Professional Documents

Culture Documents

Siwertell Screw Conveyors Original 32999

Siwertell Screw Conveyors Original 32999

Uploaded by

CesarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Siwertell Screw Conveyors Original 32999

Siwertell Screw Conveyors Original 32999

Uploaded by

CesarCopyright:

Available Formats

Horizontal and vertical

screw conveyors

Bulk handling

Siwertell screw conveyors can handle dry

bulk materials under tough conditions

Siwertell (formerly Nordstrms) screw conveyors have been a central part in loading/

unloading systems for dry bulk material handling on ships and ashore all over the world

for more than half a century. Numerous installations, undertaken by Cargotec, have

integrated these dependable and cost-efficient components with conveying systems.

Siwertell screw conveyors are designed

to handle a great variety of dry bulk materials, such as cement, lime raw meal,

apatite, urea, fly ash and gypsum, under

hard conditions. For long distance and

high lifting heights, two or more screw

conveyors are arranged in series. When

large capacities are to be handled, the

conveyors can run parallel to each other.

The screw conveyors are completely

enclosed, which reduces dust creation

to a minimum. They have been supplied

to numerous customers for installations

worldwide in e.g. industries, port terminals, ships, silos, and power plants. The

heart of Siwertell screw conveyors is the

easily replaceable intermediate bearing,

specially developed to resist wear.

Siwertell horizontal and vertical screw

conveyors operate with the helical flight

pushing and throwing the bulk material

forward by rotational action. Capacities

range from 30 to 1,700 m/h.

The rigid and heavy-duty construction

of these conveyors reduces wear

and enables easy maintenance at

infrequent intervals. They are suitable for

applications in any kind of environment

indoors and outdoors as well as on ships.

Modular construction ensures swift and

easy installation in new and existing bulk

conveying systems.

Vertical screw conveyors (VSC)

Type VSC 200-700

Single motor drive

Type VSC 300-700

Twin motor drive

H = Conveying height

45

B3

n x B2

D

Special features for VSC

specially developed long-life intermediate bearings

loading box with fluidised bottom

conveying with different angles

single or twin motor drive

v-belt transmission

speed guard included

flexible connection at outlet

B1

Dimensions (mm)

B1

B2

(max)

B3

(max)

VSC 700

VSC 600

VSC 500

VSC 400

VSC 300

VSC 200

4800

4800

4800

4200

3500

3000

3850

3850

3850

3500

2900

2700

1900

1800

1600

1400

1100

800

711

610

508

406

324

244,5

925

825

700

600

470

370

1600

1550

1400

1300

1000

800

1800

1600

1600

1250

975

800

1000

900

800

650

500

400

325

325

325

300

275

225

1600

1600

1350

1100

900

650

We reserve the right to make changes.

Capacities (m/h)

VSC 700

VSC 600

VSC 500

VSC 400

VSC 300

VSC 200

0

75

Capacities in m/h based on vertical conveying of cement.

200

350

600

1000

1500

Horizontal screw conveyors (HSC)

F

L = Conveying length

Type HSC 400-1000

B

Special features for HSC

reversible conveying direction

one or more inlets

one or more outlets

the drive unit can be located either at the loading

or the unloading end

inclined conveying possible

various types of drive units available

speed guard included

Dimensions (mm)

A

B

C

D

E

(max)

F

(max)

G

HSC 1000

HSC 800

HSC 630

HSC 500

HSC 400

4500

4500

4500

4500

3500

5500

5500

5500

5500

4500

650

550

450

375

325

1200

950

780

650

550

1070

870

700

570

455

1000

800

630

500

400

630

500

400

315

250

800

630

500

400

315

630

500

400

315

250

300

300

300

300

300

1000

800

630

500

400

We reserve the right to make changes.

Capacities (m/h)

HSC 1000

HSC 800

HSC 630

HSC 500

HSC 400

0

200

Capacities in m/h based on horisontal conveying of cement.

350

600

1000

1500

Cargotecs scope of supply for dry

bulk handling systems includes:

plant and terminal systems

ship unloaders / loaders

conveying systems

transfer terminal solutions

storage systems

Siwertell products are designed,

marketed and supplied from

Cargotecs offices in Bjuv,

Sweden, with support from local

representatives worldwide.

Cargotec is present throughout the world.

