Professional Documents

Culture Documents

Pipe Line Design Basis PDF

Pipe Line Design Basis PDF

Uploaded by

Anjani PrabhakarCopyright:

Available Formats

You might also like

- (Pdo Oman) Electrical Safety Specs.Document56 pages(Pdo Oman) Electrical Safety Specs.KT MENON100% (7)

- Site Instruction To Contractor Project Managers (Section-1, 2 & 3)Document3 pagesSite Instruction To Contractor Project Managers (Section-1, 2 & 3)Lakmal Jayashantha100% (1)

- GU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Document48 pagesGU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Ibrahim Naguib100% (1)

- Materials Log BookDocument43 pagesMaterials Log BookDaryl Badajos100% (1)

- Material Submittal - ConsultantDocument40 pagesMaterial Submittal - Consultantm13naserraja75% (4)

- 2014-09-09 Construction Meeting Minutes PDFDocument3 pages2014-09-09 Construction Meeting Minutes PDFIthacaVoiceNo ratings yet

- 9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesDocument12 pages9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesAnjani Prabhakar100% (1)

- LNG Stress AnalysisDocument22 pagesLNG Stress Analysisvijayanmks100% (1)

- Concealment Record T-1301Document1 pageConcealment Record T-1301GeneraloberstHerjunaNo ratings yet

- MB MarineSpace Concrete CenterDocument216 pagesMB MarineSpace Concrete CenterMREFAATNo ratings yet

- TS Sab 006 13Document2 pagesTS Sab 006 13Danilo Magallanes SampagaNo ratings yet

- General Specs - SBK S 07 - Section 1A - GS - Main - PIDSDocument340 pagesGeneral Specs - SBK S 07 - Section 1A - GS - Main - PIDSkyawoo.sg0% (1)

- Project List 2011Document21 pagesProject List 2011Amanpreet SinghNo ratings yet

- Laying of Interceptor Sewer Along Najafgarh, Supplementary and Shahadra Drain For Abatement of Pollution in River Yamuna - Package I List of DrawingsDocument10 pagesLaying of Interceptor Sewer Along Najafgarh, Supplementary and Shahadra Drain For Abatement of Pollution in River Yamuna - Package I List of Drawingsavdesh7777No ratings yet

- Wika Ica TR 1376 12Document2 pagesWika Ica TR 1376 12AndiWSutomoNo ratings yet

- Sls 00 PPL PR 009 HDD Procedure Rev.0Document25 pagesSls 00 PPL PR 009 HDD Procedure Rev.0Marzuqi Aqila100% (2)

- FDD CDR Changes Memo: Design Package Number: Document No.: Revision: Details of Design ChangeDocument5 pagesFDD CDR Changes Memo: Design Package Number: Document No.: Revision: Details of Design ChangeJemicah YumenaNo ratings yet

- Design Calculation (Structural Data Sheet)Document1 pageDesign Calculation (Structural Data Sheet)vasinopNo ratings yet

- Water & Sewer Capital Improvement Program 2002 - 2006: Completed ProjectsDocument33 pagesWater & Sewer Capital Improvement Program 2002 - 2006: Completed ProjectsLTE002No ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- 2014-06-03 Construction Meeting Agenda PDFDocument2 pages2014-06-03 Construction Meeting Agenda PDFIthacaVoiceNo ratings yet

- CCAS Delay AnalysisDocument9 pagesCCAS Delay AnalysisAnwesha SatpathyNo ratings yet

- Main Villa Ganadha Palace-03Document1 pageMain Villa Ganadha Palace-03miteshsuneriyaNo ratings yet

- Exw P007 0101 Ee Keo DG 00362 003 PDFDocument1 pageExw P007 0101 Ee Keo DG 00362 003 PDFshareyhouNo ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- 2key Personnel Affidavit PayladoDocument11 pages2key Personnel Affidavit PayladoRichard DamiagoNo ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- Detail - A: Sequis DevelopmentDocument1 pageDetail - A: Sequis DevelopmentAsoyNo ratings yet

- 2014-06-10 Construction Meeting Minutes PDFDocument3 pages2014-06-10 Construction Meeting Minutes PDFIthacaVoiceNo ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- Bridge Design Memorandum - Dm0112: Original Signed by James W. Kendall, Jr. On February 14, 2012Document1 pageBridge Design Memorandum - Dm0112: Original Signed by James W. Kendall, Jr. On February 14, 2012kingdbmNo ratings yet

- Calculation Notes - Dimensionare Lucrari de SustinereDocument85 pagesCalculation Notes - Dimensionare Lucrari de SustinereMocanu Alexandru CiprianNo ratings yet

- ESR FDN DesignDocument161 pagesESR FDN DesignMahata PriyabrataNo ratings yet

- 08/29/2011 NDDOT Press Release: Overpass ConstructionDocument2 pages08/29/2011 NDDOT Press Release: Overpass ConstructionCity of ArgusvilleNo ratings yet

- Monthly Progress Report Jul13-Aug13Document20 pagesMonthly Progress Report Jul13-Aug13sshastrimech86% (7)

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- Cyberzon Budget 1Document223 pagesCyberzon Budget 1vijay2528No ratings yet

- Briefing of Project: Name of Work: Improvement/Metalling of Road From Shayar To Nagar Adp No: 620Document13 pagesBriefing of Project: Name of Work: Improvement/Metalling of Road From Shayar To Nagar Adp No: 620qazalbash1109588No ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- SHB CMEC ENG DCN 018 Request For Change The Pipe Material of WaterDocument2 pagesSHB CMEC ENG DCN 018 Request For Change The Pipe Material of Waterch4mp13nNo ratings yet

- SBA2021 04 Elevated Water Storage Tower Project COMPLETE REPORTDocument171 pagesSBA2021 04 Elevated Water Storage Tower Project COMPLETE REPORTsamkelo shongweNo ratings yet

- OXY Mukhaizna Airport Daily Report 010413pdf PDFDocument3 pagesOXY Mukhaizna Airport Daily Report 010413pdf PDFonspsnonsNo ratings yet

- 11 20 2012 Final AgendaDocument3 pages11 20 2012 Final AgendaDennis YuskoNo ratings yet

- Civil Engineer FRN 5Document7 pagesCivil Engineer FRN 5Adi M. MutawaliNo ratings yet

- Concrete Pouring Requisition Record T-1301Document1 pageConcrete Pouring Requisition Record T-1301GeneraloberstHerjunaNo ratings yet

- Construction Inspector S Checklist For PDocument63 pagesConstruction Inspector S Checklist For PSuresh DevarajanNo ratings yet

- KILO-W-CAL-0403 Pipeline Expansion Calculation 8" KC-KA 3 Phase Rev. A (15!07!13)Document20 pagesKILO-W-CAL-0403 Pipeline Expansion Calculation 8" KC-KA 3 Phase Rev. A (15!07!13)lukmantralala100% (2)

- Depth Survey February 2014 Fi 769Document3 pagesDepth Survey February 2014 Fi 769Jay LeeNo ratings yet

- 5 DCN - Design Change NoticeDocument3 pages5 DCN - Design Change Noticearif99pakNo ratings yet

- Progress Photographs JulyDocument9 pagesProgress Photographs JulyAnonymous UUw70xirblNo ratings yet

- Request For Extension of Completion Period of ProjectDocument1 pageRequest For Extension of Completion Period of ProjectKabirNo ratings yet

- Aerzen D62S Blowers Rev 16-Apr PDFDocument188 pagesAerzen D62S Blowers Rev 16-Apr PDFFarid100% (1)

- MISC. Drawing (See Information Tab) : 1-0923053.01 3BD EA-690836Document9 pagesMISC. Drawing (See Information Tab) : 1-0923053.01 3BD EA-690836anbarasusivaprakasamNo ratings yet

- SWW8830 Uce PMCC 3ic & 1BCDocument66 pagesSWW8830 Uce PMCC 3ic & 1BCimranNo ratings yet

- Phaze Concrete Application To Overland Park, KansasDocument13 pagesPhaze Concrete Application To Overland Park, KansasThe Salt Lake TribuneNo ratings yet

- D1300009 Sheet 1Document1 pageD1300009 Sheet 1sanjeevchhabraNo ratings yet

- Technical Bid EvaluationDocument3 pagesTechnical Bid EvaluationAdvisNo ratings yet

- Dung Quat Refinery Additional Sulfur Recovery Unit: V-2151-201-A - 004 F BSR1301-025-A1101-0800-001-012 FDocument3 pagesDung Quat Refinery Additional Sulfur Recovery Unit: V-2151-201-A - 004 F BSR1301-025-A1101-0800-001-012 FdnbinhNo ratings yet

- California Infrastructure Projects: Legal Aspects of Building in the Golden StateFrom EverandCalifornia Infrastructure Projects: Legal Aspects of Building in the Golden StateNo ratings yet

- Design of Highway Bridges: An LRFD ApproachFrom EverandDesign of Highway Bridges: An LRFD ApproachRating: 4.5 out of 5 stars4.5/5 (4)

