Professional Documents

Culture Documents

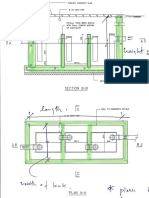

Pipierack Plan

Pipierack Plan

Uploaded by

pouyaCopyright:

Available Formats

You might also like

- 1965, Foss e Gaul PDFDocument17 pages1965, Foss e Gaul PDFJoão GadelhaNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Foss & Gaul PDFDocument17 pagesFoss & Gaul PDFnicolasbelliniNo ratings yet

- Heat Exchanger PipingDocument39 pagesHeat Exchanger PipingBhupender Sharma93% (15)

- A11vo 130 Lg1eDocument1 pageA11vo 130 Lg1exxsh100% (2)

- Iranian Petroleum Standards: Typical Unit Arrangement & Piperack Layout IPS-D-PI-102Document1 pageIranian Petroleum Standards: Typical Unit Arrangement & Piperack Layout IPS-D-PI-102reza329329No ratings yet

- ESCHandbook Chapter3 3.18Document12 pagesESCHandbook Chapter3 3.18Larry Wayne Sumpter, JrNo ratings yet

- 1 PiperackDocument8 pages1 PiperackDinesh Kumar JdNo ratings yet

- Piping LayoutDocument16 pagesPiping Layoutsanmiguel000100% (1)

- طراحی پایپینگ اطراف پمپ هاDocument25 pagesطراحی پایپینگ اطراف پمپ هاMorteza DianatfarNo ratings yet

- Drake L4BDocument26 pagesDrake L4BtrapperpgNo ratings yet

- Training ManualDocument400 pagesTraining ManualJairo Peña80% (5)

- 61fSTO PStopperDocument2 pages61fSTO PStopperBenjamin BrownNo ratings yet

- Figure 1: Location of Principal Connections and AttachmentsDocument1 pageFigure 1: Location of Principal Connections and Attachmentssmm1457No ratings yet

- CH 4 Spillways 4Document11 pagesCH 4 Spillways 4Fikir YoNo ratings yet

- 4.3 Basic Design Awwa D100 & Api 650Document7 pages4.3 Basic Design Awwa D100 & Api 650Miguel Martinez Guerrero100% (1)

- GE Lighting Systems Decaflood Family Series Spec Sheet 8-81Document4 pagesGE Lighting Systems Decaflood Family Series Spec Sheet 8-81Alan MastersNo ratings yet

- Pipe Rack Rack PipingDocument23 pagesPipe Rack Rack PipingAlessandro1975No ratings yet

- Pipe Rack & Rack PipingDocument23 pagesPipe Rack & Rack Pipingtrung652092100% (2)

- 205 Drag Valves For Boiler Feedpump RecirculationDocument6 pages205 Drag Valves For Boiler Feedpump Recirculationesakkiraj1590No ratings yet

- Pipe Rack / Ways & Rack Piping: Akshaya SharmaDocument23 pagesPipe Rack / Ways & Rack Piping: Akshaya SharmaWahyu IrwansyahNo ratings yet

- Is 6531 1994Document16 pagesIs 6531 1994ProfNDAcharyaNo ratings yet

- Progress Lighting Commercial Catalog 1977Document100 pagesProgress Lighting Commercial Catalog 1977Alan Masters100% (1)

- Centrifugal Pump PipingDocument22 pagesCentrifugal Pump PipingBhupender Sharma100% (3)

- Parcol Globe ValveDocument120 pagesParcol Globe ValveAnderson SiqueiraNo ratings yet

- Standard Sewer DetailsDocument59 pagesStandard Sewer DetailsPhanhai KakaNo ratings yet

- Coil Tubing: Lecture Notes by Prof - Sushanta SarkarDocument32 pagesCoil Tubing: Lecture Notes by Prof - Sushanta Sarkarnishant41288100% (1)

- Piping Layout and PIPERACKDocument19 pagesPiping Layout and PIPERACKRaju NaiduNo ratings yet

- Bullet PipingDocument12 pagesBullet PipingSuresh Gurram100% (2)

- Piping Design Guide-Vertical DrumsDocument9 pagesPiping Design Guide-Vertical DrumsTejas PatelNo ratings yet

