Professional Documents

Culture Documents

Spit Dynabolt

Spit Dynabolt

Uploaded by

MadePCopyright:

Available Formats

You might also like

- Azure Cognitive ServicesDocument340 pagesAzure Cognitive Servicespepsiholic dreamNo ratings yet

- Method Statement of TrenchingDocument14 pagesMethod Statement of Trenchingahmed0883949450% (2)

- First Year Progress Report NRPU-10483Document105 pagesFirst Year Progress Report NRPU-10483Obaid100% (2)

- Manual Calc Steel Column FinalDocument17 pagesManual Calc Steel Column FinalKein GrajoNo ratings yet

- Exactly The Power You Need.: The NC-B SeriesDocument12 pagesExactly The Power You Need.: The NC-B SeriesbalanNo ratings yet

- Alvedoor Marine - Product Division of R&M GroupDocument148 pagesAlvedoor Marine - Product Division of R&M Groupmauboch100% (1)

- 9110 355 EbpDocument5 pages9110 355 EbpCecep HendriyatnaNo ratings yet

- Are They Pour Lines or Cold Joints - tcm45-348413Document4 pagesAre They Pour Lines or Cold Joints - tcm45-348413محمد كاشف جاويدNo ratings yet

- MS-E011-ALF-MS For Installation of LVAC PanelsDocument7 pagesMS-E011-ALF-MS For Installation of LVAC PanelsvipinrajNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFchacNo ratings yet

- MUARA KARANG NT216 Rev00 Laying InstructionsDocument35 pagesMUARA KARANG NT216 Rev00 Laying InstructionsDio AkhbarNo ratings yet

- A Cylinder Test ReportDocument2 pagesA Cylinder Test Reportraju_420034520No ratings yet

- Dynabolt Zinc Coated Steel Design GuideDocument4 pagesDynabolt Zinc Coated Steel Design GuideMuhammad SarajevoNo ratings yet

- Anchor DesignDocument4 pagesAnchor DesignAnonymous BAzcBzWuNo ratings yet

- Design Calculation: Season 2 - Mechanical and Chemical Anchor CalculationDocument23 pagesDesign Calculation: Season 2 - Mechanical and Chemical Anchor CalculationNaveenNo ratings yet

- Stainless StudsDocument4 pagesStainless StudsNestramiNo ratings yet

- Hilti Manual For BoltDocument11 pagesHilti Manual For Boltcsengineer20% (1)

- HSA Stud AnchorDocument11 pagesHSA Stud AnchorWin ThanNo ratings yet

- 2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Document9 pages2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Difa LiuNo ratings yet

- Hilti HVZ 1Document13 pagesHilti HVZ 1Mihnea-Bogdan NicolaescuNo ratings yet

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Document9 pagesTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNo ratings yet

- Socket Screws MetricDocument32 pagesSocket Screws Metricnick10686No ratings yet

- HVZ Adhesive Anchor: Basic Loading Data (For A Single Anchor) : HAS - (E-) TZDocument10 pagesHVZ Adhesive Anchor: Basic Loading Data (For A Single Anchor) : HAS - (E-) TZBogdanBNo ratings yet

- 6 Hsa Stud Anchor 92-102Document11 pages6 Hsa Stud Anchor 92-102vkumar_625189No ratings yet

- FTM '12 HKD Push-In AnchorDocument14 pagesFTM '12 HKD Push-In AnchorShankerNo ratings yet

- Chumbador HiltDocument14 pagesChumbador HiltSamanta FigueredoNo ratings yet

- Anchor Fastening Technology ManualDocument152 pagesAnchor Fastening Technology ManualfdsafsadfNo ratings yet

- HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, MixerDocument11 pagesHIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixerlael00No ratings yet

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Document12 pagesHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuNo ratings yet

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDocument10 pagesHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruNo ratings yet

- Simplified Design Method: Tension LoadingDocument1 pageSimplified Design Method: Tension LoadingRimon GawandeNo ratings yet

- HSV-R2 Stud Anchor: Concrete (Non-Cracked)Document8 pagesHSV-R2 Stud Anchor: Concrete (Non-Cracked)Ambreen FatimaNo ratings yet

- Hydraulic Cylinders CHDocument8 pagesHydraulic Cylinders CHStoianovici CristianNo ratings yet

- 44 - HVZ Adhesive AnchorDocument14 pages44 - HVZ Adhesive AnchorHuan VoNo ratings yet

- Rigid Flexible Waveguide ComponentsDocument10 pagesRigid Flexible Waveguide Componentsapi-30606527No ratings yet

- HKD Push-In Anchor: Basic Loading Data (For A Single Anchor) : HKD-S /-EDocument8 pagesHKD Push-In Anchor: Basic Loading Data (For A Single Anchor) : HKD-S /-EsorengbhanuNo ratings yet

- DB53112610ENDocument2 pagesDB53112610ENDamian SzczypieńNo ratings yet

- RS BobbinsDocument3 pagesRS BobbinsleeboldNo ratings yet

- Minex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5Document20 pagesMinex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5HyungTae JangNo ratings yet