Cargotec improves the efficiency of cargo flows by offering solutions for loading

and unloading goods on land and at sea wherever cargo is on the move. For

handling dry bulk materials, Cargotec provides engineering solutions through its

Siwertell brand. Designed to ensure environmentally-friendly and efficient cargo

operations, Siwertell ship unloaders and loaders are based on unique screw

conveyor technology, in combination with belt conveyors and aeroslides and can

handle virtually any dry bulk cargo.

Cargotec Sweden AB

Bulk Handling

P.O. Box 566 Gunnarstorp

SE-267 25 Bjuv, Sweden

Tel +46 (0) 42 858 00

Fax +46 (0) 42 858 99

blksales@cargotec.com

www.cargotec.com

You might also like

- Sybase FundamentalsDocument70 pagesSybase FundamentalsDinakar Babu JangaNo ratings yet

- Experiment 5 11510512Document2 pagesExperiment 5 11510512Sanket DuhoonNo ratings yet

- Australian Model Railway Magazine-October 2021Document74 pagesAustralian Model Railway Magazine-October 2021Tim de Ruiter100% (1)

- Trucklift SystemDocument5 pagesTrucklift SystemwalterloliNo ratings yet

- Criteria For Pend Engg RecordDocument9 pagesCriteria For Pend Engg Recordlipi8100% (2)

- 4ps of Bajaj PulsarDocument5 pages4ps of Bajaj PulsarVivek MaluNo ratings yet

- Airframe Loads & Usage Monitoring of The CH-47DDocument33 pagesAirframe Loads & Usage Monitoring of The CH-47DnlrlibraryNo ratings yet

- Siwertell Road-Mobile Unloaders Original 32998Document4 pagesSiwertell Road-Mobile Unloaders Original 32998Gospodin RajkovićNo ratings yet

- Aumund - StakerDocument24 pagesAumund - Stakerchand_yelNo ratings yet

- Siwertell Ship Unloaders Original 33001Document6 pagesSiwertell Ship Unloaders Original 33001alireza_vatandoustNo ratings yet

- Vertical and Horizontal Screw ConveyorsDocument4 pagesVertical and Horizontal Screw ConveyorsLLNo ratings yet

- Transloaders Terminals & SystemsDocument6 pagesTransloaders Terminals & SystemscambeltinteranationaNo ratings yet

- Benson Beltings LTD.: Product InformationDocument2 pagesBenson Beltings LTD.: Product InformationSen VanNo ratings yet

- Catalogo Giunti Samiflex - GB PDFDocument8 pagesCatalogo Giunti Samiflex - GB PDFDANE80No ratings yet

- Cement Distribution Consultants - Articles - Export Terminals For AsiaDocument3 pagesCement Distribution Consultants - Articles - Export Terminals For AsiaMauricio MpintoNo ratings yet

- Scorpio Engineering Private Limited: Bulk Material HandlingDocument4 pagesScorpio Engineering Private Limited: Bulk Material HandlingRohit Gadekar100% (1)

- Ducon Technical Proposal - Rev00 - 15.01.2018Document24 pagesDucon Technical Proposal - Rev00 - 15.01.2018Swati Rohan Jadhav100% (1)

- Materials Handling Brochure-May2013Document12 pagesMaterials Handling Brochure-May2013negro83No ratings yet

- Limestone - Slurry OptimizationDocument5 pagesLimestone - Slurry OptimizationSharif M Mizanur RahmanNo ratings yet

- Bag Loading Systems PDFDocument11 pagesBag Loading Systems PDFBatsukh GanchuluunNo ratings yet

- Siwertell Ship Loaders Original 33000Document6 pagesSiwertell Ship Loaders Original 33000marcos.rochaNo ratings yet

- Marg Conveyor Bag Handling PresentationDocument8 pagesMarg Conveyor Bag Handling PresentationMarg ConveyorsNo ratings yet

- Transporte IntermodalDocument8 pagesTransporte IntermodalDavid LatorreNo ratings yet

- Apron Feeders: The Ideal Solution For Feed and Discharge Conveyors in Crushing PlantsDocument5 pagesApron Feeders: The Ideal Solution For Feed and Discharge Conveyors in Crushing PlantstonyNo ratings yet

- BMH in Stockyards and Ports WebDocument10 pagesBMH in Stockyards and Ports Webtrungnq_ktd97No ratings yet

- Fluid Couplings - Installation, Operation and MaintenanceDocument15 pagesFluid Couplings - Installation, Operation and Maintenanceatee_hua66No ratings yet

- Belt Conveyor Idler CatalogDocument160 pagesBelt Conveyor Idler CatalogFer LopezNo ratings yet

