Professional Documents

Culture Documents

Ashrae 1.1

Ashrae 1.1

Uploaded by

abidch143Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ashrae 1.1

Ashrae 1.1

Uploaded by

abidch143Copyright:

Available Formats

ERRATA SHEET FOR ASHRAE GUIDELINE 1.

1-2007

HVAC&R Technical Requirements for the Commissioning Process

July 2, 2012

The corrections listed in this errata sheet apply to all copies of ASHRAE Guideline 1.1-2007. The

first printing is identified as 86812 PC 6/08 on the outside back cover, the second printing is

identified as Product Code: 86812 8/09, the third printing is identified as Product Code: 86812

9/11. The shaded item has been added since the previously published errata sheet dated

November 7, 2011 was distributed.

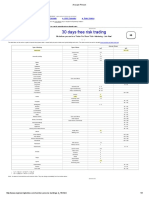

Page

Erratum

85

Table 9A. Ductwork: Installation. In Item 1.A.4 of Table 9A change the word casting to

casing.

95

Table 13. Fan Coil Unit, CW & HW: FCU-1. Renumber the items in Item 2.H of Table 13 as

follows:

H

1

2

3

4

5

6

7

8

9

TAB

Filters and coils are clean

Motor rotation verified

Motor overloads verified

Motor voltage and amps verified - each phase

Entering and leaving cooling coil air temperature (F)

Entering and leaving heating coil air temperature (F)

Entering and leaving chilled water temperature (F)

Entering and leaving hot water temperature (F)

Coil flow and air/water pressure drops verified - each coil

Yes

Yes

Yes

Yes

/

/

/

/

Yes

No

No

No

No

/

/

/

/

No

Table 17. HVAC Piping: Installation. Change Step 3 in the Instructions as follows:

98

(Note: Additions are shown in underline and deletions are shown in strikethrough.)

Step 3: Samples of installed piping ductwork will be periodically reviewed to verify compliance.

98

Table 17. HVAC Piping: Installation. In Item 1.A.4 of Table 17 change close to closed.

98

Table 17. HVAC Piping: Installation. Reformat Table 17 with indentation and bolding as

shown in the attached.

100

Table 18. VAV Box, Non Fan Powered w/HW Heat: VAV-1. Remove the Yes or No

answer in Item 2.F.4 and replace with:

4

101

Entering and leaving coil water temperatures (F)

Table 19. Pump, HVAC: P-1. Renumber the items in Item 1.B of Table 19 as follows:

B

1

2

3

4

5

6

Page 1 of 4

Physical Checks

Unit is free from physical damage

All components present

The water openings are sealed with plastic plugs

Unit tags affixed

Installation and startup manual provided

Manufacturers ratings readable/accurate

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

2012 ASHRAE. All rights reserved.

132

Figure S-1 Typical interdisciplinary coordination and ceiling section detail on drawings. The

current Figure S-1 in Guideline 1.1-2007 is unreadable. Replace it with the version attached.

Page 2 of 4

2012 ASHRAE. All rights reserved.

17. HVAC Piping: Installation

ASHRAE Guideline 1.1 Example Checklist

Instructions: Step 1: Circle Yes or No and fill in with requested information.

Step 2: Explain all "No" responses at the bottom of the checklist.

Step 3: Samples of installed piping will be periodically reviewed to verify compliance.

Item

1

A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Task Description

System Checks

Installation Checks

Piping is clean and free of damage prior to installation.

Piping is free to expand and contract without noise or damage to hangers, joints, or

the building.

Piping is installed with sufficient pitch and arranged in a manner to ensure drainage

and venting of the entire system.

Manual air vents are provided at high points in closed water systems.

Changes in pipe sizes are made with the proper size reducing fittings, reducing

fittings, reducing elbow or reducing tees. Bushings are not allowed.

All piping supports and hangers meet criteria set in Section 15140 of the

specifications.

All fittings meet specification requirements.

All equipment requiring maintenance is accessible (valves, junction boxes, etc.).

Piping does not block access to equipment that is part of this system or another

system (e.g., air terminal units).

Piping is installed in a manner to ensure that insulation will not contact adjacent

surfaces.

All pipe openings are temporarily sealed to maintain piping system cleanliness.

Record drawings have been updated to reflect any changes made.

Nipples are made of the same material as the pipe.