- PR 1754Document42 pagesPR 1754Anjani PrabhakarNo ratings yet

- Podar International School (CBSE) - Vadodara: Progress Report For Term II (2019-2020 - Morning Shift)Document1 pagePodar International School (CBSE) - Vadodara: Progress Report For Term II (2019-2020 - Morning Shift)Anjani PrabhakarNo ratings yet

- PR 1013Document38 pagesPR 1013Anjani Prabhakar100% (1)

- SP 1127 PDFDocument26 pagesSP 1127 PDFAnjani PrabhakarNo ratings yet

- Process Engineering HAZOP Procedure: Petroleum Development Oman L.L.CDocument17 pagesProcess Engineering HAZOP Procedure: Petroleum Development Oman L.L.CAnjani PrabhakarNo ratings yet

- Petroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Document15 pagesPetroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Anjani Prabhakar0% (1)

- Petroleum Development Oman L.L.C.: Unrestricted Document ID: PR-1259 September 1999-09-12 Filing KeyDocument43 pagesPetroleum Development Oman L.L.C.: Unrestricted Document ID: PR-1259 September 1999-09-12 Filing KeyAnjani PrabhakarNo ratings yet

- Ground Motion Prediction Equations 1964-2019Document651 pagesGround Motion Prediction Equations 1964-2019Anjani PrabhakarNo ratings yet

- Process Engineering HAZOP Procedure: Petroleum Development Oman L.L.CDocument17 pagesProcess Engineering HAZOP Procedure: Petroleum Development Oman L.L.CAnjani PrabhakarNo ratings yet

- Structural Analysis of Pipelines PDFDocument116 pagesStructural Analysis of Pipelines PDFAnjani PrabhakarNo ratings yet

- Vulnerability Assessment of Buried Pipelines: A Case Study: Frontiers in Geotechnical Engineering (FGE)Document11 pagesVulnerability Assessment of Buried Pipelines: A Case Study: Frontiers in Geotechnical Engineering (FGE)Anjani Prabhakar100% (1)

- IBP1941 14 Fatigue of Pipelines Subjecte PDFDocument10 pagesIBP1941 14 Fatigue of Pipelines Subjecte PDFAnjani PrabhakarNo ratings yet

- Dissertation - Aqilah Abu Bakar - 13677Document44 pagesDissertation - Aqilah Abu Bakar - 13677Anjani PrabhakarNo ratings yet

- Review of Pipeline Span Analyis-2019Document78 pagesReview of Pipeline Span Analyis-2019Anjani PrabhakarNo ratings yet

- 966 Comparison Sheet PDFDocument1 page966 Comparison Sheet PDFAnjani PrabhakarNo ratings yet

- Lateral Buckling of Above-Ground Piping CheckDocument4 pagesLateral Buckling of Above-Ground Piping CheckAnjani PrabhakarNo ratings yet

- Buried Pipe - Neven DrobnjakDocument9 pagesBuried Pipe - Neven DrobnjakAnjani PrabhakarNo ratings yet

- OMAE2015 - 42119 - Integrated Numerical Approach To Design of Offshore Pipelines Susceptible To Lateral BucklingDocument9 pagesOMAE2015 - 42119 - Integrated Numerical Approach To Design of Offshore Pipelines Susceptible To Lateral BucklingAnjani PrabhakarNo ratings yet

- Restrained and Unrestrained Zones of Buried PipelinesDocument8 pagesRestrained and Unrestrained Zones of Buried PipelinesAnjani PrabhakarNo ratings yet

- Buried Pipe - CalcstressDocument17 pagesBuried Pipe - CalcstressAnjani PrabhakarNo ratings yet

Pipe Line Design Basis PDF

Pipe Line Design Basis PDF

Uploaded by

Anjani PrabhakarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Line Design Basis PDF

Pipe Line Design Basis PDF

Uploaded by

Anjani PrabhakarCopyright:

Available Formats

PolarLNGFeedGasPipeline

BasisofDesign

Preparedfor:

Revision1

September03,2013

MichaelBakerJr.,Inc.

1400WestBensonBlvd.,Suite200

Anchorage,Alaska99503

9072731600

124937MBJDOC001

PolarLNGFeedGasPipelineProject

BasisofDesign

RevisionHistory

Comments

Rev

Date

09/14/2011

09/21/2011

10/13/2011

11/21/2012

01/08/2013

IncorporatedSPCOcommentsdated

December21,2012.

02/08/2013

IssuedForPublicComment

09/03/2013

UpdatedAlignmentatPolarPad

BakerApproval

PolarLNGLLCApproval

Draft

Updatedpercommentsreceived.

Updatedsection5.3.1toASCE710

previouslywas705.

Removedreferencetousingexisting

VSMandupdatedroutenearthe

HalliburtonPad

Updatedprojectpersonneland

incorporatedcommentsfromClient

andSPCO

Title

Name

MichaelBakerJr.,Inc.

ProjectManager

JasonGardner

MichaelBakerJr.,Inc.

ProjectEngineer

JoshGreenhill

MichaelBakerJr.,Inc.

CivilEngineer

PolarLNG,LLC

ProjectDirector

WesternIndustrialResources

Company

ProjectLead

Signature

Date

TobyLovelace,PE

DougSmith,PMP

EricFranklin,PMP

February2013

124937MBJDOC001Rev.1

Pageiofiv

PolarLNGFeedGasPipelineProject

BasisofDesign

TableofContents

1.0

INTRODUCTION...............................................................................................................................1

2.0

PROJECTOVERVIEW.........................................................................................................................3

2.1 PIPELINEROUTE................................................................................................................................3

2.2 PIPELINECONFIGURATION...................................................................................................................4

2.2.1 EXPANSIONLOOPS.......................................................................................................................4

2.2.2 SUPPORTS..................................................................................................................................5

2.3 LAUNCHERANDRECEIVERBARRELS.......................................................................................................5

3.0

DESIGNPARAMETERS.......................................................................................................................6

3.1 PIPELINEDATA..................................................................................................................................6

3.2 DESIGNLOADS..................................................................................................................................6

3.2.1 INTERNALDESIGNPRESSURE.........................................................................................................7

3.2.2 HYDROSTATICTESTLOADS............................................................................................................7

3.2.3 TEMPERATUREDIFFERENTIAL........................................................................................................7

3.2.4 GRAVITYLOADS..........................................................................................................................8

3.2.5 SNOWLOAD...............................................................................................................................8

3.2.6 WINDLOADANDWINDINDUCEDVIBRATION(WIV)........................................................................8

3.2.7 LOSSOFSUPPORT........................................................................................................................8

3.2.8 EARTHQUAKELOADS....................................................................................................................9

3.2.9 LOADCOMBINATIONS..................................................................................................................9

4.0

PIPESTRESS..................................................................................................................................10

4.1 ALLOWABLESTRESSCRITERIA............................................................................................................10

4.2 PIPELINESTRESSANALYSIS................................................................................................................11

5.0

PIPELINESUPPORTS........................................................................................................................12

5.1 SUPPORTDESCRIPTIONS....................................................................................................................12

5.2 SUPPORTDESIGN.............................................................................................................................13

5.3 STRUCTURALANALYSISOFPIPELINESUPPORTS.....................................................................................14

5.3.1 SUPPORTLOADING....................................................................................................................14

6.0

CIVILDESIGN................................................................................................................................16

6.1 ROADCROSSINGS............................................................................................................................16

February2013

124937MBJDOC001Rev.1

Pageiiofiv

PolarLNGFeedGasPipelineProject

BasisofDesign

ListofTables

TABLE1.1

TABLE3.1

TABLE3.2

TABLE3.3

TABLE4.1

TABLE5.1

FEEDGASCOMPOSITION..............................................................................................................1

PIPELINEPARAMETERS.................................................................................................................6

DESIGNLOADING.........................................................................................................................7

LOADCOMBINATIONS..................................................................................................................9

ALLOWABLESTRESSFORABOVEGROUNDPIPELINES........................................................................11

ALLOWABLEADFREEZESTRESSESFORVSM...................................................................................14

ListofFigures

FIGURE1.1

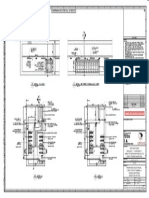

FIGURE2.1

FIGURE2.2

FIGURE5.1

FIGURE5.2

FIGURE5.3

POLARLNGPIPELINEBETWEENSEAWATERINJECTIONPLANT(SIP)PADANDPOLARLNGFACILITY.........2

TERMINATIONATPOLARPAD........................................................................................................4

TYPICALZLOOPCONFIGURATION...................................................................................................4

TYPICALSLIDINGSUPPORT..........................................................................................................13

TYPICALGUIDEDSUPPORT..........................................................................................................13

TYPICALANCHORSUPPORT.........................................................................................................13

Appendices

APPENDIXA CODES,STANDARDSANDSPECIFICATIONS..................................................................................A.1

February2013

124937MBJDOC001Rev.1

Pageiiiofiv

PolarLNGFeedGasPipelineProject

BasisofDesign

List of Abbreviations and Acronyms

AISC

AmericanInstituteofSteel

Construction

SMYS

Specifiedminimumyieldstrength

TOS

TopofSteel

Tunedvibrationabsorber

ANSI

AmericanNationalStandards

Institute

TVA

API

AmericanPetroleumInstitute

UHMWPEUltraHighMolecularWeight

Polyethylene

ASCE

AmericanSocietyofCivilEngineers

ASME

AmericanSocietyofMechanical

Engineers

BOP

Bottomofpipe

BPXA

BPExploration(Alaska),Inc.

