Professional Documents

Culture Documents

4L80E Trans Info in Bently Info

4L80E Trans Info in Bently Info

Uploaded by

Jose Garcia0 ratings0% found this document useful (0 votes)

346 views23 pagesCode information for Spirit/Spur cars.With scan tool and without on pre OBD2 cars.

Original Title

4L80E Trans Info in Bently info

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCode information for Spirit/Spur cars.With scan tool and without on pre OBD2 cars.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

346 views23 pages4L80E Trans Info in Bently Info

4L80E Trans Info in Bently Info

Uploaded by

Jose GarciaCode information for Spirit/Spur cars.With scan tool and without on pre OBD2 cars.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 23

Section T4

Automatic tran:

Introduction

‘Two versions of the new tors

Hydramatic 4L80-E four speed electronically

Controlled automatic transmission are fitted to

Rolls-Royce and Bentley motor cars.

Transmission for naturally aspirated cars

All naturally aspirated motor cars are fitted with the

Rolls-Royce Part No: UE 73284, GM Part No:

(8661771, Code: RAP.

Transmission for turbocharged cars

Turbocharged motor cars are fitted withthe Rolls-

Royce Part No: UE 73285, GM Part No: 8661772,

Code: RBP.

‘These units are not interchangeable between

marques and cannot be fitted to earlier motor cars.

ion (General Motors Hydramatic

torque converter clutch, which mechanically locks

Up the torque converter in fourth gear to optimise

{uel consumption, the principal feature of the new

transmission is the use of an electronic control

‘system in place of the mechanically complex

governor and modulator systems fitted of automatic

transmission units fitted to motor cars prior to

VIN 40000.

The use of electronic controls provides

extremely smooth and precise changes. Indeed

‘some gearchanges are only noticeable by watching

the reaction of a tachometer.

At the same time electronic controls optimise

{uel efficiency and emission control according to

Selected prevailing engine and driving parameters.

Fig. 74-1 Automatic transmission (General Motors Hydramatic 4L80-£)

rn

hh v9 bh tere, cb on bnDS Thans

é. i N¢e Section 4: Electronic Transmission Diagno:

tegenctics a 17n— (VEO Gt Laren se

Tis, PCM/TCM constantly monitors most of the inputs and outputs used for transmission contol Within the software

Conan ofthe PCM/TCM each inpuvoutput is assigned a specific tolerance or wineow fox proper operation. The

CEMITCM constantly monitors the inputs/outputs and compares their values tothe windows roe inpuvoutput goes

Tou © tht sPeciic window and other specific requirements are met, a mallunction cose wil be cer by the PCM/

TCM.

Gy'xenly total of 19 codes relate to the transmission control system. Access to maltunction codes can be attained

by two methods: manually and with a scan tool

NOTE: Reter to Figure 4-8 (pg. 4-8) for proper diagnostic steps.

Code Index

Code Number Description Actions

14 Engine Temp High PCM/TCM substitutes default temp of

90°C (195°F) and TCC applies when

engine is cold

18 Engine Temp Low Same as 14

a1 TPS Voltage High Maximum Line Pressure

Harsh/Firm Shifts

Fixed Shift Points

4th Gear Inhibited

TCC Inhibited

22 TPS Voltage Low ‘Same as 21

24 Output Speed Low Maximum Line Pressure

2nd Gear Operation Only

28 PSM Invalid Combination High Line Pressure

4th Gear Inhibited

TCC Inhibited

“33, BARO High

04 BARO Low

‘37 Brake Switch Stuck ON

“38 Brake Switch Stuck OFF

39 TCC Stuck OFF None

53 System Voltage High 2nd Gear Only

Maximum Line Pressure

TCC Inhibited

SS

Section 4: Electronic Transmission Diagnosis

a

Code Index (Cont'd)

Code Number ‘Description

58 ‘Transmission Temp High

59

“69

”

"72

73

74

75

7

79

at

82

83

85

86

87

"89

1991 model year.

42

‘Transmission Temp Low

Overdrive Ratio Incorrect,

TCC Stuck ON

Engine Speed Low

Output Speed Low

Force Motor Current Incorrect

Input Speed Low

System Voltage Low

Mode Select Switch

Transmission Hot

QDM Fault, B Solenoid

‘QDM Fault, A Solenoid

QM Fault, TCC

Undefined Ratio

Solenoid B, Stuck ON

Solenoid B, Stuck OFF

Ls

‘Actions

Substitutes Default Temp of

130°C (265°F).

Harsh Shifts

TCC in 2nd, 3rd and 4th

Substitutes Defauit Temp of

190°C (265°F)

Harsh Shifts

TCC in 2nd, 3rd and 4th

High Line Pressure

4th Gear Inhibited

TCC Inhibited

Maximum Line Pressure

Maximum Une Pressure ud

2nd Gear Only

TCC Inhibited

Maximum Line Pressure

2nd Gear Only

TCC Inhibited

2nd and 3rd Gears Only or

‘st and 4th Gears Only

None

Maximum Line Pressure ‘

Actions Inhibited

Actions Inhibited

Maximum Adaptive Learning and Long Shift

Codes have been masked. These codes are not available for scan or manual diagnostics for the

uJ

Section 4: Electronic Transmission Diagnosis

Manual Method (Diagnostic

Circuit Check)

To manually access information codes, locate the ALDL

connector (Figure 4-1), This connector contains 12

Cavities and is located on the driver's side of the vehicle

at the base of the dash assembly. Code Display may be

accessed as follows:

Install a jumper across ALDL terminals A and B.

Turn ignition to RUN position.

Note “Service Engine Soon” or “TRANS? lights

The sequence begins with the light flashing three

Code 12s, which indicates the PCW/TCM is

capable of diagnostics.