- HVU Adhesive With HAS Rod: Basic Loading Data (For A Single Anchor) : HVU Capsule With HAS, HAS-EDocument5 pagesHVU Adhesive With HAS Rod: Basic Loading Data (For A Single Anchor) : HVU Capsule With HAS, HAS-EChristopher GarciaNo ratings yet

- Hilti Bolt Connection-4 anchor-HSTDocument5 pagesHilti Bolt Connection-4 anchor-HSTTuấnThanhNo ratings yet

- Fijaciones Químicas 2012 PDFDocument0 pagesFijaciones Químicas 2012 PDFMarcelo AlbeNo ratings yet

- SL2008-491 Omission of Cylinder-Cover-Mounted Safety ValvesDocument5 pagesSL2008-491 Omission of Cylinder-Cover-Mounted Safety ValvesAman MankotiaNo ratings yet

- Apron Feeder Spare Part ListDocument17 pagesApron Feeder Spare Part ListParmeshwar Nath Tripathi100% (1)

- HKV Technical Data SheetDocument5 pagesHKV Technical Data SheetWZNo ratings yet

- Hilti HKV DatasheetDocument5 pagesHilti HKV DatasheetozkanhasanNo ratings yet

- Unbrako Catalog FastenerDocument26 pagesUnbrako Catalog Fastenerdesign_rajeev100% (2)

- 26-HVU Adhesive With HAS RodDocument9 pages26-HVU Adhesive With HAS RodAdam ChougleNo ratings yet

- 07 Assembly CS - ENDocument90 pages07 Assembly CS - ENandersson benito herreraNo ratings yet

- 07 Assembly HP - ENDocument67 pages07 Assembly HP - ENandersson benito herreraNo ratings yet

- Hvu HasDocument9 pagesHvu Hassri_amartNo ratings yet

- HST TensionDocument10 pagesHST Tensionnu.arabiaNo ratings yet

- 07 Assembly CP - ENDocument104 pages07 Assembly CP - ENandersson benito herreraNo ratings yet

- MTB500iWRTXM /22°/L241/H50 44,0350,3494,637Document26 pagesMTB500iWRTXM /22°/L241/H50 44,0350,3494,637Saranyoo CHOOTIMASNo ratings yet

- Amphennot Connectors CatalogDocument68 pagesAmphennot Connectors Catalogrr0bertNo ratings yet

- +696wxgdqfkru: HSV Stud AnchorDocument9 pages+696wxgdqfkru: HSV Stud AnchorThang VoNo ratings yet

- Hilti Bolt Connection-6 anchor-HSTDocument5 pagesHilti Bolt Connection-6 anchor-HSTTuấnThanhNo ratings yet

- 3 Hit-Hy150 HisnDocument9 pages3 Hit-Hy150 Hisndd160179No ratings yet

- Fischer FBN AnchorsDocument23 pagesFischer FBN AnchorsIstván SzékelyNo ratings yet

- Hilti HST 1Document11 pagesHilti HST 1Mihnea-Bogdan NicolaescuNo ratings yet

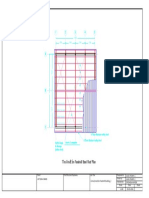

- List DrawingDocument4 pagesList DrawingMadePNo ratings yet

- Pl1250p - Open TypeDocument1 pagePl1250p - Open TypeMadePNo ratings yet

- 7a PDFDocument3 pages7a PDFMadePNo ratings yet

- Rumus DefleksiDocument2 pagesRumus DefleksiMadePNo ratings yet

- Rumus Defleksi N Rotasi Balok KantileverDocument2 pagesRumus Defleksi N Rotasi Balok KantileverMadePNo ratings yet

- Tabel Perhitungan Concrete Breakout Strength Kolom PedestalDocument1 pageTabel Perhitungan Concrete Breakout Strength Kolom PedestalMadePNo ratings yet

- Urutan Berat Profil BajaDocument1 pageUrutan Berat Profil BajaMadePNo ratings yet

- Architecture of 8086Document27 pagesArchitecture of 8086Amitabh DixitNo ratings yet

- Jost-208 ManualDocument198 pagesJost-208 ManualdamindaNo ratings yet

- 150 5345 42J Light BasesDocument48 pages150 5345 42J Light BasesHerney MarinNo ratings yet

- CIGWELD General CatalogueDocument78 pagesCIGWELD General CataloguedobolanNo ratings yet

- Sales Territories: Sales Territory Is A Usually A Geographical Area Assigned To A Salesperson or Group of PersonsDocument14 pagesSales Territories: Sales Territory Is A Usually A Geographical Area Assigned To A Salesperson or Group of PersonsPhenomenal SinghNo ratings yet

- EE272 Digital Systems Fall 2019 Instructor: Dr. Aashir WaleedDocument41 pagesEE272 Digital Systems Fall 2019 Instructor: Dr. Aashir Waleedsyed waheedNo ratings yet

- How To Modify The Styles Option On Word: Formato Código CBI-F031 Guide Versión 01 Values Fecha AprobaciónDocument5 pagesHow To Modify The Styles Option On Word: Formato Código CBI-F031 Guide Versión 01 Values Fecha AprobaciónDavid A Reyes MNo ratings yet