CFR

CodeofFederalRegulation

CVN

CharpyVNotch

DF

Designfactor

DOT

DepartmentofTransportation(U.S.)

DS12

DrillSite12

FBE

Fusionbondedepoxy

FNG

FairbanksNaturalGas,LLC

FS1

FlowStation1

Gravity

GPB

GreaterPrudhoeBay

HSM

Horizontalsupportmember

IBC

InternationalBuildingCode

ILI

Inlineinspection

LNG

Liquefiednaturalgas

LRFD

LoadandResistanceFactorDesign

MAOP

Maximumallowableoperating

pressure

VSM

Verticalsupportmember

WIV

Windinducedvibration

MMscfd Millionstandardcubicfeetperday

PBU

PrudhoeBayUnit

pcf

Poundspercubicfoot

PPM

PartsperMillion

psf

Poundspersquarefoot

SIP

SeawaterInjectionPlant

February2013

124937MBJDOC001Rev.1

Pageivofiv

PolarLNGFeedGasPipelineProject

BasisofDesign

1.0 Introduction

ThePolarLNG,LLC(PolarLNG)programwillconstructafeedgaspipelineandanaturalgasliquefaction

plantinDeadhorse,Alaska,adjacenttothePrudhoeBayOilFieldonAlaskasNorthSlope.Theliquefied

naturalgas(LNG)willbetransportedbytrucktoFairbanks,Alaska,whereitwillbestoredandvaporized

on demand. The LNG will provide Fairbanks Natural Gas (FNG) with a larger supply to increase gas

servicewithinitsservicearea.

PolarLNGisplanningtoinstallthefeedgaspipelinebythesecondquarterof2014.Thepipelinewilltie

into the Seawater Injection Plant (SIP) 10inch nominal diameter fuel gas line at an existing flanged

connection.Fromthistiein,thepipelinewillpassthroughameteringskid,tobedesignedbyothers.On

the downstream side of the metering skid, the pipeline will proceed crosscountry to the Polar LNG

facilitynearDrillSite12(DS12).ThepipelinewillbeincompliancewithDOT(49CFR192)regulations.

Thepipelinewillberoutedwithinanewrightofway.

The new pipeline will be NPS 8 (8inch nominal diameter), API 5L X65 carbon steel, and have a total

lengthofapproximately18,600feet.Thepipelinecapacitywillbe32millionstandardcubicfeetperday

(MMscfd)offeedstockgas.Table1.1showsthefeedgascomposition.Thepipelinewillbedesignedfor

a maximum allowable operating pressure (MAOP) of 1480 psig, with a normal operating pressure of

approximately 650 psig. The pipeline will be coated with two layers (approximately 40 mils) of fusion

bonded epoxy (FBE) for corrosion resistance. The pipeline will only be insulated for short distances at

each anchor support. The pipeline will be installed on new vertical and horizontal support members

(VSM/HSM).

AmapoftheprojectareaispresentedinFigure1.1.

Table1.1

FeedGasComposition

Components

DesignGas(Mole%)

RichGas(Mole%)

LeanGas(Mole%)

Methane,C1

80.1

80.6

79.4

CarbonDioxide,CO2

12.05

12.4

11.8

Ethane,C2

5.25

5.6

5.2

Propane,C3

1.65

1.9

1.5

Nitrogen,N2

0.61

0.64

0.58

Butane

0.28

0.35

0.26

Pentane

0.04

0.05

0.04

Hexane

0.02

1.02

2.02

12PPM

40PPM

20PPM

HydrogenSulfide,H2S

Water,H2O

3PPM

6PPM

3PPM

Note:CompositionsarefromthePolarLNG, FeedGasPipelineDesignBasis,RevB,receivedfromPeakOilfield

Services.

124937MBJDOC001Rev.1

Page1of16

PolarLNGFeedGasPipelineProject

Figure1.1

BasisofDesign

PolarLNGPipelinebetweenSeawaterInjectionPlant(SIP)PadandPolarLNGFacility

124937MBJDOC001Rev.1

Page2of16

PolarLNGFeedGasPipelineProject

BasisofDesign

2.0 ProjectOverview

2.1

PipelineRoute

ThepipelinewillfollowthealignmentshowninFigure1.1.Anewpipelinerightofwaywillbeobtained

byPolarLNG.ThepipelinealignmentwillstartneartheoriginoftheSIP10inchnominaldiameterfuel

gas line, travel to the metering skid, and head south along a new rightofway until turning east at a

location north of the Halliburton Pad. The pipeline will turn south toward DS12, remaining east of

Halliburton Pad, until reaching the north shore of McDermott Lake. The pipeline will then follow the

northernandeasternshoresofthelaketoitsterminusatthePolarLNGPadnearDS12.

To support the construction of the new pipeline, an ice road approximately 30 feet wide will be

required. Work and turnaround areas, roughly 120 by 120 feet, will be spaced along the route. A

minimum 7 feet of clearance will be maintained between the tundra surface and the bottom of pipe,

exceptatroadcrossingswherethepipelinewilldescendbeforeenteringasteelcasing.

AmeteringskidwillbeinstalledattheSIPPadtodeterminethevolumeofgaspurchasedbyPolarLNG.

TheportionofthelinebetweenthetieinandthemeteringskidisoutsidethejurisdictionoftheU.S.

DepartmentofTransportation(USDOT)andthereforeisnotgoverned49CFR192.Thissectionwillbe

designedinaccordancewithASMEB31.8.PolarLNGwillbetheresponsiblepartyfortheoperationand

maintenance,andtheemergencyresponseforthissectionoftheline.

The pipeline will terminate at the Polar LNG Facility pad as shown in Figure 2.1. Receiver barrel

connectionswillbeinstalledatthislocation.

124937MBJDOC001Rev.1

Page3of16

PolarLNGFeedGasPipelineProject

Figure2.1

2.2

PipelineConfiguration

2.2.1

ExpansionLoops

BasisofDesign

TerminationatPolarPad

Toaccountfortheeffectsofthermalexpansion,Zstyleexpansionloopswillbeused,showninFigure

2.2. Two 90degree bends will be used in typical sections. Stresses and displacements calculated will

governtheallowabledistancebetweenanchors.

Figure2.2

TypicalZLoopConfiguration

124937MBJDOC001Rev.1

Page4of16

PolarLNGFeedGasPipelineProject

BasisofDesign

Pipe bends used at expansion loops and piping intersections will be prefabricated induction bends.

Routingandconfigurationoptimizationwillbeconductedtominimizethenumberofinductionbends.

All pipe bends will have a minimum radius requirement of three times the nominal pipeline diameter

(3D)toaccommodatetheuseofinlineinspection(ILI)tools.

2.2.2

Supports

Aminimumspacingof3.5feetwillbemaintainedbetweentheendsoftheexistingHSMbeamsandthe

newpipesupportbeamsintheareaneartheSIPpad.

Typicalsupportspacingwillbeapproximately55feet.Considerationwillbegiventoaccommodatefield

changesupto5feetresultingfrommassiveiceorotherconditionsencounteredduringinstallationof

thesupports,variationsinsurveyinformation,andavoidanceofanynaturalormanmadestructuresnot

previouslyaddressed.

North Slope Borough regulations require a minimum clearance of 7 feet from bottom of pipe to the

tundrasurface.Thesaddleseachwillprovideadditionalelevationtothebottomofpipeandwillraise

the pipeline to an elevation to allow the midspan sag of the pipeline to exceed the clearance

requirement.Thiseliminatestheneedforcariboucrossingsalongthealignment.

2.3

LauncherandReceiverBarrels

Thepipelinewillbedesignedtoaccommodateconnectionoftemporary/portablelauncherandreceiver

barrels to allow deployment of inline inspection (ILI) and maintenance tools. The launcher barrel

connections will be located downstream of the metering skid and receiver barrel connections will be

locatedatthePolarLNGfacilityforusebyoperations.

124937MBJDOC001Rev.1

Page5of16

PolarLNGFeedGasPipelineProject

BasisofDesign

3.0 DesignParameters

3.1

PipelineData

ThePolarLNGpipelinewillbedesignedaccordingtothecodes,standards,andspecificationsasoutlined

in Appendix A of this report. The pipeline will not be insulated for the majority of the alignment. The

pipelinewillinsteadbecoatedwithtwolayersofFBEcoating,approximately4050milsthick.AsFBEis

notUVresistant,thisthicknesswillallowfortheoutersurfaceofthepipetochalkwhilestillaffording

adequate corrosion protection of the pipe steel. The pipeline will be insulated for short distances at

eachanchorsupport.Thiswillallowatypicalanchorsaddledesignthatclampsaroundtheinsulationto

beused.