Connections between copper and steel pipes are made with dielectric fittings.

A union is provided ahead of each screwed valve, trap, or strainer, and on each

side of each piece of equipment and whatever needed to dismantle piping.

Mechanical coupling if used is only used for piping and locations as described in

the specification section 15060.

The chilled water system is installed with high pressure fittings, flanges and unions.

Auxiliary drain valves are provided at all low points in hose bib piping to facilitate

seasonal draining.

A clearance of 8 ft 2 in. is maintained throughout the parking structure. Walkers

drawings have been consulted for exact location of pipe spaces, ceilings heights,

and other details before installing piping.

Page 3 of 4

Response

Submitted

Yes

Yes

Delivered

No

No

Yes

No

Yes

Yes

No

No

Yes

No

Yes

Yes

Yes

No

No

No

Yes

No

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

Yes

No

Yes

Yes

No

No

Yes

No

2012 ASHRAE. All rights reserved.

Figure S-1 Typical interdisciplinary coordination and ceiling section detail on drawings.

Page 4 of 4

2012 ASHRAE. All rights reserved.

You might also like

- ASHRAE Guideline 0-2019 The Commissioning Process PDFDocument66 pagesASHRAE Guideline 0-2019 The Commissioning Process PDFMahmoud Gwaily100% (6)

- Certification Study Guide Building Commissioning Professional (BCXP) D-90288Document135 pagesCertification Study Guide Building Commissioning Professional (BCXP) D-90288Mike KennedyNo ratings yet

- Building Energy Modeling: An ASHRAE Certification Study GuideDocument90 pagesBuilding Energy Modeling: An ASHRAE Certification Study GuideFaheem Mushtaq100% (1)

- Guideline 0.2 Commissioning Process For Existing Systems and Assemblies 2015Document80 pagesGuideline 0.2 Commissioning Process For Existing Systems and Assemblies 2015Abd Alhadi100% (2)

- ASHRAE Guideline 36-2018 PDFDocument103 pagesASHRAE Guideline 36-2018 PDFWil FridNo ratings yet

- ASHRAE Guideline 1.5-2017Document36 pagesASHRAE Guideline 1.5-2017Abdelrahman Elged50% (2)

- BCXP Candidate Guidebook PDFDocument74 pagesBCXP Candidate Guidebook PDFAakib alamNo ratings yet

- ANSI ASHRAE Standard 90.4-2019Document60 pagesANSI ASHRAE Standard 90.4-2019Arafa SalemNo ratings yet

- NFPA 99 Health Care Facilities Code 2018: NFPA 99From EverandNFPA 99 Health Care Facilities Code 2018: NFPA 99No ratings yet

- Schedule QDocument31 pagesSchedule Qabidch143100% (11)

- Ashrae 1342005 Ra 2014 Graphic Symbols For Heating VentilatiDocument84 pagesAshrae 1342005 Ra 2014 Graphic Symbols For Heating VentilatiDanZel Dan83% (6)

- Air Distribution Systems: CIBSE Commissioning Code ADocument43 pagesAir Distribution Systems: CIBSE Commissioning Code Aaxel50% (2)

- BG11 2010 Commissioning Job BookDocument97 pagesBG11 2010 Commissioning Job BookFinlay0% (1)

- ANSI - AHRI Standard I34-2005 (RA2014)Document84 pagesANSI - AHRI Standard I34-2005 (RA2014)Guy BlouinNo ratings yet

- Water Treatment For Closed Heating and C PDFDocument112 pagesWater Treatment For Closed Heating and C PDFhans30No ratings yet

- Saep 1150Document50 pagesSaep 1150abidch14383% (54)

- Ashrae 202 2013Document33 pagesAshrae 202 2013anmellaNo ratings yet

- Ashrae Icc Usgbc Ies 189.1-2017Document156 pagesAshrae Icc Usgbc Ies 189.1-2017Mahmoud Gwaily100% (5)

- Commissioning Hvac Systems Guidance On The Division of Responsibilities (Sample)Document4 pagesCommissioning Hvac Systems Guidance On The Division of Responsibilities (Sample)Neil Jastiva Sayco0% (1)

- Heating and Ventilating Contractors' AssociationDocument4 pagesHeating and Ventilating Contractors' Associationsshoeburrahman0% (2)

