Professional Documents

Culture Documents

Manufacturing of Engineering: Name: Abdul-Aziz Asheq Fahad Alshammare ID Number: 427102865

Manufacturing of Engineering: Name: Abdul-Aziz Asheq Fahad Alshammare ID Number: 427102865

Uploaded by

MaMLoOoOo7Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturing of Engineering: Name: Abdul-Aziz Asheq Fahad Alshammare ID Number: 427102865

Manufacturing of Engineering: Name: Abdul-Aziz Asheq Fahad Alshammare ID Number: 427102865

Uploaded by

MaMLoOoOo7Copyright:

Available Formats

King saud university

College of engineering

Mechanical engineering department قسم الهندسه الميكانيكية

Manufacturing of Engineering

Experiment #

1

ME-356

Name: Abdul-Aziz asheq fahad

alshammare

ID number: 427102865

Tool Maker Microscope

Objective:

To familiarize the student with various uses of a Tool Maker Microscope, and to

determine the basic dimensions of a given thread.

Apparatus:

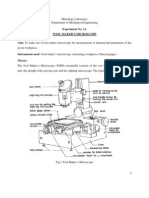

A tool maker microscope is precision optical measuring equipment, which consists of a

microscope mounted on a column. Attached to the column a table which can move longitudinally

and laterally using two precision micrometers. The table can also be swiveled or tilted to assist

in odd measurements, on the table, the work piece could be fixed between centers or it can be

laid directly on it.

The microscope has a head which consists of a clear glass screen in the focal plane of

the objective lens carrying datum lines which can be rotated through 35Q0, the angle of rotation

being measured direct to one minute and by estimation to a fraction of a minute.

Procedure:

• Mount the thread between centers, and move the table to see the thread image clearly in

the microscope.

• Swivel the microscope or tilt the table by angle to the helix angle of the thread in order to

avoid interference.

• Select a datum line at zero angle and adjust the thread to be parallel with the datum line.

• Set the datum line touching the periphery of the thread, and take micrometer reading.

Move table until the datum line touch the periphery of the thread from the other side,

and take another micrometer reading. The difference between the two readings is the

major diameter of the thread.

• Follow the same procedure to determine the minor diameter.

• Rotate the datum line to coincide with the thread flank. The thread flank angle can be

directly read on the eyepiece scale.

• Determine the thread pitch by moving the datum for several threads.

Requirements:

Work piece # 3 ……Group# 3

Major diameter = 23.1-0.13 = 22.97 mm

Minor diameter = 22.33-1.95 = 20.38 mm

Average diameter = (22.97+20.38)/2 = 21.67 mm

Simple effective diameter = 22.58-1.73 = 20.85 mm

Pitch = 17.1-15.76 =1.34 mm

Flank angle (Included angle) = 61.5°

You might also like

- Report Experiment ThreadDocument11 pagesReport Experiment Threadsparklingstars2705No ratings yet

- Roundness ExperimentDocument8 pagesRoundness ExperimentLanceal TanNo ratings yet

- Report of Milling Project Lab 2Document12 pagesReport of Milling Project Lab 2Mohd Danial H100% (2)

- 1.tool Makers MicroscopeDocument7 pages1.tool Makers MicroscopeelavarasanNo ratings yet

- The Tool MakerDocument4 pagesThe Tool MakerRitesh YadavNo ratings yet

- The ToolmakeeerDocument31 pagesThe ToolmakeeerVarunNo ratings yet

- MTM Metro Expt1 ManualDocument10 pagesMTM Metro Expt1 ManualBhargav DindukurthiNo ratings yet

- MI Tool Makers MicroscopeDocument9 pagesMI Tool Makers MicroscopeGurpreet KaurNo ratings yet

- Experiment No. 1A Tool Maker'S MicroscopeDocument4 pagesExperiment No. 1A Tool Maker'S MicroscopePraveen KumaarNo ratings yet

- Various Parameter Measurement - Jan 2022 - R1Document7 pagesVarious Parameter Measurement - Jan 2022 - R1Anih Kishor (RA1911002010062)No ratings yet