5. Following Code 12 displays, each stored code will

be displayed three times in numeric order from

lowest to highest.

6. When all codes have been displayed, Code 12 will

again begin to flash, this indicates the end of Code

Display.

7. As long as jumper is installed Code Display will

Continue to repeat.

equipment allows for a more thorough and timely ap-

roach to diagnosis. The GMP6 controller being used

with the 4L.80-E is a bidirectional, high-speed (8192

Baud) computer. When scan equipment is attached to

the ALDL, the PCM/TCM will communicate with the scan

equipment as well as allow the scan equipment to

‘communicate with it. This bidirectional ability allows you

{0 not only monitor input/output information and maifunc-

tion codes, but also affords you the opportunity to act as

{an override to the PCM/TCM to control specific output

Operations. Scan equipment will communicate with the

PCM/TCM on the ‘serial data’ line (Pin M) of the ALDL

connector.

TECH 1

Note: TECH 1 information given here is brief and subject

to change. More complete and accurate instructions are

Provided with the transmission diagnosis cartridge itselt.

The cartridge name is the Hydra-Matic 88-91 Transmis-

sion Cartridge. It covers all automatic transmissions

through the years 88-91 that interface with an ECM,

PCM or TOM.

NOTE: Attempting to use the Hydra-Matic

transmission cartridge to clear non-trans-

mission related codes or the ECM Plus

Cartridge to clear transmission only related

codes may not be successful.

‘TERMINAL IDENTIFICATION

GROUND TC.C. (IF USED)

DiAGNosric TERMINAL | G | FUEL PUMP (Ck)

JA.LR. (IF USED) BRAKE SENSE

SPEED INPUT (Ck)

‘SERIAL DATA

(SEE SPECIAL TooLs)

Figure 4-1, ALDL Connector

Scan Tools

The proper scan equipment for diagnosis of the 4L.80-E is

ther the Tech 1 or the T-100. Diagnosis with scan

ATTACHING THE TECH 1

1. Make sure the vehicle ignition is off!

2. Insert the Hydra-Matic 88-91 Transmission Car-

tridge into the Master Cartridge Slot on the bottom

of the TECH 1. Verify that no other "Master"

Cartridge is installed in the auxiliary slot at the top

of TECH 1

3. Connect the ALDL Cable to the top of the TECH 1

and tighten the screws,

4. Insert the TECH 1 power plug into the cigarette

lighter and the Power-Up display will be visible on

the TECH 1 screen

{tthe Power-Up display is correct, continue to Step

5. anything other than the Power-Up display

appears, or the screen is blank, go to Step 6

5. Turn the Ignition ON and you are ready to proceed

with selecting the model year and transmission,

43

Section 4: Electronic Transmission Diagnosis

6. Ifthe TECH 1 screen remains blank, DO NOT The TECH 1, equipped with the Hydra-Matic 88-91

CONNECT THE TECH 1 CABLE TO THE Transmission Cartridge, displays the following menu

TECHS TES ALOL CONNECTOR. Damage tothe when connected fo the ALDL ofa vetiole equipped with a

TECH 1 could result. Do the steps which follow: 4L80-E or 4L80-E/HD transmission (Figure 4-3).

‘Make sure that both the TECH 1 power plug

and cigarette lighter socket have good, clean

contacts. Cua

Verity thatthe cigarette lighter has good

fuse Stop the menu apy tom eying

©. Check that +12V power is present atthe

‘center contact of the lighter socket, and that Goto next page of menu,

the outside contacto he lghtr socket is Daraust

arounded. I the ighter socket has reverse

Polarity, either rewire the lighter socket or use Sarr Tests,

albattery adapter cable to power the TECH 1 tere

't the display is still not correct, Appendix B of F2 Engagements

the handbook provided with the cartidge lets euemeen

possible causes and remedies. I the problem invents Sew

Continues, go to the TECH 1 operator's

manual and perform the TECH 1 Selt-Test eee

Procedure. Fi Fast Data

i ise rests

Using the TECH 1 “=.

pert he TECH 1 by pressing buttons as shown in ne ecenesiee

‘Gute 4-2 to choose the desired response or operation, FP Sin Sa

F2 Shit’ Sol 8

FS Gear Shit

F6_ Force Motor

F1__ Performance Test (N/A)

Eee

Return to vehicle selection,

Answer questions asked by the TECH 1

‘and scroll through data parameters.

Return to previous step.

Figure 4-3, Main Menu

Used to control data display or to turn

‘outputs ON or OFF.

Numeric keys (KOI ~ EJ): used for FO — Data List

‘entering trouble code designations or

Program proper vehicle yeor This function enables the user to view PCM/TCM inputs

and outputs coming to or from the transmission and its i!

Funetion keys (GEI-GEI): used to

select rom functions displayed on 8 ee t

PCM

Used at end of a numeric key sequence

9¢ 10 inform TECH 1 that a requested AA representative data lst (printout) for a PCM (gas

een a emcaene engine) is shown in Figure 4-4

, General TECH 1 Key Functions

44

Section 4: Electronic Transmission Diagnosis

ee

TECH 1 DATA LIST

1. INPUT SPEED

2. OUTPUT SPEED

3. ENGINE SPEED

|. INPUT SPEED

oRPM

oRPM

RPM

RPM

1/21 3 RNG ON ON ON

PRNDL SWITCH

CURRENT GEAR

SOLA SOL B

DES. FORCE MOTOR

1. ACT. FORCE MOTOR

DRIVE 2

2

OFF OFF

8.00 AMPS

00 AMPS

BRAKE SWITCH OFF

‘SYSTEM VOLTAGE 122

1. COOLANT TEMP 28°C

|. TRANS TEMP 25°C

THROTTLE ANGLE o%

3. THROT POSITION 66 V

Tec DUTY CYCLE 0%

. TCC SLIP oRPM

1-2 SHIFT TIME SEC

2-9 SHIFT TIME SEC

. TRANS GEAR RATIO 08

TURBINE SPEED

Figure 4-4, PCM Data List

FO is a read data function only. It displays transmission

related data in preselected pairs. Data is updated at

200ms intervals. Scrolling is done with the "Yes" and

“No” keys. Items not in sequence can be custom paired

by locking one item at the top with the FO key and

Scrolling the rest of the display up. If desired, items may

‘be custom paired by locking one item at the bottom with

the F'1 key and scrolling the rest of the display down,

TCM

‘Some test features are not available on vehicles which

use a TCM:

