Professional Documents

Culture Documents

Bohler DMV 83-Ig - Gmaw

Bohler DMV 83-Ig - Gmaw

Uploaded by

Milen GeorgievCopyright:

Available Formats

You might also like

- En 1011-1 - 2009 - OkDocument18 pagesEn 1011-1 - 2009 - Oksoft4gsm100% (4)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Bohler Fox DMV 83 KB - SmawDocument1 pageBohler Fox DMV 83 KB - Smawsoft4gsmNo ratings yet

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragNo ratings yet

- Böhler C 9 Mv-Ig: DescriptionDocument1 pageBöhler C 9 Mv-Ig: DescriptionDaniel MikicNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeNguyen Anh TuanNo ratings yet

- SAW Wire / Flux: Typical Chemical Composition of Rod (WT%) Product FeaturesDocument4 pagesSAW Wire / Flux: Typical Chemical Composition of Rod (WT%) Product Featuresehsan.mNo ratings yet

- Boehler Mig DMO IGDocument1 pageBoehler Mig DMO IGदिनेश कुशवाहाNo ratings yet

- Groupe Automobile Jeandot - Wrangler-448Document1 pageGroupe Automobile Jeandot - Wrangler-448DarkedgeNo ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- MIP Bohler Welding Austwqrwq2332e3eddwria 98Document1 pageMIP Bohler Welding Austwqrwq2332e3eddwria 98maxi27No ratings yet

- FOX CN 23-12 Mo-ADocument1 pageFOX CN 23-12 Mo-AVIRPOPNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- Welding, Brazing & Cutting - 11-21-2007Document7 pagesWelding, Brazing & Cutting - 11-21-2007Jimmy ClavelNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- Bohler Eas 2-Ig (Si) - GmawDocument1 pageBohler Eas 2-Ig (Si) - Gmaw24horas2No ratings yet

- Hyundai Welding Handbook (12th) - GmawDocument30 pagesHyundai Welding Handbook (12th) - GmawErick Quan LunaNo ratings yet

- SM 80GDocument1 pageSM 80GCarlos PadillaNo ratings yet

- Manual de Alambres Solidos LincolnDocument32 pagesManual de Alambres Solidos LincolnBartolome VasquezNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- MIP - Bohler - Welding - Austria 65 PDFDocument1 pageMIP - Bohler - Welding - Austria 65 PDFAdmir TalicNo ratings yet

- Duplex MetrodeDocument6 pagesDuplex Metrodeandresrojas25No ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- MIP Bohler Welding Austria 62Document1 pageMIP Bohler Welding Austria 62Pradeepta MohantyNo ratings yet

- E8018 B8Document1 pageE8018 B8Issac GeorgeNo ratings yet

- Er 80 S GDocument2 pagesEr 80 S Gabhics67No ratings yet

- Flux CoredDocument21 pagesFlux CoredmmkattaNo ratings yet

- 1 - UTP 614 KBDocument1 page1 - UTP 614 KBKrishna VachaNo ratings yet

- Bohler EAS 2-IG TDSDocument1 pageBohler EAS 2-IG TDSIvan DulicNo ratings yet

- 570 950mpa High Tensile Strength SteelDocument32 pages570 950mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- Guia Practica Eleccion AporteDocument26 pagesGuia Practica Eleccion AporteNegrito RosarinoNo ratings yet

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- S S S S - 11018.M 11018.M 11018.M 11018.M: Hyundai Welding Co., LTDDocument6 pagesS S S S - 11018.M 11018.M 11018.M 11018.M: Hyundai Welding Co., LTDfaridshabaniNo ratings yet

- Esab Chromweld G (SPL) Ok Tigrod SG: A High Alloyed Electrodes For High Strength ApplicationsDocument1 pageEsab Chromweld G (SPL) Ok Tigrod SG: A High Alloyed Electrodes For High Strength ApplicationsGokul RajanNo ratings yet

- Esab DublexDocument8 pagesEsab DublexSuphi YükselNo ratings yet

- TH 150Document12 pagesTH 150Minh Hong PhamNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- Midalloy ER70S-2Document1 pageMidalloy ER70S-2nasirfahimNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- Data Sheet A-12Document7 pagesData Sheet A-12anon_928750560No ratings yet

