Professional Documents

Culture Documents

Conrete QQQQQQQQ 2

Conrete QQQQQQQQ 2

Uploaded by

Kwame AsamoaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conrete QQQQQQQQ 2

Conrete QQQQQQQQ 2

Uploaded by

Kwame AsamoaCopyright:

Available Formats

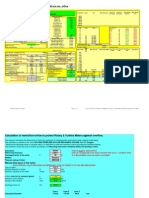

CONSTRUCTION OF BURMA CAMP ROAD PH. 1 (3.

66KM) LOT 2

TEST FOR ASPHALTIC WEARING COURSE LAID CH1+350 - CH 1+150 LHS & CH 0+800 - CH 0+900 RHS

Tray Test for Prime Coat Spread Rate

Achieved

Specification

Marshall Test

Test Average

0.45 l/m2

0.4 - 0.65 l/m2

Marshall Stability (N)

Temparatures

Achieved

Specification

167 oC

Average Departure Temparature oC

162 oC

Average Arrival Temparature oC

120oC Min

Achieved

Specification

Compaction %

97.8 %

96 - 98%

In place Air Voids %

6.5 %

6 - 8%

Bitumen Content %

4.87 %

4.70.3%

Core Test Results

43.3 mm

Average Core Thickness (mm)

8200 - 18000 N

2.6 mm

2' - 4 mm

4.8 %

3 - 5%

70.40%

Voids filled with Bitumen

Marshall Density(g/cm3)

65 - 75%

2.396

2.514

Max S.G

141 oC

Average Compaction Temparature oC

Specification

14430 N

Void in total mix

152 oC

Average Laying Temparature oC

Achieved

Flow Value (mm)

170oC Max

5-Aug-15

DATE:

40.0mm Min

GRADING FOR BINDER COURSE MATERIAL 0/14mm

6.

3

100.0

20.0

100.0

14.0

80.0

10.0

6.3

70.0

Percentage Passing (%)

Percentage of

passing

Percentage of

Passing (%)

28.0

90.0

4.0

60.0

2.0

1.0

50.0

0.425

40.0

0.300

0.150

30.0

0.075

20.0

10.0

0.0

Sizes

(mm)

Sieve

ASPHALT GRADING CURVE (Wearing Course)

0.0

0.1

1.0

Sieve Size (mm)

Percentage of

Passing

(%)

10.0

100.0

100.0

95.3

80.3

65.0

53.8

39.3

30.4

18.6

14.6

9.6

4.9

Percent by Weight

Min

Mid Point

Max

100

100

100

90

95

100

100

70

55

45

33

23

14

12

8

5

100

80

65

54

41

31

20

17

12

8

100

90

75

63

48

38

25

22

16

10

You might also like

- Presentation On Grooved Rubber Sole Plate Beneath Railway TrackDocument30 pagesPresentation On Grooved Rubber Sole Plate Beneath Railway Trackgotosud100% (1)

- Product Specifications Octane 95Document3 pagesProduct Specifications Octane 95Vishnu PillaiNo ratings yet

- Ghana Institution of Engineers: Membership Application FormDocument2 pagesGhana Institution of Engineers: Membership Application FormKwame Asamoa100% (1)

- Drying Hopper Calculation-1Document3 pagesDrying Hopper Calculation-1Gilang Adi SetyawanNo ratings yet

- Fabric Technical Specifications: AppendixDocument4 pagesFabric Technical Specifications: AppendixAani MazharNo ratings yet

- Standards For Switchyard PDFDocument9 pagesStandards For Switchyard PDFraom_2No ratings yet

- Cal FUEL TEST Book1Document1 pageCal FUEL TEST Book1aqhammamNo ratings yet

- Methodology and Experimental Programme: 4.1 Specification of Materials Used For ExperimentDocument31 pagesMethodology and Experimental Programme: 4.1 Specification of Materials Used For Experimentpradeep kankeriNo ratings yet

- Ash Handling System Design For The Power Plant: 1.0 Boiler Data: Description ParametersDocument4 pagesAsh Handling System Design For The Power Plant: 1.0 Boiler Data: Description ParametersvesselNo ratings yet

- Physical Testing of Clinker & CementDocument61 pagesPhysical Testing of Clinker & CementDineshNo ratings yet

- Test Certificate: Ultratech Cement LimitedDocument1 pageTest Certificate: Ultratech Cement LimitedkvijayasokNo ratings yet

