Professional Documents

Culture Documents

WPQP 6gr Smaw API 5lx52 Od6inch 14mm 18mm (Approved)

WPQP 6gr Smaw API 5lx52 Od6inch 14mm 18mm (Approved)

Uploaded by

ufomskiCopyright:

Available Formats

You might also like

- Isometric Pipe Support SymbolsDocument1 pageIsometric Pipe Support Symbolsufomski0% (1)

- 550 Gallon Stainless Steel Ibc Center Discharge SheetDocument1 page550 Gallon Stainless Steel Ibc Center Discharge SheetGioNo ratings yet

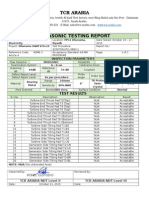

- Ultrasonic Testing ReportsDocument1 pageUltrasonic Testing ReportsRonel John Rodriguez CustodioNo ratings yet

- Ultrasonic Testing ReportDocument2 pagesUltrasonic Testing ReportRonel John Rodriguez Custodio100% (1)

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocument1 pageWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Daterohitbhat2345No ratings yet

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- WPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)Document1 pageWPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)ufomskiNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Record of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014Document2 pagesRecord of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014cisar0007No ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- WPS - 016Document11 pagesWPS - 016MAT-LIONNo ratings yet

- Errata D1.1 D1.1M 2020Document19 pagesErrata D1.1 D1.1M 2020JohnNo ratings yet

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Document24 pagesPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- Safety Comittee Report: Company Logo and Name Time Date VenueDocument2 pagesSafety Comittee Report: Company Logo and Name Time Date VenueHiren Maheta0% (1)

- Gmaw STTDocument4 pagesGmaw STTAnonymous 0rt9KWmNNo ratings yet

- Wps Model 2 PDFDocument17 pagesWps Model 2 PDFbeyNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

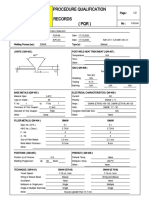

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Document1,913 pagesPipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- 1 WPS & PQRDocument2 pages1 WPS & PQRManoranjan sharmaNo ratings yet

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- WPS - D1.1Document1 pageWPS - D1.1Nam_HitechNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- SLB Check List-1Document2 pagesSLB Check List-1Jitendra BhosaleNo ratings yet

- Hemps 11.100 A1Document33 pagesHemps 11.100 A1हेमंत कुमार मीणाNo ratings yet

- Quality Docs DEP 17 0803Document7 pagesQuality Docs DEP 17 0803Edwin MPNo ratings yet

- Wps S - Ea-6gr-01.Doc Rev2 j4662Document1 pageWps S - Ea-6gr-01.Doc Rev2 j4662cisar0007No ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- PWPS 013 PRDocument2 pagesPWPS 013 PRRenjith Gopan100% (1)

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- QC - Consumables Colour Coding and IdentificationDocument3 pagesQC - Consumables Colour Coding and IdentificationfizanlaminNo ratings yet

- 12.6 Welding Procedures List (Li-002)Document31 pages12.6 Welding Procedures List (Li-002)Ana GameroNo ratings yet

- Inspection Plan - NDTDocument4 pagesInspection Plan - NDTgymadniNo ratings yet

- 6GR WPS PQR PDFDocument15 pages6GR WPS PQR PDFerwincalvoNo ratings yet

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNo ratings yet

- Class P6A6Document24 pagesClass P6A6SalimNo ratings yet

- Pm01988 Ge WG 5 1-8'' 10k SSV - Phase IDocument2 pagesPm01988 Ge WG 5 1-8'' 10k SSV - Phase IAbu UmarNo ratings yet

- 10 NDE ControlDocument6 pages10 NDE ControlShahbaz AlamNo ratings yet

- Name: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- Inspection and Quality Control in ManufacturingDocument598 pagesInspection and Quality Control in Manufacturingsaeed.pdNo ratings yet

- d1.1 Fcaw Unlimited Test Plate ConfigurationDocument77 pagesd1.1 Fcaw Unlimited Test Plate ConfigurationJuan Martinez100% (1)

- Premier Engineering Industries: List of WPS/PQRDocument1 pagePremier Engineering Industries: List of WPS/PQRBalkishan DyavanapellyNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Fit-Up and Daily Welding Visual Inspection ReportDocument1 pageFit-Up and Daily Welding Visual Inspection ReportAws AbduljaleelNo ratings yet

- A286 GIGLM 1004 PJ DOC QAR R 0006 Welding ConsumableDocument8 pagesA286 GIGLM 1004 PJ DOC QAR R 0006 Welding ConsumableMahesh PanditNo ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Hust WPS Gtaw - Smaw 6GDocument4 pagesHust WPS Gtaw - Smaw 6GtruongtrungplhdNo ratings yet

