Professional Documents

Culture Documents

Magnetic Particle Testing

Magnetic Particle Testing

Uploaded by

Adnan Atif0 ratings0% found this document useful (0 votes)

12 views1 pageMagnetic particle Inspection (MPI) is a non-destructive testing process that detects surface and subsurface discontinuities in ferromagnetic materials like iron and steel alloys. It works by magnetizing the material using either direct or indirect magnetization, where direct passes a current through the object and indirect uses an outside magnetic field source, forming lines of magnetic force perpendicular to the electric current, which can be alternating or direct current.

Original Description:

description of MT

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMagnetic particle Inspection (MPI) is a non-destructive testing process that detects surface and subsurface discontinuities in ferromagnetic materials like iron and steel alloys. It works by magnetizing the material using either direct or indirect magnetization, where direct passes a current through the object and indirect uses an outside magnetic field source, forming lines of magnetic force perpendicular to the electric current, which can be alternating or direct current.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

12 views1 pageMagnetic Particle Testing

Magnetic Particle Testing

Uploaded by

Adnan AtifMagnetic particle Inspection (MPI) is a non-destructive testing process that detects surface and subsurface discontinuities in ferromagnetic materials like iron and steel alloys. It works by magnetizing the material using either direct or indirect magnetization, where direct passes a current through the object and indirect uses an outside magnetic field source, forming lines of magnetic force perpendicular to the electric current, which can be alternating or direct current.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for

detecting surface and slightly subsurface discontinuities in ferromagnetic materials

such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic

field into the part. The piece can be magnetized by direct or indirect magnetization.

Direct magnetization occurs when the electric current is passed through the test

object and a magnetic field is formed in the material. Indirect magnetization occurs

when no electric current is passed through the test object, but a magnetic field is

applied from an outside source. The magnetic lines of force are perpendicular to the

direction of the electric current which may be either alternating current (AC) or

some form of direct current (DC) (rectified AC).

You might also like

- Magnetic Particle TestingDocument34 pagesMagnetic Particle Testingmnaseemiqbal4200No ratings yet

- Non Destructive Testing - Magnetic Particle Inspection (MPI)Document1 pageNon Destructive Testing - Magnetic Particle Inspection (MPI)Yessine Rebai100% (1)

- Magnetic Particle Inspection: Non-Destructive Testing Ferromagnetic Materials Iron Nickel Cobalt AlloysDocument1 pageMagnetic Particle Inspection: Non-Destructive Testing Ferromagnetic Materials Iron Nickel Cobalt AlloysNITIN KUMBHARNo ratings yet

- Unit-4 Magnetic Particle Testing: Course Outline .Document32 pagesUnit-4 Magnetic Particle Testing: Course Outline .Selvam ChidambaramNo ratings yet

- Magnetic Particle Test (MT) : Level IiDocument18 pagesMagnetic Particle Test (MT) : Level IiAhmed El Morsy100% (1)

- Magnetic Particle Testing (Mpi)Document111 pagesMagnetic Particle Testing (Mpi)khaled.ihabNo ratings yet

- Magnetic Particle TestingDocument1 pageMagnetic Particle TestingGoverdhan ShresthaNo ratings yet

- Magnetic Particle TestingDocument35 pagesMagnetic Particle TestingWALIDNo ratings yet

- Magnetic Particle Testing (MPT) : The Engineers Edge Institute of NDTDocument49 pagesMagnetic Particle Testing (MPT) : The Engineers Edge Institute of NDTThe Engineers EDGE, CoimbatoreNo ratings yet

- NDT Module 3Document22 pagesNDT Module 3Sajeesh SajiNo ratings yet

- MagneticDocument1 pageMagneticAbu Akhtar Aira AlthafNo ratings yet

- Magnetic Particle Inspection (MT) : Phone: (815) 282-7581 Fax: (815) 282-7583Document1 pageMagnetic Particle Inspection (MT) : Phone: (815) 282-7581 Fax: (815) 282-7583Abu Akhtar Aira AlthafNo ratings yet

