Professional Documents

Culture Documents

Compensation

Compensation

Uploaded by

pandiangv0 ratings0% found this document useful (0 votes)

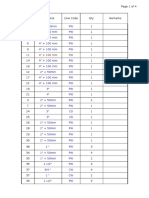

6 views1 pageThis document provides calculations for stress compensation on a piping joint. It lists dimensions of the branch and header pipes, required and actual wall thicknesses, and calculates the required and provided reinforcement areas. The provided area of 485.71 mm^2 is greater than the required area of 89.54 mm^2, therefore additional reinforcement is not needed for this piping joint.

Original Description:

piping

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides calculations for stress compensation on a piping joint. It lists dimensions of the branch and header pipes, required and actual wall thicknesses, and calculates the required and provided reinforcement areas. The provided area of 485.71 mm^2 is greater than the required area of 89.54 mm^2, therefore additional reinforcement is not needed for this piping joint.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views1 pageCompensation

Compensation

Uploaded by

pandiangvThis document provides calculations for stress compensation on a piping joint. It lists dimensions of the branch and header pipes, required and actual wall thicknesses, and calculates the required and provided reinforcement areas. The provided area of 485.71 mm^2 is greater than the required area of 89.54 mm^2, therefore additional reinforcement is not needed for this piping joint.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

`

STRESS CALCULATION

EQPT.

1

22

Rev.

GBE/1842/035

Compensation check for piping As per 104.3.1 (D)

DESCRIPTION

S.No.

01

STEAM OUTLET PIPING

MFR'S

SERIAL NO.

Sheet

DATA

Item

Half Coupling

Drg. No.

10-20-05-3023

Item No.

09

USER UNIT

SI UNIT

02

A = Additional Thickness

mm

0.00

mm

03

Tb = Actual (or) min. wall thickness of branch

mm

15.88

mm

04

Th = Actual (or) min. wall thickness of header

mm

5.27

mm

05

Dob = Outside diameter of branch pipe

mm

63.50

mm

06

07

Doh = Outside diameter of header pipe

mm

114.30

mm

d1 = Inside centerline long. dimension of

finished branch opening in run

of the pipe[ Dob - 2 ( Tb - A )]

mm

31.75

mm

08

tmh = Required min. wall thickness of header

mm

2.82

mm

09

tmb = Required min. wall thickness of branch

mm

1.38

mm

10

d2 = Half width of reinforcing Zone

= The greater of d1 ( or ) (Tb-A)+(Th-A)+(d1/2),

but in no case more than Doh.

11

d1

mm

31.75

mm

12

(Tb-A) + (Th-A) + (d1/2)

mm

37.03

mm

12

d2

mm

37.03

mm

d2 < Doh

13

Fillet / weld leg

Hence not satisfactory

mm

2

0.00

mm

89.54

mm 2

14

A7 = Required reinforcement area (tmh-A) d1

mm

15

A1 = Area provided by excess pipe wall

in the run = ( 2 d2 - d1 ) (Th - tmh )

mm 2

103.64

mm 2

16

A2 = Area provided by excess pipe wall in

the branch for a distance L4 above the run

= 2L4 (Tb - tmb)

L4 =Altitude of reinforcement zone outside of run

=2.5(Tb-A)+tr or 2.5(Th-A)whichever is smaller

17

2.5 (Tb-A) + tr

mm 2

39.70

mm 2

18

2.5 (Th-A)

mm 2

13.18

mm 2

19

L4

mm 2

13.18

mm 2

20

A2 =

mm 2

382.08

mm 2

21

A3 = Area provided by deposited weld

mm 2

0.00

mm 2

22

Provided area A1+ A2+ A3

mm 2

485.71

mm 2

23

Required area < Provided area

Hence reinforcement is not required

You might also like

- Calculation of PipeReinforcement ASMEB31.1Document3 pagesCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- Calculation of Pipe Reinforcement ASME B31 3Document3 pagesCalculation of Pipe Reinforcement ASME B31 3Brant AkkanNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document4 pagesCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Xylan Offshore FlierDocument2 pagesXylan Offshore FlierpandiangvNo ratings yet

- 31.1 Piping Calculation FormatDocument11 pages31.1 Piping Calculation FormatAvinash Vivek100% (1)

- Section Size: W200X36: Refer Appendix D For Support ReactionsDocument10 pagesSection Size: W200X36: Refer Appendix D For Support Reactionsramuce04No ratings yet

- Reinforcement Calculations For Nozzle (N1) : OD ID Thick NessDocument15 pagesReinforcement Calculations For Nozzle (N1) : OD ID Thick NessMuhammad Hassan MaqsoodNo ratings yet

- Pipe Reinforcement Calculation (ASME-B31.3)Document3 pagesPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Beam Design Detail Report: Material and Design DataDocument10 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Flat SlabDocument14 pagesFlat Slabbasanth_712982100% (1)

- RC Beam Design CCAA - Revised 1.2 JWWDocument12 pagesRC Beam Design CCAA - Revised 1.2 JWWFerdie TolosaNo ratings yet

- Branch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping CodeDocument2 pagesBranch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping Codedeua2004No ratings yet

- Pile CapDocument33 pagesPile CapSopheap BorohsNo ratings yet

- Calculation of Pipe Reinforcement ASME B31.3Document9 pagesCalculation of Pipe Reinforcement ASME B31.3yhnsharma80% (5)

- Continuous Beam Staad ReportDocument14 pagesContinuous Beam Staad ReportMuhammad Shukri Bin SaharinNo ratings yet