- NUS Ultrasonic Level Transmitter: 11.5 Feet in SolidsDocument4 pagesNUS Ultrasonic Level Transmitter: 11.5 Feet in SolidsRoy Moya HNo ratings yet

- Back Panel: Front Panel:: Downloaded From Manuals Search EngineDocument2 pagesBack Panel: Front Panel:: Downloaded From Manuals Search EngineJorgeA.GaritaNo ratings yet

- Advances in Application of ICT in Crop Pest and Disease ManagementDocument8 pagesAdvances in Application of ICT in Crop Pest and Disease Managementpaola ribeiroNo ratings yet

- TableNo19 C 1Document92 pagesTableNo19 C 1SMNo ratings yet

- AUH01-RED-D1-XX-RT-X-06000 - MEP Stage 4 Design Proposal - P7Document43 pagesAUH01-RED-D1-XX-RT-X-06000 - MEP Stage 4 Design Proposal - P7Abhilash100% (1)

- 0a-Esp8266ex Datasheet enDocument31 pages0a-Esp8266ex Datasheet enEverton PereiraNo ratings yet

- Feedmill Building - 2 PDFDocument1 pageFeedmill Building - 2 PDFlasssyNo ratings yet

- Getting Started Guide For Freebsd: Release 20.08.0Document16 pagesGetting Started Guide For Freebsd: Release 20.08.0Arindam ChakrabortyNo ratings yet

- RR TF21 Cullinan 20230929Document6 pagesRR TF21 Cullinan 20230929Miguel Couto RamosNo ratings yet

- Dap-2330 Reva Datasheet 1.00Document5 pagesDap-2330 Reva Datasheet 1.00iim ibrahimNo ratings yet

- Summative Test G 7 FINALDocument2 pagesSummative Test G 7 FINALFlorencio CoquillaNo ratings yet

- iDRAC6 2.92 A00 ReleaseNotesDocument10 pagesiDRAC6 2.92 A00 ReleaseNotesfrippiht_505702242No ratings yet

- Biological Safety Cabinet - AC2-G3 - Brochure - A4 - VG - LRDocument8 pagesBiological Safety Cabinet - AC2-G3 - Brochure - A4 - VG - LRhüseyin vururNo ratings yet

- GEO343 Final 3Document5 pagesGEO343 Final 3jameswell maestradoNo ratings yet

- WireGuard (Site To Site VPN Example) - RFCDocument12 pagesWireGuard (Site To Site VPN Example) - RFCbasilis mitzelosNo ratings yet

- Optimizing Daylight Strategies With Respect To Thermal Performance of BuildingsDocument84 pagesOptimizing Daylight Strategies With Respect To Thermal Performance of BuildingsAbhijit RastogiNo ratings yet

- ICTNWK604 - Class Activity 8Document9 pagesICTNWK604 - Class Activity 8MitchNo ratings yet

- ArchiSurance Case Study - SlidesDocument22 pagesArchiSurance Case Study - SlidesJaime ChavarriagaNo ratings yet

- Kao Corporation Study CaseDocument5 pagesKao Corporation Study CaseingNo ratings yet

- Application of Numerical Simulation at The Tunnel Site: AbstractDocument47 pagesApplication of Numerical Simulation at The Tunnel Site: AbstractDidaBouchNo ratings yet

- SAP Material DetailsDocument12 pagesSAP Material DetailsRanjeet GuptaNo ratings yet

- Sequetrol Starter Plus Flyer enDocument2 pagesSequetrol Starter Plus Flyer enEzequiel FavelukesNo ratings yet

Spit Dynabolt

Spit Dynabolt

Uploaded by

MadePOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spit Dynabolt

Spit Dynabolt

Uploaded by

MadePCopyright:

Available Formats

66-69_DYNABOLT.

qxd

25/11/05

10:02

Page 66

SPIT DYNABOLT

Zinc coated steel

1/4

Sleeve type expansion anchor

Technical data

L

d0

Tinst

tfix

DYNABOLT

HEX NUT

HN M6X40/8

HN M6X66/30

HN M6X92/56

HN M8X49/10

HN M8X76/35

HN M8X103/62

HN M8X124/84

HN M10X55/12

HN M10X70/18

HN M10X98/46

HN M10X126/74

HN M12X62/12

HN M12X106/49

HN M12X140/83

HN M16X81/20

HN M16X113/52

HN M16X157/96

Max.

anchor

depth

(mm)

hef

26

30

30

34

34

34

34

35

44

44

44

39

46

46

50

50

50

DYNABOLT

HEX HEAD

HB M6X45/8

HB M6X70/30

HB M6X95/56

HB M8X55/10

HB M8X80/35

HB M8X105/62

HB M10X75/18

HB M10X105/45

HB M12X110/49

26

30

30

28

34

34

44

44

44

8

30

56

8

35

62

18

46

49

55

55

55

65

65

65

80

80

95

M6

M6

M6

M8

M8

M8

M10

M10

M12

45

45

45

50

50

50

65

65

65

8

8

8

10

10

10

12

12

16

45

70

95

55

80

105

75

105

110

9

9

9

20

20

20

40

40

70

050252

050253

050254

050255

050256

050257

050259

050260

050262

DYNABOLT

COUNTER-SUNK

CSK M4.5X60/28

CSK M6X60/25

CSK M6X85/51

CSK M8X75/30

CSK M8X100/58

25

30

30

34

34

28

27

53

35

62

50

55

55

65

65

M4.5

M6

M6

M8

M8

35

45

45

50

50

6

8

8

10

10

60

60

85

75

100

10

20

20

40

40

050264

050267

050268

050269

050270

hef

h0

hmin

APPLICATION

Wall plates,

Porches,

Signs,

Angle rion, hand rails.