- Jayamix RM Specification (Standard Raw Material)Document6 pagesJayamix RM Specification (Standard Raw Material)Afip PullahNo ratings yet

- Inspection of ElectrodesDocument62 pagesInspection of ElectrodesARAVINDAN DNo ratings yet

- Presentasi AwalDocument77 pagesPresentasi AwalFadil AdamNo ratings yet

- Corning Fused Silica 7980Document4 pagesCorning Fused Silica 7980Mandi IndarsNo ratings yet

- 21app0808 MTR-14Document1 page21app0808 MTR-14gmendoza.logistica3No ratings yet

- Meter Selection Rev 031Document5 pagesMeter Selection Rev 031andrew_c_potocki902No ratings yet

- Soil Aggregates From Blue Book2Document10 pagesSoil Aggregates From Blue Book2Colitz D. KhenNo ratings yet

- ASTM 6751 - 02: Astm ASTM 6751 Typical Biodiesel Test Description Test Method Biodiesel Soy & YGDocument1 pageASTM 6751 - 02: Astm ASTM 6751 Typical Biodiesel Test Description Test Method Biodiesel Soy & YGSergio Rodrigues BarbedoNo ratings yet

- Current Supplied Spec: Marine Gas Oil (Mgo) SpesificationDocument2 pagesCurrent Supplied Spec: Marine Gas Oil (Mgo) SpesificationosmanyukseNo ratings yet

- Prowirl 73F DN 100Document3 pagesProwirl 73F DN 100Yohannes S. AripinNo ratings yet

- Sample Description: K17+180 Date: 2016.4.14 Sample Designation: K16-K18Document33 pagesSample Description: K17+180 Date: 2016.4.14 Sample Designation: K16-K18kwameNo ratings yet

- Specification Gasoline Regular: Test MethodsDocument5 pagesSpecification Gasoline Regular: Test MethodsAnonymous E3sSdt851XNo ratings yet

- 24th WK OPC43GDocument1 page24th WK OPC43GPandianKalaimaniNo ratings yet

- TANK Module: Sample PrintoutDocument17 pagesTANK Module: Sample PrintoutAnonymous J1vjrU2No ratings yet

- c200 High NatgasDocument2 pagesc200 High NatgashariszafarNo ratings yet

- Chimney Design CalcDocument5 pagesChimney Design CalcDenny ThomasNo ratings yet

- ASTM MethodsDocument9 pagesASTM MethodsLe Nguyen Phuc ThienNo ratings yet

- Diem Nguyen K00442734 Midterm Report PDFDocument8 pagesDiem Nguyen K00442734 Midterm Report PDFTan BoonHeongNo ratings yet

- Synopsis: Waste Lube Oil Re-Refining Using Vacuum DistillationDocument4 pagesSynopsis: Waste Lube Oil Re-Refining Using Vacuum DistillationFarah SaadNo ratings yet

- PH 90XRDocument1 pagePH 90XRBratman Man50% (2)

- Coal Gas Urea Complex DesignDocument23 pagesCoal Gas Urea Complex DesignOsama HasanNo ratings yet

- PKR MillsDocument37 pagesPKR Millsnetygen1No ratings yet

- Chimney Design CalcDocument5 pagesChimney Design CalcYoga Sam100% (1)

- Petro e SeminarDocument71 pagesPetro e SeminargandoupletaNo ratings yet

- Crgo MTCDocument4 pagesCrgo MTCGupta Gupta100% (1)

- Quality: Astm A 105Document1 pageQuality: Astm A 105lavius_mNo ratings yet

- Environmental StandardsDocument119 pagesEnvironmental Standardssoubhik1987No ratings yet

- Carlos Types of FuelDocument5 pagesCarlos Types of FuelDaiane LavrattiNo ratings yet

- PORTLAND SLAG CEMENT (IS:455-1989) Test Result AreDocument1 pagePORTLAND SLAG CEMENT (IS:455-1989) Test Result AreSue JinsueNo ratings yet

- En10083-2 - 1996 - C35eDocument3 pagesEn10083-2 - 1996 - C35ealextentwentyNo ratings yet

- Copper Accelerated Salt Spray (CASS) and Salt Spray Test For Gardobond X 4707 A2Document15 pagesCopper Accelerated Salt Spray (CASS) and Salt Spray Test For Gardobond X 4707 A2Tito Tamaro PasaribuNo ratings yet