1. Mode F1 Engagement tests cannot be run.

2. Coolant Temp is N/A.

3. Some data list items may read N/A.

‘A representative data list for a TCM (diesel) is shown in

g ”“ Figure 4-5.

TECH 1 DATA LIST

1. INPUT SPEED

2. OUTPUT SPEED

3. ENGINE SPEED oRPM

4. INPUT SPEED ORPM

5 1/2) 3 RNG ON ON ON

6. PRNDL SWITCH DRIVE 2

7. CURRENT GEAR

8 SOLA SOLB

9. DES. FORCE MOTOR

10. ACT. FORCE MOTOR

11, BRAKE SWITCH

12. SYSTEM VOLTAGE

13. COOLANT TEMP

14, TRANS TEMP

15. THROTTLE ANGLE

16. THROT POSITION

17. TCC DUTY CYCLE

18. TCC SLIP

19. 1-2 SHIFT TIME,

20. 2-3 SHIFT TIME

21. TRANS GEAR RATIO

22. TURBINE SPEED

oRPM

oRPM

Figure 4-5, TCM Data List

F1 — Shift Tests

FO — Shift Points — This function monitors and stores

engine and transmission data while a vehicle is driven

through all shift points. Based on RPM drop and TCC

‘command by the PCM/TCM, TECH 1 will recognize

each shift, calculate shift time and end the test when

‘commanded.

Engine speed, transmission output speed, TPS, TCC and

Gear are displayed, as well as printed.

F1 — TCC Test— This function resembles the shift point

test, however, TECH 1 only recognizes the TCC apply

signal. The shift time determination begins at the apply

‘command and is based on TCC Slip (RPM Drop). If TCC

fails to mechanically apply, a "NO TCC APPLY” message

willbe displayed.

TCC slip RPM, output speed (TOSS), TPS, TCC and

coolant temp are displayed as well as printed.

Section 4: Electronic Transmission Diagnosis

—_—.

F2— Engagements — This function monitors and stores,

data when the vehicle is shifted out of Park or Neutral

into a drive gear. The engagement time calculation is

started with the change in the P/N switch state and is

based on RPM drop.

PRNDL, RPM, output speed, TPS and coolant temp are.

displayed as well as printed.

F2 — Trouble Codes

On command, TECH 1 is able to display codes stored by

the PCM/TCM. Codes are identified as either Current

(C) or History (H). Codes are displayed one at a time

and scrolled automatically. Codes may be cleared while

in this mode by pressing the ENTER key following the

‘command “CLEAR CODES.”

NOTICE: A Current Code is a code which

is present all the time. To check if your

code is current, erase the codes and

operate the vehicle. If the same code

returns, the code is classified as a current

code. If the code no longer returns after

operating the vehicle within the param-

eters needed to set the code, the code

which was stored is classified as a History

Code.

Current (or “Hard") codes indicate a present fault; History

Codes indicate a fault which existed at one time, but is

not now in effect.

When dealing with certain History Codes, default actions,

as described in earlier chapters, may still be evident.

These defaults can exist if the vehicle has not yet

reached or encountered a “Valid Condition,” or same set

Of conditions for which the PCM/TCM tests for that fault.

F3 — Snapshot

‘The SNAPSHOT function allows for capturing on com-

mand a block of data and then replaying it. The SNAP-

‘SHOT can be taken anytime as an aid to detailed

examination of a given fault

Two modes of operation are possible: FO — Slow Data

and F1 — Fast Data.

46

FO — Slow Data — This mode captures data similar to

the DATA LIST mode. A sample of al items is made at

the normal rate of 200ms intervals. Selections are

offered which enable the operator to either trigger the

‘sample manually with the ENTER key, or automatically,

{as conditions occur which cause a given malfunction

code(s) to set

F1 — Fast Data — This mode captures data 20 times per

‘second. At this speed the sample is limited to certain

items. These include engine RPM, transmission output

speed, TPS and gear. The trigger is manual only, using

the ENTER key. It can be pressed up to seven (7) times

to mark points in time over the course of the SNAPSHOT

test.

Replay and printout of the SNAPSHOT are available in

either mode. A sample printout is shown in Figure 4-6.

SLOW DATA MODE

|

SINGLE CODE

!

= _KEY PRESS

| SLOW DATA MODE

Fé= REPLAY DATA =|

I I

VIEW STORED DATA

| 4: FIRST SAMPLE |

| F5= TRIGGER PT I

LAST SAMPLE

| THROTTLE ANGLE 42%

THROTTLE POSITION 2.2v |

|

|

| Teppurveveus sem |

TCC SLIP RPM 17 j

I

eee eee |

Figure 4-6, SNAPSHOT of 4L.80-E

Section 4: Electro:

Transmission Diagnosis

FULL VISUAL

INSPECTION

ROAD Test f POSSIBLE)

DiacNosTic

CIRCUIT CHECK

(WITH TECH 1)

OR MANUALLY

SES LIGHT SOLID Cove is ‘SYMPTOM WITH

OR NOT PRESENT NO CODE

FUNCTIONING | |

| FOLLOW ‘SEE 3 COLUMN

REFER TO DIAGNosTics DiAGNosTics

SECTION 7Aa4 IN SECTION 7Aa4 SECTION 7

HISTORY

CODE

CURRENT

CODE

FOLLOW CODE

‘CHART

‘TROUBLE TREE

CHECK WIRES

AND

PIN TENSION

REPAIR

CONDITION

CLEAR CODES

|

ROAD Test

VEHICLE

Figure 4-8, Diagnosis Tree Chart

NOTICE: PCM/TCM codes may be cleared

by using one of the following methods:

1. Disconnect the battery.

2. Use Tech 1 or T-100 to clear the codes.

3. Cycle the ignition key at least 50 times.

NOTICE: Do not use the code Trouble Tree

Procedures to diagnose History Faults.