MATERIAL

Bolt class 6.8

INSTALLATION

1

1 Drill a hole corresponding to the external

diameter of the anchor with a depth equal

to the minimum anchor depth plus the

diameter of the anchor.

Max. thick Min thick

of part to

of base

be fixed

material

(mm)

(mm)

tfix

hmin

8

55

30

55

56

55

8

65

35

65

62

65

83

65

12

80

18

80

46

80

74

80

12

95

49

95

83

95

20

100

52

100

96

100

thread Drilling drill

depth

bit

(mm)

d

M6

M6

M6

M8

M8

M8

M8

M10

M10

M10

M10

M12

M12

M12

M16

M16

M16

(mm)

hO

45

45

45

50

50

50

50

65

65

65

65

65

65

65

70

70

70

(mm)

dO

8

8

8

10

10

10

10

12

12

12

12

16

16

16

20

20

20

Total

rod

length

(mm)

L

40

65

90

50

75

100

125

60

70

100

125

65

110

140

80

115

160

Max.

tighten

torque

(Nm)

Tinst

9

9

9

20

20

20

20

40

40

40

40

70

70

70

150

150

150

Code

050234

050235

050236

050238

050239

050240

050241

050242

050243

050244

050245

050246

050247

050248

050249

050250

050251

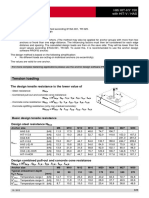

Anchor mechanical properties

2 Position the anchor into the hole until it just

touches the part to be fixed.

3 Tighten the anchor until the recommended

torque is achieved.

66

Threaded part

fuk (N/mm2) Min. tensile strength

fyk (N/mm2) Yield strength

Wel (mm3) Elastic section modulus

M0 Rk,s (Nm) Characteristic bending moment

M (Nm)

Recommended bending moment

M4,5

600

480

5,4

3,8

1,9

M6

600

480

12,7

9,15

4,5

M8

600

480

31,2

22,5

11,2

M10

600

480

62,3

44,8

22,4

M12

600

480

109,2

72

36,0

M16

600

480

277,5

166

83,0

66-69_DYNABOLT.qxd

25/11/05

10:02

Page 67

SPIT DYNABOLT

Zinc coated steel

2/4

The loads specified on this page allow judging the products performances, but cannot be used for the designing.

The data given in the pages CC method have to be applied.

Ultimate (NRu,m, VRu,m) / characteristic loads (NRk, VRk) in kN

Mean Ultimate loads are derived from test results in admissible service conditions, and characteristic loads are statistically determined.

Anchor size

SHEAR

M6

M8

M10

M12

M16

Minimum anchorage depth

hef

25

26

NRu,m

4,3

6,1

NRk

3,2

4,6

M4,5

28

8,1

6,1

35

12,2

9,2

39

14,2

10,7

50

20,6

15,5

Maximum anchorage depth

hef

30

NRu,m

7,6

NRk

5,7

34

10,8

8,1

44

17,2

12,9

46

18,2

13,7

Anchor size

VRu,m

VRk

M4,5

3,2

2,6

M6

7,3

6,1

M8

13,2

11,0

M10

20,9

17,4

M12

30,4

25,3

M16

56,4

47,0

Design Loads (NRd, VRd) for one anchor without edge or spacing influence in kN

N Rd =

N Rk *

Mc

VRd =

Mechanical anchors

TENSILE

VRk *

Ms

*Derived from test results

TENSILE

Anchor size

SHEAR

M4,5

M6

M8

M10

M12

M16

26

2,2

28

2,9

35

4,4

39

5,1

50

7,4

Maximum anchorage depth

hef

30

NRd

2,7

Mc = 2,1

34

3,9

44

6,1

46

6,5

Minimum anchorage depth

hef

NRd

25

1,5

Anchor size

VRd

Ms = 1,6

M4,5

1,6

M6

3,8

M8

6,9

M10

10,9

M12

15,8

M16

29,4

Recommended loads (Nrec, Vrec) for one anchor without edge or spacing influence in kN

N Rec =

N Rk *

M . F

VRec =

VRk *

M . F

*Derived from test results

TENSILE

Anchor size

SHEAR

M6

M8

M10

M12

M16

Minimum anchorage depth

hef

25

26

NRec

1,1

1,6

M4,5

28

2,1

35

3,1

39

3,6

50

5,3

34

2,8

44

4,4

46

4,7

Maximum anchorage depth

hef

30

NRec

1,9

Mc = 2,1

Anchor size

VRec

Ms = 1,6

M4,5

1,2

M6

2,7

M8

4,9

M10

7,8

M12

11,3

M16

21,0

Recommended loads (Nrec, Vrec) in engineering clay bricks BP 400 (fc > 40 N/mm2) in kN