ThepipelinedesignparametersaresummarizedinTable3.1.

Table3.1

PipelineParameters

Parameter

TieintoMeter

CrossCountry

HalliburtonPadto

PolarLNGPad

Product

FeedGas

FeedGas

FeedGas

GoverningCodes

ASMEB31.8

CFR49Part192

CFR49Part192

LocationClass

CodeDesignFactor(DF)

0.60

0.72

0.50

NominalPipeDiameter

8inch

8inch

8inch

MinimumWallThickness

0.226inch

0.199inch

0.259inch

DesignWallThickness

0.322inch

0.322inch

0.322inch

CorrosionAllowance

0.0625inches

0.0625inches

0.0625inches

MaterialGrade

API5LX65

API5LX65

API5LX65

SpecifiedMinimumYield

65,000psi

65,000psi

65,000psi

ASMEB16.5Rating

Class600

Class600

Class600

MaximumAllowable

OperatingPressure(MAOP)

1480psig

1480psig

1480psig

AllbendswillhaveminimumradiiofthreetimesthenominaldiametertofacilitatepassageofILIand

maintenancetools.

3.2

DesignLoads

Detailed industry requirements regarding allowable internal pressure and other loads, loading

combinations,orlimitationsoncombinedstatesofstressarepresentedinASMEB31.8,ASCE710,and

projectdesignspecifications.

The design operating conditions are defined to include all normal operating conditions and

environmentalloadings.Designloadsincludeinternalpressure,temperaturedifferential,deadandlive

loads,windload,hydrostatictestloads,andloadsimposedbyearthquakes.Pipelinedesignloadingsare

summarizedinTable3.2.

124937MBJDOC001Rev.1

Page6of16

PolarLNGFeedGasPipelineProject

BasisofDesign

Table3.2

DesignLoading

OperationalLoadingsforPipeline

1480psig

MAOP

MaximumOperatingTemperature

MinimumTemperature

TieInTemperature

100F

50F

25F

None

InsulationThickness

SpecificGravityofContents(Air=1.00)

PipeGuideSaddleFrictionCoefficient

(UHMWPElinerandFBE)

PipeSlideSaddleFrictionCoefficient

(PTFEandStainlessSteel)

0.72

0.251

0.101

DeadLoads

PipeSteelUnitWeight

489pcf

OccasionalLoads

Wind

SnowLoad(ground)

110mph

50psf

EarthquakeAcceleration

0.213g

1

Actualfrictioncoefficientsreportedbythemanufacturer(s)are

lower(0.18forguidesand0.04forslides).Analysiswillberunfor

eachsetoffrictionvaluestodeterminecontrollingcase.

3.2.1

InternalDesignPressure

The pipeline will be designed to 1480 psig (based on ASME B16.5 Class 600 flange rating) which is

greater than the MAOP of the PBU Field Fuel Gas pipeline (1440 psig). The operating pressure of the

PBUFieldFuelGaspipelineis575650psig.

3.2.2

HydrostaticTestLoads

Thepipelinewillbetestedtoatleast1.5timestheMAOP.Onehydrostatictestwillbeperformedfrom

the flange connection off the 10inch SIP fuel gas line to the metering skid, and the other will be

performed from the metering skid to the Polar LNG pad. The southern portion of the pipeline will be

Location Class 3. The maximum hoop stress during hydrostatic testing will be less than 95% of the

specified minimum yield strength (SMYS). The pipeline design is expected to accommodate the test

conditions as a contingency load. The load combination for modeling hydrostatic testing on installed

pipetypicallyincludesinternalpressure,gravity,thermaldifferential(duringtesting),and1/3windspeed

(approximately37mph).

3.2.3

TemperatureDifferential

Pipestressesfromtemperaturedifferentialwillbecalculatedperminimumdesigntemperatureandthe

maximumpipewalltemperature.

124937MBJDOC001Rev.1

Page7of16

PolarLNGFeedGasPipelineProject

BasisofDesign

PipestressesfromtemperaturedifferentialswillbecalculatedperASMEB31.8.Theoperationalrange

forthepipelineis50Fto100F,whichhasbeenverifiedwithPolarLNG.Theoperativeparagraphof

ASMEB31.8states:

The total range in temperature from minimum design temperature to the maximum

design temperature shall be considered, whether piping is coldsprung or not. Should

installation,startup,orshutdowntemperaturesbeoutsideofthedesigntemperature

range,additionalanalysiswillberequired.Inadditiontoexpansionofthelineitself,the

linear and angular movements of the equipment to which it is attached shall be

considered.

Forcesandmomentsactingonpipelinesupportswillbecalculatedbasedonacoldspringtemperature

of 25F. These forces will be determined using a temperature range specified from 25F to 50F

(contraction)and25Fto100F(expansion).

3.2.4

GravityLoads

Thegravityloadsincludetheweightofthepipe,contents,andexternalcoating.Thehighestfluidweight

thatthepipelinewillexperiencewilloccurduringhydrostatictesting.

3.2.5

SnowLoad

A minimum design ground snow load of 50 psf per Polar LNG design criteria will be converted to a

comparabledesignsnowloadasperASCE710.Itisassumedthatsnowloadingonlyappliestolocations

identifiedbyfieldoperationswheresignificantsnowdriftisexpected.Typically,snowdriftaccumulates

adjacenttopadsandroads,andanywherethepipelineisnotadequatelyelevatedfromthetundra(at

least5feetapproximately).

3.2.6

WindLoadandWindInducedVibration(WIV)

Designwindspeedforabovegroundpipelinesis110mph.Thedesignwindpressurewillbecalculated

usingASCE705asrequiredbytheInternationalBuildingCode(IBC).ThedesignwindexposureisC,

theimportancefactoris1.00,andthetopographicfactorKztisequalto1.00.Theforcecoefficientis

takentobe0.8.Thegusteffectfactoristakenas0.85.ThevelocitypressureexposurecoefficientKzis

definedas0.85.Thepipelinesareanticipatedtobebetween7and15feetabovegradeforthemajority

of the alignment. This results in a wind pressure of approximately 18 pounds per square foot on the

pipeline.

Thenewpipelinewillbeevaluatedforsusceptibilitytowindinducedvibration.Segmentsidentifiedas

susceptiblewillbemitigatedusingtunedvibrationabsorbers(TVA),reducingdistancebetweenVSM,or

other suitable techniques. Baker will perform a simplified screening analysis to determine the

susceptibility of the pipeline to WIV. If susceptibility is confirmed by this calculation, SSD, Inc. will be

consultedtouserefinedanalysistechniquestodeterminetheproperTVAconfigurationtodampenthe

predictedvibrations.

3.2.7

LossofSupport

Thedesignloadanalysiswillincludescenariosinvolvinglossofsupportduetofrostjackingorsettlingof

at least one VSM. This will ensure the pipeline will not buckle or rupture if one support is no longer

contactingthepipeline.

124937MBJDOC001Rev.1

Page8of16

PolarLNGFeedGasPipelineProject

3.2.8

BasisofDesign

EarthquakeLoads

TheNorthSlopeisconsideredalowseismicriskzone;therefore,simplifiedstaticearthquakeloadsare

usedintheanalysis.

Seismiccriteriaforpipelinedesignarebasedonmappedspectralaccelerationvalueswithanestimated

2percentprobabilityofexceedanceduringa50yearreturninterval(2500yearreturninterval),andSite

Class B soils. Based on USGS data, the project area has approximate maximum short period and

1secondspectralaccelerationsofSS=0.319gandS1=0.109g,respectively.ASCE710,Table11.41,gives

the site coefficient for Site Class B as 1.00 for short period spectral accelerations of less than 0.50.

Designspectralaccelerationisspecifiedtobe2/3ofthefactoredspectralacceleration,whichresultsin

designshortperiodand1secondspectralaccelerationsof0.213gand0.073g,respectively.Theshort

periodspectralaccelerationwillbeusedinpipestressanalysesoftheabovegroundpipelines.

3.2.9

LoadCombinations

LoadsonthepipelinesandsupportswillbeanalyzedfortheloadcombinationspresentedinTable3.3.

Table3.3

LoadCombinations

PipelineLoadCombinations

LoadType

Description

Testing

1

Primary

InternalPressure(Hoop)

Primary

InternalPressure

(Longitudinal)

Primary

HydrostaticTestPressure

Primary

GravityLoads

Primary

Operating

Contingency

4

X1

OccasionalLoad

(Wind,Seismic,Etc.)

X2

Secondary

TemperatureDifferential

(50Fto100F)

X3

Primary

LossofSupport

Secondary

TemperatureDifferential

(50Fto25F,25Fto100F)

Gravityloadforhydrostatictestincludestheweightofthehydrostatictestfluid.

Onethirdofthedesignwindspeedisincluded.

3

Temperaturedifferentialforhydrostatictestisbasedonanassumedhydrostatictesttemperatureof60F.

4

Combination7isappliedtowardsforces,moments,anddisplacementsonlyanddoesnotapplytowardsinternal

pipelinestress.

5

Stressresultingfromworstcaseoccasionalloadwillbereported.