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- BQ-ZUL-0XX10 Welding Consumable ControlDocument10 pagesBQ-ZUL-0XX10 Welding Consumable ControlRAMAKRISHNANo ratings yet

- Insulation Inspection ReportDocument1 pageInsulation Inspection ReportKarthikNo ratings yet

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- Welder Qualification Manual Revision 5Document20 pagesWelder Qualification Manual Revision 5Hugo RodriguezNo ratings yet

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocument1 pageWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiNo ratings yet

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- WPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)Document1 pageWPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)ufomskiNo ratings yet

- Schedules & Fees.Document2 pagesSchedules & Fees.ufomskiNo ratings yet

WPQP 6gr Smaw API 5lx52 Od6inch 14mm 18mm (Approved)

WPQP 6gr Smaw API 5lx52 Od6inch 14mm 18mm (Approved)

Uploaded by

ufomskiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPQP 6gr Smaw API 5lx52 Od6inch 14mm 18mm (Approved)

WPQP 6gr Smaw API 5lx52 Od6inch 14mm 18mm (Approved)

Uploaded by

ufomskiCopyright:

Available Formats

rnl

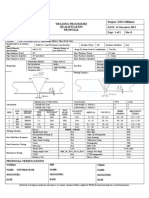

Project: DSO Offshore

WELDING PROCEDURE

QUALIFICATION

PROPOSAL

TOMBA RESOURCES

NIGERIA LIMITED

DATE: 18 NOVEMBER 2013

Page: 1 of 1

Rev 0

WPQP No: TOR/WPQR 101-6GR

Km 6 NPA Expressway by Ugbuwangue Market, Warri, Delta State

Location:

Qualification in Accordance

AWS D 1.1 and DSO project specification

with:

Parent Material

Material Group (as

API 5L X52

Specification

per AWS D1.1)

Pipe Diameter Tested

6

Pipe Diameter Qualified

4 and Above

Plate Thickness Tested

N/A

Preparation Method

Flame and cut

Fit-Up Method

Bullet

Preparation

Joint Cleaning

Light Grinding

Treatment Side 2

N/A

Position Tested

6GR

Positions Qualified

Group II, Group I and its combination

Pipe Thickness Tested

Pipe Thickness Qualified

Plate Thickness Qualified

Pre-Heat

ALL

Cast No:

Ceq:

14 mm + 18 mm

7 Unlimited

7 Unlimited

Preheat C / mm

50 0C

Heating Method

Propane touch

Max Interpass Temp

250 0C

Control Method

Tempilstick / Thermometer

Welding Sequence

Manufacturer & Trade Name

1.ESAB OK 53.70

2.ESAB OK 55.00

CONSUMABLES

SIZE

FLUX/GAS

(mm)

TYPE

Consumable

SIDE

RUN

Nos

WELDIN

G

PROCES

S

1

1

1

1

1

Hot Pass

Fill

Cap

SMAW

SMAW

SMAW

SMAW

Welding Variables

Post Weld Heat Treatment

Non Destructive Testing

Mechanical Testing

2.5

N/A

2.5

N/A

3.2/4

N/A

2.5/3.2

N/A

Process

Tig Electrode Type

Uncontrolled Heating To

Soak Temp

Slope Down Cooling

Visual

Ultrasonic

Tensile Tests

Charpy Impact Test

CTOD

Hardness Test

Classification

AWS A/SFA 5.1 E7016-1

AWS A/SFA 5.1 E7018-1

GAS

FLOW

RATE

POLARITY

(AC/DC)

N/A

DC+

N/A

DC+

N/A

DC+

N/A

DC+

SMAW + SMAW

N/A

N/A

N/A

N/A

Yes

N/A

2 sets

WM , FL

N/A

1 set

AMPS (A)

F No

4

4

VOLTS (V)

75 - 85

20 23

75 - 85

20 23

82 110

28 40

85 - 105

24 26

Gas Type

Flux Type

Slope Up Heating Rate

Soak Duration

Withdrawal Temp

Radiography

MPI / DPI

Bend Tests

Charpy Test Temp

CTOD temperature

Macro / Micro

A No

1

1

SPEED

(mm/min)

HEAT INPUT

(Kj/mm)

40 50

40 50

75 85

70 90

2.25 2.35

2.25 2.35

1.14 2.64

1.07 2.59

N/A

N/A

N/A

N/A

N/A

YES

MPI

4 sets (side)

-29 C

N/A

1 set

PROPOSAL VERIFICATIONS

TOMBA

HHI

Client

NAME:

NAME:

SIGNATURE:

SIGNATURE:

SIGNATURE:

DATE

DATE

DATE

NAME:

UFUOMA UKOR

All details of testing are proposals only please see reports contained within completed WPQR document package for recorded parameters.

