Professional Documents

Culture Documents

TPV PDF

TPV PDF

Uploaded by

Antyox StarkOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TPV PDF

TPV PDF

Uploaded by

Antyox StarkCopyright:

Available Formats

SYSTEM JRNFORSEN

SYSTEM JRNFORSEN

2

4

GAS AND OIL FUEL BOILERS

1,35 - 10,50 MW

up to 28 bar

L

BOILER TYPE

Steam production

Power

Water capacity up to water level

Mass at 8 bar

Mass in operation

Resistance at flue gas side

Volume at flue gas side

BOILER BLOCK

Length,

Width,

Height,

Exhaust gas connection , 2

Flame tube diameter

CONNECTIONS

6 bar

Steam drawing off

8 bar

for operating

10 bar

pressure , 1

13 bar

16 bar

SAFETY VALVE , 3

6 bar

8 bar

Operating pressure

10 bar

13 bar

16 bar

Feeding , 4

Bleeding , 5

Outlet , 6

TPV

t/h

MW

m3

t

t

Pa

m3

2.0

2.00

1.35

3.80

4.80

8.90

900

2.20

2.5

2.50

1.65

6.04

5.75

12.39

850

3.65

3.2

3.20

2.10

6.09

6.10

12.79

1050

3.80

4.0

4.00

2.60

8.12

8.30

19.05

1060

4.01

5.0

5.00

3.25

9.62

8.70

19.45

1050

6.25

6.0

6.00

3.90

11.15

10.40

22.40

1000

6.80

7.0

7.00

4.55

11.85

12.90

25.62

1090

7.60

8.0

8.00

5.20

13.06

12.60

26.56

1040

8.90

10.0

10.00

6.50

15.45

15.60

32.00

1300

11.20

12.0

12.00

7.80

18.60

18.50

38.20

980

12.00

15.0

15.00

10.50

21.20

26.50

49.20

1100

26.00

L

B

H

f

f

mm

mm

mm

mm

mm

4150

1850

2170

388

800

4450

2050

2500

388

850

4650

2050

2500

388

850

5050

2130

2650

438

930

5450

2300

2745

538

950

5700

2350

2900

598

1000

5900

2550

3050

638

1050

6200

2600

3100

688

1100

6500

2700

3250

738

1150

6600

2800

3250

848

1200

7450

3200

3450

948

1400

PN(1)

DN

DN

DN

DN

DN

125

100

80

80

80

150

125

100

100

100

150

125

125

100

100

150

150

125

125

100

200

150

150

125

100

250

200

150

150

125

250

200

200

150

125

250

200

200

200

150

300

250

200

200

150

300

250

200

200

200

350

300

250

250

200

DN

DN

DN

DN

DN

DN

DN

DN

40

32

32

25

25

40

40

32

32

32

50

40

40

32

32

50

50

40

40

32

65

50

50

40

40

80

65

65

50

40

80

80

65

50

50

100

80

65

50

50

100

100

65

65

50

125

100

65

65

65

125

100

80

65

65

25

20

25

25

20

25

32

20

25

32

20

32

40

20

32

50

20

40

50

20

40

50

20

40

65

20

50

65

20

50

80

20

50

PN(1)

PN(1)

PN(1)

PN(1)

PN 16

PN 16

PN 25

PN 40

PN 40

PN (2)

PN 40

PN 40

(1) up to 10 bar and up to DN 200 NP 16, more than 10 bar and up to DN 150 NP 40

(2) up to 10 bar NP 16, more than 10 bar NP 40

All dimensions are strictly informative and can be adjusted according to the customer needs

JRNFORSEN Energi System AB

Stenvinkelsgatan 2C, 302 36 Halmstad, Sweden

Tel. +46 35 17 75 50

Fax. +46 35 17 75 59

Email: info@jf-energi.se

http://www.jf-energi.com

TPV

EMO BOILERS

THREE-PASS FIRE TUBE EMO BOILER

FOR STEAM GENERATION

SYSTEM JRNFORSEN

TPV STEAM BOILER

13

14

17

15

The JRNFORSEN boiler type TPV is

horizontal type designed for saturated and

superheated steam in the range from 2 to 15

4

6

1

For this reason the Jrnforsen TPV boiler has

automatic control and special regulating system

that assures safe and effective operation. All

manufactured according to the latest

saturated or superheated steam boiler

When fuel is converted into energy the boiler

design has to meet several safety precautions.