- Magnetic Particle TestingDocument123 pagesMagnetic Particle Testinglucky kakanNo ratings yet

- MT Awade PrintDocument50 pagesMT Awade PrintYousab JacobNo ratings yet

- Magnetic Particle Testing, OrigDocument34 pagesMagnetic Particle Testing, OrigTinaNo ratings yet

- Magnetic Particle Inspection - WikipediaDocument5 pagesMagnetic Particle Inspection - Wikipediakuldeep mohiteNo ratings yet

- 6.1 NDT Magnetic TestingDocument30 pages6.1 NDT Magnetic TestingJose Gamaliel Legaspi Ibalarrosa IIINo ratings yet

- MPTDocument119 pagesMPTShahazad Shaik100% (1)

- Magnetic Properties of Materials DocsDocument6 pagesMagnetic Properties of Materials DocsJeterine AriasNo ratings yet

- Chapter 4-Part 4Document91 pagesChapter 4-Part 4zlalkrzybk77No ratings yet

- Nondestructive Evaluation Techniques Mag Particle 2Document1 pageNondestructive Evaluation Techniques Mag Particle 2shailesh jhaNo ratings yet

- Nondestructivetesting 180514185439Document113 pagesNondestructivetesting 180514185439mamillapalli sri harshaNo ratings yet

- Magnatic Particle Inspection 2023-2024Document61 pagesMagnatic Particle Inspection 2023-2024طيف ابراهيم سعيد صدامNo ratings yet

- Magnetic Particle TestingDocument34 pagesMagnetic Particle TestingYusuf BagewadiNo ratings yet

- 11 1 FIS1104-MagnetismDocument22 pages11 1 FIS1104-MagnetismDoddy HardhienataNo ratings yet

- Magnetic Particle TestingDocument87 pagesMagnetic Particle TestingMidhun SukumaranNo ratings yet

- MT Self-Study NoteDocument153 pagesMT Self-Study Notenewdao100% (5)

- Nondestructivetesting 180514185439Document88 pagesNondestructivetesting 180514185439mamillapalli sri harshaNo ratings yet

- Magnetic Materials PDFDocument78 pagesMagnetic Materials PDFDilbagh Singh SidhuNo ratings yet

- Introduction To Magnetic Particle TestingDocument58 pagesIntroduction To Magnetic Particle TestingjerryceppyNo ratings yet

- Sri Ramayanti - Tugas 2Document18 pagesSri Ramayanti - Tugas 2Sri Ramayanti SimanjuntakNo ratings yet

- Non Destructive TestingDocument118 pagesNon Destructive Testingandini dini100% (1)

- Section I Introduction To Magnetic Particle InspectionDocument130 pagesSection I Introduction To Magnetic Particle Inspectionhvu9743No ratings yet

- Definition of Magnetic Particle TestingDocument44 pagesDefinition of Magnetic Particle Testingகோகுல் இராNo ratings yet

- Magentic Materials HW - Leonardo Harrison 10 Decarteret P1Document3 pagesMagentic Materials HW - Leonardo Harrison 10 Decarteret P1Leonardo HarrisonNo ratings yet

- Magnetic Properties of MaterialsDocument31 pagesMagnetic Properties of MaterialssoumyajyotideyNo ratings yet

- Presentation 13-02-24Document13 pagesPresentation 13-02-24mishrasiju007No ratings yet

- 8 Magnetic Fields Notes 2024Document34 pages8 Magnetic Fields Notes 2024anita fathizadehNo ratings yet

- Magnetic Forces MagnesiumDocument45 pagesMagnetic Forces MagnesiumpmopakNo ratings yet

- MT Rev.1Document15 pagesMT Rev.1eka prasetyaNo ratings yet

- UNIT-3 Magnetic Particle TestingDocument40 pagesUNIT-3 Magnetic Particle TestingPratap KumarNo ratings yet

