Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

48 viewsAllowable Stress in Tension: Technical Note Calculation of Allowable Stresses

Allowable Stress in Tension: Technical Note Calculation of Allowable Stresses

Uploaded by

jirrsamaalllow

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- My Boilie MachineDocument16 pagesMy Boilie MachinejirrsamaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Spreader Bar CalculationDocument1 pageSpreader Bar Calculationjirrsama100% (1)

- Tank Foundation Design ProcedureDocument53 pagesTank Foundation Design ProcedureMichael Teo82% (11)

- Vortex BreakerDocument1 pageVortex BreakerMamank Ira SudrajatNo ratings yet

- External Insulation For Hot ServiceDocument12 pagesExternal Insulation For Hot Servicejirrsama100% (1)

- Continental Structure CatalougeDocument2 pagesContinental Structure CatalougejirrsamaNo ratings yet

- Our Engineering Department: ASME Code CalculationsDocument1 pageOur Engineering Department: ASME Code CalculationsjirrsamaNo ratings yet

- G S D L S T: Uidelines Eismic Esign of Iquid Torage AnksDocument112 pagesG S D L S T: Uidelines Eismic Esign of Iquid Torage AnksrapaigNo ratings yet

- Bolt Bolt Torque ChartDocument5 pagesBolt Bolt Torque ChartjirrsamaNo ratings yet

- SKPETRO-Cover To Page 30Document32 pagesSKPETRO-Cover To Page 30jirrsamaNo ratings yet

- Tepat Teknik SDN BHD - Welded CoverDocument1 pageTepat Teknik SDN BHD - Welded CoverjirrsamaNo ratings yet

- BS5950-1:2000 - A Designer's Practical ViewDocument8 pagesBS5950-1:2000 - A Designer's Practical Viewmarianuid100% (1)

Allowable Stress in Tension: Technical Note Calculation of Allowable Stresses

Allowable Stress in Tension: Technical Note Calculation of Allowable Stresses

Uploaded by

jirrsama0 ratings0% found this document useful (0 votes)

48 views19 pagesalllow

Original Title

Allowable Stress

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentalllow

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

48 views19 pagesAllowable Stress in Tension: Technical Note Calculation of Allowable Stresses

Allowable Stress in Tension: Technical Note Calculation of Allowable Stresses

Uploaded by

jirrsamaalllow

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 19

COMPUTERS AND STRUCTURES, INC,, BERKELEY, CALIFORNIA DECEMBER 2001

‘STEEL FRAME DesiGN AISC-ASD89

Technical Note

Calculation of Allowable Stresses

This Technical Note explains how the program calculates the allowable

stresses in compression, tension, bending, and shear for Compact, Noncom-

pact, and Slender sections. The allowable flexural stresses for all shapes of

sections are calculated based on their principal axes of bending. For the |,

Box, Channel, Circular, Pipe, T, Double-angle and Rectangular sections, the

principal axes coincide with their geometric axes. For the Angle sections, the

principal axes are determined and all computations related to flexural stresses

are based on that.

If the user specifies nonzero allowable stresses for one or more elements in

the Steel Frame Design Overwrites form (display using the Design menu >

Steel Frame Design > Review/ Revise Overwrites command), the

nonzero values will be used rather than the calculated values for those

elements. The specified allowable stresses should be based on the principal

axes of bending.

Allowable Stress in Tension

The allowable axial tensile stress value F, is assumed to be 0.60 Fy.

Fa= 0.6 Fy (ASD D1, ASD SAM 2)

It should be noted that net section checks are not made. For members

in tension, if ir is greater than 300, a message to that effect is printed (ASD

B7, ASD SAM 2). For single angles, the minimum radius of gyration, ris used

instead of rz and rag in computing Ir.

Allowable Stress in Compression

The allowable axial compressive stress is the minimum value obtained from

flexural buckling and flexural-torsional buckling. The allowable compressive

stresses are determined according to the following subsections.

‘Allowable Stress in Tension Page 1 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

For members in compression, if Ki/r is greater than 200, a warning message

is printed (ASD B7, ASD SAM 4). For single angles, the minimum radius of

gyration, rz, is used instead of rzz and raz in computing Kir.

Flexural Buckling

The allowable axial compressive stress value, Fe, depends on the slenderness

ratio Ki/r based on gross section properties and a corresponding critical value,

C., where

Kggl.

max aslo Keele ong

r 33. tee

(ASD E2, ASD SAM 4)

For single angles, the minimum radius of gyration, r,, is used instead of rp

and rgg in computing Kir.