- AAI Lab Manual PART 1 ModifiedDocument17 pagesAAI Lab Manual PART 1 ModifiedJayprakash BamboleNo ratings yet

- M.E., Cad/Cam Unit I For Non-Destructive TestingDocument17 pagesM.E., Cad/Cam Unit I For Non-Destructive TestingBarathkannan Lakshmi PalanichamyNo ratings yet

- Tool Maker MicroscopeDocument4 pagesTool Maker MicroscopeShyam SenthilNo ratings yet

- Emailing Metrology Lab Manual - Consolidated Mar2021Document113 pagesEmailing Metrology Lab Manual - Consolidated Mar2021Soham PatraNo ratings yet

- 9 Tool Maker MicroscopeDocument4 pages9 Tool Maker Microscopesomu_amuNo ratings yet

- Measurements and Metrology Laboratory ManualDocument20 pagesMeasurements and Metrology Laboratory Manualbossanand05100% (3)

- Measuring MachineDocument19 pagesMeasuring Machinegopir28No ratings yet

- Tool Makers MicroscopeDocument7 pagesTool Makers MicroscopeAnand Babu100% (2)

- MQE ExperimentDocument9 pagesMQE ExperimentashuNo ratings yet

- 5.EMM Lab ManualDocument38 pages5.EMM Lab ManualRakeshkumarcegNo ratings yet

- Metrology: BY A.Radha Krishna, Hod, Dept. of Mech. MietDocument28 pagesMetrology: BY A.Radha Krishna, Hod, Dept. of Mech. MietRadha KrishnaNo ratings yet

- Lab Manual: Machining Processes and Metrology Lab (MEE211L)Document27 pagesLab Manual: Machining Processes and Metrology Lab (MEE211L)Agnivesh SharmaNo ratings yet

- Experiment No. 4 Study and Applications of Tool Maker'S MicroscopeDocument4 pagesExperiment No. 4 Study and Applications of Tool Maker'S MicroscopeAbdulaziz almasoudiNo ratings yet

- KIT - Kalaignar Karunanidhi Institute of Technology, Coimbatore / Me6504 / V-Sem / 2015 Metrology & MeasurementsDocument14 pagesKIT - Kalaignar Karunanidhi Institute of Technology, Coimbatore / Me6504 / V-Sem / 2015 Metrology & MeasurementsPRASANTHNo ratings yet

- Am Report 1RV21MCM02Document9 pagesAm Report 1RV21MCM02venkateshaiah ktNo ratings yet

- An Investigation On Surface Characteristics of Micro Turned ComponentsDocument28 pagesAn Investigation On Surface Characteristics of Micro Turned Components04066002No ratings yet

- Study of Measuring Instruments and Gauges PDFDocument7 pagesStudy of Measuring Instruments and Gauges PDFRishabh HanseliaNo ratings yet

- ScrewDocument20 pagesScrewIxora MyNo ratings yet

- Unit 2 Screw Thread - Gear Elements - Surface FinishDocument53 pagesUnit 2 Screw Thread - Gear Elements - Surface FinishDeepak MisraNo ratings yet

- 4-Screw Thread MeasurementDocument37 pages4-Screw Thread MeasurementAdarsh KhotNo ratings yet

- Experiment No. 4 Study and Applications of Tool Maker'S MicroscopeDocument8 pagesExperiment No. 4 Study and Applications of Tool Maker'S Microscopesreejith2786No ratings yet

- Tool Makers Micro ScopeDocument7 pagesTool Makers Micro ScopeskumarNo ratings yet

- Autocollimator Angle DekkorDocument24 pagesAutocollimator Angle DekkorloganathanNo ratings yet

- Nomenclatures of Single Point Cutting Tool Using Tool Makers MicroscopeDocument7 pagesNomenclatures of Single Point Cutting Tool Using Tool Makers Microscopeविशाल पुडासैनीNo ratings yet

- Tool Makers MicroscopeDocument2 pagesTool Makers Microscopesukriti dhauni100% (1)

- JJ204 Workshop Technology Semester 2Document150 pagesJJ204 Workshop Technology Semester 2Ye ChonnNo ratings yet

