Professional Documents

Culture Documents

Evaporator Level Control

Evaporator Level Control

Uploaded by

Vijay RajaindranOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evaporator Level Control

Evaporator Level Control

Uploaded by

Vijay RajaindranCopyright:

Available Formats

Evaporator Level Control

Evaporators are popular operating units for dewatering, concentration, and crystallization in various industries. If the density or the consistency of the

product is an important quality variable, the level control will be much more difficult.

For instance, tomato processing plants use evaporators to produce tomato paste. The density of the tomato paste is the most critical quality variable. It

is desirable to control the density within a small range. The manipulated variables are the inflow and outflow, which affect both the density and level at

the same time. The evaporator, by its nature, is a multi-input, multi-output (MIMO) process. When using single-loop controllers to control the level and

density separately, both loops can fight each other causing major problems.

A multivariable MFA controller can quickly and tightly control density and level by manipulating inflow and outflow simultaneously. An MFA constraint

controller protects the evaporator level from running too high or too low. Table 2 shows what a MIMO MFA controller can accomplish and the benefits

achieved by evaporator customers.

Table 2. MFA Control Benefits for Tomato Evaporator Control

Use of MFA Control

Manipulates inflow and outflow

simultaneously.

Reduces over-drying the paste.

Enables evaporator to be started and maintained in automatic

control.

Reduces product density variation.

Improves efficiency & productivity.

Benefits

Density control is improved by reducing variability by at least 50%.

Steam consumption is reduced.

Flexible production is enabled and load disturbances on the steam generation system

are reduced.

Product quality and production efficiency is improved for better profitability.

Full investment is returned in months if not weeks.

Summary

Based on the core MFA control method, various MFA controllers have been developed to solve specific control problems. This applies to level control

applications as well.

1. The Robust MFA controller is well suited to control the conventional level loops and provides a good protection from running too high or too low.

2. Anti-delay MFA with Feedforward MFA controllers can effectively control the steam drum level.

3. MIMO MFA can control the density and level for operating units like evaporators.

You might also like

- Girbau TBS-50 PDFDocument12 pagesGirbau TBS-50 PDFmairimsp2003100% (1)

- Flotation Control and OptimisationDocument11 pagesFlotation Control and OptimisationAmalia PănescuNo ratings yet

- Case History - MBR Plant Achieves Higher Flow With PermaCareDocument4 pagesCase History - MBR Plant Achieves Higher Flow With PermaCareSandeep K TiwariNo ratings yet

- 2008 Product CatalogueDocument255 pages2008 Product Cataloguexlongg7No ratings yet

- TXRF300/3750 Application Manual: Rigaku Industrial Corp. Application Lab. Section2Document58 pagesTXRF300/3750 Application Manual: Rigaku Industrial Corp. Application Lab. Section2Vijay RajaindranNo ratings yet

- In Line MixingDocument4 pagesIn Line MixingKemas Ganesha MahendraNo ratings yet

- A Complementary Milling and Flotation Advanced Process Control System at A Platinum ConcentratorDocument4 pagesA Complementary Milling and Flotation Advanced Process Control System at A Platinum ConcentratorquinteroudinaNo ratings yet

- Foam Generation & Application: Suprafoam ForDocument4 pagesFoam Generation & Application: Suprafoam ForchayanunNo ratings yet

- Pump Boss - Intelligent Pump Control PowerpointDocument25 pagesPump Boss - Intelligent Pump Control PowerpointChem-FlowNo ratings yet

- Sugar Mill AutomationDocument5 pagesSugar Mill AutomationZishan TyagiNo ratings yet

- PRC 3601 - Minor Test 1 MemoDocument5 pagesPRC 3601 - Minor Test 1 MemononomlngnNo ratings yet

- Fact Sheet 06Document4 pagesFact Sheet 06Canh LuongtienNo ratings yet

- Assignment PressureDocument6 pagesAssignment PressureNadia RefaiNo ratings yet

- AD353-118r1 3Document5 pagesAD353-118r1 3Rodrigo LaucataNo ratings yet

- Process Control SystemDocument20 pagesProcess Control SystemObi Augustine Azubike75% (4)

- Ketchup-Homogeneizacion 2 EtapasDocument4 pagesKetchup-Homogeneizacion 2 EtapasAsunción Iguaz GainzaNo ratings yet

- My Part in ProcessDocument8 pagesMy Part in ProcessSyafiyatulMunawarahNo ratings yet

- Alumina APC TMS Conference 2004Document7 pagesAlumina APC TMS Conference 2004Rushana ThomasNo ratings yet