- ROYAL 8016 B2 (AWS:SFA 5.5, E 8016 B2) : ApplicationsDocument1 pageROYAL 8016 B2 (AWS:SFA 5.5, E 8016 B2) : Applicationssviluppi____No ratings yet

- Eutectrode 6666: Manual Arc Welding ElectrodeDocument1 pageEutectrode 6666: Manual Arc Welding ElectrodemortezaheidarianNo ratings yet

- Boehler2070-Ig de en 1Document1 pageBoehler2070-Ig de en 1Danfer De la CruzNo ratings yet

- Flux Cored Wires PDFDocument71 pagesFlux Cored Wires PDFCristian Camilo QuirogaNo ratings yet

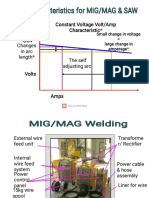

- Mig Mag Saw CswipDocument35 pagesMig Mag Saw CswipHamza DhariwalNo ratings yet

- Consumables For MIG MAG & FCAWDocument46 pagesConsumables For MIG MAG & FCAWaravindanNo ratings yet

- 02112015000000B - Boehler FOX EV 65 - CeDocument1 page02112015000000B - Boehler FOX EV 65 - CeMohamed AdelNo ratings yet

- Category GMAW-GTAW Solid Wires Type Applications Properties: Base Metal DIN EN AstmDocument1 pageCategory GMAW-GTAW Solid Wires Type Applications Properties: Base Metal DIN EN AstmAqil GhaffarNo ratings yet

- Lastek 90 Ceweld - Croni 29-9 S - 2013-06-27Document1 pageLastek 90 Ceweld - Croni 29-9 S - 2013-06-27Niksa ZekicNo ratings yet

- Ok Tigrod 13.38 Gtaw enDocument1 pageOk Tigrod 13.38 Gtaw ensoft4gsmNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Duplex UNS 32205Document1 pageDuplex UNS 32205Ercan YilmazNo ratings yet

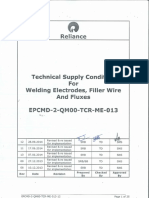

- Consumable Spec Rev 12Document24 pagesConsumable Spec Rev 12megastar0604No ratings yet

- En 10277-3 - 2008 - OkDocument9 pagesEn 10277-3 - 2008 - Oksoft4gsmNo ratings yet

- BS en 10216 Seamless Steel Tubes For Pressure Purposes Technical Delivery Conditions Part2Document43 pagesBS en 10216 Seamless Steel Tubes For Pressure Purposes Technical Delivery Conditions Part2soft4gsmNo ratings yet

- BS en 10250-2 2000Document14 pagesBS en 10250-2 2000denys7No ratings yet

- En 12680-3 - 2011 - OkDocument6 pagesEn 12680-3 - 2011 - Oksoft4gsm100% (1)

- En Iso 13916 1996 Scanned OkDocument7 pagesEn Iso 13916 1996 Scanned Oksoft4gsm100% (1)

- SBS V1.1-Compliant Gas Gauge IC: FeaturesDocument61 pagesSBS V1.1-Compliant Gas Gauge IC: Featuressoft4gsmNo ratings yet

- APT50M75JLLDocument5 pagesAPT50M75JLLsoft4gsmNo ratings yet

- A3941 DatasheetDocument21 pagesA3941 Datasheetsoft4gsmNo ratings yet

- MAX480Document7 pagesMAX480soft4gsmNo ratings yet

- Esab @: Nspecflon Certificate (3.1) - Ghemical Analysis Test (2.21-Mechanical PropertiesDocument1 pageEsab @: Nspecflon Certificate (3.1) - Ghemical Analysis Test (2.21-Mechanical Propertiessoft4gsmNo ratings yet

- 1011-2e DIN en Ion For Arc Welding of Ferritic SteelDocument58 pages1011-2e DIN en Ion For Arc Welding of Ferritic SteelЛюбомир ЛюбеновNo ratings yet

- Pic18f2553 PDFDocument46 pagesPic18f2553 PDFsoft4gsmNo ratings yet

- 599329115Document109 pages599329115soft4gsm100% (1)