- Construction of The Toolmaker'S Microscope: Working PrincipleDocument2 pagesConstruction of The Toolmaker'S Microscope: Working Principlenikhil samuelNo ratings yet

- Module Iv: Computer Aided and Laser Metrology:: The Upright With Carrying Arm, and The Sighting MicroscopeDocument9 pagesModule Iv: Computer Aided and Laser Metrology:: The Upright With Carrying Arm, and The Sighting MicroscopeShiba SahuNo ratings yet

- Toolmakersmicroscope 140722144506 Phpapp02Document32 pagesToolmakersmicroscope 140722144506 Phpapp02Arjun ReghuNo ratings yet

- 2 ND Year Mechanical Engg Material MicroprojectDocument19 pages2 ND Year Mechanical Engg Material MicroprojectTaqee MushrifNo ratings yet

- Work Shop Practice-Ii: Diploma in Mechanical EngineeringDocument36 pagesWork Shop Practice-Ii: Diploma in Mechanical EngineeringLEAGUE OF WARLORDSNo ratings yet

- Metrology Lab ManualDocument36 pagesMetrology Lab Manualuvrsunil_kumar100% (2)

- Tool Makers Microscope PPT - Siddhant SinghDocument15 pagesTool Makers Microscope PPT - Siddhant SinghSiddhant Singh100% (1)

- Micro Turn-Milling MachineDocument6 pagesMicro Turn-Milling MachineAfdhal RizkyNo ratings yet

- IQC - 6TH ME E NotesDocument27 pagesIQC - 6TH ME E NotesShobhit SinghNo ratings yet

- How To Use Micrometer On Microscopes: Biology 1Document7 pagesHow To Use Micrometer On Microscopes: Biology 1Rakeesh VeeraNo ratings yet

- Exercise No. 1 Shear Angle Measurement AimDocument14 pagesExercise No. 1 Shear Angle Measurement AimKarthick JeyaramNo ratings yet

- Machine Shop Lab Manual 2018Document16 pagesMachine Shop Lab Manual 2018S B MALLURNo ratings yet

- Screw GaugeDocument7 pagesScrew GaugeAbdul AhadNo ratings yet

- R2019 - MESBL601 - MA Lab ManualDocument30 pagesR2019 - MESBL601 - MA Lab Manualsealrohan0No ratings yet

- Experiment 6 Measureing Screw Thread Parameter With Optical Profile ProjectorDocument9 pagesExperiment 6 Measureing Screw Thread Parameter With Optical Profile ProjectorCao KhảiNo ratings yet

- Manufacturing Process Lab Manual: Waqar Ahmed BSME01183097Document98 pagesManufacturing Process Lab Manual: Waqar Ahmed BSME01183097Waqar AhmedNo ratings yet

- Workshop - and - Machine - Shop ManualDocument96 pagesWorkshop - and - Machine - Shop ManualBenjie flor CalayegNo ratings yet

- Micro-Network Creation in Industrial Surveying: Lucie Pospíšilová, Jiří Pospíšil, Hana StaňkováDocument5 pagesMicro-Network Creation in Industrial Surveying: Lucie Pospíšilová, Jiří Pospíšil, Hana StaňkováJoel Carvajal R.No ratings yet

- Murali - Metrology & Measurements Lab ManualDocument30 pagesMurali - Metrology & Measurements Lab ManualsubhashNo ratings yet

- Updated MQC ManualDocument29 pagesUpdated MQC ManualssselvaNo ratings yet

- Zeiss Ultra OptimeterDocument13 pagesZeiss Ultra OptimeterLokesh kumar MeenaNo ratings yet

- Errors, Com para Tors, and Angular MeasurementsDocument20 pagesErrors, Com para Tors, and Angular MeasurementsbmdbmdbmdNo ratings yet

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsFrom EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsNo ratings yet

- 71 Electrical & Electronic Porjects (With Cd): For beginners, intermediate and engineering studentsFrom Everand71 Electrical & Electronic Porjects (With Cd): For beginners, intermediate and engineering studentsRating: 5 out of 5 stars5/5 (3)