- Column Piping: Study Layout, Nozzle Orientation & Platforms RequirementsDocument23 pagesColumn Piping: Study Layout, Nozzle Orientation & Platforms RequirementsArindomNo ratings yet

- ML023300641 PDFDocument1 pageML023300641 PDFharryNo ratings yet

- Mooring Rules Operations SPM BerthsDocument10 pagesMooring Rules Operations SPM BerthsHRC100% (1)

- 500 GPM Electric W EnclDocument1 page500 GPM Electric W EnclmohdnazirNo ratings yet

- CPM1500 CP of Onshore Well CasingsDocument22 pagesCPM1500 CP of Onshore Well Casingskirubha_karan2000No ratings yet

- PVE Piping Layout Presentation - Part 1Document68 pagesPVE Piping Layout Presentation - Part 1Nguyen Quang Nghia100% (1)

- Shell & Tube Heat ExchangersDocument10 pagesShell & Tube Heat ExchangersMohamed SalihNo ratings yet

- Layout Arrangement For Centrifugal Pump PipingDocument20 pagesLayout Arrangement For Centrifugal Pump PipingKyaw Kyaw Aung50% (2)

- Column PipingDocument53 pagesColumn PipingSomnath Laha100% (1)

- Is 5186 1994Document17 pagesIs 5186 1994Andrés GarzónNo ratings yet

- Mechanism of Selective Oil ProducerDocument7 pagesMechanism of Selective Oil ProducerAlbert ChongNo ratings yet

- Hosereel SystemDocument5 pagesHosereel Systemrmaffireschool100% (3)

- Drilling & Completion Practices Manual Drilling For Conductor CasingDocument3 pagesDrilling & Completion Practices Manual Drilling For Conductor Casingciucalata88No ratings yet

- Oil InterceptorDocument1 pageOil InterceptorasdthuNo ratings yet

- Pi Ups 1005Document23 pagesPi Ups 1005Cristhian A. S.B.No ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Northrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950From EverandNorthrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Rating: 5 out of 5 stars5/5 (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Lin Siz PIR FASTER 30-45 FOSTER 81-84ADocument5 pagesLin Siz PIR FASTER 30-45 FOSTER 81-84ApouyaNo ratings yet

- Pipe 1.03 20ksiDocument3 pagesPipe 1.03 20ksipouyaNo ratings yet

- ASTM Bolts Grade MarkDocument8 pagesASTM Bolts Grade MarkpouyaNo ratings yet

- Welding Inspection CourseDocument23 pagesWelding Inspection CoursepouyaNo ratings yet

- Differential Pressure Unit Application Data Sheet: General SpecificationsDocument3 pagesDifferential Pressure Unit Application Data Sheet: General SpecificationspouyaNo ratings yet

- Iplex Pipelines Pty LTDDocument33 pagesIplex Pipelines Pty LTDpouyaNo ratings yet

- Hydraulic Mining Shovel 6040AC: 08. Attachment Functions - FSDocument20 pagesHydraulic Mining Shovel 6040AC: 08. Attachment Functions - FShector50% (2)

- 67 Troubleshooting Tips For Closed Loop Hydrostatic SystemsDocument2 pages67 Troubleshooting Tips For Closed Loop Hydrostatic Systemsbee140676No ratings yet

- Grundfos Cmbe Twin Booster: Cascade Booster System Constant Pressure Alternation Between Pumps Easy To InstallDocument2 pagesGrundfos Cmbe Twin Booster: Cascade Booster System Constant Pressure Alternation Between Pumps Easy To InstallIlyas AissiNo ratings yet

- Hydraulic Pumps: Service Training Manual ECM 720Document10 pagesHydraulic Pumps: Service Training Manual ECM 720victor laraNo ratings yet

- The Supreme Industries Limited: MRP PRICE LIST W.E.F. 15.09.2021 (Pn-16 Injection Moulding Items)Document1 pageThe Supreme Industries Limited: MRP PRICE LIST W.E.F. 15.09.2021 (Pn-16 Injection Moulding Items)T JNo ratings yet

- Fuel Supply Pump and Overflow Valve D12, D12A, D12BDocument2 pagesFuel Supply Pump and Overflow Valve D12, D12A, D12BHamilton MirandaNo ratings yet

