Professional Documents

Culture Documents

Energy Saving Aspect For Transformers. Applicable To Mines HOD

Energy Saving Aspect For Transformers. Applicable To Mines HOD

Uploaded by

saji kumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Saving Aspect For Transformers. Applicable To Mines HOD

Energy Saving Aspect For Transformers. Applicable To Mines HOD

Uploaded by

saji kumarCopyright:

Available Formats

GCW/EnMS/MNS/OCP/05

Issue No:01

Date of Issue : 01.07.2012

Revision No. : 00

Page No.: Page 1 of 2

1. Objective: Work instructions &

2. Scope:

Gagal Cement Works

Date of Revision :

Energy Saving Aspect for Transformers.

Applicable to Mines

3. Responsibility:

HOD

4. Performance Criteria: Implementation at site

5. Cross Reference:

6. Date: 01.07.2012

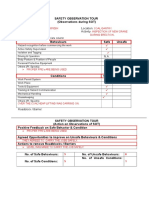

7. Operational Control Activities:

S.

No.

Activity

Responsibility

1. Take Line Work Permits before starting of the job.

Designation

2. Open Primary & Secondary side Terminal Box Covers.

HOD

3. Check for any leakage/Seepage of oil near Terminal Bushings.

4. Open Cable Connections & check for IR Values of Transformer &

Cables on Primary & Secondary side.

5. Reconnect Cables & Tighten Connections. .

6. Check Oil level in Conservator Tank, Fill if the level is below the

mark.

7. Check Bucholz relay terminal connections.

8. Check Explosion vent condition & its connections.

9. Check Radiators for any leakage or seepage of oil & check

valves position.

10. Check for Oil & Winding Temperature Indicators for working

conditions. Check contacts operation manually.

11. Check OLTC Panel connections & Motor Connections.

12. Operate On Line Tap Changer from Local.

12. Check for Oil Dielectric strength from Top & Bottom sample of

the Oil.

Prepared By:

Approved By:

GCW/EnMS/MNS/OCP/05

Issue No:01

Date of Issue : 01.07.2011

Revision No. : 00

Page No.: Page 2 of 2

Gagal Cement Works

Date of Revision :

13. Check Tap Position in Off Load Tap Changer & set as per the

required Voltage.

14. Check Neutral bushing connections & tighten connections if

required..

15. Check Earthing connections & tighten if required.

16. Check all Tools & Tackles before closing all Boxes & connection

Boxes.

17. Close all Terminal boxes & Tighten Bolts.

18. Submit Work Permit after completion of the Job.

19. Charge Transformer & check all Parameters.

20. Check the Alarm & Tripping of the Transformer operating

Manually.

ENERGY CONSERVATION :1. Visual inspection of the Transformer is to be done for any Oil

leakage, seepage, Oil level etc..

2. Put at least 75% loading on the Transformer to reduce losses.

3. Set Tap Changer Position as such to operate on bit lower output

voltage for Energy conservation.

4. Proper cooling of the Transformer is to be ensured.

Remarks:

Prepared By:

Approved By:

You might also like

- Motor Testing and General Checks FormatDocument4 pagesMotor Testing and General Checks FormatRaj Kiran79% (24)

- SOP OperationDocument68 pagesSOP OperationPamela Bradley100% (1)

- Transformer Site TestsDocument14 pagesTransformer Site TestsAhmad KalbounahNo ratings yet

- Section - 1: Meo Class 4 - Electrical Oral Questions With AnswersDocument81 pagesSection - 1: Meo Class 4 - Electrical Oral Questions With Answersbaba maachoNo ratings yet

- Power Transformer Testing ProcedureDocument4 pagesPower Transformer Testing ProcedureJustin Taylor100% (4)

- MVVNL Transformer Test ReportDocument24 pagesMVVNL Transformer Test ReportRakesh Kumar100% (2)

- Substation Site TestDocument9 pagesSubstation Site Testخالد المصرى100% (1)

- 3.1 Oil Filled Power TransformersDocument32 pages3.1 Oil Filled Power TransformersThameemul BuhariNo ratings yet

- Energy Saving Aspect For LT Motor (Slip-Ring & Induction) - Applicable To Mines HODDocument3 pagesEnergy Saving Aspect For LT Motor (Slip-Ring & Induction) - Applicable To Mines HODsaji kumarNo ratings yet

- Standard Operating Procedure: Operation and Preventive Maintenance of TransformersDocument5 pagesStandard Operating Procedure: Operation and Preventive Maintenance of TransformersMaryanthony NamyaloNo ratings yet

- Energy Saving Aspect Apron Conveyor Motor. Applicable To Mines HODDocument2 pagesEnergy Saving Aspect Apron Conveyor Motor. Applicable To Mines HODsaji kumarNo ratings yet

- Work - Instruction 66-33KV TRANSFORMERDocument5 pagesWork - Instruction 66-33KV TRANSFORMERTAHIR HUSAINNo ratings yet

