Professional Documents

Culture Documents

CA6NM

CA6NM

Uploaded by

William ThompsonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CA6NM

CA6NM

Uploaded by

William ThompsonCopyright:

Available Formats

25 Commerce Road, Orillia, Ontario, Canada L3V 6L6

Phone (705) 325-2781

Fax (705) 325-5887

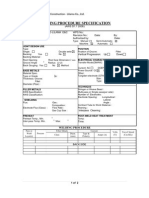

ALLOY DATA SHEET

CORROSION RESISTANT ALLOY

CA6NM

REVISION: 09/96

DESCRIPTION

CA-6NM is a hardenable Fe-Cr-Ni-Mo alloy based on the 13% chromium stainless steel alloy CA-15. Ductility,

impact properties and resistance to salt water corrosion are raised by the addition of nickel and molybdenum.

Castability in thick or intricate sections is better than that of the 13% chromium alloy. Similarly the alloy is more

readily welded and requires lower preheat temperatures. The alloy is most generally used in the normalized and

tempered condition, but variations in heat treatment are used to enhance specific properties.

COMPOSITION

Min %

Max %

Mn

Si

0.06

1.0

1.0

Cr

11.5

14.0

Ni

3.5

4.5

Mo

0.4

1.0

Cu+W+V

0.04

0.03

0.50

APPLICATIONS

Pump casings, bowls, impellers and diffusers, valve bodies, water turbine components, ships propellers,

concast rolls

PRODUCT FORMS

Horizontal and vertical centrifugal castings; static castings.

PHYSICAL PROPERTIES

Density (lbs/in3)

0.278

Liquidus( oF)

Solidus( oF)

2715

2670

Thermal Conductivity

(Btu/h/ft2/ft/oF)

14.5 @ 212oF

16.7 @ 1000oF

Thermal Expansion

(10-6in/in oF)

6.0

Magnetic Permeability

Ferromagnetic

7.0

@ 70-212oF

@ 70-1000oF

MECHANICAL PROPERTIES (Typical Values -1950oF Air Cool. Tempered 1100-1150oF)

U.T.S.

Y.S.

Elong.

R.A.

Charpy "V"

K.S.I.

K.S.I.

%

%

ft-lbs

-200

-100

30

50

70

118

98

20

60

58

400

104

92

18

58

600

102

82

17

57

800

90

78

16

54

1000oF

68

65

24

70

C0RR0SION RESISTANT ALLOY CA-6NM Page 2

HARDNESS

CA-6NM hardness can be controlled through the amount of carbon used in the material and the type of heat

treatment, however ductility and toughness can suffer when hardness is increased.

Carbon (%)

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.10

0.11

0.12

0.13

0.14

0.15

Max. Hardness (BHN)

315

327

338

351

362

- standard CA-6NM carbon content

374

387

400

414

428

443

460

477

496

WELDABILITY

CA-6NM may be welded by the SMAW or GTAW processes.

Electrodes

Same composition.

Preheat

212 to 300oF

Post weld heat treatment

1100 to 1150oF.

Procedures for welding CA6-NM alloy are available from Kubota Metal Corporation.

CREEP-RUPTURE PROPERTIES

Long term creep-rupture properties were extrapolated from Larson-Miller Parameter versus stress plots

HOURS

100.

1,000.

10,000.

100,000

RUPTURE-STRESS-KSI

oF

800

900

1000

AVG.

MIN.

AVG.

MIN.

AVG

MIN

AVG.

MIN.

>50

>50

54

50

41

37

52

47.5

37

35

28

25

20

18.5

28

26

20

18

14

13

(10)

Note: Creep-rupture stresses are subject to periodic revisions as the results from long term tests become

available.

RELATED SPECIFICATIONS

ASTM: A352(CA6NM), A 487(CA6NM); A743(CA-6NM), A757(E3N), UNS J91540

Nearest wrought grade: None

HEAD OFFICE, FOUNDRY & INTERNATIONAL SALES

Kubota Metal Corporation, Fahramet Division

25 Commerce Road, P.O. Box 1700,

Orillia, Ontario, Canada, L3V 6L6.