- Bending Bs 5400Document2 pagesBending Bs 5400Sharyn PolleyNo ratings yet

- Scantling Calculation PDFDocument6 pagesScantling Calculation PDFShyamshesha GiriNo ratings yet

- Single Shear Steel ConnectionDocument36 pagesSingle Shear Steel ConnectionNatalie WestNo ratings yet

- Beam Design Detail Report: Material and Design DataDocument10 pagesBeam Design Detail Report: Material and Design DataazwanNo ratings yet

- Aspen HX Design ReportDocument78 pagesAspen HX Design ReportberylqzNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Beam DesignsDocument123 pagesBeam DesignssitehabNo ratings yet

- Design of RCC Rectangular Columns: 230 X 300 Column With Reinf Safe Summary of DesignDocument1 pageDesign of RCC Rectangular Columns: 230 X 300 Column With Reinf Safe Summary of DesignAnonymous YDwBCtsNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 pagesDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNo ratings yet

- Typ-Base PlateDocument11 pagesTyp-Base PlateManoj Jaiswal100% (2)

- Beam - Roof Beam - GM1Document20 pagesBeam - Roof Beam - GM1FrederickV.VelascoNo ratings yet

- Pipe Design Thikness For PipingDocument1 pagePipe Design Thikness For PipingKanit ChobNo ratings yet

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadNo ratings yet

- Base Plate and Anchor Bolt DesignDocument9 pagesBase Plate and Anchor Bolt DesignShaikh Muhammad Ateeq100% (2)

- Bell Method Example 7 5Document9 pagesBell Method Example 7 5jnmanivannanNo ratings yet

- RCC Beam Design Task-01Document29 pagesRCC Beam Design Task-01Mohamed SaheelNo ratings yet

- Cutting Speed May BeDocument14 pagesCutting Speed May BeJibin Jose100% (1)

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Document12 pagesInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)ibmsherNo ratings yet

- Breech Lock CalculationsDocument11 pagesBreech Lock CalculationsPrasad PingleNo ratings yet

- Reinforcement CheckDocument2 pagesReinforcement Checkviv0102No ratings yet

- Miter B1 ADocument55 pagesMiter B1 AFarid TataNo ratings yet

- L 8 IhjnmklgfDocument27 pagesL 8 IhjnmklgfbrintopvNo ratings yet

- RC Beam Design ManualDocument4 pagesRC Beam Design ManualYugatheeran Thavaratnasingam100% (1)

- Design and Fabrication of Wedge Milling FixtureDocument28 pagesDesign and Fabrication of Wedge Milling FixturedbzdivikNo ratings yet

- Beam Desgin SheetDocument5 pagesBeam Desgin SheetKamYingLamNo ratings yet

- Pressure Design Straight Pipe (Run Pipe)Document6 pagesPressure Design Straight Pipe (Run Pipe)gembirasekaliNo ratings yet

- Calculation of Beam/Column Splice: HB-300x300x10x15Document5 pagesCalculation of Beam/Column Splice: HB-300x300x10x15amachmouchiNo ratings yet

- DG Consulting Engineers: Job NoDocument52 pagesDG Consulting Engineers: Job NosthakshyNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- As Me Certificate Holder ReportDocument5 pagesAs Me Certificate Holder ReportpandiangvNo ratings yet

- UBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffDocument4 pagesUBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffpandiangvNo ratings yet

- Crosby Eye Bolt G 291Document1 pageCrosby Eye Bolt G 291pandiangvNo ratings yet

- Studding Outlet DimensionDocument2 pagesStudding Outlet DimensionpandiangvNo ratings yet

- Input:-: Design of Base Plate Length of Base Plate (MM) W 0.11 Width of Base Plate (MM) A (MM) B (MM) Axil Load (M.T)Document6 pagesInput:-: Design of Base Plate Length of Base Plate (MM) W 0.11 Width of Base Plate (MM) A (MM) B (MM) Axil Load (M.T)pandiangvNo ratings yet

- Wind Load SheetDocument2 pagesWind Load SheetpandiangvNo ratings yet

- Peppers Catalogue Approved AccessoriesDocument16 pagesPeppers Catalogue Approved AccessoriespandiangvNo ratings yet

- S2 - Jaw and Jaw-136Document1 pageS2 - Jaw and Jaw-136pandiangvNo ratings yet

- Guidance Notes RevisionDocument8 pagesGuidance Notes RevisionpandiangvNo ratings yet

- Design and Development PlanningDocument6 pagesDesign and Development PlanningpandiangvNo ratings yet

- WRC Input InstructionDocument2 pagesWRC Input InstructionpandiangvNo ratings yet

- Load-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigDocument12 pagesLoad-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigpandiangvNo ratings yet

- TMCP Steels For Offshore StructuresDocument3 pagesTMCP Steels For Offshore StructurespandiangvNo ratings yet

- N1192-ST - Colour CoadingDocument4 pagesN1192-ST - Colour CoadingpandiangvNo ratings yet

- Graphite PSM AsDocument2 pagesGraphite PSM AspandiangvNo ratings yet

- WRC Input InstructionDocument1 pageWRC Input InstructionpandiangvNo ratings yet

- Level Gauge, Level Switch ModelDocument8 pagesLevel Gauge, Level Switch ModelpandiangvNo ratings yet

- ASME Section II C 2015 ChangesDocument3 pagesASME Section II C 2015 Changespandiangv0% (1)

- Api2000rev.6 02-13Document33 pagesApi2000rev.6 02-13pandiangvNo ratings yet

- Heat TreatmentDocument13 pagesHeat TreatmentpandiangvNo ratings yet