History Codes are usually the result of

ther than component

oor connections rat

failures.

Section 4: Electronic Transmission Diagnosis

ee Ee

F4 — Misc Tests

FO — Output Tests — This enables the user to override

certain key PCM/TCM outputs. Currently, the following

options are available (Figure 4-7):

F4—TCC PWM SOL

This option gives the user abilty to toggle the TCC

ON or OFF, overriding commands from the PCM/

TCM. This function will “Time Out" after a certain

period allowing the PCM/TCM to resume control of

Tce.

F5— Gear Control

Selecting either solenoid for manual control auto-

matically disables the other. Consequently, the

‘transmission will operate only in gears called for by

‘combinations having one or both solenoids OFF,

‘not those requiring both solenoids be ON.

F1— Shift Solenoid “A” — This option gives

the user control of Solenoid A," overriding

commands from the PCM/TCM. Use the UP

and DOWN arrows to switch the solenoid On

and OFF.

F2— Shift Solenoid “B" — This option gives

the user control of Solenoid “B," overriding

‘commands from the PCM/TCM. Use the UP

and DOWN arrows to switch the solenoid ON

and OFF.

F3.— Gear Shifts — This option enables the

User to select any forward gear, overriding the

PCM/TCM command. This function does not

“Time Out,” as does the TCC function, but

gear override operation is limited. See the

TECH 1 Cartridge Manual for specific imita-

tions

F6 — Force Motor — This option enables the user

to control desired Force Motor amperage up or

down. Amperage reads directly and operates

within the range of 0.5 to 1.0 amps.

All Output Tests, with the exception of the Force

Motor Test, can be run while driving the vehicle or

‘operating it on a hoist. The Force Motor Test can

‘only be run with the vehicle idling in Park.

| QUTRUT opTions

Fis SHIFT SOL A |

| Fee SHIFT SOLB |

F32 GEAR SHIFTS

‘OUTPUT OPTIONS

| Fa= TCC PWM SOL

| F5= GEAR CONTROL |

Fé= FORCE MOTOR

Figure 4-7, MISC TESTS Menu

F1 — Performance Test — TECH 1 is currently unable to

give Performance Tests with the 4L80-E because 4L80-E

shift points are determined not from mph but transmis-

sion output speed.

47

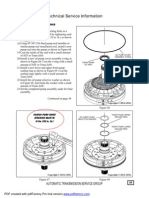

Fig. 74-2 Automatic transmission (General Motors Hydramatic 4L80-E) main components

1 Torque converter

2 Torque converter clutch

3. Oil pump

4 Epicyclic gear train

‘The General Motors Hydramatic 4L80-E automatic

transmission comprises two main elements, a

torque converter (see fig. T4-2, item 1) and an

epicyclic gear train (see fig. T4-2, item 2).

The epicyciic gear train consists of three

planetary gearsets which provide four forward and

one reverse gear ratio,

First == 2.48:1

Second - 1.48:1

Third == 1.00:1

Fourth - 0.75:

Reverse - 2.08:1

‘The torque converter is a fluid coupling which

transfers engine torque to the transmission

‘smoothly and at the same time provides torque

multiplication of up to 2.2 times the input torque

when required.

The torque converter fitted to the Hydramatic

4L80-E transmission incorporates a torque

5 Clutch assembly

6 Brake band assembly

7 Control valve block assembly

8 Gear change actuator

converter clutch which locks up the torque

converter when required to provide a direct drive

from the engine to the transmission.

Selection of the required gear ratios is

achieved by the hydraulic engagement of

‘appropriate clutch assemblies and/or brake bands,

the operation of which is controlled by valves

contained in the control valve block assembly. The

Control valves respond to inputs from the gear

change actuator and an electronic control system,

Hydraulic pressure for the torque converter

‘and control system is produced the transmission’s

oil pump. The hydraulic system includes a heat

exchanger located in the bottom half of the radiator

matrix.

face Bor 1h:

Driver's control of the General Motors Hydramatic

4L80-E automatic transmission is provided by a

conventional Rolls-Royce gear range selector lever

‘which controls the operation of the gear change

actuator to select the required gear range.

Selection of the appropriate gear ratio within

the chosen gear range is achieved automatically by

the valves in the control vaive block assembly

which react to inputs from the control system's

electronic control unit, the powertrain control

‘module transmission (PCMT) which responds to:

driver's inputs from:

* a full throttle kickdown function derived

from operation of the accelerator pedal

+ a’Manual mode’ selection switch (all

Rolls-Royce and Bentley motor cars)

+ a ‘Sport mode’ selection switch (Bentley

turbocharged motor cars only);

‘engine inputs from:

* a throttle position sensor

+ a boost pressure sensor (Bentley

turbocharged motor cars only)

+ _an engine speed sensor;

transmission inputs from:

+ a transmission input shaft speed sensor

+ a transmission output shaft speed

sensor

+ apressure switch manifold

+ _atransmission temperature sensor;

and inputs from:

* an air conditioning compressor clutch

signal

+ barometric pressure sensor

+ the brake switch

The electronic control system optimises the

ratio selected, upshift and downshift patterns and

feel according to prevailing operating conditions

and diver selected modes of operation.