TENSILE

Anchor size

hef

NRec

SHEAR

M6

30

1,6

M8

34

2,1

M10

44

3,8

M12

46

4,2

Anchor size

VRec

M6

2,0

M8

3,65

M10

5,8

M12

8,45

67

66-69_DYNABOLT.qxd

25/11/05

10:02

Page 68

SPIT DYNABOLT

Zinc coated steel

3/4

SPIT CC- Method

TENSILE in kN

N

SHEAR in kN

V

Pull-out resistance

N Rd,p = N ORd , p .fb

N0Rd,p

Anchor size

M4,5

M6

Minimum anchorage depth

hef

25

26

N0Rd,p (C20/25)

1,5

2,2

Maximum anchorage depth

hef

30

N0Rd,p (C20/25)

2,7

Mc = 2,1

N

O

VRd,c = VRd

,c .fb .f ,V .S C ,V

Design pull-out resistance

M8

M10 M12 M16

35

4,4

39

5,1

50

7,4

34

3,9

44

6,1

46

6,5

M6

Minimum anchorage depth

hef

25

26

N0Rd,c (C20/25)

3,0

3,2

Maximum anchorage depth

hef

30

N0Rd,c (C20/25)

3,9

Mc = 2,1

M4,5

Minimum anchorage depth

hef

25

Cmin

45

Smin

85

V0Rd,c (C20/25)

2,1

Maximum anchorage

hef

Cmin

Smin

V0Rd,c (C20/25)

Mc = 1,5

N Rd,c = N ORd ,c .fb .s .c, N

M4,5

V0Rd,c

Anchor size

28

2,9

Concrete cone resistance

N0Rd,c

Anchor size

Concrete edge resistance

Design cone resistance

M8

M10 M12 M16

28

3,6

35

5,0

39

5,8

50

8,5

34

4,8

44

7,0

46

7,5

Design concrete edge resistance

at minimum edge distance (Cmin)

M6

M8

M10 M12 M16

26

45

85

2,3

28

50

100

2,9

35

60

115

4,2

39

70

170

5,9

50

110

220

13,0

depth

30

50

95

2,7

34

60

120

3,9

44

75

145

6,1

46

100

200

10,4

Steel resistance

VRd,s

Anchor size

VRd,s

Ms = 1,6

M4,5

1,6

M6

3,8

Steel design shear resistance

M8

M10 M12 M16

6,9

10,9

15,8

-

Steel resistance

NRd,s

Anchor size

NRd,s

Ms = 2

M4,5

2,7

Steel design tensile resistance

M6

M8

M10 M12 M16

6,3

11,5

18,1

26,4

-

NRd = min(NRd,p ; NRd,c ; NRd,s)

VRd = min(VRd,c ; VRd,s)

N = NSd / NRd 1

V = VSd / VRd 1

N1,5 + V1,5 1

fB INFLUENCE OF CONCRETE

Concrete class

C20/25

C30/40

C40/60

C50/60

68

fB

1

1,14

1,26

1,34

f,V INFLUENCE OF SHEAR LOADING DIRECTION

Angle []

0 to 55

60

70

80

90 to 180

f,V

1

1,1

1,2

1,5

2

90

180

66-69_DYNABOLT.qxd

25/11/05

10:02

Page 69

SPIT DYNABOLT

Zinc coated steel

4/4

SPIT CC- Method

s INFLUENCE OF SPACING FOR CONCRETE CONE RESISTANCE IN TENSILE LOAD

85

100

115

170

220

S = 0, 5 +

s

4.hef

M4,5

1,00

Reduction factor s

Minimum anchorage depth

M6

M8

M10 M12 M16

1,00

1,00

1,00

1,00

1,00

SPACING S

Reduction factor s

Maximum anchorage depth

M6

M8 M10 M12

95

1,00

120

1,00

145

1,00

200

1,00

Mechanical anchors

SPACING S

Smin < S < Scr,N

Scr,N = 3.hef

S must be used for each spacing

influenced the anchors group.

c,N INFLUENCE OF EDGE FOR CONCRETE CONE RESISTANCE IN TENSILE LOAD

N

EDGE C

45

50

60

70

110

c, N = 0, 27 + 0, 725.

c

hef

M4,5

1,00

Reduction factor s

Minimum anchorage depth

M6

M8

M10 M12 M16

1,00

1,00

1,00

1,00

1,00

EDGE C

50

60

75

100

Reduction factor s

Maximum anchorage depth

M6

M8 M10 M12

1,00

1,00

1,00

1,00

Cmin < C < Ccr,N

Ccr,N = 1,5.hef

c,N must be used for each distance

influenced the anchors group.

s-c,V INFLUENCE OF SPACING AND EDGE DISTANCE FOR CONCRETE EDGE RESISTANCE IN SHEAR LOAD

Factor s-c,V

Non-cracked concrete

For single anchor fastening

C

Cmin

1,0

1,2

1,4

1,6

1,8

2,0

2,2

2,4

2,6

2,8

3,0

3,2

s-c,V

1,00

1,31

1,66

2,02

2,41

2,83

3,26

3,72

4,19

4,69

5,20

5,72

h>1,5.c

s c,V =

c

cmin

c

C

Cmin 1,0

S

s

c

h>1,5.c

s c,V =

3.c + s

c

.

