Professional Documents

Culture Documents

Suscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, Aquí

Suscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, Aquí

Uploaded by

Carlos Nombela PalaciosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Suscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, Aquí

Suscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, Aquí

Uploaded by

Carlos Nombela PalaciosCopyright:

Available Formats

Suscribete GRATIS a la revista: SOLDADURA LATINOAMERICA, aqu:

http://www.egrupos.net/grupo/soldaduralatinoamerica/alta

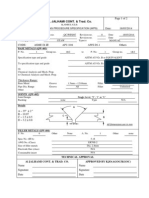

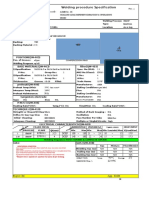

AWS D1.1 Prequalified Welding Procedure Specification (pWPS)

Identification #

P1-A-Lh-Structural Rev. 0

Originated by

Z.N.G. Neer

Date

9/19/00

Authorised by

John Smith

Date

9/19/00

Joint design used

Position

Joint type

B - Butt joint

Welding

Groove All

Joint design

Single V groove (2)

position:

Backing

Yes

Fillet n/a

Backing material Carbon Steel

Vertical

Up

progression

Root opening

(in.) 1/4, +1/16, -0 (+1/4, -1/16)

Electrical characteristics

(R)*

Transfer mode

Root face (f)* (in.) n/a

N/A

(GMAW)

Grove angle

(deg.) 45, +10, -0 (+10, -5)

Current type

DCEP

(a)*

Other

Radius (J (deg.) n/a

Technique

U)*

Stringer or weave

Back gouging

No

Stringer or Weave

bead

Back gouging

n/a

Multi/single pass

method

Single or Multiple

Base metals

*Datum AsDetailed (As Fit-Up) (per side)

Number of electrodes Single electrode

Spec. type or grade SA-36 (UNS K02600)

Longitudinal

Groove

Spacing:

Thickness:

T1:unlimited

(in.)

(in.)

Lateral (in.) Fillet (in.) n/a

Angle (deg.) Diameter

(in.) (Pipe)

Contact tube to

(in.) work

Filler metals

AWS Specification 5.1

Peening

Not permitted

AWS

Interpass cleaning

Brushing or grinding

E7018

Classification

Preheat

Shielding

Min.

Preheat

See notes

Flux

temp.:

(F)

Electrode-flux

Interpass

(class)

See notes

temp.: Min.(F)

Gas composition Max.(F)) See notes

Gas flow rate (cfh) Post weld heat treatment

Gas cup size (in.) Company name

Welding process

Process type

ASME IX Corporation

SMAW

Manual

Temperature (F) None

Time

(hrs) -

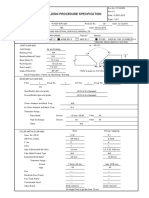

Welding procedure

Wire

Filler

Travel

Filler

Current

feed

metal

speed

Layer Pass Process metal

type / Amps speed Volts

diameter

class

polarity

(in.)

(in./min)

(in./min)

70All All SMAW E7018 3/32 DCEP

manual manual

110

90 All All SMAW E7018

1/8

DCEP

manual manual

150

120All All SMAW E7018 5/32 DCEP

manual manual

190

170All All SMAW E7018 3/16 DCEP

manual manual

280

Joint details

Designation B-U2a

NOTES

PREHEAT/INTERPASS

For thickness 1/8 to 3/4(in.): 32(F). Preheat to 70(F) if the base metal temperature is below

32(F).

Over 3/4 thru 1-1/2(in.): 50(F).

Over 1-1/2 thru 2-1/2(in.): 150(F).

Over 2-1/2(in.): 225(F).

Welding Engineer

Name

Z.N.G. Neer

Date

9/19/00

Signature

QA Manager

Name

John Smith

Date

9/19/00

Signature

You might also like

- Wps For SS 304Document3 pagesWps For SS 304MuraliKrishna87% (23)

- Ami-003 WPSDocument2 pagesAmi-003 WPSBenjamin BrownNo ratings yet

- Wps SawDocument2 pagesWps Sawdevendrasingh2021100% (7)

- Metrode WPS SuperduplexDocument4 pagesMetrode WPS SuperduplexClaudia Mms100% (3)

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- WPS - D1.1 - Prequalified Procedures QSSLDocument26 pagesWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedNo ratings yet

- 1015 To Hastelloy VickoDocument14 pages1015 To Hastelloy Vickovgestantyo100% (1)

- Welding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauDocument5 pagesWelding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauTharakeshNo ratings yet

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- MIG Welding PWPSDocument1 pageMIG Welding PWPSelectronicmail2ughf6525No ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Wps ExampleDocument2 pagesWps ExampleAnonymous stV08Js44VNo ratings yet

- WPS B-U2a-GF - GMAWDocument1 pageWPS B-U2a-GF - GMAWwentropremNo ratings yet

- PQR SAW ProcessDocument1 pagePQR SAW Processdevendrasingh202133% (3)

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationSAKDA MAPRADITKULNo ratings yet