- Symbols - STD 134Document32 pagesSymbols - STD 134Joaquim MonteiroNo ratings yet

- Nfpa 92BDocument3 pagesNfpa 92BsnakiiiNo ratings yet

- Direct Digital Controls and Commissioning - Shadpour PDFDocument30 pagesDirect Digital Controls and Commissioning - Shadpour PDFalexander alvaradoNo ratings yet

- Ashrae CX Plan SpecDocument312 pagesAshrae CX Plan SpecSchreiber_Dieses100% (1)

- CIBSE Commissioning Code L - Lighting PDFDocument30 pagesCIBSE Commissioning Code L - Lighting PDFThomas Or100% (2)

- Ansi Ashrae Acca 183-2007 (Ra 2014)Document10 pagesAnsi Ashrae Acca 183-2007 (Ra 2014)Ahmed Labib100% (3)

- BSC - PS - 3 26 13Document72 pagesBSC - PS - 3 26 13arifzakirNo ratings yet

- Sprinkler Symbol PDFDocument1 pageSprinkler Symbol PDFabidch143No ratings yet

- Fire Rated Door CertificateDocument1 pageFire Rated Door Certificateabidch143No ratings yet

- SBC 601 2007 - Saudi Building Code (Energy Conservation)Document13 pagesSBC 601 2007 - Saudi Building Code (Energy Conservation)abidch143No ratings yet

- Saep 14Document53 pagesSaep 14abidch143100% (1)

- ASHRAE Guideline 0-2013 The Commissioning ProcessDocument72 pagesASHRAE Guideline 0-2013 The Commissioning ProcessLNo ratings yet

- Introduction To ASHRAE Standard 202: Commissioning Process For Buildings and SystemsDocument19 pagesIntroduction To ASHRAE Standard 202: Commissioning Process For Buildings and SystemsOmar ArdilaNo ratings yet

- Commissioning Process For Buildings and Systems: ANSI/ASHRAE/IES Addendum A To ANSI/ASHRAE/IES Standard 202-2013Document6 pagesCommissioning Process For Buildings and Systems: ANSI/ASHRAE/IES Addendum A To ANSI/ASHRAE/IES Standard 202-2013anmellaNo ratings yet

- Energy For The BuildingsDocument75 pagesEnergy For The Buildingssasikala100% (1)

- Comissioning PlanDocument54 pagesComissioning PlanNARUNCFD100% (1)

- ASHRAE Standard 202 - Commissioning Buildings - Schneider ElectricDocument6 pagesASHRAE Standard 202 - Commissioning Buildings - Schneider Electricangel_rojas_38No ratings yet

- NEBBinar ASHRAE 202 PDFDocument42 pagesNEBBinar ASHRAE 202 PDFrasheedillikkal100% (3)

- CIBSE GuideMAppendix12 A1 IELC PDFDocument43 pagesCIBSE GuideMAppendix12 A1 IELC PDFAbdullah AlawadhiNo ratings yet

- High Performance Sequences of Operation For HVAC Systems: ASHRAE Addendum H To ASHRAE Guideline 36-2018Document26 pagesHigh Performance Sequences of Operation For HVAC Systems: ASHRAE Addendum H To ASHRAE Guideline 36-2018suhasNo ratings yet

- Ashrae - Ashrae189.1Document33 pagesAshrae - Ashrae189.1jimmiilongNo ratings yet

- 170 2013 Ae 20141008 PDFDocument8 pages170 2013 Ae 20141008 PDFDamir ĆavarNo ratings yet

- Preview ASHRAE+Guideline+1.4-2019Document4 pagesPreview ASHRAE+Guideline+1.4-2019pol100% (1)

- NIBS Guideline 3-2012 Building Enclosure Commissioning ProcessDocument337 pagesNIBS Guideline 3-2012 Building Enclosure Commissioning ProcessJohn CleggNo ratings yet

- Ashrae Qatar Presentation - 23 March 19Document97 pagesAshrae Qatar Presentation - 23 March 19Jose Luis Alvarez GonzalvesNo ratings yet

- BEAP Candidate GuidebookDocument44 pagesBEAP Candidate GuidebookSuhaib JuwaleNo ratings yet