The system incorporates intelligent adaptive

‘selfearning functions which account for operation

at high altitude and wear of the transmission

‘components.

The electronic control system incorporates a

fail-safe limp home mode which automatically

selects second gear in the event the electronic

‘system being disabled. At the same time, a self-

diagnostic function continually monitors the

operation of the automatic transmission’s electrical

and electronic control components and compares

their operation against specific acceptable

‘operating criteria, thereby recognising the presence

of faults which may cause the transmission to

‘malfunction. it records the presence of any such

faults in the form of fault codes each comprising

two digits. The fault codes can be retrieved by

technicians to assist with fault diagnosis.

area

1 uogeede eu swos pu serosa

» ard

[A6E Se Neo 7 Se

i

ST

dee

SR Rpt Car Lane 8d

14-5

pace 6 OF

—_

Powertrain Control Module

Transmission (PCMT)

The Powertrain Control Module - Transmission

(PCMT) is located next to the steering column (see

fig. T4-5),

The same PCMT is used for all motor cars,

‘naturally aspirated and turbocharged.

Configuration is achieved by a set of

parameter coding connections taped into the wiring

loom to the PCMT.

Parameter coding connections

(See fig. T4-5, item 1)

The coding connections consist of three wires

a black wire, a blue orange wire and a white

orange wire.

‘The correct parameter coding combinations

are:

Turbocharged engines with catalyst

Blue orange connected to the black

Turbocharged engines without catalyst

Black disconnected.

Naturally aspirated engines with catalyst

Blue orange and white orange connected to

the black.

Naturally aspirater' ~-~ines without catalyst

White orange connected to the black.

Important tis most important that the PMT is

Configured correctly for the motor car.

Gearchanges on turbocharged

‘motor cars occur at higher road speeds

and clutch and band engagements are

firmer to control the increased torque

‘output from the turbocharged engine.

a PCMT, fitted to a turbocharged

‘motor car, is Configured as a naturally

aspirated unit, increased clutch slip will

cause damage to the transmission.

@ sweat €t

‘AoizeinensrT

Fig. T4-5 Powertrain control module -

Transmission (PCMT)

1 Parameter coding connections

M

2 me

D0 snetnewad, &

2 StUs2019 SNOT 8 ‘

Yeoubensy eruaema vis mesey@ towne fepe* T

rosneg Rolisag eteNAT

Section T6

pee

oar

om

Transmission operating characteristics

Introduction

The incorporation of electronic controls on the

4L.80-E automatic transmission optimise gear ratio

Selection and gearchange point selection to

achieve maximum fuel efficiency and emission

Control according to designated engine and driving

Parameters. At the same time, they provide

‘extremely smooth and precise gearchanges.

!n addition to the conventional park (P),

reverse (R) and neutral (N) gear ranges, the

driver's controls of the 4L.80-E automatic

transmission provide three separate forward drive

ranges, D, 3, and 2 of the four available gear ratios

and torque converter clutch engagement as

follows:

D- 1st, 2nd, 3rd, 4th and torque

converter clutch engaged.

3 - 1st, 2nd and 3rd.

2 - 1stand 2nd,

Dependant on marque and model, these

ranges are enhanced by the availability of two (on

on-turbocharged motor cars) or three (on

turbocharged motor cars) driver selectable

‘operating modes, normal, manual and sport

(turbocharged motor cars only) available on each

‘gear range selection.

Normal mode provides a standard set of

characteristics appropriate to driving on normal

‘oad surfaces under normal weather and driving

‘conditions.

Manual mode minimises the torque

transmitted to the wheels by inhibiting first gear

Operation and changing up at low road speeds to

provide a set of operating characteristics suitable

{or driving in adverse weather conditions where

oor tyre adhesion prevails, such as on snow, ice

oF loose surfaces.

Sport mode, which is available on

turbocharged motor cars only, provides a set of

characteristics which make the transmission more

responsive under transient conditions.

Fig. T6-1 summarises the gear ratios

available for each driver selectable gear range and

mode option.

Inall cases the PCMT selects and times the

Lupchanges and downchanges according to pre-

Programmed maps which define gearchange points

according to selected gear range, selected

operating mode, prevailing throttle position, engine

speed and road speed.

Fig. 6-1 4L80E Gear ratios available for each

‘gear range and mode option

Gearchanges on turbocharged motor cars

Occur at higher road speeds than their equivalent

Gearchanges on non-turbocharged motor cars.

Printed in England

TS0 5230

—_

Position D - Drive

Normal mode

When the gear range selector lever is in position D

(Drive) with Normal mode selected, all four forward

Gear ratios, 1st, 2nd, 3rd and 4th, and torque

‘converter clutch engagement are available.

The transmission automatically selects the

‘most appropriate forward gear, first, second, third

or fourth according to prevailing operating

conditions.

Manual mode

‘When the gear range selector lever is in position D

(Drive) with the Manual mode selected, 2nd, 3rd

‘and 4th gear ratios, and torque converter clutch

‘engagement only are available.

Upchanges occur at lower road speeds than

those achieved when Normal mode is selected.

Sport mode (Turbocharged motor cars only)

When the gear range selector lever is in position D

(Drive) with the Sport mode selected, all four

forward gear ratios, 1st, 2nd, 3rd and 4th, and

torque converter clutch engagement are available.

Upchanges occur at higher road speeds than

those achieved when Normal mode is selected,

Position 3 - Third

Normal mode

‘When the gear range selector lever is in position 3

(Third) with Normal mode selected, 1st, 2nd and

3rd gear ratios only are available.