6.cmin cmin

s1

s2

Factor s-c,V

Non-cracked concrete

For 2 anchors fastening

cmin

s3

sn-1

Cmin

1,0

1,5

2,0

2,5

3,0

3,5

4,0

4,5

5,0

5,5

6,0

0,67

0,75

0,83

0,92

1,00

1,2

1,4

1,6

1,8

2,0

2,2

2,4

2,6

2,8

3,0

3,2

0,84

0,93

1,02

1,11

1,20

1,30

1,03

1,12

1,22

1,32

1,42

1,52

1,62

1,22

1,33

1,43

1,54

1,64

1,75

1,86

1,96

1,43

1,54

1,65

1,77

1,88

1,99

2,10

2,21

2,33

1,65

1,77

1,89

2,00

2,12

2,24

2,36

2,47

2,59

2,71

2,83

1,88

2,00

2,12

2,25

2,37

2,50

2,62

2,74

2,87

2,99

3,11

2,12

2,25

2,38

2,50

2,63

2,76

2,89

3,02

3,15

3,28

3,41

2,36

2,50

2,63

2,77

2,90

3,04

3,17

3,31

3,44

3,71

3,71

2,62

2,76

2,90

3,04

3,18

3,32

3,46

3,60

3,74

4,02

4,02

2,89

3,03

3,18

3,32

3,46

3,61

3,75

3,90

4,04

4,33

4,33

3,16

3,31

3,46

3,61

3,76

3,91

4,05

4,20

4,35

4,65

4,65

For other case of fastenings

s c,V =

h>1,5.c

3.c + s1 + s2 + s3 + ... + sn 1

c

.

3.n.cmin

cmin

69

You might also like

- Azure Cognitive ServicesDocument340 pagesAzure Cognitive Servicespepsiholic dreamNo ratings yet

- Method Statement of TrenchingDocument14 pagesMethod Statement of Trenchingahmed0883949450% (2)

- First Year Progress Report NRPU-10483Document105 pagesFirst Year Progress Report NRPU-10483Obaid100% (2)

- Manual Calc Steel Column FinalDocument17 pagesManual Calc Steel Column FinalKein GrajoNo ratings yet

- Exactly The Power You Need.: The NC-B SeriesDocument12 pagesExactly The Power You Need.: The NC-B SeriesbalanNo ratings yet

- Alvedoor Marine - Product Division of R&M GroupDocument148 pagesAlvedoor Marine - Product Division of R&M Groupmauboch100% (1)

- 9110 355 EbpDocument5 pages9110 355 EbpCecep HendriyatnaNo ratings yet

- Are They Pour Lines or Cold Joints - tcm45-348413Document4 pagesAre They Pour Lines or Cold Joints - tcm45-348413محمد كاشف جاويدNo ratings yet

- MS-E011-ALF-MS For Installation of LVAC PanelsDocument7 pagesMS-E011-ALF-MS For Installation of LVAC PanelsvipinrajNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFchacNo ratings yet

- MUARA KARANG NT216 Rev00 Laying InstructionsDocument35 pagesMUARA KARANG NT216 Rev00 Laying InstructionsDio AkhbarNo ratings yet

- A Cylinder Test ReportDocument2 pagesA Cylinder Test Reportraju_420034520No ratings yet

- Dynabolt Zinc Coated Steel Design GuideDocument4 pagesDynabolt Zinc Coated Steel Design GuideMuhammad SarajevoNo ratings yet

- Anchor DesignDocument4 pagesAnchor DesignAnonymous BAzcBzWuNo ratings yet

- Design Calculation: Season 2 - Mechanical and Chemical Anchor CalculationDocument23 pagesDesign Calculation: Season 2 - Mechanical and Chemical Anchor CalculationNaveenNo ratings yet

- Stainless StudsDocument4 pagesStainless StudsNestramiNo ratings yet

- Hilti Manual For BoltDocument11 pagesHilti Manual For Boltcsengineer20% (1)

- HSA Stud AnchorDocument11 pagesHSA Stud AnchorWin ThanNo ratings yet

- 2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Document9 pages2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Difa LiuNo ratings yet

- Hilti HVZ 1Document13 pagesHilti HVZ 1Mihnea-Bogdan NicolaescuNo ratings yet

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Document9 pagesTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNo ratings yet

- Socket Screws MetricDocument32 pagesSocket Screws Metricnick10686No ratings yet

- HVZ Adhesive Anchor: Basic Loading Data (For A Single Anchor) : HAS - (E-) TZDocument10 pagesHVZ Adhesive Anchor: Basic Loading Data (For A Single Anchor) : HAS - (E-) TZBogdanBNo ratings yet

- 6 Hsa Stud Anchor 92-102Document11 pages6 Hsa Stud Anchor 92-102vkumar_625189No ratings yet

- FTM '12 HKD Push-In AnchorDocument14 pagesFTM '12 HKD Push-In AnchorShankerNo ratings yet