Reference:ASMEB31.8,GasTransmissionandDistributionPipingSystems

2

124937MBJDOC001Rev.1

Page9of16

PolarLNGFeedGasPipelineProject

BasisofDesign

4.0 PipeStress

ASME B31.8 addresses detailed industry requirements for gas pipelines. Based on the nature and

durationoftheimposedloads,pipelinestressesarecategorizedasprimaryorsecondarystresses.The

primaryandsecondarystresscriteriaaresummarizedasfollows:

Primary Stresses Primary stresses are stresses developed by imposed loads with sustained

magnitudesthatareindependentofthedeformationofthestructure.Thebasiccharacteristicofa

primarystressisthatitisnotselflimiting.Thestressescausedbythefollowingloadsareconsidered

as primary stresses: internal pressure, external pressure including overburden, and dead and live

loads.

Secondary Stresses Secondary stresses are stresses developed by the selfconstraint of the

structure.Generally,theysatisfyanimposedstrainpatternratherthanbeinginequilibriumwithan

external load. The basic characteristic of a secondary stress is that it is selflimiting. The stresses

caused by the following loads are considered as secondary stresses: temperature differential,

differentialsettlement,andearthquakemotion.

Combined Stresses The three principal stresses acting in the circumferential, longitudinal, and

radialdirectionsdefinethestressstateinanyelementofthepipeline.Limitationsareplacedonthe

magnitude of primary and secondary principal stresses and on combinations of these stresses in

accordancewithacceptablestrengththeoriesthatpredictyielding.

4.1

AllowableStressCriteria

Circumferential, longitudinal, shear, and effective stresses are typically calculated taking into account

stresses from all relevant load combinations. Calculations consider flexibility and stress concentration

factors of components other than straight pipe. Allowable stresses for aboveground pipeline are

presentedinTable4.1.

124937MBJDOC001Rev.1

Page10of16

PolarLNGFeedGasPipelineProject

Table4.1

BasisofDesign

AllowableStressforAbovegroundPipelines

Criterion

Value

Basis

LoadComb.

HoopStress(hydrostatictestpressure)

0.95SMYS

ProjectDefined1

LongitudinalStress(hydrostatictestpressure,

hydrostatictesttemperature,hydrostatictestlive,

gravityloadandtheoccasionalload)

0.95SMYS

ProjectDefined1

HoopStress(designpressure)

(DF)SMYS2

B31.8,805.2.3

LongitudinalStress(designpressure,gravityload)

0.75SMYS

B31.8,833.6

LongitudinalStress(designpressure,gravityload,and

otheroccasionalloads)

0.75SMYS

B31.8,833.6

0.75*T

SMYS

B31.8,833.6,

841.1.8,841.1.81

EffectiveStress(sustainedloads,i.e.,pressure,gravity,

andtemperaturedifferential)

0.90SMYS

ProjectDefined

EffectiveStress(sustainedloads,i.e.,pressure,gravity,

temperaturedifferential,andlossofsupport)

0.90SMYS

ProjectDefined

Testing

Primary

Secondary

ExpansionStress(temperaturedifferential)

Combined

Sincetestpressureisstipulatedas1.25timesthedesignoperatingpressure,theminimumtestpressurefor

themajorityofthelinewouldcorrelateto0.90SMYS(1.250.72);thereforetheprojectdefinedvalueof0.95

SMYSwaschosentoaccountforhydrostaticheadeffectsduetoelevationchangesalongthepipelineroute.

DF=0.50,0.72

4.2

PipelineStressAnalysis

Acompletestressanalysiswillbeperformedtoassurethatthedesignwillperforminaccordancewith

specifications,codes,andstandardstocovereachPipelineLoadCombination(Table3.3)andAllowable

StressesforAbovegroundPipelines(Table4.1).

124937MBJDOC001Rev.1

Page11of16

PolarLNGFeedGasPipelineProject

BasisofDesign

5.0 PipelineSupports

NewpipesupportswillbeevaluatedinaccordancewiththeLoadandResistanceFactorDesign(LRFD)

methodpresentedinAISCSteelConstructionManual,13thEdition.Thestressesinthesupportswillbe

evaluated using the interaction formulae presented in Chapter H of AISC 36005 within the Steel

ConstructionManual.

5.1

SupportDescriptions

Typically,threevarietiesofpipesupportsareusedinabovegroundarcticpipelines:sliding,guided,and

anchorsupports.

Sliding supports allow lateral and longitudinal movement of the pipeline (to relieve stresses due to

thermalexpansion(andcontraction).Slidingsupportsaremostoftenusednearbends.Forthisproject,

sliding supports will be designed as a single VSM (typically pipe) with a welded cap plate, to which is

boltedanHSM(typicallyawideflangedbeam).Aslidebearingplate(PTFE,e.g.,Teflon)isweldedviaa

carbonsteelmountingplatetothetopsurfaceoftheHSM.Thepipelinesaddleisfixedtothepipeline

andfreetoslideonthebearingplate(polishedstainlesssteelstripsweldedtothebottomofthesaddle

furtherreducefrictiononthebearingplate).SeeFigure5.1

Guidedpipesupportsallowlongitudinalmovementofthepipeline,butrestrictlateralmovement,and

areusedinstraightrunsofthealignment.ConstructedofasingleVSMandHSMwithcapplatesimilar

to the sliding support, the guided saddle is attached to the beam and the pipeline rests on a liner

(UHMWPE,e.g.,Tivar)withinthesaddle.SeeFigure5.2.

Anchorsupportshavetheprimaryfunctionofresistingthelongitudinalmovementofthepipeline,but

are also designed to resist rotations and lateral movement. Due to the fixed boundary condition the

anchorsupportprovidesforthepipeline,anchorsrequiremorestrength;assuch,theyaredesignedto

be constructed of two VSM and cap plates connected to a single HSM. Typical moment resistance

required necessitates an HSM able to resist torsion. Since wideflanged beams do not economically

resist torsion and rectangular tube shapes are not able to meet low temperature Charpy impact

requirements,abuiltupbeamusuallyconsistingofawideflangedbeamwithplatesteelboxinginthe

flanges,isusedinstead.SeeFigure5.3.

124937MBJDOC001Rev.1

Page12of16

PolarLNGFeedGasPipelineProject

Figure5.1

TypicalSlidingSupport

Figure5.3

5.2

BasisofDesign

Figure5.2

TypicalGuidedSupport

TypicalAnchorSupport

SupportDesign

VSM will be installed vertically in oversized, drilled holes and backfilled with dense sandwater slurry.

TheVSMdesignwillincludeevaluationofthethermalregimeandgeotechnicalconditions.

The capacity of a VSM to support longterm loads in adfreeze is temperature and soil property

dependent. A lower temperature below freezing corresponds to higher adfreeze strength. A design

temperatureprofiletofullembedmentwillbebasedontypicalactivelayerdepthmeasurements,VSM

skinmeltallowance,andinsitusoiltemperature.ThedesignsoilstrengthvaluesappliedtoresistVSM

loads, both long term and short term, will be for icerich soils and will be dependent on the soil

temperatureprofile.

The VSM design is limited by the strength of the VSM steel, the strength of the steel/sand adfreeze

bond,andthestrengthoftheinsitusoils.DesignadfreezecapacityforVSMiscalculatedassumingthe

bond strength profile presented in Table 5.1. Minimum embedment will be 15 feet. No adfreeze

strength is allowed for embedment in massive ice. Embedment will be increased 1 foot per foot of

massiveiceencountered,ificeinexcessof3feetisencountered(thebasedesignprovidesforupto3

feetofmassiveice).

124937MBJDOC001Rev.1

Page13of16

PolarLNGFeedGasPipelineProject

Table5.1

BasisofDesign

AllowableAdfreezeStressesforVSM

Depth (Feet)

Design Adfreeze

5.3

From

To

Land Surface

40 psi jacking (upward)

12.5 psi

14

18.75 psi

14

25

25 psi

25

Bottom of VSM

31.25 psi

StructuralAnalysisofPipelineSupports

The typical descriptions of new pipeline supports are assumed based on previous experience. New

pipelinesupportswillbecategorizedintogroupsbasedonsimilarstickupheights(fromtundratoTOS),

depth of active layer, support type, and magnitude of pipeline operating forces. A model of each

support group will be created using RISA Structural Analysis software. A structural analysis of each

modelwillverifycompliancewithAISC36005coderequirements.

The structural connections for each type of support will be designed to adequately resist the applied

loadings,alsoinaccordancewithAISC36005.

VSMfoundationdesignistypicallybasedonstrengthaswellasdeflectionrequirements.Inadditionto

thestrengthrequirementsofAISC36005,theVSMwillbedesignedtoresistlateraldeflectionsdueto

environmentalforces,andlongtermcreepunderoperationalloadingassociatedwiththerelaxationof

the soil VSM interface. As detailed geotechnical investigation of each VSM location is not practical,

standardassumptionswillbeusedtodeterminethedesigndeflectionduetoeachoftheseeffects;as

such,thedeflectionscalculatedwillnotbefieldverifiable.

