Professional Documents

Culture Documents

Casting Process Comparison

Casting Process Comparison

Uploaded by

IPSITCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Casting Process Comparison

Casting Process Comparison

Uploaded by

IPSITCopyright:

Available Formats

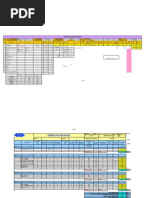

CASTING

PROCESS

DESCRIPTION

METALS

SIZE RANGE

TOLERANCES

GREEN SAND

Process that mixes raw sand, clay and water, which is

then compacted around a pattern to create a mold.

Most common type of molding, suitable for any

production volume, and typically a low-cost option.

Most Castable

Metals

All sizes per

foundry

capabilities

0-3" = 0.03" per in.

+ 0.005" per in.

for each additional in.

Across parting line add

0.020" to small castings,

0.090" to large castings

NO BAKE /

AIRSET

Molding method utilizing raw sand combined with

resins and binder to create a hard mold capable of

improved surface finishes. Excellent for lower-volume

parts where superior dimensional stability is required.

Most Castable

Metals

All sizes per

foundry

capabilities

0-3" = 0.03" per in.

+ 0.005" per in.

for each additional in.

Across parting line add

0.020" to small castings,

0.090" to large castings

SHELL

Resin-coated sand, typically of a smaller grain size

than green sand, which is applied to a heated pattern

that activates the resin to create a hard-shell mold.

Exceptional surface finishes can be achieved with

reduced machine stock and/or draft.

Casting process in which wax replicas are coated with

a slurry mix of ceramic refractory and sand, allowed to

dry, and then heated to extract the wax, leaving

INVESTMENT

behind a near-net-shape cavity. Capable of creating

shapes that are not possible by any other molding

method, particularly for small or intricate components.

Widely used to eliminate additional machining expense.

Most Castable

Metals

Typical max

mold area =

3000 in2

Ferrous:

+/-0.008" per in. up to 3"

add 0.003" per in. over 3"

Non-Ferrous:

Add 0.005-0.010" per in.

across parting lines,

under 1" = +/-0.004"

1-3" = +/-0.010"

3-6" = +/-0.013"

6-12" = +/-0.016"

12-20" = +/-0.020"

SURFACE

FINISH

MINIMUM DRAFT

REQUIRED

MINIMUM

SECTION

THICKNESS

EASE OF

CASTING

COMPLEX

DESIGNS

EASE OF

CHANGING

DESIGN

COMMENTS

Low

Ferrous:

420-900 RMS

Aluminum:

175-350 RMS

Copper Base:

300-560 RMS

1-5 degrees

Ferrous:

0.250-0.375"

Non-Ferrous:

0.125-0.250"

Fair to

Good

Best

Most widely used casting process for

both small and large production runs.

Low

Ferrous:

420-900 RMS

Aluminum:

175-350 RMS

Copper Base:

300-560 RMS

3-5 degrees

Ferrous:

0.250-0.375"

Non-Ferrous:

0.125-0.250"

Fair to

Good

Best

Widely used casting process for both

small and large production runs.

Medium

Ferrous:

200-350 RMS

Aluminum:

75-150 RMS

Copper Base:

150-200 RMS

0.5-2 degrees

Ferrous:

0.125"

Non-Ferrous:

0.080"

Good

Fair

Used for production of fairly small

parts for which closer tolerances and

improved surface finishes are required

than are obtainable from sand

castings. Widely used in core

production.

Best

Fair

Used for precision castings,

particularly for complex designs.

Good

Good

Widely used for prototypes and low

usage parts. In some cases patterns

can be used more than once.

AVERAGE RELATIVE RELATIVE

TOOLING COST FOR COST FOR

COST

HIGH QTY LOW QTY

Low

Low

Medium

Low

Low

Medium

0.1 to 100 lbs

+/-0.005" per in. up to 3"

add 0.002" per in. over 3"

Medium

High

Medium

60-120 RMS

0-1 degrees

Carbon Steel:

0.090"

Stainless Steel:

0.125"

Aluminum:

0.030"

Copper Base:

0.030"

Most Castable

Metals

Up to several

hundred pounds

0-3" = 0.03" per in.