- Energy Saving Aspect For 6.6 KV H.T.Motors. Applicable To Mines HODDocument2 pagesEnergy Saving Aspect For 6.6 KV H.T.Motors. Applicable To Mines HODsaji kumarNo ratings yet

- Service Manual: TransformerDocument18 pagesService Manual: TransformerPierre EyebeNo ratings yet

- Isolation & Maintenance of Power Transformers.Document4 pagesIsolation & Maintenance of Power Transformers.अभिषेक कुमार उपाध्यायNo ratings yet

- 400 KV MSDS-1, JSPL Angul: Title Department Maintenance Format For Transformer Department: Electrical &instrumentationDocument16 pages400 KV MSDS-1, JSPL Angul: Title Department Maintenance Format For Transformer Department: Electrical &instrumentationAnonymous vcadX45TD7No ratings yet

- Work - Instruction Transformer 33-11KV TRANSFORMERDocument5 pagesWork - Instruction Transformer 33-11KV TRANSFORMERTAHIR HUSAINNo ratings yet

- Testing & CommissioningDocument11 pagesTesting & CommissioningK.Ramachandran100% (2)

- Importance of Sub-Station Equipment Maintenance: Presented by MD - Golam Mowla XEN (G&P)Document23 pagesImportance of Sub-Station Equipment Maintenance: Presented by MD - Golam Mowla XEN (G&P)rajshahieeeNo ratings yet

- Problems in OLTC PDFDocument2 pagesProblems in OLTC PDFSellappan Muthusamy100% (1)

- Maintenance Procedures of Electrical EquipmentDocument4 pagesMaintenance Procedures of Electrical EquipmentEdwin Cob GuriNo ratings yet

- Procedure of Maintenance For Electrical EquipmentDocument16 pagesProcedure of Maintenance For Electrical EquipmentThức Võ100% (2)

- 14 CUX Cold Start UpdateDocument16 pages14 CUX Cold Start UpdateAldous Cosmo GitlesNo ratings yet

- Testing and COmmissioningDocument2 pagesTesting and COmmissioningsatya_swamy20002943No ratings yet

- P000b-Bank 1 Camshaft 2 Position Slow ResponseDocument7 pagesP000b-Bank 1 Camshaft 2 Position Slow Responseflash_24014910No ratings yet

- Transformer TestingDocument4 pagesTransformer Testingengr.ayaz7772No ratings yet

- MM-18 - Bilge Separator - OPERATION MANUALDocument24 pagesMM-18 - Bilge Separator - OPERATION MANUALKyaw Swar Latt100% (2)

- LTS: Locomotive Testing ShopDocument4 pagesLTS: Locomotive Testing ShoprockeygreatNo ratings yet

- Oil Filled Transformers Standard Testing ProcedureDocument17 pagesOil Filled Transformers Standard Testing ProcedureNajeeb AbbasiNo ratings yet

- Technical Audit Report 500 KV Grid Station NTDC ShikarpurDocument10 pagesTechnical Audit Report 500 KV Grid Station NTDC ShikarpurEngr Fahimuddin QureshiNo ratings yet

- DGW200MS/UK: Operator'S ManualDocument36 pagesDGW200MS/UK: Operator'S ManualthuanNo ratings yet

- TrafoDocument5 pagesTrafoAnonymous vcadX45TD7No ratings yet

- Transformer Daily Checklist Month:: Description of The Equipment Location CapacityDocument10 pagesTransformer Daily Checklist Month:: Description of The Equipment Location Capacityabdulkadir aliNo ratings yet

- TRANING DOCUMENT-3630 kVADocument12 pagesTRANING DOCUMENT-3630 kVAruddy matiasNo ratings yet

- Checklist For Shunt Reactor Rev01Document4 pagesChecklist For Shunt Reactor Rev01Santhosh Kumar VinayagamNo ratings yet

- Void SubstationDocument46 pagesVoid SubstationPrabhat HambireNo ratings yet

- Transformer Service ManualDocument11 pagesTransformer Service Manualshivaram100% (1)

- Section - 1: Meo Class 4 - Electrical Oral Questions With AnswersDocument81 pagesSection - 1: Meo Class 4 - Electrical Oral Questions With AnswersHelna joseph JOSENo ratings yet

- 154 KV CIRCUIT BREAKER PDFDocument9 pages154 KV CIRCUIT BREAKER PDFCelil GOZELNo ratings yet

- Method Statement For Erectiion of TransformerDocument3 pagesMethod Statement For Erectiion of TransformerUlhas NalavadeNo ratings yet

- Checklist For Shunt ReactorDocument4 pagesChecklist For Shunt ReactorSanthosh Kumar VinayagamNo ratings yet

- Erection Ing Maintenance of Power TfsDocument82 pagesErection Ing Maintenance of Power TfskameshNo ratings yet

- Transformer: Power/TractionDocument9 pagesTransformer: Power/Tractionappy sagarNo ratings yet

- For Energising The Drive: Pellet Plant-2 BarbilDocument3 pagesFor Energising The Drive: Pellet Plant-2 BarbilShatrughna SamalNo ratings yet

