Professional Documents

Culture Documents

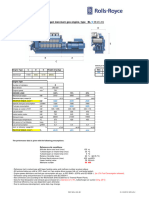

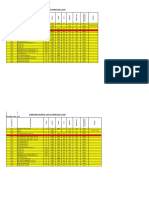

Various Unit Sizes and Main Parameters

Various Unit Sizes and Main Parameters

Uploaded by

Parmasamy SubramaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Various Unit Sizes and Main Parameters

Various Unit Sizes and Main Parameters

Uploaded by

Parmasamy SubramaniCopyright:

Available Formats

Various Unit Sizes and Main

Parameters

Main

steam

pressure

Kg/cm2

MS/RH

temperature

C

Gross Design

Efficiency %

30-50

60

482

28.2

60-100

210

LMZ

210

KWU

90

535

31.3

130

535/535

35.63

150

535/535

37.04

250

150

535/535

38.3

500

169

538/538

38.6

660

247

538/565

39.5

565/593

40.5

565/593

40.5

MW

800

247

Steam consumption approximate 3 T/hr

For 250 MW approximate = 250x3 = 750 T/hr

Minimum steam generator efficiency on GCV basis guaranteed by vendor for coal

and lignite as per CEA

= 92.5

- (50A + 630 ( M+ 9H ))

HHV

A Ash %

M Moisture %

H Hydrogen %

HHV High heating value Kcal /kg

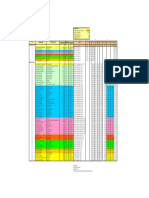

Gross Turbine Cycle Heat Rate

Unit rating ( MW

)

Heat Rate

(Kcal/Kwh) at

100% MCR

with motor

driven BFP

Heat Rate

(Kcal/Kwh) at

100% MCR with

turbine driven

BFP

50 MW to less than

100 MW

2280

100 MW to less

than 200 MW

2000

200 MW to less

than 250 MW

1970

250 MW to less

than 500 MW

500 MW and

above

Supercritical units

1955

1895

1935

1810

1850

Reference : 33 Deg.C cooling water temperature and 0% DM water make up

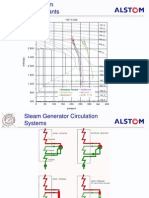

The leading producers of large power steam turbines in the world today

are European-based multinationals ALSTOM and Siemens AG; GE Power

Systems (GE) in the U.S.; Mitsubishi Heavy Industries (MHI), Hitachi and

Toshiba Corp. in Japan; Leningrad Metallic Works (LMZ) in Russia; Ansaldo

Energia in Italy; Turboatom in Ukraine; and Skoda in Czech Republic.

You might also like

- TBG 616Document4 pagesTBG 616sdiaman50% (2)

- Brochure Gas Turbine SGT-800 For Power GenerationDocument4 pagesBrochure Gas Turbine SGT-800 For Power GenerationJuan AraqueNo ratings yet

- Combined Cycle Gas TurbineDocument188 pagesCombined Cycle Gas TurbineAbbas_Makki94% (18)

- Gas Turbine30.06.09Document119 pagesGas Turbine30.06.09charzree95% (19)

- CG260 16Document8 pagesCG260 16erick_fer_b0% (2)

- Gas Turbine PerformanceDocument15 pagesGas Turbine PerformanceKevin J. Mills0% (2)

- Tbg620k 50hz enDocument4 pagesTbg620k 50hz enEhsanur RahmanNo ratings yet

- Super Critical Salient FeaturesDocument16 pagesSuper Critical Salient Featureshanumehrotra100% (1)

- Metodo Directo e IndirectoDocument15 pagesMetodo Directo e IndirectoGiovanny Enrique AltamarNo ratings yet

- History of Thermal Power PlantsDocument9 pagesHistory of Thermal Power PlantsAnonymous gr5Pr9AV100% (1)

- Apg1000 Specs 74hc595 NXPDocument7 pagesApg1000 Specs 74hc595 NXPNatgas WebmasterNo ratings yet

- MS3-ASME Gas Turbine Technologies PresentationDocument54 pagesMS3-ASME Gas Turbine Technologies PresentationVeerabhadra Rao Korimilli100% (2)