- Magnetic FieldDocument2 pagesMagnetic Fieldkhopo ALzainNo ratings yet

- KME-061 Unit-2. Magnet Particle TestingDocument56 pagesKME-061 Unit-2. Magnet Particle Testingabhip2041No ratings yet

- Magnetism: Magnetic FieldsDocument12 pagesMagnetism: Magnetic FieldsShaikh IradNo ratings yet

- Magnetic Particle InspectionDocument58 pagesMagnetic Particle InspectionnikafiqNo ratings yet

- Spin Thermoelectric: Spincaloritronics: Gaurav Kumar Shukla (P.HD) Supervisor:Dr. Sanjay SinghDocument21 pagesSpin Thermoelectric: Spincaloritronics: Gaurav Kumar Shukla (P.HD) Supervisor:Dr. Sanjay SinghGAURAV SHUKLANo ratings yet

- Magnetism in Nanomaterials: Principles of NanomagnetismDocument49 pagesMagnetism in Nanomaterials: Principles of NanomagnetismMananNo ratings yet

- MPT Ndt-EdDocument53 pagesMPT Ndt-EdSaiKumarNo ratings yet

- Nondestructive TestingDocument12 pagesNondestructive TestingJoby Jobzz SebellinoNo ratings yet

- MagnetismDocument17 pagesMagnetismOdeke GeorgeNo ratings yet

- Physics Pre - Ig Yr9 Islam Abbas Notes (Elec&Magent)Document13 pagesPhysics Pre - Ig Yr9 Islam Abbas Notes (Elec&Magent)Saja Al-SultanNo ratings yet

- Magnetizm Notes-2022Document5 pagesMagnetizm Notes-2022tmoatshe96No ratings yet

- Material Lab-35Document1 pageMaterial Lab-35AhmadNo ratings yet

- PHYSICS FORM 5 NewDocument29 pagesPHYSICS FORM 5 NewIdriss DjatsaNo ratings yet

- Chapter TwoDocument81 pagesChapter TwoStricker ManNo ratings yet

- MPT NDTDocument60 pagesMPT NDTpraveentienNo ratings yet

- Reporting 16Document7 pagesReporting 16mobile legend practiceNo ratings yet

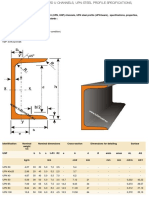

- UPN (UNP) European Standard U Channels, UPN Steel Profile Specifications, DimenDocument2 pagesUPN (UNP) European Standard U Channels, UPN Steel Profile Specifications, DimenAdnan Atif100% (1)

- HEB Beams, European Standard Wide Flang..Document2 pagesHEB Beams, European Standard Wide Flang..Adnan AtifNo ratings yet

- UC - British Universal Columns - Metric UnitsDocument7 pagesUC - British Universal Columns - Metric UnitsAdnan AtifNo ratings yet

- Duty TimeDocument1 pageDuty TimeAdnan AtifNo ratings yet

- Hydrostatic Testing Equipment: S.NO. Item DescriptionDocument2 pagesHydrostatic Testing Equipment: S.NO. Item DescriptionAdnan AtifNo ratings yet

- Magnetic Particle TestingDocument1 pageMagnetic Particle TestingAdnan AtifNo ratings yet

- Penetrant Testing (PT), Is A Widely Applied and Low-Cost Inspection Method UsedDocument1 pagePenetrant Testing (PT), Is A Widely Applied and Low-Cost Inspection Method UsedAdnan AtifNo ratings yet

- Information About Hydrostatic Testing.: Pressure Vessels Pipelines Plumbing Gas Cylinders BoilersDocument1 pageInformation About Hydrostatic Testing.: Pressure Vessels Pipelines Plumbing Gas Cylinders BoilersAdnan AtifNo ratings yet