- Chumbador HiltDocument14 pagesChumbador HiltSamanta FigueredoNo ratings yet

- Anchor Fastening Technology ManualDocument152 pagesAnchor Fastening Technology ManualfdsafsadfNo ratings yet

- HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, MixerDocument11 pagesHIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixerlael00No ratings yet

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Document12 pagesHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuNo ratings yet

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDocument10 pagesHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruNo ratings yet

- Simplified Design Method: Tension LoadingDocument1 pageSimplified Design Method: Tension LoadingRimon GawandeNo ratings yet

- HSV-R2 Stud Anchor: Concrete (Non-Cracked)Document8 pagesHSV-R2 Stud Anchor: Concrete (Non-Cracked)Ambreen FatimaNo ratings yet

- Hydraulic Cylinders CHDocument8 pagesHydraulic Cylinders CHStoianovici CristianNo ratings yet

- 44 - HVZ Adhesive AnchorDocument14 pages44 - HVZ Adhesive AnchorHuan VoNo ratings yet

- Rigid Flexible Waveguide ComponentsDocument10 pagesRigid Flexible Waveguide Componentsapi-30606527No ratings yet

- HKD Push-In Anchor: Basic Loading Data (For A Single Anchor) : HKD-S /-EDocument8 pagesHKD Push-In Anchor: Basic Loading Data (For A Single Anchor) : HKD-S /-EsorengbhanuNo ratings yet

- DB53112610ENDocument2 pagesDB53112610ENDamian SzczypieńNo ratings yet

- RS BobbinsDocument3 pagesRS BobbinsleeboldNo ratings yet

- Minex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5Document20 pagesMinex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5HyungTae JangNo ratings yet

- HVU Adhesive With HAS Rod: Basic Loading Data (For A Single Anchor) : HVU Capsule With HAS, HAS-EDocument5 pagesHVU Adhesive With HAS Rod: Basic Loading Data (For A Single Anchor) : HVU Capsule With HAS, HAS-EChristopher GarciaNo ratings yet

- Hilti Bolt Connection-4 anchor-HSTDocument5 pagesHilti Bolt Connection-4 anchor-HSTTuấnThanhNo ratings yet

- Fijaciones Químicas 2012 PDFDocument0 pagesFijaciones Químicas 2012 PDFMarcelo AlbeNo ratings yet

- SL2008-491 Omission of Cylinder-Cover-Mounted Safety ValvesDocument5 pagesSL2008-491 Omission of Cylinder-Cover-Mounted Safety ValvesAman MankotiaNo ratings yet

- Apron Feeder Spare Part ListDocument17 pagesApron Feeder Spare Part ListParmeshwar Nath Tripathi100% (1)

- HKV Technical Data SheetDocument5 pagesHKV Technical Data SheetWZNo ratings yet

- Hilti HKV DatasheetDocument5 pagesHilti HKV DatasheetozkanhasanNo ratings yet

- Unbrako Catalog FastenerDocument26 pagesUnbrako Catalog Fastenerdesign_rajeev100% (2)

- 26-HVU Adhesive With HAS RodDocument9 pages26-HVU Adhesive With HAS RodAdam ChougleNo ratings yet

- 07 Assembly CS - ENDocument90 pages07 Assembly CS - ENandersson benito herreraNo ratings yet

- 07 Assembly HP - ENDocument67 pages07 Assembly HP - ENandersson benito herreraNo ratings yet

- Hvu HasDocument9 pagesHvu Hassri_amartNo ratings yet

- HST TensionDocument10 pagesHST Tensionnu.arabiaNo ratings yet

- 07 Assembly CP - ENDocument104 pages07 Assembly CP - ENandersson benito herreraNo ratings yet

- MTB500iWRTXM /22°/L241/H50 44,0350,3494,637Document26 pagesMTB500iWRTXM /22°/L241/H50 44,0350,3494,637Saranyoo CHOOTIMASNo ratings yet

- Amphennot Connectors CatalogDocument68 pagesAmphennot Connectors Catalogrr0bertNo ratings yet

- +696wxgdqfkru: HSV Stud AnchorDocument9 pages+696wxgdqfkru: HSV Stud AnchorThang VoNo ratings yet

- Hilti Bolt Connection-6 anchor-HSTDocument5 pagesHilti Bolt Connection-6 anchor-HSTTuấnThanhNo ratings yet

- 3 Hit-Hy150 HisnDocument9 pages3 Hit-Hy150 Hisndd160179No ratings yet

- Fischer FBN AnchorsDocument23 pagesFischer FBN AnchorsIstván SzékelyNo ratings yet

- Hilti HST 1Document11 pagesHilti HST 1Mihnea-Bogdan NicolaescuNo ratings yet

- List DrawingDocument4 pagesList DrawingMadePNo ratings yet

- Pl1250p - Open TypeDocument1 pagePl1250p - Open TypeMadePNo ratings yet

- 7a PDFDocument3 pages7a PDFMadePNo ratings yet

- Rumus DefleksiDocument2 pagesRumus DefleksiMadePNo ratings yet

- Rumus Defleksi N Rotasi Balok KantileverDocument2 pagesRumus Defleksi N Rotasi Balok KantileverMadePNo ratings yet