Gearchanges occur at higher road speeds

than when D is selected, providing quicker

acceleration characteristics.

Caution Do not select the third range position

(3) at speeds above:

* 105 milesshour (170 km/hr) on

naturally aspirated motor cars and

Bentley Continental R motor cars,

+120 miles/nour (193 km/hr) on

Bentley Turbo R motor cars,

as the transmission is not able to

change up to top gear.

Manual mode

When the gear range selector lever is in position 3

(Third) with the Manual mode selected, 2nd and

3rd gear ratios only are available.

Upchanges ocour at lower road speeds than

those achieved when Normal mode is selected.

fur 8 0%

1)

Sport mode (Turbocharged motor cars only)

‘When the gear range selector lever is in position 3

(Third) with the Sport mode selected, 1st, 2nd and

8rd gear ratios only are available.

Upchanges occur at higher road speeds than

those achieved when Normal mode is selected.

Position 2 - Second

Normal mode

When the gear range selector lever is in position 2

(Second) with Normal mode selected, 1st and 2nd

‘gear ratios only are available.

Gearchanges ocour at higher road speeds

than when D is selected, providing quicker

acceleration characteristics.

Caution Do not select the second range position

at speeds above:

+ 70 miles/hour (113 km/hr) on

‘naturally aspirated motor cars and

Bentley Continental R motor cars,

+ 80 milesshour (128 km/hr) on

Bentley Turbo R motor cars,

as the transmission is not able to

change up to top gear.

Sport mode (Turbocharged motor cars only)

‘When the gear range selector lever is in position 2

(Second) with the Sport mode selected, ist and

2nd gear ratios only are available.

‘The 1st - 2nd upchange occurs at a higher

‘oad speed than the gearchange achieved when

Normal mode is selected.

Okmse wre Wiad

Quo BF Pte 5 5 r000

Saou cement sone:

oh TWpoe conv

Ten

oa

Section T10

pre

to BF

IS

Automatic transmission service procedures

Transmission fluid check

(See fig. T10-1)

Transmission fluid checks have made easier by

repositioning the filer tube. It is no longer

necessary to remove the protective cover from the

windscreen wiper mechanism when checking the

transmission fluid level.

To check the transmission fluid level correctly,

ark the car on a level surface and chock the

wheels.

1. Start and run the engine in Park for 3 to 4

‘minutes to allow it to reach normal operating

temperature and normal idle speed.

2. While the engine is warming up, clean the top

of the dipstick.

3. Now sit in the driver's seat and firmly apply

the footbrake and move the gear selector to each

of the gear range positions in turn, pausing briefly

{at each selector position. This ensures that all the

“hydraulic circuits are correctly filled with fluid,

Warning _Itis most important to keep the

footbrake applied throughout this

operation as the parking brake will

release automatically as soon as the

‘gear range selector is moved to a gear

Position.

4. Return the gear selector to the park position

and re-apply the parking brake.

5. Release the footbrake.

6. Then withdraw the dipstick from the filler tube

and check the fluid level, while the engine is stil

idling

lt should be between the two circular dot

‘marks which represent the cold check level (See

fig. T10-2, A).

7. _ Next drive the car to warm up the

transmission. This will equire a journey of about 15

miles (24 kilometres) open road driving or 10 miles

(16 kilometres) driving in town.

8. Then repeat the complete transmission fluid

level check

This time the level should be in the

crosshatched area which represents the hot check

level (See fig. T10-2, B)

9. _ Ifthe level is incorrect, top up with the fluid

Specified in the appropriate workshop manual. Do

Not overfill the transmission.