- HY10 1630US 5 2012-Accumulator AccessoriesDocument12 pagesHY10 1630US 5 2012-Accumulator AccessoriesFelipe DiazNo ratings yet

- Artificial Lift (Overview)Document13 pagesArtificial Lift (Overview)adlinaNo ratings yet

- Rexroth Relief ValveDocument10 pagesRexroth Relief ValveAdnanNo ratings yet

- DRG Pump Control SystemDocument36 pagesDRG Pump Control SystemRafael Ricardo Zacarias Castillo100% (1)

- Hydraulics Basics: Medium Head Safety Injection Pump For Acp1000 ReactorDocument56 pagesHydraulics Basics: Medium Head Safety Injection Pump For Acp1000 ReactorJorge Athié Huitrón MorenoNo ratings yet

- ICH3800 Class 7: 1st Semester 2022Document92 pagesICH3800 Class 7: 1st Semester 2022catalinaNo ratings yet

- Guideline Pump SystemDocument16 pagesGuideline Pump SystemBehroozRaadNo ratings yet

- Diagrama Bomba 9010B 1 de 2Document4 pagesDiagrama Bomba 9010B 1 de 2Comassur SA de CVNo ratings yet

- Tekba Dosing PumpDocument4 pagesTekba Dosing PumpDony SucionoNo ratings yet

- KKS Missing List 15.01.2020Document66 pagesKKS Missing List 15.01.2020Kasthuri CoimbatoreNo ratings yet

- Residential Plumbing Inspection Checklist PDFDocument4 pagesResidential Plumbing Inspection Checklist PDFNaing Win TunNo ratings yet

- TURK PLAST (PPRC Green+Blue+PE GAS) 01-02-2021 - OutstationDocument1 pageTURK PLAST (PPRC Green+Blue+PE GAS) 01-02-2021 - OutstationicrcgisNo ratings yet

- 950 GC Main Controle ValveDocument23 pages950 GC Main Controle ValveAbdellahNo ratings yet

- Va1048 2Document1 pageVa1048 2陆军No ratings yet

- High Flow Hydraulics (S - N A5GK20356 & Below, A5GL20029 & Below) - S220Document3 pagesHigh Flow Hydraulics (S - N A5GK20356 & Below, A5GL20029 & Below) - S220Joan CzNo ratings yet

- Pipes and FittingsDocument9 pagesPipes and FittingsRaquel MonsalveNo ratings yet

- ABUBAKAR MODEL 1-Layout1Document1 pageABUBAKAR MODEL 1-Layout1bahir AbubakarNo ratings yet

- Radial Piston Pumps Type R and RGDocument4 pagesRadial Piston Pumps Type R and RGdriss echanchniNo ratings yet

- Advanced Water Distribution Modeling and Management: AuthorsDocument14 pagesAdvanced Water Distribution Modeling and Management: AuthorsJalijashNo ratings yet

- En Power Master IIIDocument4 pagesEn Power Master IIIdarwin100% (1)

- QCDD 1.1 Basic Requirements Rev ADocument4 pagesQCDD 1.1 Basic Requirements Rev ADinesh GuptaNo ratings yet

- Graco Autolube Mode 12Document2 pagesGraco Autolube Mode 12Riyan AditiaNo ratings yet

Pipierack Plan

Pipierack Plan

Uploaded by

pouyaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipierack Plan

Pipierack Plan

Uploaded by

pouyaCopyright:

Available Formats

C

L

C4

C5

C1

C1

4000 MIN.

600 MIN.

C7

C1

C1

A1

A1

C1

AISLEWAY

ALTERNATE

ACCESSWAY

P12

C4

PASSAGE

WAY(TYP.)

C1

A1

C7

C5

C

L PS. COL.S

4000 MIN.

A1

A3

C3

C

L PS. COL.S

P11-THE NORMALLY DESIRABLE LOCATION OF RELIEF AND

BLOWDOWN HEADERS ELEVATED ABOVE PIPERACK IS

OVER THE PIPERACK COLUMNS.

P12-THE CENTERLINE TO CENTERLINE OF PIPERACK

COLUMNS SHALL BE 7600 WITH THE FOLLOWING

EXCEPTIONS:

P12.1-IF THE PREDOMINATE PORTION OF THE PIPING IN

THE RACK IS UNDER 3" (DN80) SEE TABLE-1 FOR

ALLOWABLE PIPE SPANS.