- CBIP PublicationDocument6 pagesCBIP PublicationVamsi ManojNo ratings yet

- CONTRACT No.14023 DATE 20.03.2014 Sirajganj 225Mw Combined Cycle Power Plant Project (2 Unit-Dual Fuel)Document11 pagesCONTRACT No.14023 DATE 20.03.2014 Sirajganj 225Mw Combined Cycle Power Plant Project (2 Unit-Dual Fuel)VictorNo ratings yet

- Emergency Instructions For Total Power FailureDocument11 pagesEmergency Instructions For Total Power FailureSelvaNo ratings yet

- Opgs 0 BLR Opn 19-27-00 Sop For DM Make Up PumpDocument5 pagesOpgs 0 BLR Opn 19-27-00 Sop For DM Make Up PumpAnbu MathiNo ratings yet

- SOP For Grid FailureDocument9 pagesSOP For Grid FailureAmit BiswasNo ratings yet

- Job Scope For Over Hauling of Power Transformers - FinalDocument7 pagesJob Scope For Over Hauling of Power Transformers - Finalrambihari100% (1)

- Shindaiwa DGW400DM-ANZ-Owners-Manual-1Document40 pagesShindaiwa DGW400DM-ANZ-Owners-Manual-1Guruh SuprayitnoNo ratings yet

- Indiabulls Power Limited: SOP/OPNS/09 Operations DepartmentDocument3 pagesIndiabulls Power Limited: SOP/OPNS/09 Operations DepartmentAmit Soni100% (1)

- Maintenance Schedule For SubstationDocument21 pagesMaintenance Schedule For SubstationSajid Shaikh100% (1)

- DGW500 ANZ Operation ManualDocument42 pagesDGW500 ANZ Operation ManualJoseNo ratings yet

- Oil Flow RelayDocument6 pagesOil Flow RelayPhạm Lê Quốc ChínhNo ratings yet

- Power Transformer Pre Commisioning ChecklistDocument26 pagesPower Transformer Pre Commisioning ChecklistRajesh TK100% (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- TASK - Clinker - Loading - in - RakeDocument2 pagesTASK - Clinker - Loading - in - Rakesaji kumarNo ratings yet

- Unloading by TrucksDocument2 pagesUnloading by Truckssaji kumarNo ratings yet

- Sop For Operation of EotDocument2 pagesSop For Operation of Eotsaji kumarNo ratings yet

- Pre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)Document3 pagesPre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)saji kumarNo ratings yet

- Dammurage Study FormatDocument2 pagesDammurage Study Formatsaji kumarNo ratings yet

- Invoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare WeightDocument1 pageInvoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare Weightsaji kumarNo ratings yet

- Ot SlipDocument1 pageOt Slipsaji kumarNo ratings yet

- North - PV Var - Summary LK MarDocument3 pagesNorth - PV Var - Summary LK Marsaji kumarNo ratings yet

- Standard Operating Procedures 1Document1 pageStandard Operating Procedures 1saji kumarNo ratings yet

- Heo Operator: Token Empolyee Name Mobile Number DOZAR/Loader Clain ShellDocument6 pagesHeo Operator: Token Empolyee Name Mobile Number DOZAR/Loader Clain Shellsaji kumarNo ratings yet

- Please Tick in Appropriate Column: Roadblock / BarrierDocument1 pagePlease Tick in Appropriate Column: Roadblock / Barriersaji kumarNo ratings yet

- 1.microscopy - Glass Content in Slag SOPDocument1 page1.microscopy - Glass Content in Slag SOPsaji kumarNo ratings yet

- Visit To DelhiDocument11 pagesVisit To Delhisaji kumarNo ratings yet

- 1.1 Program KymoreDocument2 pages1.1 Program Kymoresaji kumarNo ratings yet

- SOP - 22 - Preparation of Activated GypsumDocument2 pagesSOP - 22 - Preparation of Activated Gypsumsaji kumarNo ratings yet

- M.P.Singh & B.K.Singh Coal Mill CCR 27/03/06 Mill Operation: Observer's Name: Location: Date: ActivityDocument2 pagesM.P.Singh & B.K.Singh Coal Mill CCR 27/03/06 Mill Operation: Observer's Name: Location: Date: Activitysaji kumarNo ratings yet

- Chapter 3a Geometry of CrystalsDocument72 pagesChapter 3a Geometry of Crystalssaji kumar100% (1)

- Compliance Checklist - PlantDocument36 pagesCompliance Checklist - Plantsaji kumarNo ratings yet

- Procurement Process Guide V 5.0 - Final CompressedDocument114 pagesProcurement Process Guide V 5.0 - Final Compressedsaji kumar100% (1)

- B K Singh Sot Dec06Document1 pageB K Singh Sot Dec06saji kumarNo ratings yet

- BH15/SN23 BH15/SN30Document17 pagesBH15/SN23 BH15/SN30saji kumarNo ratings yet

- Mines Bore Hole Sample Analysis Test Results (Durg)Document4 pagesMines Bore Hole Sample Analysis Test Results (Durg)saji kumarNo ratings yet