- TBG 620Document4 pagesTBG 620sdiamanNo ratings yet

- Final Ea R-Infra SummaryDocument29 pagesFinal Ea R-Infra Summaryer_sanjaypatelNo ratings yet

- Spilling Steam EnginesDocument23 pagesSpilling Steam EnginesSimEnzNo ratings yet

- KPIs of Thermal Power Plants (TPPS)Document41 pagesKPIs of Thermal Power Plants (TPPS)Naveen Chodagiri100% (3)

- Gea31744 9ha HDGT Factsheet PDFDocument2 pagesGea31744 9ha HDGT Factsheet PDFtriplbingaziNo ratings yet

- Sommer Energy 23.10.2012 PDFDocument30 pagesSommer Energy 23.10.2012 PDFojopoderosoNo ratings yet

- Gas Turbine Technologies For Electric GenerationDocument54 pagesGas Turbine Technologies For Electric GenerationFabbrox100% (5)

- RdO Power Island - Allegato E - Data Sheet MotoreDocument1 pageRdO Power Island - Allegato E - Data Sheet Motoreufficio.tecnicoNo ratings yet

- TBG616K PDFDocument4 pagesTBG616K PDFTyler GoodwinNo ratings yet

- DR ModelCBR May09Document8 pagesDR ModelCBR May09scax25No ratings yet

- FT Vitodens 300-W, 9-35kW GB 2007Document46 pagesFT Vitodens 300-W, 9-35kW GB 2007Corina RosuNo ratings yet

- Alstom Gas-Turbines-Technical-Performance PDFDocument2 pagesAlstom Gas-Turbines-Technical-Performance PDFPoull SteeadyNo ratings yet

- Final TL - CVL ComparativeDocument6 pagesFinal TL - CVL ComparativeRavi ChandarNo ratings yet

- ICES CM 2007/M:07 Design Concept For Low Energy Fishing VesselDocument8 pagesICES CM 2007/M:07 Design Concept For Low Energy Fishing VesselSaatnya TersenyumNo ratings yet

- Dados Tec - c2500Document5 pagesDados Tec - c2500Sandro MunizNo ratings yet

- Gas-Steam Turbine Technical Data 2012Document8 pagesGas-Steam Turbine Technical Data 2012Ninh Quoc Trung100% (1)

- Kawasaki Gas TurbineDocument45 pagesKawasaki Gas Turbinepramasenja100% (2)

- Brochure Gas Turbine SGT-300 For Power GenerationDocument4 pagesBrochure Gas Turbine SGT-300 For Power GenerationIvo SilvaNo ratings yet

- Turbinas de GasDocument170 pagesTurbinas de Gasjose-consuelo100% (1)

- Cooling - Tower and Boiler CalculationDocument47 pagesCooling - Tower and Boiler CalculationDavid LambertNo ratings yet

- Gas Turbine PerformancexlsDocument15 pagesGas Turbine PerformancexlsMahmood ElnagarNo ratings yet

- 7.8 Typical Cogeneration Performance ParametersDocument5 pages7.8 Typical Cogeneration Performance ParametersaizatmaricanNo ratings yet

- USC BoilerDocument31 pagesUSC Boilerscribd.123No ratings yet

- An Overview of Combined Cycle Power PlantDocument71 pagesAn Overview of Combined Cycle Power PlantDreamie Blue100% (3)

- 60 TPH Technical SheduleDocument32 pages60 TPH Technical SheduleSeenu HassanNo ratings yet

- SGT-600 GT PowerGen ENDocument4 pagesSGT-600 GT PowerGen ENBehnamayoubzadehNo ratings yet

- Generador Cumming FundadorDocument4 pagesGenerador Cumming FundadorMarcos Montiel ChableNo ratings yet

- ORC Technology For Waste Heat Recovery Power Generation: DR Vijayakumar Kunche, M.Tech., PH.DDocument45 pagesORC Technology For Waste Heat Recovery Power Generation: DR Vijayakumar Kunche, M.Tech., PH.Dandri.motoGNo ratings yet

- Energy Audit & Efficiency Improvement of Operating Power PlantsDocument56 pagesEnergy Audit & Efficiency Improvement of Operating Power Plantsmhdsoleh100% (1)

- Cat cG132: Series Gas Generator SetsDocument8 pagesCat cG132: Series Gas Generator SetsCesário GuimarãesNo ratings yet