- CN0146Document3 pagesCN0146soft4gsmNo ratings yet

- Ad8421 PDFDocument28 pagesAd8421 PDFsoft4gsmNo ratings yet

- 4100 FBDocument30 pages4100 FBsoft4gsmNo ratings yet

- CN0146Document3 pagesCN0146soft4gsmNo ratings yet

- Product Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'Document2 pagesProduct Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'soft4gsmNo ratings yet

- Product Data Sheet OK Tigrod 13.12: W 'Tungsten Inert Gas Arc Welding'Document2 pagesProduct Data Sheet OK Tigrod 13.12: W 'Tungsten Inert Gas Arc Welding'soft4gsmNo ratings yet

- Ok Tigrod 13.38 Gtaw enDocument1 pageOk Tigrod 13.38 Gtaw ensoft4gsmNo ratings yet

- Product Data Sheet OK 76.18: ESAB AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: ESAB AB Swedensoft4gsmNo ratings yet

- Ok Tigrod 12.64 Gtaw enDocument2 pagesOk Tigrod 12.64 Gtaw ensoft4gsmNo ratings yet

- Thermanit Mts-3 Gtaw enDocument1 pageThermanit Mts-3 Gtaw ensoft4gsmNo ratings yet

Bohler DMV 83-Ig - Gmaw

Bohler DMV 83-Ig - Gmaw

Uploaded by

Milen GeorgievOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bohler DMV 83-Ig - Gmaw

Bohler DMV 83-Ig - Gmaw

Uploaded by

Milen GeorgievCopyright:

Available Formats

www.boehler-welding.

com

High Temperature and Creep-resistant Filler Metals GMAW Solid Wires

EN ISO 21952-A:2008:

AWS A5.28-05:

AWS A5.28M-05:

W.No.:

G MoVSi

ER80S-G

ER55S-G

1.5407

BHLER DMV 83-IG

GMAW solid wire,

low-alloyed, high temperature

Description

GMAW wire for boiler, plate and tube steels. Designed specially for 14MoV6-3 (1/2 Cr 1/2 Mo

1/4 V). Approved in long-term condition up to +560 C service temperature. Tough, cracking

resistant deposit with good creep rupture strength. The wire shows very good feeding characteristics, resulting in smooth welding and wetting behaviour.

Typical Composition of Solid Wire

Wt-%

C

0.08

Si

0.6

Mn

0.9

Cr

0.45

Mo

0.85

V

0.35

Mechanical Properties of All-weld Metal

(*)

a

Yield strength Re N/mm2 (MPa):

610

( 550)

710

( 630)

Tensile strength Rm N/mm2 (MPa):

20

( 318)

Elongation A (L0 = 5d0) %:

Impact work ISO-V KV J

+ 20 C:

80

( 347)

(*) a annealed, 700 C/2 h/furnace down to 300 C/air shielding gas Ar + 18 % CO2

Operating Data

shielding gases:

mm

1.2

Argon + 15 - 25 % CO2

100 % CO2

Using 100% CO2 the mechanical properties can be different.

Preheating and interpass temperatures 200-300 C. Tempering at 700-720 C for at least 2 hrs

followed by cooling in furnace down to 300 C and still air.

Base Materials

similar alloyed high temperature steels and cast steels

1.7715 14MoV6-3, 1.7733 24CrMoV5-5, 1.7709 21CrMoV5-7, 1.8070 21CrMoV5-11,

1.7706 G17CrMoV5-10,

ASTM A389 Gr. C23 a. C24; A405 Gr. P24; UNS I21610

Approvals and Certificates

TV-D (1322.), TV-A (121), SEPROZ, CE

Same Alloy Filler Metals

SMAW electrode:

GTAW rod:

FOX DMV 83 Kb

DMV 83-IG

2-144

You might also like

- En 1011-1 - 2009 - OkDocument18 pagesEn 1011-1 - 2009 - Oksoft4gsm100% (4)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Bohler Fox DMV 83 KB - SmawDocument1 pageBohler Fox DMV 83 KB - Smawsoft4gsmNo ratings yet

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragNo ratings yet

- Böhler C 9 Mv-Ig: DescriptionDocument1 pageBöhler C 9 Mv-Ig: DescriptionDaniel MikicNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeNguyen Anh TuanNo ratings yet