P12.2-ALUMINIUM OR OTHER SPECIAL MATERIALS CONSTITUTE THE MAJORITY.

P12.3-SPANS MAY BE SHORTENED SLIGHTLY TO MAKE

EVEN SPACING ACROSS A PLOT.

P12.4-SUPPORT SPACING SHALL BE INCREASED FOR

SINGLE OR MULTIPLE LINES 200 & LARGER.(SEE

TABLE-1 FOR ALLOWABLE PIPE SPANS.)

P12.5-SMALL LINES UNABLE TO SPAN THE NORMAL 7600

SPACING SHALL BE SUPPORTED BY INTERMEDIATE

PICK-UP.

P13-FOR LINE SPACING SEE DWG. IPS-D-PI-103.

C1

ACCESSWAY

C3

TYPICAL UNIT PLOT PLAN ARRANGEMENT

SHOWING MINIMUM CLEARANCES

ARRANGEMENT

PIPEWAY

1000 MIN.

P6- GENERALLY LARGEST PIPE DIAMETER AND/ OR HOT

LINES SHALL BE ROUTED ON THE OUTSIDE

PIPERACK TO PERMIT MAXIMUM EXPANSION

MOVEMENTS IN A MIN. OF SPACE.

P7- WHEN CONDENSATE REMOVAL IS REQUIRED IN UTILITY AIR OR STEAM HEADERS, DRIP OR BOOT LEGS

SHALL BE PROVIDED AT PIPING LOW POINTS OR

OTHER CONVENIENT LOCATIONS.

P8- GENERALLY, PIPERACK HEADER BRANCH CONNECTINS

FOR UTILITY & PROCESS GASES, AIR, STEAM, ETC.

WILL BE MADE ON THE TOP OF THE LINE TO AVOID

HEADER LOW POINTS WHERE COND. MAY COLLECT.

P9- PIPERACK HEADER BRANCH CONNECTIONS FOR

LIQUIDS GENERALLY ARE ON THE BOTTOM OF THE

HEADER TO AVOID BRANCH HIGH POINTS WHERE

GASES MAY COLLECT AND PREVENTING LIQUID FLOW.

P10-WHEN ECONOMICALLY FEASIBLE, OR AS STIPULATED

BY PROCESS CONDITIONS, FLAT TURNS & DIAGONAL

RUNS SHALL BE USED WHEN PRACTICABLE.

C7

C2

LINE UP HORIZONTAL EQUIPMENTS WHEN PRACTICAL

LINE UP FRONT OF ALL VERTICAL

COLUMNS WHEN PRACTICAL

BATTERY LIMITS

45

MAX.

BATTERY LIMITS

PIPERACK

P1- DIFFERENCE IN PIPERACK ELEV.S SHALL GENERALLY

BE 760 MIN.

P2- ALLOW 350 DROP SPACE FOR UTILITY, STEAM TRAP,

VENT PIPING, ETC.

P3- GENERALLY THE CENTERLINE OF LINE DROPS SHALL

BE BASED ON MIN. 50 CLEARANCE BETWEEN THE

EDGE OF THE PIPE SUPPORT AND/ OR INSTRUMENT

RACK AND THE BACK OF THE LARGEST PIPE AND/

OR INSULATION. OTHER DROPS SHALL BE ON

APPROX. THE SAME CL AS THE LARGEST PIPE .

P4- LOOPS ARE REQUIRED WHEN IT IS IMPRACTICABLE

TO TAKE PIPING EXPANSION MOVEMENTS AT

CORNERS OR AT EQUIP., THEY SHALL NORMALLY BE

OBTAINED BY FOLDING BACK OVER THE PIPERACK.

P5- IF ANCHORS ARE REQUIRED TO MINIMIZE FORCES

ON EQUIPMENT OR REDUCE PIPING EXPANSION

MOVEMENT, THEY SHALL BE SO LOCATED THAT ANY

NECESSARY BRACING DOES NOT INTERFER WITH

PASSAGEWAY OR EQUIPMENT CLEARANCES.

