig.mkNo ratings yet

- Footing Design - Studio AoartmentDocument23 pagesFooting Design - Studio AoartmentMUKESH RAJENDRANo ratings yet

- Abutment Design For 30mDocument40 pagesAbutment Design For 30mManvendra NigamNo ratings yet

- 15m RC TG Superstructure DesignDocument22 pages15m RC TG Superstructure DesignEngineeri TadiyosNo ratings yet

- Example 20m Span RCDGDocument17 pagesExample 20m Span RCDGIyœ Møsisæ100% (2)

- Retaining WallDocument212 pagesRetaining Wallabhijeet.singhsainfraNo ratings yet

- Deck Girder ExampleDocument28 pagesDeck Girder ExampleEng'r Mohammed HamzaNo ratings yet

- Desain AbutmentDocument75 pagesDesain AbutmentLouce PatriciaNo ratings yet

- RCC Bridge and Culvert DesignDocument113 pagesRCC Bridge and Culvert DesignDeepak Kr GuptaNo ratings yet

- Irrigation DesignDocument7 pagesIrrigation DesignDeepak Kr GuptaNo ratings yet

- Manual Bridge PDFDocument768 pagesManual Bridge PDFDeepak Kr Gupta100% (1)

- Methodology For Detailed Geotechnical Investigation of Bridge Sites PDFDocument4 pagesMethodology For Detailed Geotechnical Investigation of Bridge Sites PDFDeepak Kr GuptaNo ratings yet

- Civil Geo Lab Pvt. Ltd. Lalitpur Test Result Summary SheetDocument1 pageCivil Geo Lab Pvt. Ltd. Lalitpur Test Result Summary SheetDeepak Kr GuptaNo ratings yet

- Abutment Pier and WallDocument29 pagesAbutment Pier and WallDeepak Kr GuptaNo ratings yet

- Section 11 Abutment, Piers, and Retaining Walls Section 11 Abutment, Piers, and Retaining WallsDocument48 pagesSection 11 Abutment, Piers, and Retaining Walls Section 11 Abutment, Piers, and Retaining WallsDeepak Kr GuptaNo ratings yet

- Abutment DesignDocument38 pagesAbutment DesignDeepak Kr GuptaNo ratings yet

- Section 11 Abutment, Piers, and Retaining Walls Section 11 Abutment, Piers, and Retaining WallsDocument48 pagesSection 11 Abutment, Piers, and Retaining Walls Section 11 Abutment, Piers, and Retaining WallsDeepak Kr GuptaNo ratings yet

- Methodology For Detailed Geotechnical Investigation of Bridge Sites PDFDocument4 pagesMethodology For Detailed Geotechnical Investigation of Bridge Sites PDFDeepak Kr GuptaNo ratings yet

- Grain Size Distribution: Project: Ghatte Khola Client: Mopid, Hetauda, MakawanpurDocument1 pageGrain Size Distribution: Project: Ghatte Khola Client: Mopid, Hetauda, MakawanpurDeepak Kr GuptaNo ratings yet

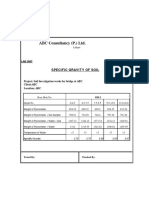

- ABC Consultancy (P.) LTD.: Specific Gravity of SoilDocument2 pagesABC Consultancy (P.) LTD.: Specific Gravity of SoilDeepak Kr GuptaNo ratings yet

- Civil Geo Lab Pvt. LTD.: Direct Shear TestDocument1 pageCivil Geo Lab Pvt. LTD.: Direct Shear TestDeepak Kr GuptaNo ratings yet

- Borehole Log: No. of Blows Total SPT/D CP Value N-ValueDocument1 pageBorehole Log: No. of Blows Total SPT/D CP Value N-ValueDeepak Kr GuptaNo ratings yet

- A BC Consultancy (P.) Ltd. Lalitpur: Project: Soil Investigation Works For Bridge at A BC Client:A BC Location: A BCDocument1 pageA BC Consultancy (P.) Ltd. Lalitpur: Project: Soil Investigation Works For Bridge at A BC Client:A BC Location: A BCDeepak Kr GuptaNo ratings yet

- Bore HoleDocument2 pagesBore HoleDeepak Kr GuptaNo ratings yet

- Direct Shear Test ResultDocument7 pagesDirect Shear Test ResultDeepak Kr GuptaNo ratings yet

- Grain Size Distribution: Project: Soil Investigation Works For Bridge at ABC Client: ABC Location: ABC Bore Hole No.: 1Document5 pagesGrain Size Distribution: Project: Soil Investigation Works For Bridge at ABC Client: ABC Location: ABC Bore Hole No.: 1Deepak Kr GuptaNo ratings yet

- ABC Consultancy (P.) LTD.: Natural Moisture ContentDocument2 pagesABC Consultancy (P.) LTD.: Natural Moisture ContentDeepak Kr GuptaNo ratings yet

- Qtty ModDocument135 pagesQtty ModDeepak Kr GuptaNo ratings yet

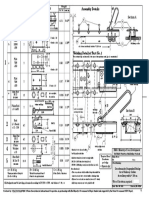

- Assembly Details: HMG / Ministry of Local DevelopmentDocument1 pageAssembly Details: HMG / Ministry of Local DevelopmentDeepak Kr GuptaNo ratings yet