For Compact or Noncompact sections, Fz,is evaluated as follows:

ae ip Bee, , (ASD E2-1, SAM 4-1)

5 3(Kl/r) (Klin) r

3° 8C, 8C3

2

re, it Loc, (ASD E2-2, SAM 4-2)

23(KI/ r) r

If Ki/r is greater than 200, the calculated value of F, is taken not to exceed

the value of Fa, calculated by using the equation ASD E2-2 for Compact and

Noncompact sections (ASD E1, B7).

For Slender sections, except slender Pipe sections, Fy is evaluated as follows:

2

1.9 (KL ) Jn

KL

—__26< J __ it Co. (E2-2, A-B5-12)

23(KI/ 1) ¢

where,

and (ASD E2, A-B5.2c, SAM 4)

(ASD C-E2-2, SAM 4-4)

‘Allowable Stress in Compression Page 4 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

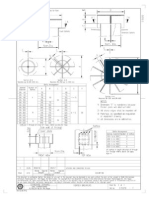

Table 1 Reduction Factor for Unstiffened Slender Elements, Q,

Section Reduction Factor for Unstiffened Slender Elements Equation

Type (a) Reference

10 if BiQ= WT eR

I-SHAPE 1,293 0.00309[6/2t] JF 7k. it 95/ jay < br2t<195/ JF 7R,, | ASDABSS.

26.200ke / {[b/2t}2F;,} if bi2te 198 Je Tk. ASD A-B5-4

BOX Qs=1 ASD A-B5.2c

ASD A853,

CHANNEL As for shapes with by! 2t replaced by by! t ASD A-BE-4

For flanges, as for flanges in I-shapes. For web, see below. ASD ASS

1.0 if biivs 127 JF, ASD ABS-4

TSHAPE | Qs. 4 1.908-0.00715 [dt] je it 1271 fe, 176! fF, ASD A-B5-6

10 i bts 761 IF, ASD A-BS-1,

DOUBLE: | Qs. 41,340-0.00447 [bid JF it 65 ksi. (ASD F1-5)

For Noncompact sections:

Faso = (0 79 - 0.002 aim Fi if rolled and f,<65 ksi, (ASD F1-3)

b, [Fy -

Fuss = |0.79-0.002°" |-¥ Fit welded and f,< 65 ksi, (ASDF1-4)

Bt, Vk.

Fagg = 0.60 F, it f,> 65 ksi (ASD F1-5)

If the unbraced length /2 is greater than |,, then for both Compact and Non-

compact |-sections the allowable bending stress depends on the /z2 /rr ratio

f

For 22 < |102,0006,

mV %

Foss = 0.60 Fy, (ASD F1-6)

02,0000, _ re _ [510,0000,

|= c Bs PS

Y& ny

‘Allowable Stress in Bending Page 9 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

Fy (loo f rr)®

gg = | 2 ule)" |g <0.60 6, and (ASD F1-6)

3 1,530,006,

lop _ [510,000C,

ey [Pee

for I

rT Y Fy

(leo! tr)

and Figs is taken not to be less than that given by the following formula:

12,0006,

Frag = <0.60 F; ASD F1-8

88" ald] A, * ‘ :

where,

ry is the radius of gyration of a section comprising the compression flange

and 1/3 the compression web taken about an axis in the plane of the web,

2

Cy = 1.75 + 1.05 (| +03 (in| <2.3, where (ASD F1.3)

Mp Mp

M, and Mp are the end moments of any unbraced segment of the member and

M, is numerically less than M,; M,/ M, being positive for double curvature

bending and negative for single curvature bending. Also, if any moment

within the segment is greater than Ms, Cp is taken as 1.0. Also, Gp is taken as

1.0 for cantilevers and frames braced against joint translation (ASD F1.3).

The program defaults C; to 1.0 if the unbraced length, /z2, of the member is

redefined by the user (i.e., it is not equal to the length of the member). The

user can overwrite the value of Cy for any member by specifying it.

The allowable bending stress for Slender sections bent about their major axis

is determined in the same way as for a Noncompact section. Then the follow-

ing additional considerations are taken into account.