1000 MIN.

1000 MIN.

BATTERY LIMITS

A1- SPACE FOR PIPING CONTROL VALVE MANIFOLDS, BY

PASSES, ETC. (USE 600 BEYOND ADJACENT EQUIPMENT FOR LAYOUT)

A2- IN A LIMITED PLOT WHEN PROCESS CONDITIONS

PERMIT AND IT IS ECONOMICALLY, PREFERABLE,

AIR COOLER MAY BE INSTALLED ABOVE OVERHEAD

PIPERACKS.

A3- PUMPS WITH PROCESS REQUIREMENTS OF LOW

SUCTION LINES SHALL NORMALLY BE LOCATED AS

SHOWN IF ECONOMICALLY FEASIBLE PROVIDING

SUFFICIENT SPACE OR ACCESS IS AVAILABLE FOR

MAINTENANCE.

A4- PUMP SUCTION & DISCHARGE VALVES SHALL , IF

POSSIBLE, BE ACCESSIBLE FOR OPERATION

WITHOUT THE USE OF CHAIN OR EXTENSION STEMS.

A5- DISCHARGE CHECK VALVES SHALL, IF PRACTICABLE,

BE LOCATED IN THE VERTICAL.

A6- PUMP SUCTION LINES SHALL BE AS SHORT AND

DIRECT AS POSSIBLE UNLESS OTHERWISE REQUIRED

FOR FLEXIBILITY REASONS.

You might also like

- 1965, Foss e Gaul PDFDocument17 pages1965, Foss e Gaul PDFJoão GadelhaNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Foss & Gaul PDFDocument17 pagesFoss & Gaul PDFnicolasbelliniNo ratings yet

- Heat Exchanger PipingDocument39 pagesHeat Exchanger PipingBhupender Sharma93% (15)

- A11vo 130 Lg1eDocument1 pageA11vo 130 Lg1exxsh100% (2)

- Iranian Petroleum Standards: Typical Unit Arrangement & Piperack Layout IPS-D-PI-102Document1 pageIranian Petroleum Standards: Typical Unit Arrangement & Piperack Layout IPS-D-PI-102reza329329No ratings yet

- ESCHandbook Chapter3 3.18Document12 pagesESCHandbook Chapter3 3.18Larry Wayne Sumpter, JrNo ratings yet

- 1 PiperackDocument8 pages1 PiperackDinesh Kumar JdNo ratings yet

- Piping LayoutDocument16 pagesPiping Layoutsanmiguel000100% (1)

- طراحی پایپینگ اطراف پمپ هاDocument25 pagesطراحی پایپینگ اطراف پمپ هاMorteza DianatfarNo ratings yet

- Drake L4BDocument26 pagesDrake L4BtrapperpgNo ratings yet

- Training ManualDocument400 pagesTraining ManualJairo Peña80% (5)

- 61fSTO PStopperDocument2 pages61fSTO PStopperBenjamin BrownNo ratings yet

- Figure 1: Location of Principal Connections and AttachmentsDocument1 pageFigure 1: Location of Principal Connections and Attachmentssmm1457No ratings yet

- CH 4 Spillways 4Document11 pagesCH 4 Spillways 4Fikir YoNo ratings yet

- 4.3 Basic Design Awwa D100 & Api 650Document7 pages4.3 Basic Design Awwa D100 & Api 650Miguel Martinez Guerrero100% (1)

- GE Lighting Systems Decaflood Family Series Spec Sheet 8-81Document4 pagesGE Lighting Systems Decaflood Family Series Spec Sheet 8-81Alan MastersNo ratings yet

- Pipe Rack Rack PipingDocument23 pagesPipe Rack Rack PipingAlessandro1975No ratings yet

- Pipe Rack & Rack PipingDocument23 pagesPipe Rack & Rack Pipingtrung652092100% (2)

- 205 Drag Valves For Boiler Feedpump RecirculationDocument6 pages205 Drag Valves For Boiler Feedpump Recirculationesakkiraj1590No ratings yet

- Pipe Rack / Ways & Rack Piping: Akshaya SharmaDocument23 pagesPipe Rack / Ways & Rack Piping: Akshaya SharmaWahyu IrwansyahNo ratings yet

- Is 6531 1994Document16 pagesIs 6531 1994ProfNDAcharyaNo ratings yet

- Progress Lighting Commercial Catalog 1977Document100 pagesProgress Lighting Commercial Catalog 1977Alan Masters100% (1)