- Tabel Perhitungan Concrete Breakout Strength Kolom PedestalDocument1 pageTabel Perhitungan Concrete Breakout Strength Kolom PedestalMadePNo ratings yet

- Urutan Berat Profil BajaDocument1 pageUrutan Berat Profil BajaMadePNo ratings yet

- Architecture of 8086Document27 pagesArchitecture of 8086Amitabh DixitNo ratings yet

- Jost-208 ManualDocument198 pagesJost-208 ManualdamindaNo ratings yet

- 150 5345 42J Light BasesDocument48 pages150 5345 42J Light BasesHerney MarinNo ratings yet

- CIGWELD General CatalogueDocument78 pagesCIGWELD General CataloguedobolanNo ratings yet

- Sales Territories: Sales Territory Is A Usually A Geographical Area Assigned To A Salesperson or Group of PersonsDocument14 pagesSales Territories: Sales Territory Is A Usually A Geographical Area Assigned To A Salesperson or Group of PersonsPhenomenal SinghNo ratings yet

- EE272 Digital Systems Fall 2019 Instructor: Dr. Aashir WaleedDocument41 pagesEE272 Digital Systems Fall 2019 Instructor: Dr. Aashir Waleedsyed waheedNo ratings yet

- How To Modify The Styles Option On Word: Formato Código CBI-F031 Guide Versión 01 Values Fecha AprobaciónDocument5 pagesHow To Modify The Styles Option On Word: Formato Código CBI-F031 Guide Versión 01 Values Fecha AprobaciónDavid A Reyes MNo ratings yet

- NUS Ultrasonic Level Transmitter: 11.5 Feet in SolidsDocument4 pagesNUS Ultrasonic Level Transmitter: 11.5 Feet in SolidsRoy Moya HNo ratings yet

- Back Panel: Front Panel:: Downloaded From Manuals Search EngineDocument2 pagesBack Panel: Front Panel:: Downloaded From Manuals Search EngineJorgeA.GaritaNo ratings yet

- Advances in Application of ICT in Crop Pest and Disease ManagementDocument8 pagesAdvances in Application of ICT in Crop Pest and Disease Managementpaola ribeiroNo ratings yet

- TableNo19 C 1Document92 pagesTableNo19 C 1SMNo ratings yet

- AUH01-RED-D1-XX-RT-X-06000 - MEP Stage 4 Design Proposal - P7Document43 pagesAUH01-RED-D1-XX-RT-X-06000 - MEP Stage 4 Design Proposal - P7Abhilash100% (1)

- 0a-Esp8266ex Datasheet enDocument31 pages0a-Esp8266ex Datasheet enEverton PereiraNo ratings yet

- Feedmill Building - 2 PDFDocument1 pageFeedmill Building - 2 PDFlasssyNo ratings yet

- Getting Started Guide For Freebsd: Release 20.08.0Document16 pagesGetting Started Guide For Freebsd: Release 20.08.0Arindam ChakrabortyNo ratings yet

- RR TF21 Cullinan 20230929Document6 pagesRR TF21 Cullinan 20230929Miguel Couto RamosNo ratings yet

- Dap-2330 Reva Datasheet 1.00Document5 pagesDap-2330 Reva Datasheet 1.00iim ibrahimNo ratings yet

- Summative Test G 7 FINALDocument2 pagesSummative Test G 7 FINALFlorencio CoquillaNo ratings yet

- iDRAC6 2.92 A00 ReleaseNotesDocument10 pagesiDRAC6 2.92 A00 ReleaseNotesfrippiht_505702242No ratings yet

- Biological Safety Cabinet - AC2-G3 - Brochure - A4 - VG - LRDocument8 pagesBiological Safety Cabinet - AC2-G3 - Brochure - A4 - VG - LRhüseyin vururNo ratings yet

- GEO343 Final 3Document5 pagesGEO343 Final 3jameswell maestradoNo ratings yet

- WireGuard (Site To Site VPN Example) - RFCDocument12 pagesWireGuard (Site To Site VPN Example) - RFCbasilis mitzelosNo ratings yet

- Optimizing Daylight Strategies With Respect To Thermal Performance of BuildingsDocument84 pagesOptimizing Daylight Strategies With Respect To Thermal Performance of BuildingsAbhijit RastogiNo ratings yet

- ICTNWK604 - Class Activity 8Document9 pagesICTNWK604 - Class Activity 8MitchNo ratings yet

- ArchiSurance Case Study - SlidesDocument22 pagesArchiSurance Case Study - SlidesJaime ChavarriagaNo ratings yet

- Kao Corporation Study CaseDocument5 pagesKao Corporation Study CaseingNo ratings yet

- Application of Numerical Simulation at The Tunnel Site: AbstractDocument47 pagesApplication of Numerical Simulation at The Tunnel Site: AbstractDidaBouchNo ratings yet

- SAP Material DetailsDocument12 pagesSAP Material DetailsRanjeet GuptaNo ratings yet

- Sequetrol Starter Plus Flyer enDocument2 pagesSequetrol Starter Plus Flyer enEzequiel FavelukesNo ratings yet