If the web is slender, the previously computed allowable bending stress is re-

duced as follows:

Foss = ReaReFoss, where (ASD G2-1)

‘Allowable Stress in Bending Page 10 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

Reg = 1.0- 0.0005 4x |" _ 760 | <4 9, (ASD G2)

ALE VFoss

12+ (@a- 08) Ae

Re= ———_*_ <1.0, (hybrid girders) (ASD G2)

Aw

12424

A

Re= 1.0, (non-hybrid girders) (ASD G2)

Ay = Area of web, in?,

A;= Area of compression flange, in’,

_ 0.6,

a= <1.0 (ASD G2)

Figg= Allowable bending stress assuming the section is non-compact, and

F'p3s= Allowable bending stress after considering web slenderness.

In the above expressions, Re is taken as 1, because currently the program

deals with only non-hybrid girders.

If the flange is slender, the previously computed allowable bending stress is

taken to be limited, as follows.

F'oas < Q; (0.6 Fy), where (ASD A-B5.2a, A-B5.2d)

Qzis defined earlier.

Minor Axis of Bending

The minor direction allowable bending stress Fy22 is taken as follows:

For Compact sections:

Fooo = 0.75 Fy if f,< 65 ksi, (ASD F2-1)

Foz = 0.60 Fy if f)> 65 ksi. (ASD F2-2)

For Noncompact and Slender sections:

‘Allowable Stress in Bending Page 11 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

Foe = ( 075-0 005 2, Fy, if fy 65 ksi, (ASD F2-3)

1

Fiz2 = 0.60 Fy if f,> 65 ksi. (ASD F2-2)

Channel Sections

For Channel sections, the length parameter is taken as the laterally unbraced

length, /z2, which is compared to a critical length, J. The critical length is de-

fined as

in 4 261 20,000 Ay | , where (ASD F1-2)

Ve Oy

Avis the area of compression flange.

Major Axis of Bending

If lz is less than Jc, the major allowable bending stress for Compact and Non-

compact sections is taken depending on whether the section is welded or

rolled and whether f, is greater than 65 ksi or not.

For Compact sections:

Foss = 0.66 Fy if f,< 65 ksi, (ASD F1-1)

Fosg = 0.60 Fy if f)> 65 ksi. (ASD F1-5)

For Noncompact sections:

Fig3 = (0 79 0.00274 F, | F, if rolled and f,< 65 ksi, (ASD F1-3)

'

[F,

Foss = ° 79 -0.002 t lk |p if welded and f,<65 ksi, (ASD F1-4)

1 Vke

Foa3= 0.60 Fy if fy> 65 ksi. (ASD F1-5)

If the unbraced length /2 is greater than /,, then for both Compact and Non-

compact Channel sections the allowable bending stress is taken as follows:

‘Allowable Stress in Bending Page 12 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

12,0000,

ee < 0.60 Fy (ASD F1-8)

lea(dl Ar)

Fogg =

The allowable bending stress for Slender sections bent about their major axis

is determined in the same way as for a Noncompact section. Then the follow-

ing additional considerations are taken into account.

If the web is slender, the previously computed allowable bending stress is re-

duced as follows:

Fys3= ReRpaFoss (ASD G2-1)

If the flange is slender, the previously computed allowable bending stress is

taken to be limited as follows:

F'33= Qs (0.60 Fy) (ASD A-B5.2a, A-B5.2d)

The definitions for rp, Cy, Ay An Re, Rec, Qs, Fisg, and F'pg3 are given earlier

Minor Axis of Bending

The minor direction allowable bending stress Fozo is taken as follows:

Fo22= 0.60 Fy (ASD F2-2)

T Sections and Double Angles

For T sections and Double angles, the allowable bending stress for both major

and minor axes bending is taken as,

Fo = 0.60 Fy

Box Sections and Rectangular Tubes

For all Box sections and Rectangular tubes, the length parameter is taken as

the laterally unbraced length, /z2, measured compared to a critical length, [c.

The critical length is defined as

(ASD F3-2)

Fy

5

Io= max {980 +1,.200M,/ My) 2, seo

ion as noted earlier in the formula for

1,200b

y

where M, and M, have the same defi

in the program.