- TSD CogenDocument5 pagesTSD CogenGaurav SushrutNo ratings yet

- Steam ConsumptionDocument4 pagesSteam ConsumptionhuahmedNo ratings yet

- 16.efficiency Management Sytems PresentationsDocument67 pages16.efficiency Management Sytems Presentationsrahul100% (1)

- Super Critical PresentationDocument46 pagesSuper Critical PresentationSam100% (1)

- IEA Workshop Copenhagen Small Scale Biomass Co-Generation With Modern Steam EnginesDocument23 pagesIEA Workshop Copenhagen Small Scale Biomass Co-Generation With Modern Steam EnginesPhong Hoang LeNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignFrom EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignNo ratings yet

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Hydrogen Production TechnologiesFrom EverandHydrogen Production TechnologiesMehmet SankirNo ratings yet

- The Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattFrom EverandThe Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Sugar Plant HR Bagasse Turbine HR 2550 Kcal/Kwhr Boiler Ef 70 %Document1 pageSugar Plant HR Bagasse Turbine HR 2550 Kcal/Kwhr Boiler Ef 70 %Parmasamy SubramaniNo ratings yet

- Grease Refill QtyDocument3 pagesGrease Refill QtyParmasamy SubramaniNo ratings yet

- Saltaion VelocityDocument2 pagesSaltaion VelocityParmasamy SubramaniNo ratings yet

- Drum Type Boiler Characteristics: Water Chemistry Is Maintained Within A BandDocument1 pageDrum Type Boiler Characteristics: Water Chemistry Is Maintained Within A BandParmasamy SubramaniNo ratings yet

- Dry Flue Gas Loss (LDG) : LDG (24 X DG X (FGT - CAT) ) ÷ HHV, WhereDocument1 pageDry Flue Gas Loss (LDG) : LDG (24 X DG X (FGT - CAT) ) ÷ HHV, WhereParmasamy SubramaniNo ratings yet

- Thomas EdisonDocument7 pagesThomas EdisonParmasamy SubramaniNo ratings yet

- The - Provide(s) The Permissives and The Interlocks Necessary For Safe OperationDocument1 pageThe - Provide(s) The Permissives and The Interlocks Necessary For Safe OperationParmasamy SubramaniNo ratings yet

- Product Overview Control Valves: SempellDocument20 pagesProduct Overview Control Valves: SempellParmasamy SubramaniNo ratings yet

- Technical Data of 60Document3 pagesTechnical Data of 60Parmasamy SubramaniNo ratings yet

- Silica BricksDocument1 pageSilica BricksParmasamy SubramaniNo ratings yet

- Steam Pressure 2200 PSI and 1000 FDocument1 pageSteam Pressure 2200 PSI and 1000 FParmasamy SubramaniNo ratings yet

- Al2O3 30.05% 30% Fe2O3 1.46% 1.50% A.P. 18 15% C.C.S 320 Kg/Cm2 50 Mpa B.D.-G/CC 2.11 g/cm3 2.14 g/cm3 RUL 1365ºC 1350ºC P.L.C - 0.71 Theraml ShockDocument1 pageAl2O3 30.05% 30% Fe2O3 1.46% 1.50% A.P. 18 15% C.C.S 320 Kg/Cm2 50 Mpa B.D.-G/CC 2.11 g/cm3 2.14 g/cm3 RUL 1365ºC 1350ºC P.L.C - 0.71 Theraml ShockParmasamy SubramaniNo ratings yet

- Alumina BricksDocument1 pageAlumina BricksParmasamy SubramaniNo ratings yet

- Back Pressure 1 PSI To 2 PSIDocument1 pageBack Pressure 1 PSI To 2 PSIParmasamy SubramaniNo ratings yet

- EFFICIENCY at 2200 Psia (152 Bar)Document1 pageEFFICIENCY at 2200 Psia (152 Bar)Parmasamy SubramaniNo ratings yet

- The World MusicDocument1 pageThe World MusicParmasamy SubramaniNo ratings yet

- Steam Pressure 2400 PSI and 1000 FDocument2 pagesSteam Pressure 2400 PSI and 1000 FParmasamy SubramaniNo ratings yet