- Brochure - Slide Gate Valve - Pubc-0502-SvDocument2 pagesBrochure - Slide Gate Valve - Pubc-0502-SvedgarspalaciosNo ratings yet

- Conveyor BrochureDocument6 pagesConveyor BrochuresurachsNo ratings yet

- Predicting Viscosity of Limestone-Water SlurryDocument19 pagesPredicting Viscosity of Limestone-Water SlurryahaniouiNo ratings yet

- D-Bucket ChainsDocument45 pagesD-Bucket ChainsMuhammad Irvan FNo ratings yet

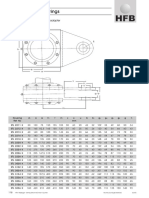

- Soportes Take UP STL Series - Rodamientos SmilovicDocument4 pagesSoportes Take UP STL Series - Rodamientos SmilovicAlejandro SmilovicNo ratings yet

- Gas Bank DPRDocument18 pagesGas Bank DPRselvakumar sNo ratings yet

- Ship Unloader LargepneumaticDocument10 pagesShip Unloader LargepneumaticTaufik SinggihNo ratings yet

- Fenner GearsDocument28 pagesFenner Gearsmanoj983@gmail.comNo ratings yet

- TeleStacker Conveyor SPLT1123ENWB 03Document12 pagesTeleStacker Conveyor SPLT1123ENWB 03Surekha Ajay SatputeNo ratings yet

- Flender HandbookDocument79 pagesFlender Handbookjbertral100% (1)

- Brochure Key Features Geho Piston Diaphragm PumpsDocument6 pagesBrochure Key Features Geho Piston Diaphragm PumpsGonzalo Barelli MunNo ratings yet

- Ship Unloading Systems: Mechanical Vs Pneumatic?Document6 pagesShip Unloading Systems: Mechanical Vs Pneumatic?Milling and Grain magazineNo ratings yet

- Automatic Samplers: Proven & DependableDocument6 pagesAutomatic Samplers: Proven & DependableHarish KumarNo ratings yet

- Hydraulic Ash DisposalDocument26 pagesHydraulic Ash Disposalami miaNo ratings yet

- Determination of Slurry S Viscosity Using Case Based Reasoning ApproachDocument64 pagesDetermination of Slurry S Viscosity Using Case Based Reasoning Approachyulianus_srNo ratings yet

- Bruks Siwertell-Port-mobile UnloadersDocument6 pagesBruks Siwertell-Port-mobile UnloadersUdien HamzahNo ratings yet

- Ropecon Conveyor SystemDocument4 pagesRopecon Conveyor Systemjayaraman3No ratings yet

- Conveyor PulleyDocument4 pagesConveyor Pulleyprashant mishraNo ratings yet

- Pneumatic Ship and Barge UnloadersDocument6 pagesPneumatic Ship and Barge Unloadersomni_partsNo ratings yet

- 376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enDocument8 pages376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enrajeevkumarrajeevNo ratings yet

- BalancingDocument6 pagesBalancingmetalworkerNo ratings yet

- 7300en PDFDocument9 pages7300en PDFWaris La Joi WakatobiNo ratings yet

- Indian StandardDocument108 pagesIndian StandardAlvin SmithNo ratings yet

- Shaft Mounted Speed Reducers SMSR & SMSR Plus SeriesDocument32 pagesShaft Mounted Speed Reducers SMSR & SMSR Plus SeriesAmit KumarNo ratings yet

- (17CrNiMo6) 4317 Case Hardening SteelDocument3 pages(17CrNiMo6) 4317 Case Hardening Steelazhar mohammedNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFWilliam VillamizarNo ratings yet

- Disclosure To Promote The Right To InformationDocument29 pagesDisclosure To Promote The Right To InformationkaustavNo ratings yet

- Worm Gears PremiumDocument56 pagesWorm Gears PremiumNagi Reddy BooshipallyNo ratings yet

- Alwasy Step Ahead in TechnologyDocument6 pagesAlwasy Step Ahead in TechnologyDxFx100% (1)

- Drive Coupling SKFDocument19 pagesDrive Coupling SKFFrank MwafulirwaNo ratings yet

- SL01 397Document2 pagesSL01 397thiseus25No ratings yet

- Ship Unloaders InfoDocument4 pagesShip Unloaders InfojagrutNo ratings yet

- Forklifts AUSADocument35 pagesForklifts AUSAcornel_lupu0% (1)