+ 0.005" per in.

for each additional in.

Across parting line add

0.020" to small castings,

0.090" to large castings

Low

High

Low

Per type of

foam used

None

Ferrous:

0.250-0.375"

Non-Ferrous:

0.125-0.250"

All sizes per

foundry

capabilities;

Aluminum =

0.5 to 100 lbs.

Aluminum:

+/-0.015" per in. up to 1"

add 0.002" per in. over 1"

Across parting line add

0.010" to small castings,

0.030" to large castings

High

Aluminum:

125-200 RMS

Copper Base:

175-225 RMS

Ferrous:

3-5 degrees

Aluminum:

2-4 degrees

Copper Base:

3-5 degrees

Ferrous:

0.187-0.250"

Aluminum:

0.100-0.150"

Copper Base:

0.100-0.150"

Fair

Poor

Used for moderate quantities of semiprecision castings. Normally less

expensive than sand casting for

100's - 1000's of parts. Limited

applicability for ferrous metals.

Aluminum:

0.050" Small

0.080" Med

Zinc & Mag.:

0.025" Small

0.040" Med

Good

Poorest

Very widely used for high production

of aluminum and zinc castings. An

inexpensive way of obtaining

precision parts.

Most Castable

Metals

LOST FOAM

Can be utilized in two different methods; The first

method is similar to investment, in which a

polystyrene replica is coated with ceramic refractory

and then molded in sand. The second method consists

of foam patterns that are molded into a media similar

to no bake or airset. In either method, molten metal

is poured directly into the sand mold and evaporates

the foam during the casting process, creating a part

with no draft or parting lines.

PERMANENT

MOLD

Reusable metal tooling that can be used to create

repeatable dimensional accuracy, typically used for

decorative or ornamental products made from

nonferrous materials.

Aluminum &

Copper Base

DIE CAST

Method in which molten metal is forced into a metal

die under pressure. This process is suitable for

repeatability of medium- to high-volume, intricate or

close-tolerance parts.

Aluminum, Zinc,

Magnesium, &

Copper Base

CENTRIFUGAL

Process utilizing permanent tooling that is rotated

horizontally or vertically while molten metal is

introduced, typically used to manufacture pipe or

other cylindrical products.

Most Castable

Metals

V-PROCESS

Dry sand molding method that uses a vacuum to hold

a membrane on the surface of the pattern, which is

then backfilled with sand. Advantages are exceptional

surface finish and tighter dimensional control than

most conventional sand casting processes.

Most Castable

Metals

Medium

Medium

0.0015" per in.

Not less than 0.002" on any

one dimension.

Across parting line add

0.010"

High

Low

High

20-90 RMS

Aluminum:

1-3 degrees

Zinc & Mag:

0.5-2 degrees

OD 2 to 50 in;

Length & wall

thickness per

foundry

capabilities

OD = 0.1"

Small Dia ID = 0.03-0.06"

None

Low

Medium

250-500 RMS

None

Per foundry

capabilities

Not

Practical

Good

Used for round tubular or cylindrical

castings. ID will likely require

machining due to impurities. Excellent

casting soundness.

All sizes per

foundry

capabilities

+/-0.010" per in. up to 1"

add 0.002" per in. over 1"

Across parting line add

0.020" max

Medium

Medium

High

125-250 RMS

None

0.090-0.125"

Good

Good

Unlimited pattern life. Used for

medium to high volumes.

Typical max

mold area =

3 ft2

Dominion Metallurgical, Inc.