- SAW Wire / Flux: Typical Chemical Composition of Rod (WT%) Product FeaturesDocument4 pagesSAW Wire / Flux: Typical Chemical Composition of Rod (WT%) Product Featuresehsan.mNo ratings yet

- Boehler Mig DMO IGDocument1 pageBoehler Mig DMO IGदिनेश कुशवाहाNo ratings yet

- Groupe Automobile Jeandot - Wrangler-448Document1 pageGroupe Automobile Jeandot - Wrangler-448DarkedgeNo ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- MIP Bohler Welding Austwqrwq2332e3eddwria 98Document1 pageMIP Bohler Welding Austwqrwq2332e3eddwria 98maxi27No ratings yet

- FOX CN 23-12 Mo-ADocument1 pageFOX CN 23-12 Mo-AVIRPOPNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- Welding, Brazing & Cutting - 11-21-2007Document7 pagesWelding, Brazing & Cutting - 11-21-2007Jimmy ClavelNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- Bohler Eas 2-Ig (Si) - GmawDocument1 pageBohler Eas 2-Ig (Si) - Gmaw24horas2No ratings yet

- Hyundai Welding Handbook (12th) - GmawDocument30 pagesHyundai Welding Handbook (12th) - GmawErick Quan LunaNo ratings yet

- SM 80GDocument1 pageSM 80GCarlos PadillaNo ratings yet

- Manual de Alambres Solidos LincolnDocument32 pagesManual de Alambres Solidos LincolnBartolome VasquezNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- MIP - Bohler - Welding - Austria 65 PDFDocument1 pageMIP - Bohler - Welding - Austria 65 PDFAdmir TalicNo ratings yet

- Duplex MetrodeDocument6 pagesDuplex Metrodeandresrojas25No ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- MIP Bohler Welding Austria 62Document1 pageMIP Bohler Welding Austria 62Pradeepta MohantyNo ratings yet

- E8018 B8Document1 pageE8018 B8Issac GeorgeNo ratings yet

- Er 80 S GDocument2 pagesEr 80 S Gabhics67No ratings yet

- Flux CoredDocument21 pagesFlux CoredmmkattaNo ratings yet

- 1 - UTP 614 KBDocument1 page1 - UTP 614 KBKrishna VachaNo ratings yet

- Bohler EAS 2-IG TDSDocument1 pageBohler EAS 2-IG TDSIvan DulicNo ratings yet

- 570 950mpa High Tensile Strength SteelDocument32 pages570 950mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- Guia Practica Eleccion AporteDocument26 pagesGuia Practica Eleccion AporteNegrito RosarinoNo ratings yet

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- S S S S - 11018.M 11018.M 11018.M 11018.M: Hyundai Welding Co., LTDDocument6 pagesS S S S - 11018.M 11018.M 11018.M 11018.M: Hyundai Welding Co., LTDfaridshabaniNo ratings yet

- Esab Chromweld G (SPL) Ok Tigrod SG: A High Alloyed Electrodes For High Strength ApplicationsDocument1 pageEsab Chromweld G (SPL) Ok Tigrod SG: A High Alloyed Electrodes For High Strength ApplicationsGokul RajanNo ratings yet

- Esab DublexDocument8 pagesEsab DublexSuphi YükselNo ratings yet

- TH 150Document12 pagesTH 150Minh Hong PhamNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- Midalloy ER70S-2Document1 pageMidalloy ER70S-2nasirfahimNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- Data Sheet A-12Document7 pagesData Sheet A-12anon_928750560No ratings yet

- ROYAL 8016 B2 (AWS:SFA 5.5, E 8016 B2) : ApplicationsDocument1 pageROYAL 8016 B2 (AWS:SFA 5.5, E 8016 B2) : Applicationssviluppi____No ratings yet

- Eutectrode 6666: Manual Arc Welding ElectrodeDocument1 pageEutectrode 6666: Manual Arc Welding ElectrodemortezaheidarianNo ratings yet

- Boehler2070-Ig de en 1Document1 pageBoehler2070-Ig de en 1Danfer De la CruzNo ratings yet

- Flux Cored Wires PDFDocument71 pagesFlux Cored Wires PDFCristian Camilo QuirogaNo ratings yet

- Mig Mag Saw CswipDocument35 pagesMig Mag Saw CswipHamza DhariwalNo ratings yet

- Consumables For MIG MAG & FCAWDocument46 pagesConsumables For MIG MAG & FCAWaravindanNo ratings yet