- Centrifugal Pump PipingDocument22 pagesCentrifugal Pump PipingBhupender Sharma100% (3)

- Parcol Globe ValveDocument120 pagesParcol Globe ValveAnderson SiqueiraNo ratings yet

- Standard Sewer DetailsDocument59 pagesStandard Sewer DetailsPhanhai KakaNo ratings yet

- Coil Tubing: Lecture Notes by Prof - Sushanta SarkarDocument32 pagesCoil Tubing: Lecture Notes by Prof - Sushanta Sarkarnishant41288100% (1)

- Piping Layout and PIPERACKDocument19 pagesPiping Layout and PIPERACKRaju NaiduNo ratings yet

- Bullet PipingDocument12 pagesBullet PipingSuresh Gurram100% (2)

- Piping Design Guide-Vertical DrumsDocument9 pagesPiping Design Guide-Vertical DrumsTejas PatelNo ratings yet

- Column Piping: Study Layout, Nozzle Orientation & Platforms RequirementsDocument23 pagesColumn Piping: Study Layout, Nozzle Orientation & Platforms RequirementsArindomNo ratings yet

- ML023300641 PDFDocument1 pageML023300641 PDFharryNo ratings yet

- Mooring Rules Operations SPM BerthsDocument10 pagesMooring Rules Operations SPM BerthsHRC100% (1)

- 500 GPM Electric W EnclDocument1 page500 GPM Electric W EnclmohdnazirNo ratings yet

- CPM1500 CP of Onshore Well CasingsDocument22 pagesCPM1500 CP of Onshore Well Casingskirubha_karan2000No ratings yet

- PVE Piping Layout Presentation - Part 1Document68 pagesPVE Piping Layout Presentation - Part 1Nguyen Quang Nghia100% (1)

- Shell & Tube Heat ExchangersDocument10 pagesShell & Tube Heat ExchangersMohamed SalihNo ratings yet

- Layout Arrangement For Centrifugal Pump PipingDocument20 pagesLayout Arrangement For Centrifugal Pump PipingKyaw Kyaw Aung50% (2)

- Column PipingDocument53 pagesColumn PipingSomnath Laha100% (1)

- Is 5186 1994Document17 pagesIs 5186 1994Andrés GarzónNo ratings yet

- Mechanism of Selective Oil ProducerDocument7 pagesMechanism of Selective Oil ProducerAlbert ChongNo ratings yet

- Hosereel SystemDocument5 pagesHosereel Systemrmaffireschool100% (3)

- Drilling & Completion Practices Manual Drilling For Conductor CasingDocument3 pagesDrilling & Completion Practices Manual Drilling For Conductor Casingciucalata88No ratings yet

- Oil InterceptorDocument1 pageOil InterceptorasdthuNo ratings yet

- Pi Ups 1005Document23 pagesPi Ups 1005Cristhian A. S.B.No ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Northrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950From EverandNorthrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Rating: 5 out of 5 stars5/5 (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Lin Siz PIR FASTER 30-45 FOSTER 81-84ADocument5 pagesLin Siz PIR FASTER 30-45 FOSTER 81-84ApouyaNo ratings yet

- Pipe 1.03 20ksiDocument3 pagesPipe 1.03 20ksipouyaNo ratings yet

- ASTM Bolts Grade MarkDocument8 pagesASTM Bolts Grade MarkpouyaNo ratings yet

- Welding Inspection CourseDocument23 pagesWelding Inspection CoursepouyaNo ratings yet

- Differential Pressure Unit Application Data Sheet: General SpecificationsDocument3 pagesDifferential Pressure Unit Application Data Sheet: General SpecificationspouyaNo ratings yet

- Iplex Pipelines Pty LTDDocument33 pagesIplex Pipelines Pty LTDpouyaNo ratings yet

- Hydraulic Mining Shovel 6040AC: 08. Attachment Functions - FSDocument20 pagesHydraulic Mining Shovel 6040AC: 08. Attachment Functions - FShector50% (2)

- 67 Troubleshooting Tips For Closed Loop Hydrostatic SystemsDocument2 pages67 Troubleshooting Tips For Closed Loop Hydrostatic Systemsbee140676No ratings yet