2/19/2010

You might also like

- TIG Welding Amp ChartsDocument3 pagesTIG Welding Amp ChartsHikmet ParakNo ratings yet

- Die and Punch - Project ReportDocument29 pagesDie and Punch - Project ReportPawan mehta100% (1)

- RAK Bathware-2012Document107 pagesRAK Bathware-2012kishanm77No ratings yet

- Building A Raku KilnDocument8 pagesBuilding A Raku KilnJanković DušanNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- EA Plasma, Laser, OxyfuelDocument5 pagesEA Plasma, Laser, OxyfuelSaravanan VelayuthamNo ratings yet

- Final ReportDocument25 pagesFinal ReportAdil SaleemNo ratings yet

- IV ReportDocument22 pagesIV ReportMuhammad Zulhilmi0% (1)

- Lost Foam Cast ProcemssDocument22 pagesLost Foam Cast ProcemssSebastian PeterNo ratings yet

- IPD Costing PDFDocument10 pagesIPD Costing PDFSaddy DipoNo ratings yet

- Design and Analysis of Progressive Tool For An Automobile ComponentDocument9 pagesDesign and Analysis of Progressive Tool For An Automobile ComponentAnna100% (1)

- Tailor Welded BlanksDocument52 pagesTailor Welded BlanksYuvaraj YuvarajNo ratings yet

- Material: NRE Pricing Sheet Quantity CostDocument1 pageMaterial: NRE Pricing Sheet Quantity CostAnonymous VRspXsmNo ratings yet

- Production of Automotive Components: Jerome GDocument24 pagesProduction of Automotive Components: Jerome GMr. Jerome Nithin Gladson100% (1)

- Budget Casting Supply LLCDocument4 pagesBudget Casting Supply LLCBaaaatarNo ratings yet

- Prodsheet Pb50 en 01Document2 pagesProdsheet Pb50 en 01Amândio PintoNo ratings yet

- Unit - Iv: Milling MachineDocument74 pagesUnit - Iv: Milling MachineDevarakonda KondayyaNo ratings yet

- Drawing Forming Be 00 New yDocument44 pagesDrawing Forming Be 00 New yMarudhasalam VelusamyNo ratings yet

- Solder Paste LiteratureDocument1 pageSolder Paste LiteraturescmeswarNo ratings yet

- Lost Foam Foundry SystemDocument28 pagesLost Foam Foundry SystemDeepak Khanna100% (1)

- End MillsDocument140 pagesEnd MillsGuru PrasadNo ratings yet

- The Design of Plastic Cutting Tools PDFDocument3 pagesThe Design of Plastic Cutting Tools PDFmuhammad imam100% (1)

- KORLOY Product Catalog - English: Aerospace Industry Automotive Industry Railway Industry Medical IndustryDocument1,333 pagesKORLOY Product Catalog - English: Aerospace Industry Automotive Industry Railway Industry Medical IndustryD3nnSGTAVNo ratings yet

- Basic Heat TreatmentDocument8 pagesBasic Heat TreatmentAnonymous VRspXsmNo ratings yet

- Hot Forge UpsetDocument13 pagesHot Forge UpsetAnonymous QiMB2lBCJLNo ratings yet

- Welded Tube PDFDocument17 pagesWelded Tube PDFhirenkumar patelNo ratings yet

- PCD Wire Edm Technology PDFDocument6 pagesPCD Wire Edm Technology PDFyorf1989No ratings yet

- Advantages of LPDCDocument2 pagesAdvantages of LPDCSuhas KrishnaNo ratings yet

- Heat TreatmentDocument4 pagesHeat TreatmentAshish BoraNo ratings yet

- 2019 Afab Press Brake ToolsDocument30 pages2019 Afab Press Brake ToolsAFAB Machinery and Tools LtdNo ratings yet

- Pneumatic Auto Feed Sheet Cutting MachineDocument5 pagesPneumatic Auto Feed Sheet Cutting MachineVigneshwaran Srinivasan100% (1)

- Rotational Molding: 1 History 2 Equipment and ToolingDocument8 pagesRotational Molding: 1 History 2 Equipment and ToolingEnachi Georgiana FlorinaNo ratings yet

- 1.0 Basic of PCB - 1Document30 pages1.0 Basic of PCB - 1FirmanSyah ChaniagoNo ratings yet

- Incremental Forming in Tailor Welded BlanksDocument24 pagesIncremental Forming in Tailor Welded BlanksSitanshu S0% (1)