- Kreiskott Image Brochure enDocument16 pagesKreiskott Image Brochure enKreiskottNo ratings yet

- Horse Shoe Rig ™ Fast Moving Semisubmersible Drilling TenderDocument8 pagesHorse Shoe Rig ™ Fast Moving Semisubmersible Drilling TenderSouadHadjadjNo ratings yet

- Flexowell - 2013 - EnglischDocument5 pagesFlexowell - 2013 - Englischeduardo_chaban100% (1)

- Bucket ElevatorsDocument16 pagesBucket Elevatorssdmel100% (3)

- BMH Offering Guide 2010Document15 pagesBMH Offering Guide 2010Srini KumarNo ratings yet

- The Privatisation Classes: A Pictorial Survey of Diesel and Electric Locomotives and Units Since 1994From EverandThe Privatisation Classes: A Pictorial Survey of Diesel and Electric Locomotives and Units Since 1994No ratings yet

- Project FinalDocument89 pagesProject Finalroshaneswar bolaganaNo ratings yet

- Yilmaz - Abdurrahim-In The Apparel Industry and A Model ProposalDocument7 pagesYilmaz - Abdurrahim-In The Apparel Industry and A Model ProposalMianAbrarAnjumNo ratings yet

- Oracle HRMS For UAE SupplementDocument204 pagesOracle HRMS For UAE Supplementxulfii100% (1)

- Crane Rail 45 Kgs Per MeterDocument2 pagesCrane Rail 45 Kgs Per Metermanjucad100% (1)

- Project at InfosysDocument8 pagesProject at InfosysAyush AgrawalNo ratings yet

- Module 1-OPERATION MANAGEMENTDocument34 pagesModule 1-OPERATION MANAGEMENTskimpee pilayNo ratings yet

- SAP Billing and Revenue Innovation Management - 2018-11Document8 pagesSAP Billing and Revenue Innovation Management - 2018-11Martin De Leo100% (1)

- CV - Muhammad Taufiq FDocument2 pagesCV - Muhammad Taufiq FM Taufiq KhanNo ratings yet

- Example RFP Development GuideDocument17 pagesExample RFP Development Guidelaconically100% (1)

- Product Range Edition 2010-01: Rubber ChemicalsDocument20 pagesProduct Range Edition 2010-01: Rubber Chemicalsersin_uckunNo ratings yet

- Sumit Pandey: Career ObjectiveDocument3 pagesSumit Pandey: Career ObjectiveSumit PandeyNo ratings yet

- BUSI410 Lab Session 1Document10 pagesBUSI410 Lab Session 1J.Cie SunNo ratings yet

- FlangeDocument3 pagesFlangeAnson AndrewsNo ratings yet

- Board of Directors Corporate Information Directors' Report: Pakistan Telecommunication Company LimitedDocument26 pagesBoard of Directors Corporate Information Directors' Report: Pakistan Telecommunication Company LimitedTahir ArfiNo ratings yet

- Analysis of Delay Damages For Site Overhead: Dr. William Ibbs and Long D. NguyenDocument4 pagesAnalysis of Delay Damages For Site Overhead: Dr. William Ibbs and Long D. NguyenarqsarqsNo ratings yet

- Assign 4 SolutionDocument2 pagesAssign 4 SolutionChaynesh RathoreNo ratings yet

- Manuale d'uso User's manual Manuel de l'utilisateur Bedienerhandbuch Manual de uso Аналоговые приборыDocument11 pagesManuale d'uso User's manual Manuel de l'utilisateur Bedienerhandbuch Manual de uso Аналоговые приборыIzzu IsuramuNo ratings yet

- Prototype FinalDocument7 pagesPrototype Finaleu da silvaNo ratings yet

- PTR 2Document2 pagesPTR 2petroexamsNo ratings yet

- Honeycomb Sandwich Design TechnologyDocument22 pagesHoneycomb Sandwich Design TechnologyBasant SharmaNo ratings yet

- ST 14Document40 pagesST 14harshNo ratings yet

- Michelin TruckLtTruck DatabookDocument94 pagesMichelin TruckLtTruck DatabookjomirosaNo ratings yet

- Icing 02 EffectsDocument22 pagesIcing 02 EffectsDhaneswar MajhiNo ratings yet

- 01 Vesda Vli TT Clean Air Zero A4 Lores PDFDocument2 pages01 Vesda Vli TT Clean Air Zero A4 Lores PDFfaruk hossainNo ratings yet