Fig. T10-1 Automatic transmission fluid

dipstick

Fig. 710-2 Automatic transmission fluid

dipstick level markings

A Cold check level

B Hot check level

[4

© OFT 7

Minimum throttle

fs

ies

Tec

Full throttle to kickdown

BITE site

Normal

10 milem 16 kmh

20 mile 32 km/h

26 miler 42 kv

50 mile 80 krvh

32 mile 51 kmh

‘56 milerh 90 krvh

83 mile 134 kmvh

118 mile 185 kmvh

41 mileyh 68 kr

7Omileh — 113 kmvh

105 mile/h 170 krvh

115 mile 185 km/h

Sport

Not available

Not

lable

Not available

Not available

Not available

Not available

Not avaitable

Not available

Not available

Not available

Not avaiiable

Not available

Manual

Not available

30mileh 16 kmh

30 mileth 48 krvh

‘50 mile 80 kmh

Not available

20mileh 32 kmh

45 mile 72 krvh

70 mile — 113 km/h

41 mileh 66 kmvh

70 mileh 113 kmh

405 miley 170 krvh

41145 milem 185 krvh

Fig. 76-2 4L60E Gearchange speeds- range D, All non- turbocharged motor cars

Minimum throttle

Full throttle to kickdown

1-2

23

a4

Tec

Kickdown

2

3

a4

Tec

Normal

12mileh — 19 kv

20mileh — 32 km/n

30 mile — 48 kmh

45 mileh 72 km/h

40 mile — 64 km

70 mileh — 113 kmh

85 mile 197 kv

325 mileh 201 kmvh

45mileh 72 km/h

80 miley 128 km/h

120 mile 193 kmvh

125 mile — 201 kmvh

Sport

12mileh 19 kmvh

20 mileh — 32 km/h

30 mile 48 kmvh

45 mile — 72 kmh

45mileh —72km/h

78 mileth 126 km/h

109 mileh 175 kmvh

125 mileh 201 km/h

45 mile 72 kmvhy

80 mileh 128 kmvh

120 mile 193 km/n

125 mile 201 km/h

Manual

Not available

10milem — 16 krvh

30mileh 48 kn

‘50 milerh 80 krvh

Not available

20 miler 32 krvh

45 miley 72 kmvh

7Omieh —113km/h

45 mileyh 72 krvh

80 mile 128 kmvh

120 milem 193 km/h

125 mile 201 kmh

Fig. T6-3 4L80E Gearchange speeds- range D, Bentley Turbo R motor cars

[_ Normal ‘Sport ‘Manual

Minimum throtio

1-2 11 mien —18kmh 41 mlm 18kmh Not avaiable

2-3 1emlom —254ewh —1@mlem 29mm “Oren 16 kmm

3-4 27 mioh 43kmh 27 mln Ahm ~—«dmlem AER

Tec S0mlem —sOkmm © SOmilom eDAmm —SOmiom SAT

Full throttle to kickdown

1-2 37 miem —6oKmn G4kmm Not avaliable

2-3 Simm — SBkmn taBkmvy—20miem Sekmh

3-4 75miem —i2thmh 1S4kmm 45 mlem—7ekmh

Tec Omiem 17kmm —110miom 177kmm — 2m ToDo

Kickdown

1-2 4omiom —Sekmm —4omiloh—6&kmh AO mom Bb mm

23 7omiom 113mm © 70mlem—t1Shmm omen SaaS

34 110mm 177kmh 110 mlem 177k ~— Nomen SKIN

Toc 125mlem 20tkmm —_425mleh 20tkmm — t28mlom sor ken

Fig. T6-4 4L80E Gearchange speeds- range D, Bentley Continental R motor cars

ose

Printed in Enaland

TS0 5230,

Section T11

fe

Automatic transmission fault codes

Introduction

‘The PCMT continually monitors the Operation and

Performance of the automatic transmission, its

electrical and electronic control systems and their

‘components and compares their operation and

performance against specific acceptable criteria,

thereby recognising the occurrence of faults which

may Cause the transmission to malfunction. It

records the occurrence of any such faults in the

form of fault codes in a memory unction used

‘specifically for this purpose. Each fault code

comprises two digits. The fault codes can be

retrieved by technicians to assist with fault

diagnosis. Fault codes can be retrieved from the

PCMT either by using the Mastercheck diagnostic

test equipment RH 12600 or by a manual method

similar to the retrieval of fault codes from the

PCME (K-Motronic engine management system

electronic control unit).

Note The PCMT checks the validity of any fault

Code it registers by checking whether or not

the condition which generated the code

originally is repeated during the following 50

ignition switch on-off cycles. If the fault is not

repeated, the PCMT then erases the code.

‘When investigating a reported

transmission fault, always check the PCMT

for fault codes before carrying out any other

‘work to avoid the possibilty of erasing any

registered fault codes by switching the

ignition on and off when checking the motor

car.

Ve OF AS

7805230

£m

Manual retrieval and deletion of PCMT

fault codes

‘The fault codes can be retrieved and deleted

‘manually in a similar manner to the retrieval and

erasure of K-Motronic diagnostic codes on motor

cars from VIN 30001.

trip odometer and warning panel

TRIP and CANCEL control buttons simultaneously

{and hold them for 8 seconds until the driver's

information and warming panel enters the

diagnostic mode.

This is indicated by the trip-odometer display

‘showing the unit's serial number for two seconds

followed by the option select display of vertical

characters.

2. _ Press the combined K-Motronic Transmission

diagnostic switch on the fuseboard downwards for

at least a second to instruct the PCMT to deliver

blink code signals to the dot matrix panel.

3. The fault codes are displayed in the form of a

sequence of blink codes, each comprising two

digits, in the form of flashes of the CHECK

GEARBOX legend in the warning panel in a similar

manner to other fault code displays.

Each flash comprises a half a second

illumination of the CHECK GEARBOX legend

followed by a halt a second extinguished panel.

The warning panel extinguishes for one

second between digits and for three seconds

between fault codes.

‘The sequence for the PCMT fault codes

always begins with the code 12 which is displayed

three times. If any fault codes are stored in the

memory, each code is displayed three times before

the next code is displayed. At the end of the

sequence code 12 is displayed again.

Fig. T11-2 shows the flashing action of the

CHECK GEARBOX legend for an example where

fault code 22 only has been recorded.

Tm

all

mit

zs =a

Fig. T11-1 Combined K-Motronic Transmission

diagnostic switch

4, _ Ifo fault codes are stored in the PCMT, code

12 will be displayed continuously.

5. _Alist of fault codes appears in the appropriate

‘section of the workshop manual and is repeated on

pages T11-4 and T11-5 of this Service Training

Data book.

Note The fault codes can also be read without

Placing the driver's information and warning

panel in the diagnostic mode.

Pressing the combined K-Motronic Transmission

diagnostic switch on the fuseboard downwards for

at least a second will cause the PCMT to display its

recorded fault codes in a series of flash codes

‘comprising half a second illumination of the

CHECK GEARBOX legend followed by half a

‘second illumination of the combined battery and oil

ccan symbol. At the same time each fault code is

‘accompanied by audible beeps corresponding to

the digits of the fault code.

Manual deletion of PCMT fault codes

To delete the PCMT fault codes, press the

combined K-Motronic/4L80E diagnostic switch on

the fuseboard downwards for at least 15 seconds.

onl t cA 1

lczaroox

xX»

2 1 rz

=»>X

Fig. T11-2 Transmission fault code sequence, fault code 22 recorded

prge (7 OF

Mastercheck diagnostic test unit

‘The new Mastercheck diagnostic test unit can be

connected to the diagnostic plug in the fuseboard

and the codes can be read and deleted using the

fault code routine provided in the automatic

transmission test card.

Procedure for retrieval and deletion of PCMT

fault codes using Mastercheck

1. Ensure that the parking brake is firmly

applied.