Cy. If zg is specified by the user, ,is taken as

‘Allowable Stress in Bending Page 13 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

Major Axis of Bending

If fis less than /,, the allowable bending stress in the major direction of

bending is taken as

Fosg= 0.66 Fy (for Compact sections) (ASD F3-1)

Fos3= 0.60 Fy (for Noncompact sections) (ASD F3-3)

If zp exceeds |,, the allowable bending stress in the major direction of bend-

ing for both Compact and Noncompact sections is taken as:

Fos3= 0.60 Fy (ASD F3-3)

The major direction allowable bending stress for Slender sections is deter-

mined in the same way as for a Noncompact section. Then the following addi-

tional consideration is taken into account. If the web is slender, the previously

computed allowable bending stress is reduced as follows

Fo3g= ReReaFoss (ASD G2-1)

The definitions for Re, Ree, Foss and F'pss are given earlier.

If the flange is slender, no additional consideration is needed in computing

allowable bending stress. However, effective section dimensions are calcu-

lated and the section modulus is modified according to its slenderness.

Minor Axis of Bending

If zz is less than J,, the allowable bending stress in the minor direction of

bending is taken as

Foz2= 0.66 Fy (for Compact sections) (ASD F3-1)

Fizo= 0.60 Fy (for Noncompact and Slender sections) (ASD F3-3)

If zp exceeds |, the allowable bending stress in the minor direction of bend-

ing is taken, irrespective of compactness, as

Foz2= 0.60 Fy (ASD F3-3)

Pipe Sections

For Pipe sections, the allowable bending stress for both major and minor axes

of bending is taken as

‘Allowable Stress in Bending Page 14 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

Fy= 0.66 Fy (for Compact sections), and (ASD F3-1)

Fo= 0.60 Fy (for Noncompact and Slender sections). (ASD F3-3)

Round Bars

The allowable stress for both the major and minor axis of bending of round

bars is taken as,

Fy= 0.75 Fy. (ASD F2-1)

Rectangular and Square Bars

The allowable stress for both the major and minor axis of bending of solid

square bars is taken as,

Fy= 0.75 Fy. (ASD F2-1)

For solid rectangular bars bent about their major axes, the allowable stress is

given by

Fo= 0.60 Fy, and

the allowable stress for minor axis bending of rectangular bars is taken as

Foz 0.75 Fy. (ASD F2-1)

Single-Angle Sections

The allowable flexural stresses for Single-angles are calculated based on their

principal axes of bending (ASD SAM 5.3).

Major Axis of Bending

The allowable stress for major axis bending is the minimum considering the

limit state of lateral-torsional buckling and local buckling (ASD SAM 5.1).

The allowable major bending stress for Single-angles for the limit state of lat-

eral-torsional buckling is given as follows (ASD SAM 5.1.3):

Fomajor = [ 25-0105] Fs if Foo SF, (ASD SAM 5-3a)

y

[Fr

Fo,major = |0 95 -0.50- Fy,S0.66F, if Fo > Fy (ASD SAM 5-3b)

ob

‘Allowable Stress in Bending Page 15 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

where, Fy, is the elastic lateral-torsional buckling stress as calculated below.

The elastic lateral-torsional buckling stress, Fs», for equal-leg angles is taken

as

28,250

Fon = Ci

OS TE

(ASD SAM 5-5)

and for unequal-leg angles, F,yis calculated as

Fon = 143,1000,, [68 +£0.052(It J tnin)® +bu | (ASD SAM 5-6)

where,

t = min(ty, t,

I = max(lz2,133),

Inn = minor principal moment of inertia,

Imax = major principal moment of inertia,

Smajor = Major section modulus for compression at the tip of one leg,

Tmin = radius of gyration for minor principal axis,

Bu= | Ia zw? + 24)dA|-220, (ASD SAM 5.3.2)

Z = coordinate along the major principal axis,

w_ = coordinate along the minor principal axis, and

Zo = coordinate of the shear center along the major principal axis with

respect to the centroid.

By is a special section property for angles. It is positive for short leg in com-

pression, negative for long leg in compression, and zero for equal-leg angles

(ASD SAM 5.3.2). However, for conservative design in the program, it is al-

ways taken as negative for unequal-leg angles.

‘Allowable Stress in Bending Page 16 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

In the previous expressions, C; is calculated in the same way as is done for |

sections, with the exception that the upper limit of C, is taken here as 1.5 in-

stead of 2.3.