- 3060 Wps 1Document4 pages3060 Wps 1api-280725686No ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Welder Operators Qualification TestDocument2 pagesWelder Operators Qualification Testlokifarad100% (1)

- Company Name: Uhde Enpc: Pr0JectDocument1 pageCompany Name: Uhde Enpc: Pr0Jecteldobie3No ratings yet

- Manual Structural WeldingDocument12 pagesManual Structural WeldingwalitedisonNo ratings yet

- WPS Aws D1 1Document2 pagesWPS Aws D1 1Rohit MalhotraNo ratings yet

- WPS - D1.1Document1 pageWPS - D1.1Nam_HitechNo ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- WPS (Welding of Hub To Blade)Document2 pagesWPS (Welding of Hub To Blade)workshop13.asaNo ratings yet

- PQR02 (For SMAW)Document2 pagesPQR02 (For SMAW)workshop13.asaNo ratings yet

- WPS Aws D1.1Document2 pagesWPS Aws D1.1tuatk67% (6)

- Group 5 13crmo 4-5: Company Name: Uhde EnpcDocument1 pageGroup 5 13crmo 4-5: Company Name: Uhde Enpceldobie3No ratings yet

- 3060 Guess WpsDocument4 pages3060 Guess Wpsapi-280725686No ratings yet

- Aws D1 1 PQRDocument2 pagesAws D1 1 PQRHermanNo ratings yet

- P1 A C LHDocument2 pagesP1 A C LHMohamed Reda HusseinNo ratings yet

- Pwps 06Document1 pagePwps 06eldobie3No ratings yet

- Formato AWSDocument3 pagesFormato AWSDuverlyOrlandoMattaVásquezNo ratings yet

- Data Collection For Shrinkage2Document97 pagesData Collection For Shrinkage2SagarNo ratings yet

- WPS-021, 09.07.07, Page-1Document2 pagesWPS-021, 09.07.07, Page-1nidhinchandranvsNo ratings yet

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- Company Name: Uhde Enpc: Pr0JectDocument1 pageCompany Name: Uhde Enpc: Pr0Jecteldobie3No ratings yet

- Welding Procedure Specification Structural-3GDocument3 pagesWelding Procedure Specification Structural-3Gdndudc80% (10)

- Company Name: Uhde Enpc: Pr0JectDocument1 pageCompany Name: Uhde Enpc: Pr0Jecteldobie3No ratings yet

- FCAW Overlay WPSDocument2 pagesFCAW Overlay WPSAsad Bin Ala Qatari100% (1)

- HOMOLOGACIONES 8 GTAW - SMAW - Setiembre 2014 PDFDocument8 pagesHOMOLOGACIONES 8 GTAW - SMAW - Setiembre 2014 PDFklapton1276No ratings yet

- Welding Book Revised 2012 07 14Document15 pagesWelding Book Revised 2012 07 14surya1960No ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Ami-001 WPSDocument2 pagesAmi-001 WPSPramod Athiyarathu100% (1)

- Visual and NDT Examination Certificate: Cargo Carrying Unit (Ccu)Document1 pageVisual and NDT Examination Certificate: Cargo Carrying Unit (Ccu)Michael OkwuwaNo ratings yet

- AWSPWPSDocument1 pageAWSPWPSVrangalov PeroNo ratings yet

- AWS - Prequalified Welding Procedure Specification (PWPS) : Joint Design Used PositionDocument1 pageAWS - Prequalified Welding Procedure Specification (PWPS) : Joint Design Used PositionMarcelle PollNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Harshad100% (1)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- Company Name: Uhde Enpc: Pr0JectDocument1 pageCompany Name: Uhde Enpc: Pr0Jecteldobie3No ratings yet

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Quality Control SystemsDocument8 pagesQuality Control SystemsCarlos Nombela PalaciosNo ratings yet

- Welding News 1 - 2012: Super Duplex Miscellanea New ColleaguesDocument10 pagesWelding News 1 - 2012: Super Duplex Miscellanea New ColleaguesCarlos Nombela PalaciosNo ratings yet

- Fontargen Sales ProgramDocument20 pagesFontargen Sales ProgramCarlos Nombela PalaciosNo ratings yet

- Boehler Dcms Ti-Fd Fde en 1Document1 pageBoehler Dcms Ti-Fd Fde en 1Carlos Nombela PalaciosNo ratings yet

- Alform 700 MCDocument9 pagesAlform 700 MCCarlos Nombela PalaciosNo ratings yet

- Suscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, AquíDocument1 pageSuscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, AquíCarlos Nombela PalaciosNo ratings yet

- PQR Asme Ix - CompletedDocument3 pagesPQR Asme Ix - CompletedCarlos Nombela Palacios100% (1)

- 112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Document33 pages112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Carlos Nombela PalaciosNo ratings yet

- Welding Procedure For Asme Code SwpsDocument1 pageWelding Procedure For Asme Code SwpsCarlos Nombela PalaciosNo ratings yet

- Antrag 15085 Engl KoA RichtlinieDocument9 pagesAntrag 15085 Engl KoA RichtlinieCarlos Nombela PalaciosNo ratings yet