- Grundfos Cmbe Twin Booster: Cascade Booster System Constant Pressure Alternation Between Pumps Easy To InstallDocument2 pagesGrundfos Cmbe Twin Booster: Cascade Booster System Constant Pressure Alternation Between Pumps Easy To InstallIlyas AissiNo ratings yet

- Hydraulic Pumps: Service Training Manual ECM 720Document10 pagesHydraulic Pumps: Service Training Manual ECM 720victor laraNo ratings yet

- The Supreme Industries Limited: MRP PRICE LIST W.E.F. 15.09.2021 (Pn-16 Injection Moulding Items)Document1 pageThe Supreme Industries Limited: MRP PRICE LIST W.E.F. 15.09.2021 (Pn-16 Injection Moulding Items)T JNo ratings yet

- Fuel Supply Pump and Overflow Valve D12, D12A, D12BDocument2 pagesFuel Supply Pump and Overflow Valve D12, D12A, D12BHamilton MirandaNo ratings yet

- HY10 1630US 5 2012-Accumulator AccessoriesDocument12 pagesHY10 1630US 5 2012-Accumulator AccessoriesFelipe DiazNo ratings yet

- Artificial Lift (Overview)Document13 pagesArtificial Lift (Overview)adlinaNo ratings yet

- Rexroth Relief ValveDocument10 pagesRexroth Relief ValveAdnanNo ratings yet

- DRG Pump Control SystemDocument36 pagesDRG Pump Control SystemRafael Ricardo Zacarias Castillo100% (1)

- Hydraulics Basics: Medium Head Safety Injection Pump For Acp1000 ReactorDocument56 pagesHydraulics Basics: Medium Head Safety Injection Pump For Acp1000 ReactorJorge Athié Huitrón MorenoNo ratings yet

- ICH3800 Class 7: 1st Semester 2022Document92 pagesICH3800 Class 7: 1st Semester 2022catalinaNo ratings yet

- Guideline Pump SystemDocument16 pagesGuideline Pump SystemBehroozRaadNo ratings yet

- Diagrama Bomba 9010B 1 de 2Document4 pagesDiagrama Bomba 9010B 1 de 2Comassur SA de CVNo ratings yet

- Tekba Dosing PumpDocument4 pagesTekba Dosing PumpDony SucionoNo ratings yet

- KKS Missing List 15.01.2020Document66 pagesKKS Missing List 15.01.2020Kasthuri CoimbatoreNo ratings yet

- Residential Plumbing Inspection Checklist PDFDocument4 pagesResidential Plumbing Inspection Checklist PDFNaing Win TunNo ratings yet

- TURK PLAST (PPRC Green+Blue+PE GAS) 01-02-2021 - OutstationDocument1 pageTURK PLAST (PPRC Green+Blue+PE GAS) 01-02-2021 - OutstationicrcgisNo ratings yet

- 950 GC Main Controle ValveDocument23 pages950 GC Main Controle ValveAbdellahNo ratings yet

- Va1048 2Document1 pageVa1048 2陆军No ratings yet

- High Flow Hydraulics (S - N A5GK20356 & Below, A5GL20029 & Below) - S220Document3 pagesHigh Flow Hydraulics (S - N A5GK20356 & Below, A5GL20029 & Below) - S220Joan CzNo ratings yet

- Pipes and FittingsDocument9 pagesPipes and FittingsRaquel MonsalveNo ratings yet

- ABUBAKAR MODEL 1-Layout1Document1 pageABUBAKAR MODEL 1-Layout1bahir AbubakarNo ratings yet

- Radial Piston Pumps Type R and RGDocument4 pagesRadial Piston Pumps Type R and RGdriss echanchniNo ratings yet

- Advanced Water Distribution Modeling and Management: AuthorsDocument14 pagesAdvanced Water Distribution Modeling and Management: AuthorsJalijashNo ratings yet

- En Power Master IIIDocument4 pagesEn Power Master IIIdarwin100% (1)

- QCDD 1.1 Basic Requirements Rev ADocument4 pagesQCDD 1.1 Basic Requirements Rev ADinesh GuptaNo ratings yet

- Graco Autolube Mode 12Document2 pagesGraco Autolube Mode 12Riyan AditiaNo ratings yet