t\h. It is a three-pass fire tube boiler unit

burning gas or oil fuel. The boiler is

SAFETY TECHNOLOGY AND AUTOMATION

devices and elements are provided by the

10

optimum manufacturing engineering

manufacturer.

large power range

thermodinamically optimized

flexible and economical performance

16

11

ECOLOGY

the highest techically possible efficiency

For boilers manufactured by Jrnforsen

stable operation and rapid heat transfer

environmentally compatible materials are used. In

high quality components for combustion chamber

order to reduce emissions, the latest research

low emissions and noise

results are incorporated in production and tuning

inspection and approval by TV

of the firing system. Therefore fuel is converted

CE certificate

into heat with reduced level of harmful

easy operation and maintenance

substances, which means stress on the

automatic control and regulating system

environment is minimized.

maximum service availability

2

18

12

ECONOMY

CONSTRUCTION

The boiler pressure part, which is set on the boiler

frame, consists of the boiler body, combustion

chamber, front and rear inverting chamber, flue

gas tubes, supervision openings and appropriate

connections. The cylindrical boiler body forms the

Boiler body

Rear inverting chamber

13

Feed valve

Boiler frame

Convective part cleaning opening

14

Steam valve

Combustion chamber (fire tube)

Smoke outlet

15

Safety valve

2. pass gas-flue tubes

10

Insulation

16

Mud valve

3. pass gas-flue tubes

11

Oil or gas burner

17

Manometer

Front inverting chamber

12

Feed pump

18

Control panel

water and steam space. Dimension of the

The design is improved so the high level of

combustion heat (over 90 %) is transfered to the

water. The special insulating materials are used to

keep the radiation heat losses to minimum. The

firing system is optimized to reduce fuel

consumption. The boiler is monitored and

regulated to achieve optimal efficiency in all

operating conditions.

combustion chamber, flue gas tubes, water space

and steam space are thermodinamically

FRONT AND REAR INVERTING CHAMBER

STEAM PRODUCTION

APPLICATION

The gases from the combustion chamber change

The boiler is fed with treated degasified water,

The boiler is used to produce technological steam

COMBUSTION CHAMBER AND FLUE-GAS TUBES

direction in the rear and front inverting chamber to

which is evenly distributed to all tube walls and

and hot water. It is suitable for industrial

The arrangement of the combustion chamber and

enter the second and the third pass. Perfect

surroundings like fire tube, flue gas tubes and

applications such as food, textile, building

flue gas tubes guarantees smooth heat transfer

cooling of inverting chambers contributes to

inverting chambers. That guarantees efficient

materials, chemicals, cheramics and paper

and stable water circulation under all operating

economical operation. The front inverting

heat transfer from gases to the water and assures

industry with large heat and steam consumption

conditions. Gas flue tubes form a second and third

chamber is equiped with large doors to enable

minimal thermal stresses. Superheated steam is

for processing, production and heating. It can be

pass of the boiler and represent the convective

convective boiler part cleaning or simple

generated with superheater modules placed on

used with small steam engines or turbines.

part of the heating surfaces.

exchange of possible damaged flue gas tubes.

the top of the boiler body.

optimized for flexible performance.

You might also like

- Manual: For Tublar BoilerDocument99 pagesManual: For Tublar BoileryahiateneNo ratings yet

- Boiler Water TreatmentDocument1 pageBoiler Water TreatmentRommel Cena Nepalar100% (1)

- System Automatic Control Level Dan Temperature Dearator: Pt. Multi Ganda ScoteknikDocument18 pagesSystem Automatic Control Level Dan Temperature Dearator: Pt. Multi Ganda Scoteknikichsan100% (1)