- Sess 9 (Ceramic Mould - Pressure Die Casting - Centrifugal Casting)Document7 pagesSess 9 (Ceramic Mould - Pressure Die Casting - Centrifugal Casting)Prakash RagupathyNo ratings yet

- Near Net Shape CastingDocument3 pagesNear Net Shape CastingNURNo ratings yet

- Sheet Metal WorkingDocument23 pagesSheet Metal WorkingSujit MishraNo ratings yet

- Aluminum Alloy Specification'Document12 pagesAluminum Alloy Specification'ArjunNo ratings yet

- 2013 Theory All Inc Casting PDFDocument65 pages2013 Theory All Inc Casting PDFaamir_00No ratings yet

- 17.0 Compression MouldDocument54 pages17.0 Compression MouldMd ShareefNo ratings yet

- Lost Foam CastingDocument31 pagesLost Foam CastingokicirdarNo ratings yet

- Piercing Process Cost CalculationDocument3 pagesPiercing Process Cost CalculationVenkateswaran venkateswaranNo ratings yet

- Machine Cost & Set Up TimeDocument11 pagesMachine Cost & Set Up TimeGanesh SunderNo ratings yet

- How To Compute Tonnage RequirementsDocument5 pagesHow To Compute Tonnage RequirementsPrabhat SharmaNo ratings yet

- Dry MachiningDocument13 pagesDry Machiningbanteshyam100% (3)

- Compound Die PDFDocument4 pagesCompound Die PDFNhan Le100% (1)

- 09 Strip LayoutDocument28 pages09 Strip LayoutvivekNo ratings yet

- Rapid Sheet Metal Design GuideDocument17 pagesRapid Sheet Metal Design GuideNageswar ReddyNo ratings yet

- Manufacturing Technology: Unit - IvDocument37 pagesManufacturing Technology: Unit - IvramadanNo ratings yet

- Grinding WheelsDocument26 pagesGrinding Wheelsznovak77No ratings yet

- MoldDie enDocument28 pagesMoldDie enM. AguiarNo ratings yet

- Types of CastingDocument14 pagesTypes of CastingRamoji Aditya Chary100% (1)

- Expendable Mold CastingDocument18 pagesExpendable Mold CastingCheeragNo ratings yet

- Internal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00Document2 pagesInternal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00ramabhplNo ratings yet

- Stock Strip LayoutDocument3 pagesStock Strip LayoutSwaran Singh67% (3)

- FoundryDocument10 pagesFoundryAnjana_EdathadanNo ratings yet

- Advanced Metalurgy: Charpy TestDocument15 pagesAdvanced Metalurgy: Charpy Testsayhigaurav07No ratings yet

- Article - Screw Threads DesignDocument7 pagesArticle - Screw Threads DesignjdfdfererNo ratings yet

- Casting Processes: DR Ajay BatishDocument46 pagesCasting Processes: DR Ajay BatishAlisha GuptaNo ratings yet

- Manufacturing Processes - Moulding & ShapingDocument20 pagesManufacturing Processes - Moulding & ShapingSteven GoddardNo ratings yet

- Sand Casting: Low Cost Tooling Largest Casting Sizes Achievable Very Low Gas Porosity General VersatilityDocument13 pagesSand Casting: Low Cost Tooling Largest Casting Sizes Achievable Very Low Gas Porosity General VersatilityEmba MadrasNo ratings yet

- Faqs On Ekyc Process (Aadhaar XML Based)Document4 pagesFaqs On Ekyc Process (Aadhaar XML Based)psprajkotNo ratings yet

- Assignment Problem Air CrewDocument4 pagesAssignment Problem Air CrewpsprajkotNo ratings yet

- Step 1: Develop The Cost Table From The Given Problem:: Assignment TechniqueDocument2 pagesStep 1: Develop The Cost Table From The Given Problem:: Assignment TechniquepsprajkotNo ratings yet