You might also like

- Isometric Pipe Support SymbolsDocument1 pageIsometric Pipe Support Symbolsufomski0% (1)

- 550 Gallon Stainless Steel Ibc Center Discharge SheetDocument1 page550 Gallon Stainless Steel Ibc Center Discharge SheetGioNo ratings yet

- Ultrasonic Testing ReportsDocument1 pageUltrasonic Testing ReportsRonel John Rodriguez CustodioNo ratings yet

- Ultrasonic Testing ReportDocument2 pagesUltrasonic Testing ReportRonel John Rodriguez Custodio100% (1)

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocument1 pageWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Daterohitbhat2345No ratings yet

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- WPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)Document1 pageWPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)ufomskiNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Record of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014Document2 pagesRecord of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014cisar0007No ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- WPS - 016Document11 pagesWPS - 016MAT-LIONNo ratings yet

- Errata D1.1 D1.1M 2020Document19 pagesErrata D1.1 D1.1M 2020JohnNo ratings yet

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Document24 pagesPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- Safety Comittee Report: Company Logo and Name Time Date VenueDocument2 pagesSafety Comittee Report: Company Logo and Name Time Date VenueHiren Maheta0% (1)

- Gmaw STTDocument4 pagesGmaw STTAnonymous 0rt9KWmNNo ratings yet

- Wps Model 2 PDFDocument17 pagesWps Model 2 PDFbeyNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Document1,913 pagesPipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- 1 WPS & PQRDocument2 pages1 WPS & PQRManoranjan sharmaNo ratings yet

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- WPS - D1.1Document1 pageWPS - D1.1Nam_HitechNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- SLB Check List-1Document2 pagesSLB Check List-1Jitendra BhosaleNo ratings yet

- Hemps 11.100 A1Document33 pagesHemps 11.100 A1हेमंत कुमार मीणाNo ratings yet

- Quality Docs DEP 17 0803Document7 pagesQuality Docs DEP 17 0803Edwin MPNo ratings yet

- Wps S - Ea-6gr-01.Doc Rev2 j4662Document1 pageWps S - Ea-6gr-01.Doc Rev2 j4662cisar0007No ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- PWPS 013 PRDocument2 pagesPWPS 013 PRRenjith Gopan100% (1)

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- QC - Consumables Colour Coding and IdentificationDocument3 pagesQC - Consumables Colour Coding and IdentificationfizanlaminNo ratings yet

- 12.6 Welding Procedures List (Li-002)Document31 pages12.6 Welding Procedures List (Li-002)Ana GameroNo ratings yet

- Inspection Plan - NDTDocument4 pagesInspection Plan - NDTgymadniNo ratings yet

- 6GR WPS PQR PDFDocument15 pages6GR WPS PQR PDFerwincalvoNo ratings yet

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNo ratings yet

- Class P6A6Document24 pagesClass P6A6SalimNo ratings yet

- Pm01988 Ge WG 5 1-8'' 10k SSV - Phase IDocument2 pagesPm01988 Ge WG 5 1-8'' 10k SSV - Phase IAbu UmarNo ratings yet

- 10 NDE ControlDocument6 pages10 NDE ControlShahbaz AlamNo ratings yet

- Name: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- Inspection and Quality Control in ManufacturingDocument598 pagesInspection and Quality Control in Manufacturingsaeed.pdNo ratings yet

- d1.1 Fcaw Unlimited Test Plate ConfigurationDocument77 pagesd1.1 Fcaw Unlimited Test Plate ConfigurationJuan Martinez100% (1)

- Premier Engineering Industries: List of WPS/PQRDocument1 pagePremier Engineering Industries: List of WPS/PQRBalkishan DyavanapellyNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Fit-Up and Daily Welding Visual Inspection ReportDocument1 pageFit-Up and Daily Welding Visual Inspection ReportAws AbduljaleelNo ratings yet

- A286 GIGLM 1004 PJ DOC QAR R 0006 Welding ConsumableDocument8 pagesA286 GIGLM 1004 PJ DOC QAR R 0006 Welding ConsumableMahesh PanditNo ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Hust WPS Gtaw - Smaw 6GDocument4 pagesHust WPS Gtaw - Smaw 6GtruongtrungplhdNo ratings yet

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- BQ-ZUL-0XX10 Welding Consumable ControlDocument10 pagesBQ-ZUL-0XX10 Welding Consumable ControlRAMAKRISHNANo ratings yet

- Insulation Inspection ReportDocument1 pageInsulation Inspection ReportKarthikNo ratings yet

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- Welder Qualification Manual Revision 5Document20 pagesWelder Qualification Manual Revision 5Hugo RodriguezNo ratings yet

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocument1 pageWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiNo ratings yet

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- WPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)Document1 pageWPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)ufomskiNo ratings yet

- Schedules & Fees.Document2 pagesSchedules & Fees.ufomskiNo ratings yet