2. _Ensure that the gear range selector lever is in

the Park position (P).

3. Ensure that the ignition is switched off.

4. Assemble and connect the Mastercheck

diagnostic test unit to the diagnostic plug in the

fuseboard (see fig. T11-3).

5. _ Insert the transmission data card into the key

pad unit

6. _ Press button F2 to switch the Mastercheck

diagnostic test unit on.

7. _ Follow the test procedure as directed by the

Mastercheck diagnostic test unit's screen to read

the fault codes.

8. Carry out any appropriate diagnostic test

Sequence using the Mastercheck diagnostic test

unit

9. Camry out any required repairs.

10. Follow the test procedure as directed by the

Mastercheck diagnostic test unit's screen to delete

the fault codes.

Fig. 111-3 Mastercheck diagnostic test unit

ouse

oon

connected to the diagnostic plug in

the fuseboard

Keypad unit

Keypad unit to analogue interface unit

connecting harness |

Analogue interface unit |

Probe connector plug

48-way connector

‘Analogue intertace unit to 48-way

connector hares.

Data card

Printer

Probe

LE OF

fa

E [Ase

=z

ee oe) eee en oe eee

eee =

aoe

es See eee

(TP) out ara gh ‘strona and qn conve ah (TCR) oons — poaionaut outvougeraven mee See ns geng so

Trane pain ase (mae Saree Fad gece pane Cons a wit nance © Seniors ar

(eSomatson oo Stee ratome ome Such TCO sont pacer capatvhge artes. Stmeateespeecang pe

‘oan lnepessue eatin ‘Fave error anc 5 moe irene

Ceara [poe Searing see 60 mach amo) Goda Be pom Deep © Ses re sae a

SS, Eeeeceeceee Fe anor

erm pr ated orton Sedipesear iicimaseetes” —« Cosans pt tnaion et

ry r aha gnc pwr anioe Ca 0 os mame Bo PORT 7 Rasaos bag ge Dz

somn ‘Sta ach To apa ese ae toe conan t mang oun

SSrantonbemesmse manmariod © prs Tbr

a Fon uacnae a aoe ‘Code 3 cao free pea a

coen to nee soe cat ag oge at

Senora ate saa

Renee mae ae Fen aaa am Code 34 be mcd he ores 1 Fanpop wa

bs aeealad Scone sanbavetir aaa

Rea pease he ‘Womran ne pee ‘Code 35 wl oid fo et 7 aie Ra

So (nesccargecao Se Ses ep ae

a Namonapeare ote 35 wi oe coe tet 7 Saipan ma

Sone (ores Booher

a Tsun sone au TERT ‘oe 7 we case Fatwa sprals a ge Soee AT

pemarert pa scorns ‘ioc i tseen ung eta Tod

Bate teh ois Ta cone eT ‘ode 38 cad reba sr tn wn ane

pean ca Someones ‘Scene yh (Teche

Tosa ete shh “ge anda covet ose 9th TDS aa cape

(Tetipemareay OFF eR cortepece (Pe an aac 2 nna eon ach

(iezjepemon

iO Chea oe Wr aipar owy pea a Calg nt nae OT Seine passe or

pose hacked Seeca aguas

Senate Yor 2s pea apes Mn Case core ye ‘es are 9 TO

‘eto To oo oc (20) ‘Som iobvom er Sonne & Seecw geo

Srocnot ene | 2 mmo racmrroen

(ecjepwate

2 aaa he Ta sa TCE op oie a aad ra Fens gaps ra cone

ne inva Sh Hann ge ‘Seeman 0 Bey aera

eee ie Tan covete aun TOD apes Case 9 a OST ‘Eagan one ch TOD

on he an tm hang ‘Sposa ctor soc Se Sissies

T11-4

E

~~

ream ntti wen meting cane un co ny

a eeetatia

SS Sasa

eaten See | aeons

Bicones. | jenn

Sieceew caer BE

Co

RENSeio —— eee tere” | Same

Saas ee

cae Sleeao ese

Seteessne sas aes cata eetiocts —

waar capac pes

a a A SaaS

ace

Saas $e —

— Sageeeee «pane

See

Roearn pas Sa sae ans —

SSinao” | GG Aeae, 6 Senn

cones Saiaicca * RSs

cones once

Seem,

ies

eee Sareea aS

a

Sane

eS ee

isan Sonaowane” | Genera

aa caneaaaEes eter

ESasa «Sa, Se

ane SSeS

ait Siiveremsouen | ~ Seater

a es eee

= Seen eee

na RAR — SaaS

aan oS

=a ae Seas aa

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 944 Workshop ManualDocument369 pages944 Workshop ManualJose Garcia100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PDF Created With Pdffactory Pro Trial VersionDocument2 pagesPDF Created With Pdffactory Pro Trial VersionJose Garcia100% (3)

- Ford 6R60, 6R75, 6R80 NEW OEM Solenoid Kit - Alto 183570Document1 pageFord 6R60, 6R75, 6R80 NEW OEM Solenoid Kit - Alto 183570Jose GarciaNo ratings yet

- 15 Vacuum Regulator Adjustment For c4Document2 pages15 Vacuum Regulator Adjustment For c4Jose GarciaNo ratings yet

- Lube GuardDocument40 pagesLube GuardJose GarciaNo ratings yet

- 4 Front Seal Pop Out For c4Document2 pages4 Front Seal Pop Out For c4Jose GarciaNo ratings yet

- 722.7 K-1 Drum Update-1Document2 pages722.7 K-1 Drum Update-1Jose GarciaNo ratings yet

- ZOOM TechnologyDocument1 pageZOOM TechnologyJose GarciaNo ratings yet

- May/Jun 2012Document76 pagesMay/Jun 2012Rodger Bland100% (1)