- Chapter Two: Factors Distribution Generation andDocument15 pagesChapter Two: Factors Distribution Generation andAwol AbduNo ratings yet

- HRSGDocument36 pagesHRSGDumitrescuNo ratings yet

- (3X800 MW) Patratu: 11Kv HT Feedr List - (1ua) Package Code PXXDocument23 pages(3X800 MW) Patratu: 11Kv HT Feedr List - (1ua) Package Code PXXrahul.srivastavaNo ratings yet

- Gas Turnine Power PlantDocument19 pagesGas Turnine Power Plantvaibhav guptaNo ratings yet

- Nota Kursus Design PV 13-15.7.2020Document125 pagesNota Kursus Design PV 13-15.7.2020Sayuti SidikNo ratings yet

- Ca CTL AmsDocument69 pagesCa CTL AmsEngineer WaseemNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument9 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAbdo MajidNo ratings yet

- Ignition and Flame Safety Solutions: I G N I T I N G I N N O V A T I O NDocument3 pagesIgnition and Flame Safety Solutions: I G N I T I N G I N N O V A T I O NaliNo ratings yet

- 3 System Process Outline - SLP R2Document56 pages3 System Process Outline - SLP R2Pirun Sirimangkalo100% (1)

- PGCB Job PreparationDocument25 pagesPGCB Job PreparationShamim MollaNo ratings yet

- PTC CodesDocument6 pagesPTC CodeskannanNo ratings yet

- Steam BoilerDocument7 pagesSteam BoilerVishnu VardhanNo ratings yet

- Analysis of Dynamic Behaviour of Electric Power Systems WithDocument4 pagesAnalysis of Dynamic Behaviour of Electric Power Systems WithayalmalikiNo ratings yet

- Mission Solar BrochureDocument2 pagesMission Solar Brochureiyer34No ratings yet

- Sample Guided Generalization With Questions and ArticleDocument8 pagesSample Guided Generalization With Questions and ArticleCatherine De Luna100% (1)

- Gas Turbine Cogeneration - Principles and Practice: R. P. AllenDocument6 pagesGas Turbine Cogeneration - Principles and Practice: R. P. AllenGustavo Tnqp100% (1)

- HRSG Interactive PDF v40Document7 pagesHRSG Interactive PDF v40noor kareemNo ratings yet

- Nuclear Power Plant: By, Shweta Chaudhari Parag Darade Mtech (Construction Management)Document34 pagesNuclear Power Plant: By, Shweta Chaudhari Parag Darade Mtech (Construction Management)Nikita BhagatNo ratings yet

- Solar Final PaperDocument18 pagesSolar Final PaperSteve Patrick BesarioNo ratings yet

- Energies: Design and Installation of 500-kW Floating Photovoltaic Structures Using High-Durability SteelDocument14 pagesEnergies: Design and Installation of 500-kW Floating Photovoltaic Structures Using High-Durability Steelibrahim irhomaNo ratings yet

- ACW Flow Calculation BasisDocument4 pagesACW Flow Calculation Basisdebu1985No ratings yet

- HBA Juli 2010Document1 pageHBA Juli 2010Ichsan NNNo ratings yet

- BM Version: Exit ForwardDocument60 pagesBM Version: Exit ForwardSY ChowNo ratings yet

- ProposalDocument20 pagesProposalGetie Tesfaye ZelieNo ratings yet

- Aluminum Extrusions in Solar Power ApplicationsDocument4 pagesAluminum Extrusions in Solar Power ApplicationsСтанислав ПодольскийNo ratings yet

- Tsing Hua GasifierDocument17 pagesTsing Hua GasifierDeepak LuintelNo ratings yet

- Inverter Topology For Grid Connected PV SystemDocument11 pagesInverter Topology For Grid Connected PV SystemMuhammad Talha NaveedNo ratings yet

- Renewable EnergyDocument20 pagesRenewable EnergyAhsan FauziNo ratings yet

- Fun Facts About Solar PowerDocument2 pagesFun Facts About Solar PowerYoudont CareatallNo ratings yet

- Grid Connected PV System, Techniques, Types and Technical FundamentalsDocument26 pagesGrid Connected PV System, Techniques, Types and Technical FundamentalsDipak KhadkaNo ratings yet