5.3.1

SupportLoading

PipelinesupportswillbeanalyzedwithconsiderationtoloadingperASCE710andthissection.Seven

loadcombinationsarelistedinsection2.3.2ofASCE710,forusewiththeLRFDmethod.

Severalloadtypesdonotapplytopipelinesupports,suchasfloodload,lateralearthpressureload,roof

liveload,andrainload.Gravityloadsfromthepipelinecontentsaretreatedasdeadloads;therefore,

live loads also do not apply. Fluid load is considered part of dead load and therefore is included

whereverdeadloadisincludedperASCE710.

Loadingfromthermaleffectson thepipelineisnot specificallyaddressedin ASCE710.LoadcaseT

referstoselfstrainingloads,whichareequivalenttothermaleffectsonstructuralmembers,butdonot

pertain to external loads applied to the structure. Section 2.3.5 of ASCE 710 elaborates on the

applicationofselfstrainingloads,effectivelyleavingtheapplicationofthermalloadstotheengineers

discretion.Forthepurposeofpipelinesupports,thermalloadingfromthepipelinewillbeappliedasa

dead load with the corresponding load factors. This assumption is based on the high probability of

thermaleffectsandthesustainednatureofthermalloadingduringpipelineoperation.

124937MBJDOC001Rev.1

Page14of16

PolarLNGFeedGasPipelineProject

BasisofDesign

Removingloadsthatdonotapplyandotherassumptionsleavesthefollowingloadcombinationsfrom

ASCE710:

1.

2.

3.

4.

5.

6.

7.

1.4D

1.2D+0.5S

1.2D+1.6S+0.5W

1.2D+1.0W+0.5S

1.2D+1.0E+0.2S

0.9D+1.0W

0.9D+1.0E

Loadcombinations6and7willnotbeincludedintheanalysisastheyareintendedtoconsiderwindand

earthquakeloadonastructurewithreducedweight.Toaccomplishthisinamoreconservativemanner,

load combinations 4 and 5 will be modified to have a dead load corresponding to that of empty

pipelines.

HydrostatictestloadingisnotspecificallyaddressedinASCE710;however,sinceitisatransientevent,

itisassumedthatequation4isthemostappropriateloadcombination.Inthiscase,deadloadisbased

on water with a specific gravity of 1 and will not include thermal loading from the pipeline. Thermal

effects are considered negligible since it is assumed the hydrostatic test medium will be at ambient

temperature. Wind loading is reduced since hydrostatic tests are not conducted during high wind

events.Itisalsoassumedthehydrostatictestwilloccurduringthesummerseason,andthereforesnow

loading,S,doesnotapply.Basedontheseassumptions,theloadcombinationforthehydrostatictestis:

4a. 1.2D+1.0((1/9)W)

Operating,thermal,test,earthquake,anddeadloadswillbedeterminedfromtheresultsofthepipeline

stressanalysis.

SnowloadingwillbedeterminedaspreviouslydescribedinSection3.2.5.

Windloadingwillbedeterminedbytheformula

Where: qZ=Velocitypressureevaluatedattheelevationofthepipe(Equation29.3.1ofASCE710)

G=Gusteffectfactor

Cf=ForceCoefficient

Af=Projectedareanormaltothewind

124937MBJDOC001Rev.1

Page15of16

PolarLNGFeedGasPipelineProject

BasisofDesign

6.0 CivilDesign

6.1

RoadCrossings

Thecurrentroutehasthreeroadcrossings.Typically,casingsareaminimumoftwostandarddiameters

greaterthanthepipeline.Casingisolatorswillbeinstalledaroundtheinsulatedpipeandwillserveto

electricallyisolatethepipelinefromthecasing.Wallthicknessofcasingswillbebasedoncommercially

availablematerialsandfitforpurpose.

Spacing between new casings and existing casings will be based on the anticipated compaction

equipmentandcompactiontestingmethods.Typically,newcasingsarespaced18inchesfromoutside

ofnewcasingtooutsideofexistingcasing;however,theexactspacingwillbeevaluatedonacaseby

casebasis.

Invertelevationsfornewcasingswillbelocatedtoachievetheminimumcoverdeterminedbydesign,

typically12inches.Ifnecessary,theexistingroadsurfacewillberaisedtoprovidetheminimumcover,

usingpitrungravelonsecondaryroadsorcrushedrockfinishingcourseonhightrafficroads.Material

requirementsforgravelandfinishingcoursewillbespecifiedonthedrawingsandwillbedetermined

based on what is available at the permitted pit source and prior experience with the materials. The

minimumcoverateachroadcrossingwillbeevaluatedspecificallywhengravelfillisrequired,basedon

thetypeofroadandtheexpectedtrafficanddesignvehicle.

MinimumcoverandwallthicknessrequirementsforcasingsatroadcrossingswillbeevaluatedperAPI

RP1102,withloadingfromadesignvehicledeterminedbyinformationprovidedbythePBUOperator.

Typically, the design vehicle is the most recent and heaviest drill rig in use at the time of design.

Currently,Doyon14andParkerDrilling272Land273Ldrillrigsarethecontrollingdesignvehicles.

124937MBJDOC001Rev.1

Page16of16

PolarLNGFeedGasPipelineProject

AppendixA

BasisofDesign

Codes,StandardsandSpecifications

Pipeline and pipeline support design will be performed in accordance with the codes, standards,

specifications,andrecommendedpracticeslistedbelow.

49CFR192,TransportationofNaturalandOtherGasbyPipeline:MinimumSafetyStandards

AlaskaGeneralSafetyCode(AGSC),OccupationalSafetyandHealthStandards

ASCEStandard7,MinimumDesignLoadsforBuildingandOtherStructures

AmericanInstituteofSteelConstruction(AISC),AllowableStressDesign(ASD)/Loadand

ResistanceFactorDesign(LRFD),SteelConstructionManual,13thEdition

AmericanPetroleumInstitute(API)5L,SpecificationforLinePipe,44thEdition,2007

API6D,SpecificationsforPipeLineValves

API1102,SteelPipelinesCrossingRailroadsandHighways,6thEdition

API1104,WeldingPipelineandRelatedFacilities,20thEdition

API1163,QualificationSystemsStandards

ASMEB16.5,PipeFlangesandFlangedFittingsNPSthroughNPS24

ASME31.8,GasTransmissionandDistributionPipingSystem

ASTMA572/A572M07StandardSpecificationforHighStrengthLowAlloyColumbium

VanadiumStructuralSteel

ASMEBPVSectionVIIIBoilerandPressureVesselCodeSectionVIIIPressureVessels

IBC,InternationalBuildingCode,asadoptedasAlaskaBuildingCode

IMC2006,InternationalMechanicalCode,asadoptedasAlaskaBuildingCode

NFPA70NationalElectricalCode

ThefollowingtableisapplicableforthedesignandengineeringofthepipelinetiedintoaBPXAsystem.

2009PROJECTDIRECTORATEPROJECTSTECHNICALSPECIFICATIONS

DOCUMENTINDEXWITHREVISIONNUMBER/DATEASOFOCTOBER27,2009

Number

Title

Revision

Dateof

Latest

Revision

GENERAL

CRTGA00004

NationalCodesandStandardsDesign

8/23/2004

CRTGA00005

PEStamping

1/31/2003

SPCGA00003

SpecificationStyleGuide

7/16/2002

SPCGA00004

BPXAEngineeringDrawingandDocumentRequirements

5/00/2007

BPXAAsBuiltDrawingProcedures

2/15/2006

GeneralSiteConditionsDesign

9/14/2007

SPCPRNSS00007001

ARCTIC

CRTAK0402

124937MBJDOC001Rev.1

PageA.1

PolarLNGFeedGasPipelineProject

BasisofDesign

2009PROJECTDIRECTORATEPROJECTSTECHNICALSPECIFICATIONS

DOCUMENTINDEXWITHREVISIONNUMBER/DATEASOFOCTOBER27,2009

Revision

Dateof

Latest

Revision

Health,Safety&EnvironmentalProtectionDesign

9/2/2008

CRTAK0420

CivilEngineering

6/2/2008

CRTAR00001

ArchitecturalDesign

8/23/2004

CRTSS00001

StructuralDesign

10/5/2006

SPCAK04902

MaterialToughnessRequirementsforStructuralSteel

6/2/2008

SPCCE00001

CivilMaterialandConstruction

3/25/2002

SPCSS00001

StructuralSteelWelding

1/15/2002

SPCSS00003

VSMandPileInstallation

10/27/2010

SPCSS00008

BeamandPileCapFabrication

12/20/2001

SPCSS00013

StructuralSteelFabrication,DetailingandErection

7/23/2002

SPCSS00014

StructuralLowTemperatureSteelPlatesSpecificationfor

PipelineSupports

1/15/2002

SPCSS00015

ModulePileMaterialsandFabrication

1/15/2002

SPCSS00016

StructuralPipeforSupportPiling

1/15/2002

SPCMA00002

ExternalCoatingsforModeratelyCorrosiveService

9/22/2004

SPCMA00004

External Pipe Coating Application of Fusion Bonded

Epoxy

2/20/2003

GP0670

CorrosionMonitoring

ETP

8/29/2005

Number

Title

HSE

CRTAK7602

CIVIL/STRUCTURAL

CORROSIONANDCOATING

MECHANICALEQUIPMENT

CRTAK4335

ValvesforPipelines

4/12/2007

CRTAK6201

Valves

4/12/2007

CRTAK6202

ValveSpecificationandProcurement

4/12/2007

API608MetalBallValves(NPS1/4toNPS20uptoClass

800)