- 02112015000000B - Boehler FOX EV 65 - CeDocument1 page02112015000000B - Boehler FOX EV 65 - CeMohamed AdelNo ratings yet

- Category GMAW-GTAW Solid Wires Type Applications Properties: Base Metal DIN EN AstmDocument1 pageCategory GMAW-GTAW Solid Wires Type Applications Properties: Base Metal DIN EN AstmAqil GhaffarNo ratings yet

- Lastek 90 Ceweld - Croni 29-9 S - 2013-06-27Document1 pageLastek 90 Ceweld - Croni 29-9 S - 2013-06-27Niksa ZekicNo ratings yet

- Ok Tigrod 13.38 Gtaw enDocument1 pageOk Tigrod 13.38 Gtaw ensoft4gsmNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Duplex UNS 32205Document1 pageDuplex UNS 32205Ercan YilmazNo ratings yet

- Consumable Spec Rev 12Document24 pagesConsumable Spec Rev 12megastar0604No ratings yet

- En 10277-3 - 2008 - OkDocument9 pagesEn 10277-3 - 2008 - Oksoft4gsmNo ratings yet

- BS en 10216 Seamless Steel Tubes For Pressure Purposes Technical Delivery Conditions Part2Document43 pagesBS en 10216 Seamless Steel Tubes For Pressure Purposes Technical Delivery Conditions Part2soft4gsmNo ratings yet

- BS en 10250-2 2000Document14 pagesBS en 10250-2 2000denys7No ratings yet

- En 12680-3 - 2011 - OkDocument6 pagesEn 12680-3 - 2011 - Oksoft4gsm100% (1)

- En Iso 13916 1996 Scanned OkDocument7 pagesEn Iso 13916 1996 Scanned Oksoft4gsm100% (1)

- SBS V1.1-Compliant Gas Gauge IC: FeaturesDocument61 pagesSBS V1.1-Compliant Gas Gauge IC: Featuressoft4gsmNo ratings yet

- APT50M75JLLDocument5 pagesAPT50M75JLLsoft4gsmNo ratings yet

- A3941 DatasheetDocument21 pagesA3941 Datasheetsoft4gsmNo ratings yet

- MAX480Document7 pagesMAX480soft4gsmNo ratings yet

- Esab @: Nspecflon Certificate (3.1) - Ghemical Analysis Test (2.21-Mechanical PropertiesDocument1 pageEsab @: Nspecflon Certificate (3.1) - Ghemical Analysis Test (2.21-Mechanical Propertiessoft4gsmNo ratings yet

- 1011-2e DIN en Ion For Arc Welding of Ferritic SteelDocument58 pages1011-2e DIN en Ion For Arc Welding of Ferritic SteelЛюбомир ЛюбеновNo ratings yet

- Pic18f2553 PDFDocument46 pagesPic18f2553 PDFsoft4gsmNo ratings yet

- 599329115Document109 pages599329115soft4gsm100% (1)

- CN0146Document3 pagesCN0146soft4gsmNo ratings yet

- Ad8421 PDFDocument28 pagesAd8421 PDFsoft4gsmNo ratings yet

- 4100 FBDocument30 pages4100 FBsoft4gsmNo ratings yet

- CN0146Document3 pagesCN0146soft4gsmNo ratings yet

- Product Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'Document2 pagesProduct Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'soft4gsmNo ratings yet

- Product Data Sheet OK Tigrod 13.12: W 'Tungsten Inert Gas Arc Welding'Document2 pagesProduct Data Sheet OK Tigrod 13.12: W 'Tungsten Inert Gas Arc Welding'soft4gsmNo ratings yet

- Ok Tigrod 13.38 Gtaw enDocument1 pageOk Tigrod 13.38 Gtaw ensoft4gsmNo ratings yet

- Product Data Sheet OK 76.18: ESAB AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: ESAB AB Swedensoft4gsmNo ratings yet

- Ok Tigrod 12.64 Gtaw enDocument2 pagesOk Tigrod 12.64 Gtaw ensoft4gsmNo ratings yet

- Thermanit Mts-3 Gtaw enDocument1 pageThermanit Mts-3 Gtaw ensoft4gsmNo ratings yet