- (2003) Wagner. Prediction of Deactivation Rates and Mechanisms of Methane Reforming Over Nickel CatalystsDocument2 pages(2003) Wagner. Prediction of Deactivation Rates and Mechanisms of Methane Reforming Over Nickel CatalystsSarahEkaPutriDarlismawantyaniNo ratings yet

- RP44B TocDocument13 pagesRP44B TocPiespi PitwomNo ratings yet

- 118 - Package Boiler BrochureDocument8 pages118 - Package Boiler BrochureBayu Pramana PutraNo ratings yet

- Steam Boiler - Fluidized BedDocument10 pagesSteam Boiler - Fluidized BedEdhi SutantoNo ratings yet

- Tugas Kelas A Termodinamika Industri KimiaDocument1 pageTugas Kelas A Termodinamika Industri KimiaayatbimaNo ratings yet

- Mengatasi Masalah Silica Sand MeltingDocument9 pagesMengatasi Masalah Silica Sand MeltingTb RamdaniNo ratings yet

- 91 - Package Boilers Profile Final PDFDocument3 pages91 - Package Boilers Profile Final PDFMiftah HijriawanNo ratings yet

- Hoken Boiler 2015 CatalogueDocument8 pagesHoken Boiler 2015 CatalogueJose Lorenzo Toral100% (1)

- Beda Nm3 Dengan Sm3Document2 pagesBeda Nm3 Dengan Sm3Ahmad Yusuf AffandiNo ratings yet

- Omron E5CWL PDFDocument12 pagesOmron E5CWL PDFmaloyNo ratings yet

- 72 Europac BrochureDocument2 pages72 Europac BrochureAntyox Stark100% (1)

- 1.3 Boiler OperationDocument23 pages1.3 Boiler OperationLydia RupidaraNo ratings yet

- Catalogue Air Dryer ARXDocument8 pagesCatalogue Air Dryer ARXtrantrunghoa1984No ratings yet

- Tugas PAP Latihan Soal Bab 7Document2 pagesTugas PAP Latihan Soal Bab 7IvanaMargaretNo ratings yet

- Loos Parni Kotlovi enDocument20 pagesLoos Parni Kotlovi enŽarko Krkeljić100% (1)

- Hydrazine DosingDocument2 pagesHydrazine DosingAnonymous 3HTgMDO100% (1)

- 10 Soal Turbin Uap LengkapDocument4 pages10 Soal Turbin Uap Lengkaptoys deeNo ratings yet

- Checklist Stasiun Engine Room-TurbinDocument11 pagesChecklist Stasiun Engine Room-Turbinslamet supriyadiNo ratings yet

- 02 Logsheet Turbin DeskDocument7 pages02 Logsheet Turbin DeskKeniBataraNo ratings yet

- Prosedur Operational Turbine ElliotDocument2 pagesProsedur Operational Turbine ElliotDeni DeniNo ratings yet

- Technical Specification: Omnibloc DdhoDocument5 pagesTechnical Specification: Omnibloc DdhoRyan PatraNo ratings yet

- StartupDocument28 pagesStartupAjay Chauhan100% (1)

- Pabrik Baturaja III PT. Semen Baturaja (Persero) TBKDocument3 pagesPabrik Baturaja III PT. Semen Baturaja (Persero) TBKIzzy Rss Outsiders100% (1)

- Ruzicka CP Estimation MethodDocument11 pagesRuzicka CP Estimation MethodAndreea Cristina PetcuNo ratings yet

- Reaktor Trickle BedDocument8 pagesReaktor Trickle BedAgaNo ratings yet

- Fire-Tube Steam-Boiler BWB Babcock Wanson PDFDocument2 pagesFire-Tube Steam-Boiler BWB Babcock Wanson PDFAlejandroNo ratings yet

- BAB III Air Umpan BoilerDocument36 pagesBAB III Air Umpan BoilermasnawatiNo ratings yet

- Power Plant Numerical PDFDocument3 pagesPower Plant Numerical PDFAhsan Ali0% (1)

- Prarancangan Pabrik Sodium Nitrat Dari Caustic Soda Dan Nitric AcidDocument1 pagePrarancangan Pabrik Sodium Nitrat Dari Caustic Soda Dan Nitric AcidAnggit Dwi WNo ratings yet