- The Everyday Pocket Handbook For Visual Inspection and Weld Discontinuities - Causes and RemediesDocument35 pagesThe Everyday Pocket Handbook For Visual Inspection and Weld Discontinuities - Causes and RemediesBurag Hamparyan0% (1)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Using Welding Inspection ToolsDocument9 pagesUsing Welding Inspection ToolsMadan YadavNo ratings yet

- Taguchi Review LiteratureDocument6 pagesTaguchi Review LiteraturepsprajkotNo ratings yet

- Bottles: Mold SeamsDocument2 pagesBottles: Mold SeamsAdália TovNo ratings yet

- Lang KacangDocument5 pagesLang KacangChloe KongNo ratings yet

- Çadır Höyük - Ancient ZippalandaDocument97 pagesÇadır Höyük - Ancient ZippalandaRon GornyNo ratings yet

- Quotation: M/S. North East Construction HosurDocument9 pagesQuotation: M/S. North East Construction HosurramalingammNo ratings yet

- Romuel Christian Enriquez (MIDTERM ATIVITY)Document1 pageRomuel Christian Enriquez (MIDTERM ATIVITY)Jenny StypayNo ratings yet

- Eco Flo Leathercraft Dyeing Finishing GuideDocument8 pagesEco Flo Leathercraft Dyeing Finishing GuideAna Maria GruiaNo ratings yet

- 2626B ModernDocument188 pages2626B ModernSkinnerAuctions100% (4)

- Material ConsumptionDocument3 pagesMaterial ConsumptionDarshit VejaniNo ratings yet

- Rebecca Wolstein: PortfolioDocument34 pagesRebecca Wolstein: PortfolioBecca LeeNo ratings yet

- Arts of The Indus ValleyDocument13 pagesArts of The Indus ValleyPrashant PatelNo ratings yet

- 20th Century Design - Skinner Auction 2603BDocument140 pages20th Century Design - Skinner Auction 2603BSkinnerAuctions100% (1)

- Maitum JarsDocument2 pagesMaitum Jarsmkst123No ratings yet

- Art Samples by Eliseo Art SilvaDocument26 pagesArt Samples by Eliseo Art SilvaEliseo Art Arambulo SilvaNo ratings yet

- Pebeo PriceList 2015 USADocument148 pagesPebeo PriceList 2015 USAsdfflflk100% (1)

- Sculpture 2013 05Document84 pagesSculpture 2013 05Dragan Cvetkovic100% (1)

- Identifying Your Finds - First Steps in Identifying PotteryDocument9 pagesIdentifying Your Finds - First Steps in Identifying PotteryMacedon1anNo ratings yet

- Half Circle BagDocument2 pagesHalf Circle Baggaladrijela123No ratings yet

- Arts ExamDocument2 pagesArts ExamjomielynricafortNo ratings yet

- Color Theory Research PresentationDocument27 pagesColor Theory Research PresentationMadison Todd100% (1)

- Nigerian ARTDocument3 pagesNigerian ARTapi-253254509No ratings yet

- John Blick Ceramica ArtisticaDocument8 pagesJohn Blick Ceramica Artisticaedgar_2222No ratings yet

- Catalogue of A Collection of Continental Porcelain Lent and DescribedDocument160 pagesCatalogue of A Collection of Continental Porcelain Lent and DescribedPuiu Vasile ChiojdoiuNo ratings yet

- Milk Paint, Tempera, Casein Plastic, Bakers Clay and GessoDocument3 pagesMilk Paint, Tempera, Casein Plastic, Bakers Clay and GessoStephen MurtaughNo ratings yet

- OrientalceramicaDocument827 pagesOrientalceramicapstrlNo ratings yet

- Jhawwan (A Research by Osama Siddiq)Document2 pagesJhawwan (A Research by Osama Siddiq)ZedBoltmanNo ratings yet

- 01.carolyn Kinder - JuneDocument34 pages01.carolyn Kinder - JunenjlaporteNo ratings yet

- SürrealismDocument123 pagesSürrealismSandra Turina Vuk100% (1)

- Imagery of Chess ChecklistDocument8 pagesImagery of Chess Checklistanon-355439No ratings yet