Phone (705) 325-2781

Fax (705) 325 5887

You might also like

- ASTM A355 Standard Spec For Nitriding PDFDocument3 pagesASTM A355 Standard Spec For Nitriding PDFAntonio J100% (1)

- Sand Mould Casting Multiple Choice QuestionsDocument9 pagesSand Mould Casting Multiple Choice QuestionsAyoub Mohamed100% (1)

- Design of Heat Treatment CyclesDocument5 pagesDesign of Heat Treatment CyclesAnonymous s6xbqCpvSWNo ratings yet

- Intergranular Corrosion Test As Per ASTM A262Document1 pageIntergranular Corrosion Test As Per ASTM A262Muhammad RidwanNo ratings yet

- E186-10 Standard Reference Radiographs For Heavy-Walled (2 To 41 2-In. (50.8 To 114-mm) ) Steel Castings PDFDocument4 pagesE186-10 Standard Reference Radiographs For Heavy-Walled (2 To 41 2-In. (50.8 To 114-mm) ) Steel Castings PDFVarunSharma100% (1)

- Material Alloy KHR32CDocument2 pagesMaterial Alloy KHR32CKHNo ratings yet

- Chemical DetailsDocument3 pagesChemical Detailsemmas18No ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- ST 35.8 (Germany / DIN) : Material PropertiesDocument3 pagesST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiNo ratings yet

- E768 1999 PDFDocument5 pagesE768 1999 PDFTuan Nguyen BaNo ratings yet

- ASTM A747-Standard-Specification-For-Steel-Castings-Stainless-Precipitation-Hardening PDFDocument4 pagesASTM A747-Standard-Specification-For-Steel-Castings-Stainless-Precipitation-Hardening PDFRaul Dela Rosa Malanog100% (1)

- Additive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionDocument9 pagesAdditive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionRaj Rajesh100% (1)

- TGN-PE-01 Hardness Testing of Welds PDFDocument6 pagesTGN-PE-01 Hardness Testing of Welds PDFTeoTyJayNo ratings yet

- Astm A800Document6 pagesAstm A800utreshwarmiskinNo ratings yet

- Alloy Steel Forgings For Pressure and High-Temperature PartsDocument8 pagesAlloy Steel Forgings For Pressure and High-Temperature PartsDarwin Darmawan100% (1)

- Martensite and Retained AusteniteDocument4 pagesMartensite and Retained Austenitemp87_ing100% (1)

- Astm A788Document10 pagesAstm A788Lucas Prezotto Puertas ErnandesNo ratings yet

- Metallurgical and Weldability Aspects of The New-Generation Martensitic Stainless Steels: A Case StudyDocument19 pagesMetallurgical and Weldability Aspects of The New-Generation Martensitic Stainless Steels: A Case Studyvasea100% (1)

- ASTM E 1245 - 03 (Reapproved 2008)Document8 pagesASTM E 1245 - 03 (Reapproved 2008)Ali Saleh Saad AL-isawiNo ratings yet

- The Role Stainless Steel in Industrial Heat ExchangersDocument46 pagesThe Role Stainless Steel in Industrial Heat ExchangerswholenumberNo ratings yet

- SP1Document25 pagesSP1mugu12No ratings yet

- Astm A27Document4 pagesAstm A27MAX ALBERTO JUAREZ AVALOSNo ratings yet

- Sae Ams 5387Document8 pagesSae Ams 5387desingbuschprojectsNo ratings yet

- 625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFDocument5 pages625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFKara WhiteNo ratings yet

- A367-11 Standard Test Methods of Chill Testing of Cast Iron PDFDocument4 pagesA367-11 Standard Test Methods of Chill Testing of Cast Iron PDFCarlos Guillermo Somoza Alvarenga100% (1)

- Spring Grade 52cr4mo2v ChemicalDocument1 pageSpring Grade 52cr4mo2v ChemicalSujin SujiNo ratings yet

- Bearing Steel Material Specification Sheet SAE52100Document1 pageBearing Steel Material Specification Sheet SAE52100Christy Vijay Roy HenryNo ratings yet

- Determining Volume Fraction by Systematic Manual Point CountDocument7 pagesDetermining Volume Fraction by Systematic Manual Point CountRahmat Ramadhan Pasaribu100% (1)

- (UNS S66286) : NAS Heat-Resistant Stainless SteelDocument4 pages(UNS S66286) : NAS Heat-Resistant Stainless Steelsafat parNo ratings yet

- Metallography and Microstructures of Stainless Steel Vandervoort Met-Of-SS-Vol-9Document31 pagesMetallography and Microstructures of Stainless Steel Vandervoort Met-Of-SS-Vol-9Andrea CalderaNo ratings yet

- The Role of Niobium in Austenitic and Duplex Stainless SteelsDocument25 pagesThe Role of Niobium in Austenitic and Duplex Stainless SteelsZoe SideriNo ratings yet

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocument12 pages253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulNo ratings yet

- 1570 (Part II Sec I) Revised - Wrought Steeks For PlatesDocument20 pages1570 (Part II Sec I) Revised - Wrought Steeks For PlatesKaushik Sengupta67% (3)

- 6-12-0002 Rev 8 Supplementary Specification For Carbon Steel VesselsDocument7 pages6-12-0002 Rev 8 Supplementary Specification For Carbon Steel Vesselsravi2007No ratings yet