2

M, M,

= 175+ 1.05/72 |+0.9 | 72] <1.5 (ASD F1.3, SAM 5.2.2)

ly A

The allowable major bending stress for Single-angles for the limit state of lo-

cal buckling is given as follows (ASD SAM 5.1.1):

Fomajor = 0.66 Fy if a (ASD SAM 5-1a)

vey

Fimajor = 0.60 Fy if (ASD SAM 5-1b)

Fomajor = Q(0.60 F)) if (ASD SAM 5-1c)

where,

t= thickness of the leg under consideration,

b= length of the leg under consideration, and

Q= slenderness reduction factor for local buckling.(ASD A-B5-2, SAM 4)

In calculating the allowable bending stress for Single-angles for the limit state

of local buckling, the allowable stresses are calculated considering the fact

that either of the two tips can be under compression. The minimum allowable

stress is considered.

Minor Axis of Bending

The allowable minor bending stress for Single-angles is given as follows (ASD

SAM 5.1.1, 5.3.1b, 5.3.2b):

Fo,minor = 0.66 Fy if (ASD SAM 5-1a)

‘Allowable Stress in Bending Page 17 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

Fominor = 0.60 Fy if 2 <

(ASD SAM 5-1b)

Fi, minor = Q(0.60 Fy) if (ASD SAM 5-1)

In calculating the allowable bending stress for Single-angles, it is assumed

that the sign of the moment is such that both the tips are under compression.

The minimum allowable stress is considered.

General Sections

For General sections, the allowable bending stress for both major and minor

axes bending is taken as

Fo = 0.60 Fy.

Allowable Stress in Shear

The allowable shear stress is calculated along the geometric axes for all sec-

tions. For 1, Box, Channel, T, Double angle, Pipe, Circular and Rectangular

sections, the principal axes coincide with their geometric axes. For Single-

angle sections, principal axes do not coincide with the geometric axes.

Major Axis of Bending

The allowable shear stress for all sections except I, Box and Channel sections

is taken in the program as

F, = 0.40 Fy (ASD F4-1, SAM 3-1)

The allowable shear stress for major direction shears in |-shapes, boxes and

channels is evaluated as follows:

F, = 0.40 Fy, it 2 < 380 | ang (ASD F4-1)

w VF

vFy

380 A

it <2 <260. ASD F4-2

WF tw “oe

where,

‘Allowable Stress in Shear Page 18 of 19

Steel Frame Design AISC-ASD89 Calculation of Allowable Stresses

28.000ky i 2h 2 56,2504

F,(h/ ty) tw Fy

G= fw) (ASD F4)

190 [ky i 2 <56,250

hjty VF, ty Fy

(ASD F4)

4.004 8.84 | it 24

ky= (a/ hy h

5.34400 By

(a/ hy A

ty = Thickness of the web,

a = Clear distance between transverse stiffeners, in. Currently it is

taken conservatively as the length, /z2, of the member in the pro-

gram,

h = Clear distance between flanges at the section, in

Minor Axis of Bending

The allowable shear stress for minor direction shears is taken as:

F,= 0.40 Fy (ASD F4-1, SAM 3-1)

‘Allowable Stress in Shear Page 19 of 19

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- My Boilie MachineDocument16 pagesMy Boilie MachinejirrsamaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Spreader Bar CalculationDocument1 pageSpreader Bar Calculationjirrsama100% (1)

- Tank Foundation Design ProcedureDocument53 pagesTank Foundation Design ProcedureMichael Teo82% (11)

- Vortex BreakerDocument1 pageVortex BreakerMamank Ira SudrajatNo ratings yet

- External Insulation For Hot ServiceDocument12 pagesExternal Insulation For Hot Servicejirrsama100% (1)

- Continental Structure CatalougeDocument2 pagesContinental Structure CatalougejirrsamaNo ratings yet

- Our Engineering Department: ASME Code CalculationsDocument1 pageOur Engineering Department: ASME Code CalculationsjirrsamaNo ratings yet

- G S D L S T: Uidelines Eismic Esign of Iquid Torage AnksDocument112 pagesG S D L S T: Uidelines Eismic Esign of Iquid Torage AnksrapaigNo ratings yet

- Bolt Bolt Torque ChartDocument5 pagesBolt Bolt Torque ChartjirrsamaNo ratings yet

- SKPETRO-Cover To Page 30Document32 pagesSKPETRO-Cover To Page 30jirrsamaNo ratings yet

- Tepat Teknik SDN BHD - Welded CoverDocument1 pageTepat Teknik SDN BHD - Welded CoverjirrsamaNo ratings yet

- BS5950-1:2000 - A Designer's Practical ViewDocument8 pagesBS5950-1:2000 - A Designer's Practical Viewmarianuid100% (1)