- 19DCON106Document1 page19DCON106Deepak Kr GuptaNo ratings yet

- Section A-A Front Elevation: Fractured RockDocument1 pageSection A-A Front Elevation: Fractured RockkoklenderNo ratings yet

- Chapter-II-physical Characteristics of SoilDocument34 pagesChapter-II-physical Characteristics of SoilVijaykumar NagnaikNo ratings yet

- Approval of LPT ProcedureDocument14 pagesApproval of LPT ProcedureimranNo ratings yet

- Odic Table Periodicity NeetDocument59 pagesOdic Table Periodicity NeetAnubhav KohliNo ratings yet

- Equinox International LTD - Stainless Steel - ST ST Corrosion Resistance - 106 PDFDocument2 pagesEquinox International LTD - Stainless Steel - ST ST Corrosion Resistance - 106 PDFeugenio.gutenbertNo ratings yet

- Waterproofing Details - Design Under Constrained ConditionsDocument18 pagesWaterproofing Details - Design Under Constrained ConditionsAmit KumarNo ratings yet

- Introductiontoprestressedconcrete 111211203113 Phpapp02Document17 pagesIntroductiontoprestressedconcrete 111211203113 Phpapp02kiet20002000No ratings yet

- Hot Forging Die Failure - Causes and Analysis - MachineMfgDocument20 pagesHot Forging Die Failure - Causes and Analysis - MachineMfgPunkajGupta100% (1)

- Catalogs: Material (Articles)Document3 pagesCatalogs: Material (Articles)NishanthanNo ratings yet

- Structural Analysis & DesignDocument8 pagesStructural Analysis & Designkurt paulo manaloNo ratings yet

- HARDNESSDocument18 pagesHARDNESSK33Prathvi S KundarNo ratings yet

- Adsorption of MB Onto ACDocument53 pagesAdsorption of MB Onto ACtkjingNo ratings yet

- Structured Question Form 4 Chapter 2: The Structure of The Atom Struktur Atom SUBTOPIC: Matter JirimDocument10 pagesStructured Question Form 4 Chapter 2: The Structure of The Atom Struktur Atom SUBTOPIC: Matter JirimbbbNo ratings yet

- Metals MCQ PDFDocument21 pagesMetals MCQ PDFMunshatia Islam MerryNo ratings yet

- Certified System Solution: NiretaDocument15 pagesCertified System Solution: NiretaImam SyahroniNo ratings yet

- CFD Simulation and Heat Transfer Analysis of A Radiator With Helical TubesDocument4 pagesCFD Simulation and Heat Transfer Analysis of A Radiator With Helical TubespugazhNo ratings yet

- Determination of Heavy Metals in Ground Water by Icp-MS in Selected Coastal Areas of SPSR Nellore District, Andhra Pradesh, IndiaDocument4 pagesDetermination of Heavy Metals in Ground Water by Icp-MS in Selected Coastal Areas of SPSR Nellore District, Andhra Pradesh, IndiaDennis WeldyNo ratings yet

- Gasification ReactivityDocument19 pagesGasification ReactivityNavneet KaurNo ratings yet

- Solid and Hazardous Waste Questions & Mark SchemeDocument8 pagesSolid and Hazardous Waste Questions & Mark SchemeJohn Osborne100% (4)

- Hazrath Seyyid Madani English Medium SchoolDocument14 pagesHazrath Seyyid Madani English Medium SchoolMumthaz ANo ratings yet

- Aftek Fyreflex Jun14 Tds - Fire SealantDocument4 pagesAftek Fyreflex Jun14 Tds - Fire SealantYndia SorianoNo ratings yet

- Ferro-Chrome Lignosulfonate Manufacturer - Modified Lignosulfonate - GDFCLDocument3 pagesFerro-Chrome Lignosulfonate Manufacturer - Modified Lignosulfonate - GDFCLMannarNo ratings yet

- 2017 ct2Document1 page2017 ct2Anonymous BoP7nnBNo ratings yet

- Acid-Base Indicators For Use in TitrationDocument7 pagesAcid-Base Indicators For Use in TitrationMaxNo ratings yet

- Assessment 1 Form 1Document2 pagesAssessment 1 Form 1Bhoosan AncharazNo ratings yet

- Tecnology Silo Rings - Metal Grain Silo - Prado SilosDocument4 pagesTecnology Silo Rings - Metal Grain Silo - Prado SilosRomeu Branco SimõesNo ratings yet

- Amount of Dissolved Oxygen in WaterDocument2 pagesAmount of Dissolved Oxygen in WaterNitinSrivastavaNo ratings yet

- VSTEP-Reading Test 1Document14 pagesVSTEP-Reading Test 1Ph DiNo ratings yet

- Chemistry 5070 Learner Guide From Examination From 2016Document48 pagesChemistry 5070 Learner Guide From Examination From 2016Neen NaazNo ratings yet

- FDGSDFGDDocument7 pagesFDGSDFGDhemanth45No ratings yet