8/10/2007

SPCAK62012

SPCAK62013

API6DBallValves

5/9/2007

SPCAK62015

API602Gate,Globe,andCheckValvesuptoNPS2

5/9/2007

Ball, Plug, and Other QuarterTurn Valves Common

Material

5/9/2007

SPCAK62016

124937MBJDOC001Rev.1

PageA.2

PolarLNGFeedGasPipelineProject

BasisofDesign

2009PROJECTDIRECTORATEPROJECTSTECHNICALSPECIFICATIONS

DOCUMENTINDEXWITHREVISIONNUMBER/DATEASOFOCTOBER27,2009

Revision

Dateof

Latest

Revision

RisingStem(GateandGlobe)ValvesCommonMaterial

5/9/2007

ValveDataSheetIndex

4/3/2006

CRTAK4300

PipelineSystems(OverviewDocument)

5/9/2007

Criteria for Onshore Pipeline Design and Project

Execution

4/12/2007

CRTAK4301

CRTAK4304

QA&QCforPipelineProjects

6/2/2008

CRTAK4307

SelectionoftheDesignBasisforPipelines

4/12/2007

CRTAK4308

SelectionandUseofPipelineCodesandStandards

9/28/2007

CRTAK4309

HydraulicDesignofPipelineSystems

5/9/2007

CRTAK4317

PipelineRiskManagement

8/10/2007

CRTAK4320

OnshorePipelineSystemDesign

9/28/2007

CRTAK4322

AbovegroundPipelineFacilities

9/28/2007

CRTAK4328

PipelineCrossings

12/5/2007

CRTAK4331

LinePipeMaterialSelectionandProcurement

12/20/2006

CRTAK4332

PipeHandlingandLogisticsforPipelines

4/12/2007

CRTAK4340

OnshorePipelineConstruction

5/9/2007

CRTAK4346

CriteriaforPipelineHydrotestandPrecommissioning

4/03/2009

CRTAK4347

PipelineCommissioningandHandovertoOperations

6/2/2008

CRTAK4392

WindinducedVibration(WIV)AssessmentandDesign

12/17/2007

Assessment of Pipe Spans Deformed by Extreme Snow

Loads

CRTAK4394

SPCAK42201

LowyieldCarbonSteelPipe,FlangesandFittings

11/18/2007

SPCAK42203

GasketProcurement

8/10/2007

SPCAK42204

StudBoltingProcurement

8/10/2007

SPCAK43311

Manufacture of Longitudinal or Helical Seam SAW

LinepipeinGradesuptoX80

5/9/2007

SPCAK43312

ManufactureofHFIorERWLinepipeinGradesuptoX70

5/9/2007

SPCAK43313

SeamlessLinePipeinGradesuptoX80

9/14/2007

SPCAK43317

Manufacture of Carbon Steel Induction Bends for

PipelinestoISO15590inGradesuptoX80

8/10/2007

Number

Title

SPCAK62017

SPCPP00081

MECHANICALPIPING

9/27/2007

124937MBJDOC001Rev.1

PageA.3

PolarLNGFeedGasPipelineProject

BasisofDesign

2009PROJECTDIRECTORATEPROJECTSTECHNICALSPECIFICATIONS

DOCUMENTINDEXWITHREVISIONNUMBER/DATEASOFOCTOBER27,2009

Revision

Dateof

Latest

Revision

InductionBends(ASMEB16.49)

5/9/2007

SPCAK43401

AbovegradeArcticPipelineConstruction

5/9/2007

SPCAK43411

PipelineSupportSaddles

9/28/2007

SPCAK43412

PipelineSupports

9/28/2007

SPCAK43413

TeflonSlidePlates

9/28/2007

SPCAK43414

PipelineSupportAnchors

9/28/2007

SPCAK43901

PipelineMaterialsandLineClasses

9/11/2007

SPCAK43927

HighyieldCarbonSteelFlangesandForgedFittings

9/28/2007

SPCAK43928

HighyieldCarbonSteelFittings

9/28/2007

SPCAK52102

ShopAppliedInsulation

9/27/2007

SPCAK52103

PreformedInsulation

8/10/2007

SPCAK52104

FoaminPlaceInsulation

9/18/2007

CRTAK4802

HazardandOperability(HAZOP)Study

4/15/2009

GP4801

HSSEReviewofProjects(PHSSER)

6/8/2009

GP4804

InherentlySaferDesign(ISD)

5/5/2009

GP4805

HazardIdentification(HAZID)Study

2/13/2009

CRTAK4354

DepressurizationandRepressurizationofPipeline

Systems

6/2/2008

CRTAK1801

WeldedFabricationandConstruction

6/2/2008

CRTAK1802

StorageandControlofWeldingConsumables

6/2/2008

CRTAK4333

WeldingofPipelines

9/14/2007

SPCAK18012

InServiceWelding

6/2/2008

SPCAK42103

BranchConnectionWelding

5/9/2007

SPCAK42104

HotTapping

12/5/2007

Number

Title

SPCAK43317A

PROCESSSAFETY

WELDINGANDFABRICATION

124937MBJDOC001Rev.1

PageA.4

You might also like

- (Pdo Oman) Electrical Safety Specs.Document56 pages(Pdo Oman) Electrical Safety Specs.KT MENON100% (7)

- Site Instruction To Contractor Project Managers (Section-1, 2 & 3)Document3 pagesSite Instruction To Contractor Project Managers (Section-1, 2 & 3)Lakmal Jayashantha100% (1)

- GU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Document48 pagesGU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Ibrahim Naguib100% (1)

- Materials Log BookDocument43 pagesMaterials Log BookDaryl Badajos100% (1)

- Material Submittal - ConsultantDocument40 pagesMaterial Submittal - Consultantm13naserraja75% (4)

- 2014-09-09 Construction Meeting Minutes PDFDocument3 pages2014-09-09 Construction Meeting Minutes PDFIthacaVoiceNo ratings yet

- 9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesDocument12 pages9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesAnjani Prabhakar100% (1)

- LNG Stress AnalysisDocument22 pagesLNG Stress Analysisvijayanmks100% (1)

- Concealment Record T-1301Document1 pageConcealment Record T-1301GeneraloberstHerjunaNo ratings yet

- MB MarineSpace Concrete CenterDocument216 pagesMB MarineSpace Concrete CenterMREFAATNo ratings yet

- TS Sab 006 13Document2 pagesTS Sab 006 13Danilo Magallanes SampagaNo ratings yet

- General Specs - SBK S 07 - Section 1A - GS - Main - PIDSDocument340 pagesGeneral Specs - SBK S 07 - Section 1A - GS - Main - PIDSkyawoo.sg0% (1)

- Project List 2011Document21 pagesProject List 2011Amanpreet SinghNo ratings yet

- Laying of Interceptor Sewer Along Najafgarh, Supplementary and Shahadra Drain For Abatement of Pollution in River Yamuna - Package I List of DrawingsDocument10 pagesLaying of Interceptor Sewer Along Najafgarh, Supplementary and Shahadra Drain For Abatement of Pollution in River Yamuna - Package I List of Drawingsavdesh7777No ratings yet

- Wika Ica TR 1376 12Document2 pagesWika Ica TR 1376 12AndiWSutomoNo ratings yet

- Sls 00 PPL PR 009 HDD Procedure Rev.0Document25 pagesSls 00 PPL PR 009 HDD Procedure Rev.0Marzuqi Aqila100% (2)

- FDD CDR Changes Memo: Design Package Number: Document No.: Revision: Details of Design ChangeDocument5 pagesFDD CDR Changes Memo: Design Package Number: Document No.: Revision: Details of Design ChangeJemicah YumenaNo ratings yet

- Design Calculation (Structural Data Sheet)Document1 pageDesign Calculation (Structural Data Sheet)vasinopNo ratings yet

- Water & Sewer Capital Improvement Program 2002 - 2006: Completed ProjectsDocument33 pagesWater & Sewer Capital Improvement Program 2002 - 2006: Completed ProjectsLTE002No ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- 2014-06-03 Construction Meeting Agenda PDFDocument2 pages2014-06-03 Construction Meeting Agenda PDFIthacaVoiceNo ratings yet

- CCAS Delay AnalysisDocument9 pagesCCAS Delay AnalysisAnwesha SatpathyNo ratings yet

- Main Villa Ganadha Palace-03Document1 pageMain Villa Ganadha Palace-03miteshsuneriyaNo ratings yet