- Coal Fired Fluid Bed Boiler: Salient FeaturesDocument12 pagesCoal Fired Fluid Bed Boiler: Salient FeaturesBangto YibsipNo ratings yet

- Something Related To Catalysts.Document2 pagesSomething Related To Catalysts.Deepro BhattacharyaNo ratings yet

- Conversion Table (Tabel Konversi)Document1 pageConversion Table (Tabel Konversi)Kevin ArdiansyahNo ratings yet

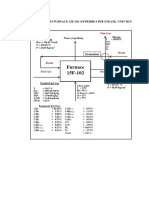

- Blok Diagram Furnace 15F-102Document1 pageBlok Diagram Furnace 15F-102aribas100% (1)

- Root Cause Failure AnalysisDocument12 pagesRoot Cause Failure AnalysisHaidar YafieNo ratings yet

- CFBC Boiler Training ManualDocument4 pagesCFBC Boiler Training ManualGusti Prasetyo Rendy AnggaraNo ratings yet

- Burner ManualDocument28 pagesBurner ManualTesfaye ejetaNo ratings yet

- Mollier Diagram ColoredDocument1 pageMollier Diagram ColoredhalerNo ratings yet

- Pengenalan Teknik MesinDocument21 pagesPengenalan Teknik MesinReinaldy MaslimNo ratings yet

- Perhitungan Cooling TowerDocument8 pagesPerhitungan Cooling TowermeimeiNo ratings yet

- 5.1 Combustion of OilDocument6 pages5.1 Combustion of Oilkcp1986No ratings yet

- Prarancangan Pabrik Alumunium Klorida Dari Bauksit Dan HCL Dengan Kapasitas 35000 Ton Per TahunDocument49 pagesPrarancangan Pabrik Alumunium Klorida Dari Bauksit Dan HCL Dengan Kapasitas 35000 Ton Per TahunGhina Fatikah SalimNo ratings yet

- Tugas Bab 2Document6 pagesTugas Bab 2Wibowo Unggul0% (1)

- Siklus RankineDocument26 pagesSiklus RankineArialdi Almonda0% (1)

- Desain Dan Uji Kinerja Alat Pembakar SampahDocument54 pagesDesain Dan Uji Kinerja Alat Pembakar SampahAzieZunMaulanaAhmadNo ratings yet

- 0053Document1 page0053superowelNo ratings yet

- BoilerDocument35 pagesBoilerrizkydjonhansemitNo ratings yet

- Seminar Kerja PraktekDocument24 pagesSeminar Kerja PraktekRicky UtamaNo ratings yet

- Ref List of Boiler - PT. Grand Kartech TBKDocument6 pagesRef List of Boiler - PT. Grand Kartech TBKMirwan PrasetiyoNo ratings yet

- Tugas 1 Perancangan Alat ProsesDocument6 pagesTugas 1 Perancangan Alat ProsesAldo HoseaNo ratings yet

- Esp Ash Hopper & Blow Tank SystemDocument13 pagesEsp Ash Hopper & Blow Tank SystemZaid ChelseaNo ratings yet

- Oilon Duoblock Burners For Liquid and Gaseous FuelsDocument94 pagesOilon Duoblock Burners For Liquid and Gaseous FuelsDian PriengadiNo ratings yet

- Steam EjectorDocument2 pagesSteam EjectoralmengarunNo ratings yet

- Test for Half of Condenser Operation冷凝器半面运行试验Document2 pagesTest for Half of Condenser Operation冷凝器半面运行试验erwin5sambas5aryanaNo ratings yet

- Turbine Supervisory InstrumentationDocument3 pagesTurbine Supervisory InstrumentationMAS98No ratings yet

- Steam Turbine Basic TheoryDocument34 pagesSteam Turbine Basic TheoryEliyanto E BudiartoNo ratings yet

- Tugas BoilerDocument33 pagesTugas BoilerAgus Dwi Nurcahyo JemberNo ratings yet

- Prextherm RSW 2010 GB - 1Document8 pagesPrextherm RSW 2010 GB - 1kasztakatikaNo ratings yet