- Lecture 2Document10 pagesLecture 2mahad adam OmariNo ratings yet

- CamaronesDocument4 pagesCamaroneswilkiprcNo ratings yet

- IPCDocument15 pagesIPCHamza NaseerNo ratings yet

- Automation of Palm Oil MillsDocument7 pagesAutomation of Palm Oil MillsKalana Jayatillake100% (2)

- Topic 2.0 Introduction To Process Control DynamicsDocument16 pagesTopic 2.0 Introduction To Process Control DynamicsByron MawoyoNo ratings yet

- Matching Antisurge Control Valve Performance With Integrated Turbomachinery Control SystemsDocument4 pagesMatching Antisurge Control Valve Performance With Integrated Turbomachinery Control SystemsPankaj TiwariNo ratings yet

- HTTP WWW - Spiraxsarco.com Resources Steam-Engineering-tutorials Control-Applications Pressure-Contr NewDocument15 pagesHTTP WWW - Spiraxsarco.com Resources Steam-Engineering-tutorials Control-Applications Pressure-Contr NewPalash KayathwalNo ratings yet

- Biogas in DistilleryDocument6 pagesBiogas in Distillerysatnam1979No ratings yet

- Grain DryerDocument12 pagesGrain Dryerચેતન સુથારNo ratings yet

- Control and Optimisation of A Multiple Effect Evaporator PDFDocument6 pagesControl and Optimisation of A Multiple Effect Evaporator PDFFanilo RazafindralamboNo ratings yet

- 257 771 1 SMDocument7 pages257 771 1 SMverna85mNo ratings yet

- Advanced Pressure Control and Pumping Protection Using Variable Frequency DrivesDocument9 pagesAdvanced Pressure Control and Pumping Protection Using Variable Frequency DrivesM. FakNo ratings yet

- f0362900 - Expiotech On-Line Transformer Drying - enDocument8 pagesf0362900 - Expiotech On-Line Transformer Drying - enknsbNo ratings yet

- Motor Control SystemDocument1 pageMotor Control SystemVivek AgrawalNo ratings yet

- Bulletin2005 05prd02 PDFDocument2 pagesBulletin2005 05prd02 PDFHeryanto SyamNo ratings yet

- Icroprocessor Controlled Injection Moulding AchineDocument26 pagesIcroprocessor Controlled Injection Moulding AchineRaj ThakurNo ratings yet

- ECS Ball+Mill+applicationDocument4 pagesECS Ball+Mill+applicationAmin BaigNo ratings yet

- 08 Chapter3Document15 pages08 Chapter3sunnu vermaNo ratings yet

- GEA Homogenizing Valves: in Your ProcessDocument8 pagesGEA Homogenizing Valves: in Your ProcessN srinivasan SrinivasanNo ratings yet

- Unit 1. Activity 3. Parts That Make Up A Flexible Manufacturing SystemDocument12 pagesUnit 1. Activity 3. Parts That Make Up A Flexible Manufacturing Systemjesiel valdiviesoNo ratings yet

- ALFA LAVAL - Fuel Conditioning ModuleDocument4 pagesALFA LAVAL - Fuel Conditioning ModuleJoan Maria Carulla100% (1)

- Process Control Fundamentals: Revision Date: January 2020Document202 pagesProcess Control Fundamentals: Revision Date: January 2020Didi100% (1)

- Entech Control Valve Dynamic SpecificationDocument21 pagesEntech Control Valve Dynamic SpecificationsgcurraNo ratings yet

- Filter Press Feed System Theory NETZSCH 10-28-2008Document5 pagesFilter Press Feed System Theory NETZSCH 10-28-2008Kevin DudleyNo ratings yet

- User ManualDocument32 pagesUser ManualAljun LumbaoNo ratings yet

- Automation, Control To Save FfeDocument10 pagesAutomation, Control To Save Ffenghi100% (1)

- PB302 S3 Plus Performance ControllerDocument2 pagesPB302 S3 Plus Performance ControllerZuñiga AntonioNo ratings yet

- Matching ASC Valve Performance With Integrated Turbomachinery Control System PDFDocument4 pagesMatching ASC Valve Performance With Integrated Turbomachinery Control System PDFfri_13th100% (1)

- Procidia Control Solutions Coarse/Fine Control: Application DataDocument5 pagesProcidia Control Solutions Coarse/Fine Control: Application DataRodrigo LaucataNo ratings yet

- Full Download PDF of Designing Controls For The Process Industries 1st Seames Solution Manual All ChapterDocument33 pagesFull Download PDF of Designing Controls For The Process Industries 1st Seames Solution Manual All Chapternadeeraliff100% (6)