- Legend V128Document1 pageLegend V128Rodrigo BneryNo ratings yet

- LP FLARE Final PDFDocument14 pagesLP FLARE Final PDFgiangvspNo ratings yet

- Presentation Transformer OilDocument44 pagesPresentation Transformer Oilravi_bagga2000100% (3)

- Base SN SpecificationDocument4 pagesBase SN SpecificationElman AskerovNo ratings yet

- PV 1390 Cal R1Document44 pagesPV 1390 Cal R1namasralNo ratings yet

- LX 300plusII SpecDocument1 pageLX 300plusII SpecxuxantoNo ratings yet

- 36CrNiMo4 10083 98 ENG 01 PDFDocument1 page36CrNiMo4 10083 98 ENG 01 PDFanon_308531351No ratings yet

- 3249F532 TabelaDocument1 page3249F532 TabelaLIONN SOFTWARESNo ratings yet

- Drier Bed SizingDocument14 pagesDrier Bed SizingvkumaranNo ratings yet

- 08 Preheating, PWHT & Sand Blasting - PaintingDocument23 pages08 Preheating, PWHT & Sand Blasting - PaintingFasil ParuvanathNo ratings yet

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDocument1 pageGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsRicardo Perez VerdugoNo ratings yet

- Quick Process DesignDocument35 pagesQuick Process DesignAkshat JainNo ratings yet

- Description of Ash Handling System: PT - PLN (Persero) Job No. E07007 PT - PLN (Persero)Document16 pagesDescription of Ash Handling System: PT - PLN (Persero) Job No. E07007 PT - PLN (Persero)E.D.W “vet” witokoNo ratings yet

- Bagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesDocument15 pagesBagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesSoleh SulaemanNo ratings yet

- Presentation - ICS 2019 - JamshedpurDocument16 pagesPresentation - ICS 2019 - JamshedpurIndranil RoyNo ratings yet

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityFrom EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNo ratings yet

- Reverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsFrom EverandReverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsNo ratings yet

- 130 KMDocument967 pages130 KMKwame AsamoaNo ratings yet

- Bridges-2 - 1Document99 pagesBridges-2 - 1Kwame AsamoaNo ratings yet

- Field Density (Sand Replacement Method) : Tested By: Checked By: Approved byDocument1 pageField Density (Sand Replacement Method) : Tested By: Checked By: Approved byKwame AsamoaNo ratings yet

- Ministry of Public Works, LiberiaDocument2 pagesMinistry of Public Works, LiberiaKwame AsamoaNo ratings yet

- SievesDocument1 pageSievesKwame AsamoaNo ratings yet

- Urban Transportation Project-Traffic Management Works Batch 1 Concrete Cube Test ResultsDocument3 pagesUrban Transportation Project-Traffic Management Works Batch 1 Concrete Cube Test ResultsKwame AsamoaNo ratings yet

- Construction of Burma Camp Roads PH 1-Lot 2 Concrete Cube Test ResultsDocument7 pagesConstruction of Burma Camp Roads PH 1-Lot 2 Concrete Cube Test ResultsKwame AsamoaNo ratings yet

- Construction of Burma Camp Road Ph. 1 (3.66Km) - Lot 2 Summary of Backfill Density Test Results, March 2015Document1 pageConstruction of Burma Camp Road Ph. 1 (3.66Km) - Lot 2 Summary of Backfill Density Test Results, March 2015Kwame AsamoaNo ratings yet

- System Telephones Data Communications Lines Exchange Information Long Routers ServersDocument2 pagesSystem Telephones Data Communications Lines Exchange Information Long Routers ServersKwame AsamoaNo ratings yet

- Best Practice Guide West Africa (2013:4)Document8 pagesBest Practice Guide West Africa (2013:4)Kwame AsamoaNo ratings yet

- Aggregate Crushing Value BS 812-110 and BS en 1097-2Document3 pagesAggregate Crushing Value BS 812-110 and BS en 1097-2Kwame Asamoa0% (1)

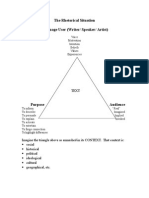

- The Rhetorical Situation Language User (Writer/ Speaker/ Artist)Document2 pagesThe Rhetorical Situation Language User (Writer/ Speaker/ Artist)Kwame AsamoaNo ratings yet

- FiazDocument3 pagesFiazKwame AsamoaNo ratings yet

- Table 18.3: Classes of ConcreteDocument1 pageTable 18.3: Classes of ConcreteKwame AsamoaNo ratings yet