- Exw P007 0101 Ee Keo DG 00362 003 PDFDocument1 pageExw P007 0101 Ee Keo DG 00362 003 PDFshareyhouNo ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- 2key Personnel Affidavit PayladoDocument11 pages2key Personnel Affidavit PayladoRichard DamiagoNo ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- Detail - A: Sequis DevelopmentDocument1 pageDetail - A: Sequis DevelopmentAsoyNo ratings yet

- 2014-06-10 Construction Meeting Minutes PDFDocument3 pages2014-06-10 Construction Meeting Minutes PDFIthacaVoiceNo ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- Bridge Design Memorandum - Dm0112: Original Signed by James W. Kendall, Jr. On February 14, 2012Document1 pageBridge Design Memorandum - Dm0112: Original Signed by James W. Kendall, Jr. On February 14, 2012kingdbmNo ratings yet

- Calculation Notes - Dimensionare Lucrari de SustinereDocument85 pagesCalculation Notes - Dimensionare Lucrari de SustinereMocanu Alexandru CiprianNo ratings yet

- ESR FDN DesignDocument161 pagesESR FDN DesignMahata PriyabrataNo ratings yet

- 08/29/2011 NDDOT Press Release: Overpass ConstructionDocument2 pages08/29/2011 NDDOT Press Release: Overpass ConstructionCity of ArgusvilleNo ratings yet

- Monthly Progress Report Jul13-Aug13Document20 pagesMonthly Progress Report Jul13-Aug13sshastrimech86% (7)

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- Cyberzon Budget 1Document223 pagesCyberzon Budget 1vijay2528No ratings yet

- Briefing of Project: Name of Work: Improvement/Metalling of Road From Shayar To Nagar Adp No: 620Document13 pagesBriefing of Project: Name of Work: Improvement/Metalling of Road From Shayar To Nagar Adp No: 620qazalbash1109588No ratings yet

- Notes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/ADocument1 pageNotes: Key Plan: Rayyan Road Project 7: Contract 1 West of New Rayyan R/A To East of Bani Hajer R/AshareyhouNo ratings yet

- SHB CMEC ENG DCN 018 Request For Change The Pipe Material of WaterDocument2 pagesSHB CMEC ENG DCN 018 Request For Change The Pipe Material of Waterch4mp13nNo ratings yet

- SBA2021 04 Elevated Water Storage Tower Project COMPLETE REPORTDocument171 pagesSBA2021 04 Elevated Water Storage Tower Project COMPLETE REPORTsamkelo shongweNo ratings yet

- OXY Mukhaizna Airport Daily Report 010413pdf PDFDocument3 pagesOXY Mukhaizna Airport Daily Report 010413pdf PDFonspsnonsNo ratings yet

- 11 20 2012 Final AgendaDocument3 pages11 20 2012 Final AgendaDennis YuskoNo ratings yet

- Civil Engineer FRN 5Document7 pagesCivil Engineer FRN 5Adi M. MutawaliNo ratings yet

- Concrete Pouring Requisition Record T-1301Document1 pageConcrete Pouring Requisition Record T-1301GeneraloberstHerjunaNo ratings yet

- Construction Inspector S Checklist For PDocument63 pagesConstruction Inspector S Checklist For PSuresh DevarajanNo ratings yet

- KILO-W-CAL-0403 Pipeline Expansion Calculation 8" KC-KA 3 Phase Rev. A (15!07!13)Document20 pagesKILO-W-CAL-0403 Pipeline Expansion Calculation 8" KC-KA 3 Phase Rev. A (15!07!13)lukmantralala100% (2)

- Depth Survey February 2014 Fi 769Document3 pagesDepth Survey February 2014 Fi 769Jay LeeNo ratings yet

- 5 DCN - Design Change NoticeDocument3 pages5 DCN - Design Change Noticearif99pakNo ratings yet

- Progress Photographs JulyDocument9 pagesProgress Photographs JulyAnonymous UUw70xirblNo ratings yet

- Request For Extension of Completion Period of ProjectDocument1 pageRequest For Extension of Completion Period of ProjectKabirNo ratings yet

- Aerzen D62S Blowers Rev 16-Apr PDFDocument188 pagesAerzen D62S Blowers Rev 16-Apr PDFFarid100% (1)

- MISC. Drawing (See Information Tab) : 1-0923053.01 3BD EA-690836Document9 pagesMISC. Drawing (See Information Tab) : 1-0923053.01 3BD EA-690836anbarasusivaprakasamNo ratings yet

- SWW8830 Uce PMCC 3ic & 1BCDocument66 pagesSWW8830 Uce PMCC 3ic & 1BCimranNo ratings yet

- Phaze Concrete Application To Overland Park, KansasDocument13 pagesPhaze Concrete Application To Overland Park, KansasThe Salt Lake TribuneNo ratings yet

- D1300009 Sheet 1Document1 pageD1300009 Sheet 1sanjeevchhabraNo ratings yet

- Technical Bid EvaluationDocument3 pagesTechnical Bid EvaluationAdvisNo ratings yet

- Dung Quat Refinery Additional Sulfur Recovery Unit: V-2151-201-A - 004 F BSR1301-025-A1101-0800-001-012 FDocument3 pagesDung Quat Refinery Additional Sulfur Recovery Unit: V-2151-201-A - 004 F BSR1301-025-A1101-0800-001-012 FdnbinhNo ratings yet

- California Infrastructure Projects: Legal Aspects of Building in the Golden StateFrom EverandCalifornia Infrastructure Projects: Legal Aspects of Building in the Golden StateNo ratings yet

- Design of Highway Bridges: An LRFD ApproachFrom EverandDesign of Highway Bridges: An LRFD ApproachRating: 4.5 out of 5 stars4.5/5 (4)

- PR 1754Document42 pagesPR 1754Anjani PrabhakarNo ratings yet

- Podar International School (CBSE) - Vadodara: Progress Report For Term II (2019-2020 - Morning Shift)Document1 pagePodar International School (CBSE) - Vadodara: Progress Report For Term II (2019-2020 - Morning Shift)Anjani PrabhakarNo ratings yet

- PR 1013Document38 pagesPR 1013Anjani Prabhakar100% (1)

- SP 1127 PDFDocument26 pagesSP 1127 PDFAnjani PrabhakarNo ratings yet

- Process Engineering HAZOP Procedure: Petroleum Development Oman L.L.CDocument17 pagesProcess Engineering HAZOP Procedure: Petroleum Development Oman L.L.CAnjani PrabhakarNo ratings yet

- Petroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Document15 pagesPetroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Anjani Prabhakar0% (1)

- Petroleum Development Oman L.L.C.: Unrestricted Document ID: PR-1259 September 1999-09-12 Filing KeyDocument43 pagesPetroleum Development Oman L.L.C.: Unrestricted Document ID: PR-1259 September 1999-09-12 Filing KeyAnjani PrabhakarNo ratings yet

- Ground Motion Prediction Equations 1964-2019Document651 pagesGround Motion Prediction Equations 1964-2019Anjani PrabhakarNo ratings yet

- Process Engineering HAZOP Procedure: Petroleum Development Oman L.L.CDocument17 pagesProcess Engineering HAZOP Procedure: Petroleum Development Oman L.L.CAnjani PrabhakarNo ratings yet

- Structural Analysis of Pipelines PDFDocument116 pagesStructural Analysis of Pipelines PDFAnjani PrabhakarNo ratings yet

- Vulnerability Assessment of Buried Pipelines: A Case Study: Frontiers in Geotechnical Engineering (FGE)Document11 pagesVulnerability Assessment of Buried Pipelines: A Case Study: Frontiers in Geotechnical Engineering (FGE)Anjani Prabhakar100% (1)

- IBP1941 14 Fatigue of Pipelines Subjecte PDFDocument10 pagesIBP1941 14 Fatigue of Pipelines Subjecte PDFAnjani PrabhakarNo ratings yet

- Dissertation - Aqilah Abu Bakar - 13677Document44 pagesDissertation - Aqilah Abu Bakar - 13677Anjani PrabhakarNo ratings yet

- Review of Pipeline Span Analyis-2019Document78 pagesReview of Pipeline Span Analyis-2019Anjani PrabhakarNo ratings yet

- 966 Comparison Sheet PDFDocument1 page966 Comparison Sheet PDFAnjani PrabhakarNo ratings yet

- Lateral Buckling of Above-Ground Piping CheckDocument4 pagesLateral Buckling of Above-Ground Piping CheckAnjani PrabhakarNo ratings yet

- Buried Pipe - Neven DrobnjakDocument9 pagesBuried Pipe - Neven DrobnjakAnjani PrabhakarNo ratings yet

- OMAE2015 - 42119 - Integrated Numerical Approach To Design of Offshore Pipelines Susceptible To Lateral BucklingDocument9 pagesOMAE2015 - 42119 - Integrated Numerical Approach To Design of Offshore Pipelines Susceptible To Lateral BucklingAnjani PrabhakarNo ratings yet

- Restrained and Unrestrained Zones of Buried PipelinesDocument8 pagesRestrained and Unrestrained Zones of Buried PipelinesAnjani PrabhakarNo ratings yet

- Buried Pipe - CalcstressDocument17 pagesBuried Pipe - CalcstressAnjani PrabhakarNo ratings yet