- Reducing Energy Costs Through Closed Loop Refiner Control: Daniel WätzigDocument4 pagesReducing Energy Costs Through Closed Loop Refiner Control: Daniel WätzigDavid Alejandro GomezNo ratings yet

- Main Steam Turbine Controls Retrofit ISA FinalDocument13 pagesMain Steam Turbine Controls Retrofit ISA Finalvankayalasurya100% (1)

- Operation ManagementDocument9 pagesOperation Managementally jumanneNo ratings yet

- Pressurisation Range Brochure April 18Document24 pagesPressurisation Range Brochure April 18afzal_aabNo ratings yet

- 11.0 Instrumentation and Process Control: 11.1 ObjectivesDocument6 pages11.0 Instrumentation and Process Control: 11.1 ObjectivesAthar IqbalNo ratings yet

- PCT FormulaDocument5 pagesPCT FormulaFatih FıratNo ratings yet

- Mercedes-Benz TransmissionDocument4 pagesMercedes-Benz TransmissionSergio SantosNo ratings yet

- JISKOOT Bunker Blending Brochure PDFDocument6 pagesJISKOOT Bunker Blending Brochure PDFMich SpikeNo ratings yet

- C3controls Whitepaper Compressor Control System BasicsDocument10 pagesC3controls Whitepaper Compressor Control System BasicsasfsndNo ratings yet

- PB308Document2 pagesPB308parrastevens930No ratings yet

- FUOOTECH Series LOP Vacuum Lubricating Oil PurifierDocument15 pagesFUOOTECH Series LOP Vacuum Lubricating Oil PurifierKevin ChiangNo ratings yet

- BOilerDocument5 pagesBOilerHimanshu SharmaNo ratings yet

- 300 Wafers RunDocument8 pages300 Wafers RunVijay RajaindranNo ratings yet

- Metallic Data - F573Document8 pagesMetallic Data - F573Vijay RajaindranNo ratings yet

- Surveillance of Metallic Impurities 1Document20 pagesSurveillance of Metallic Impurities 1Vijay RajaindranNo ratings yet

- JOB Description: Position Title Department Position Reports To Job Class Job SummaryDocument2 pagesJOB Description: Position Title Department Position Reports To Job Class Job SummaryVijay RajaindranNo ratings yet

- Fats and Derivatives of Fats Consist of Mixtures of Components Differing in Chain Length and SaturationDocument1 pageFats and Derivatives of Fats Consist of Mixtures of Components Differing in Chain Length and SaturationVijay RajaindranNo ratings yet

- Name: N.Rajasegar Pillaiy A/L Nadesan Nric: 861225-14-5011 Contact: 016-2525443 Email Qualification: Bachelor in Forensic ScienceDocument2 pagesName: N.Rajasegar Pillaiy A/L Nadesan Nric: 861225-14-5011 Contact: 016-2525443 Email Qualification: Bachelor in Forensic ScienceVijay RajaindranNo ratings yet

- Pioneer - CheahDocument3 pagesPioneer - CheahVijay RajaindranNo ratings yet

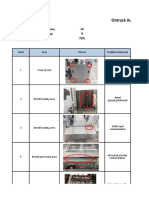

- Ontrack Audit Summary: Total Action Items 12 Total Completion 9 % Completion 75%Document8 pagesOntrack Audit Summary: Total Action Items 12 Total Completion 9 % Completion 75%Vijay RajaindranNo ratings yet

- Pioneer - Cheah2Document2 pagesPioneer - Cheah2Vijay RajaindranNo ratings yet

- Peregrine Metal Surveillance LogDocument21 pagesPeregrine Metal Surveillance LogVijay RajaindranNo ratings yet

- Rework ProcedureDocument4 pagesRework ProcedureVijay RajaindranNo ratings yet

- Surveillance of Metallic ImpuritiesDocument10 pagesSurveillance of Metallic ImpuritiesVijay RajaindranNo ratings yet

- 4 Contamination Control 2Document61 pages4 Contamination Control 2Vijay RajaindranNo ratings yet

- 6 Sept 2013Document7 pages6 Sept 2013Vijay RajaindranNo ratings yet

- Documents of Daily Check Sheets For WDs and CR10K - 20130530Document37 pagesDocuments of Daily Check Sheets For WDs and CR10K - 20130530Vijay RajaindranNo ratings yet

- Engineering Test Results FormDocument2 pagesEngineering Test Results FormVijay RajaindranNo ratings yet

- Ontrack Detail InvestigationDocument20 pagesOntrack Detail InvestigationVijay RajaindranNo ratings yet

- Engineering Test Results FormDocument1 pageEngineering Test Results FormVijay RajaindranNo ratings yet