- Microstructural Changes in Austenitic Stainless Steels During Long Term Aging. Minami1986 PDFDocument12 pagesMicrostructural Changes in Austenitic Stainless Steels During Long Term Aging. Minami1986 PDFAndrea CalderaNo ratings yet

- Wrought Seamless and Welded and Drawn Cobalt Alloy Small Diameter Tubing For Surgical Implants (UNS R30003, UNS R30008, UNS R30035, UNS R30605, and UNS R31537)Document6 pagesWrought Seamless and Welded and Drawn Cobalt Alloy Small Diameter Tubing For Surgical Implants (UNS R30003, UNS R30008, UNS R30035, UNS R30605, and UNS R31537)masoudNo ratings yet

- SG Cast Iron Grade 400 12Document2 pagesSG Cast Iron Grade 400 12vinod100% (1)

- A 247 - 17 PDFDocument13 pagesA 247 - 17 PDFأسامة وحيد الدين رمضانNo ratings yet

- Asme Sa-812 Specification For Steel Sheet, High-Strength, Low-Alloy, Hot-Rolled, For Welded Layered Pressure VesselsDocument3 pagesAsme Sa-812 Specification For Steel Sheet, High-Strength, Low-Alloy, Hot-Rolled, For Welded Layered Pressure Vesselslucecita1902No ratings yet

- Astm A537-A537m-95-2000Document4 pagesAstm A537-A537m-95-2000NadhiraNo ratings yet

- Astm e 930 1999 (R 2015)Document6 pagesAstm e 930 1999 (R 2015)Salvatore Manni OcchinoNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationnmclaughNo ratings yet

- Microstructure and Mechanical Properties of ASTM A743 CA6NM Steel Welded by FCAW ProcessDocument8 pagesMicrostructure and Mechanical Properties of ASTM A743 CA6NM Steel Welded by FCAW ProcessretrogradesNo ratings yet

- Reducing The Risk of High Temperature Hydrogen Attack (HTHA) FailuresDocument5 pagesReducing The Risk of High Temperature Hydrogen Attack (HTHA) FailuresAgustin Fabian HaddadNo ratings yet

- IBR 73-80 Steel CastingsDocument5 pagesIBR 73-80 Steel CastingsRajivharolikarNo ratings yet

- WWW Wollastonalloys Com Materials 2Document8 pagesWWW Wollastonalloys Com Materials 2Mark RomeroNo ratings yet

- Sa 351Document6 pagesSa 351Anil0% (1)

- AISI 1040 Carbon Steel (UNS G10400)Document4 pagesAISI 1040 Carbon Steel (UNS G10400)عابد زاهدNo ratings yet

- Astm B487Document2 pagesAstm B487Srinivasa RaghavanNo ratings yet

- Automotive Gray Iron Castings: Standard Specification ForDocument5 pagesAutomotive Gray Iron Castings: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Analysis of Cast Iron by Spark Atomic Emission Spectrometry: Standard Test Method ForDocument7 pagesAnalysis of Cast Iron by Spark Atomic Emission Spectrometry: Standard Test Method ForTuan AnhNo ratings yet

- General Requirements For Nickel and Nickel Alloys Seamless Pipe and TubeDocument6 pagesGeneral Requirements For Nickel and Nickel Alloys Seamless Pipe and Tubenicu1212No ratings yet

- 347623-Po 4503181944-Li 1Document6 pages347623-Po 4503181944-Li 1Rita WilliamsNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- Cd-4Mcu: Alloy Data SheetDocument2 pagesCd-4Mcu: Alloy Data SheetFlowline PumpsNo ratings yet

- Astm A-297 HPDocument2 pagesAstm A-297 HPeduardo_exsys100% (1)

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 04/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 04/91Azize RazamNo ratings yet

- HK 40Document2 pagesHK 40hawyegNo ratings yet

- KHR 35Ct: Alloy Data SheetDocument2 pagesKHR 35Ct: Alloy Data SheetFebri Ramdani NugrahaNo ratings yet

- Ca 15Document2 pagesCa 15Naraen GandhiNo ratings yet

- Ship Resistance: Wärtsilä Encyclopedia of Marine TechnologyDocument2 pagesShip Resistance: Wärtsilä Encyclopedia of Marine Technologyjoene3No ratings yet

- Resistance and Propulsion of Ships, Kuiper, G.Document343 pagesResistance and Propulsion of Ships, Kuiper, G.joene3100% (1)

- Bouckaert, Et Al, A Life Cycle Cost Analysis of The Application of A Hull Vane To An Offshore Patrol Vessel (FAST2105)Document10 pagesBouckaert, Et Al, A Life Cycle Cost Analysis of The Application of A Hull Vane To An Offshore Patrol Vessel (FAST2105)joene3No ratings yet