- 140 2004Document160 pages140 2004Joaquim MonteiroNo ratings yet

- CIBSE Commissioning Code A - Air Distribution Systems (1996 Confirmed 2006)Document33 pagesCIBSE Commissioning Code A - Air Distribution Systems (1996 Confirmed 2006)Thomas Or100% (6)

- Previews ASHRAE D 90453 PreDocument25 pagesPreviews ASHRAE D 90453 PreronychavesNo ratings yet

- TAB Procedures From An Engineering FirmDocument18 pagesTAB Procedures From An Engineering Firmtestuser180No ratings yet

- HVAC Commissioning Report PDFDocument117 pagesHVAC Commissioning Report PDFbambang sudarsono100% (1)

- HVAC Handbook Commissioning GuidelineDocument145 pagesHVAC Handbook Commissioning Guidelinebabmech600795% (21)

- Procedural Standards Certified Testing Cleanrooms: 2009 - Third EditionDocument140 pagesProcedural Standards Certified Testing Cleanrooms: 2009 - Third EditionAraya Job Dhananukulkit100% (2)

- Ashrae 55Document74 pagesAshrae 55Temitope Vic100% (1)

- Building Enclosure Commissioning: Standard Practice ForDocument19 pagesBuilding Enclosure Commissioning: Standard Practice ForAdán Cogley CantoNo ratings yet

- NABB FORMS WatermarkDocument35 pagesNABB FORMS Watermarkmarjan 01100% (1)

- DG251 14 Electrical ServicesDocument3 pagesDG251 14 Electrical Servicesnirmalb21No ratings yet

- GDL1.1 2007errata - 7 2 2012Document4 pagesGDL1.1 2007errata - 7 2 2012Bisho AtefNo ratings yet

- PEAKE Package A-CDocument14 pagesPEAKE Package A-CEduardo PierluissiNo ratings yet

- Shiller York ManualDocument54 pagesShiller York ManualUndibal Alejandro Rivas100% (1)

- Vaq RaqDocument4 pagesVaq RaqgreismarNo ratings yet

- Specification For Control ValveDocument5 pagesSpecification For Control ValveamilasriNo ratings yet

- SBM Technology: Cooling / Air Recovery ValveDocument8 pagesSBM Technology: Cooling / Air Recovery ValveEricsson BotchweyNo ratings yet

- HFCC D Iom 03Document16 pagesHFCC D Iom 03geovany_villagraNo ratings yet

- Sys A CDocument40 pagesSys A Cdnageshm4n244No ratings yet

- Air Curtain PDFDocument8 pagesAir Curtain PDFabidch143No ratings yet

- CLimate DEsign Condition - ASHRAEDocument1 pageCLimate DEsign Condition - ASHRAEabidch143No ratings yet

- 3 Ways To Align A Centrifugal Pump PDFDocument4 pages3 Ways To Align A Centrifugal Pump PDFabidch143No ratings yet

- Design of Air Conditioning DuctsDocument15 pagesDesign of Air Conditioning Ductsabidch143No ratings yet

- National Factory 3 Way DiffusersDocument16 pagesNational Factory 3 Way Diffusersabidch143No ratings yet

- Kitchen Hoods GeneralDocument55 pagesKitchen Hoods Generalabidch143No ratings yet

- Heatexchanger TestDocument6 pagesHeatexchanger Testabidch143No ratings yet

- Ceiling DiffuserDocument2 pagesCeiling Diffuserabidch143No ratings yet

- Moisture Barrier On Metal Jacketing & Kraft PaperDocument2 pagesMoisture Barrier On Metal Jacketing & Kraft Paperabidch143No ratings yet

- Ventilation & Exhaust CalculationDocument4 pagesVentilation & Exhaust Calculationabidch143100% (1)

- Velocity of Water in PipeDocument4 pagesVelocity of Water in Pipeabidch143100% (1)

- admissible: لوبق لباق یدنب گنج cease fireDocument1 pageadmissible: لوبق لباق یدنب گنج cease fireabidch143No ratings yet

- Area Per PersonDocument5 pagesArea Per Personabidch143No ratings yet

- Installation Instructions For Fire Dampers: in Drywall Type Construction 1 Hour and 2 Hour RatedDocument4 pagesInstallation Instructions For Fire Dampers: in Drywall Type Construction 1 Hour and 2 Hour Ratedabidch143No ratings yet

- Chiller CompressorDocument41 pagesChiller Compressorabidch143No ratings yet