- Anthony F Molland - Stephen R Turnock - Dominic A Hudson-Ship Resistance and Propulsion - Practical Estimation of Ship Propulsive Power-Cambridge University Press (2011)Document563 pagesAnthony F Molland - Stephen R Turnock - Dominic A Hudson-Ship Resistance and Propulsion - Practical Estimation of Ship Propulsive Power-Cambridge University Press (2011)ghanbari8668100% (1)

- Resistance and Propulsion of Ships, Kuiper, G.Document343 pagesResistance and Propulsion of Ships, Kuiper, G.joene3100% (1)

- College 7 - Hydro PowerDocument28 pagesCollege 7 - Hydro Powerjoene3No ratings yet

- Industrial Buildings: Case Study: (Suhana Masale Warehouse, Yewat)Document1 pageIndustrial Buildings: Case Study: (Suhana Masale Warehouse, Yewat)Rajeshwari YeoleNo ratings yet

- LandminesDocument11 pagesLandminesNicu. 555.No ratings yet

- Joy Product Data SheetDocument1 pageJoy Product Data Sheetsantosh mhetreNo ratings yet

- American Society of Mechanical Engineers (ASME) CodesDocument6 pagesAmerican Society of Mechanical Engineers (ASME) CodesanishgirmeNo ratings yet

- Hose Full Catalog 03 PDFDocument173 pagesHose Full Catalog 03 PDFruloNo ratings yet

- Mark Scheme (Results) January 2012: International GCSE Chemistry (4CH0) Paper 2CDocument16 pagesMark Scheme (Results) January 2012: International GCSE Chemistry (4CH0) Paper 2C謝利米No ratings yet

- Petersenplgpckrcats PDFDocument112 pagesPetersenplgpckrcats PDFEdixon ZambranoNo ratings yet

- MS SCI PS Unit 2 Chapter 7 Acids Bases and SolutionsDocument36 pagesMS SCI PS Unit 2 Chapter 7 Acids Bases and SolutionsgaNo ratings yet

- ISO 82492000 (En) Ferrite Number FNDocument3 pagesISO 82492000 (En) Ferrite Number FNMurad AlmoudiNo ratings yet

- Apollo 73A-100 TSDocument5 pagesApollo 73A-100 TSechavarriNo ratings yet

- Caravan SpecificationDocument5 pagesCaravan SpecificationVimala PonnusamyNo ratings yet

- ASTM C33 - 2007 - Standard Specification For Concrete AggregatesDocument11 pagesASTM C33 - 2007 - Standard Specification For Concrete AggregatesDayana HernandezNo ratings yet

- Magnetic PDFDocument19 pagesMagnetic PDFErdi Sofyandra AdikriNo ratings yet

- Steam TableDocument10 pagesSteam TableJohnNo ratings yet

- Sulfinol D Evaluation.Document24 pagesSulfinol D Evaluation.Clibert RodríguezNo ratings yet

- QC ReportDocument12 pagesQC ReportManikandan MNo ratings yet

- ME6302-SCAD-MSM-by WWW - LearnEngineering.inDocument130 pagesME6302-SCAD-MSM-by WWW - LearnEngineering.inKKNo ratings yet

- Ty4251 - FMDocument7 pagesTy4251 - FMRafael CardosoNo ratings yet

- Analisis Spot TestDocument19 pagesAnalisis Spot TestAnggun Yulfiastanti MalakaNo ratings yet

- Influence of Feroel Filler Size and Clustering of Ag-BT - PVDF - ACSami - 2023Document16 pagesInfluence of Feroel Filler Size and Clustering of Ag-BT - PVDF - ACSami - 2023Cristina CiomagaNo ratings yet

- Blasocut 2000 UniversalDocument1 pageBlasocut 2000 UniversalzaqNo ratings yet

- 8-The Chemistry of The Environment PDFDocument52 pages8-The Chemistry of The Environment PDFJewel LimNo ratings yet

- Ran J. Sharon President & CeoDocument19 pagesRan J. Sharon President & CeoLuan NguyenNo ratings yet

- Cis 18 IbsDocument35 pagesCis 18 IbsAce Ven Ven100% (2)

- 4 LappingDocument21 pages4 LappingMohammadHossein BahramiNo ratings yet

- Brosur Katalog Valve Flange Fitting Elbow Reducer Tee JakartaDocument13 pagesBrosur Katalog Valve Flange Fitting Elbow Reducer Tee JakartaAlvindo Catur SentosaNo ratings yet

- WPS Aws D1.1Document2 pagesWPS Aws D1.1tuatk67% (6)

- CustomersDocument56 pagesCustomersrajeev_snehaNo ratings yet

- APPENDIX B Filler Metal Comparison Chart ABS-AWS-OCRDocument3 pagesAPPENDIX B Filler Metal Comparison Chart ABS-AWS-OCRMohamed Ahmed MaherNo ratings yet