Professional Documents

Culture Documents

1921 GB186082

1921 GB186082

Uploaded by

Nemanja Stojanovic0 ratings0% found this document useful (0 votes)

109 views4 pagesNikola TESLA patent turbine

Original Title

1921_GB186082

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentNikola TESLA patent turbine

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

109 views4 pages1921 GB186082

1921 GB186082

Uploaded by

Nemanja StojanovicNikola TESLA patent turbine

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

PATENT SPECIFICATION

Application Date:

Mar, 24, 1921,

Complete Left:

186,082

No, 9097 [2

Sept. 2, 1921,

Complete Accepted : Sept. 25, 1922,

PROVISIONAL SPHCIFICATION,

Improvements in the Construction of Steam and Gas Turbines.

1, Nixons Testa, Mechanical

Electrical Engineer, citizen of the

States of America, of 8, West 40th s

New York City A., do heieby

and

United

vet,

declare

5 ithe nature of this invention fo be as

follows:—

Ina British Patent, Number 24.001 of

W910, T have described a bladeless turbine

having a rotor consisting of dises with

10 openings in the central portions and

arating star-washers, these parts when

assembled being riveted together into a

single solid structure and keyed to the

shait. "This form of rotor operates satis:

factorily but in Jong experience certain

improvements in its. construction have

been found desirable and these constitute

my present invention,

In the new design Lemploy two heavier

end-plates which are machined tapering

toward the periphery for the purpose of

reducing the maximum centrifugal stress

as much as practicable. ‘The inside dises,

of relatively thin material, are rolled,

forged or ground tapering in like manner

and with the same object in view, but this

may not always be necessary and plates,

made of sheet metal of substantially

uniform thickness as furnished by the

mills, can ke employed. Each of the thick

as well as thin plates is provided with

exhaust openings, leaving a solid central

portion like the hw and spokes of a wheel,

Star-washers of similar configuration

serve the purpose of keeping the dises

apart in the center and for the peripheral

ing the thin plates have small holes

drilled in them on a circle, or circles, of

suitable diameter, and in these are driven

tight-fitting studs which are upset at both

ends by a special tool so that they will

project beyond the metal on each ‘side a

trifle more than the thickness of the star-

washers. When the plates are put

45 iogether the separating studs do not come

20

30

40

in line but are straddled in order to give

opportunity tor slight yielding, thereby

climinaline constructional difficulties

which might be caused by unevenness or

other mechanical imperfecti Thus 50

the rotor ean he finished closely to pre-

determined overall dimensions ‘and will

vin fre on the outside even if the thin

inside plates should vary a little in thick-

ness or he slightly warped. To simplify 55

this amungemeni I provide only every

second plate with studs, using plain ones

between, Furthermore, with the object

of cheapening the manufacture T dispense

altogether with the former, accomplishing 60

the sparing by means of ‘small bosses or

protrberances which are raised in the

plates by blows or pressure and provide a

die, pravtically reducing all the machine

work ona thin plate to a single operation 65

in a stamping press. Phe star-washers,

while preterable, are not indispensable

and nay he replaced by round separating

washers of a diameter about equal to that

of the bub part of the discs, 70

AML the plates and washers are fitted on

and keyed toa sleeve threaded at the ends

and equipped with nuts and collars for

drawing the thick end-plates together or,

if desired, the collars may be simply 75

forced onto it and the ends upset. The

sleeve has a hole fitting snugly on the

shaft and is fastened to the same as usual

‘This construction permits free expan-

sion and contraction of each plate 80

individually wnder the varying influence

of heat and centrifugal foree and posesses

a nuniber of other ailvanitages Hien ave ot

considerable practical moment. A larger

active plate area and consequently more

power is obtained for a given width, th

improving — efficiency. Warping

virtually eliminated and smaller. si

clearances may he used which reselts in

diminished leakage and friction losses.

85,

90

15

20

30

40

45

50

a

60

The rotor is better adapted for dynamic

balancing and through rubbing jriction

resists disturbing influences thereby

insuring quieter running. For this reason

and also because the dises are not rigidly

COMPLETE

joined it is safer against damage which

might otherwise be caused by. vibration

oy excessive speed,

Dated this 24th day of March, 1921,

NIKOLA TESLA

SPECIFICATION

Improvements in the Construction of Steam and Gas Turbines.

1, Nixons Testa, Blectrical and Mech-

anieal Engineer, citizen of the United

States of America, of No. 8, West 10th

Street, New York, N.Y. U.S.A. do

hereby declare the natwre of this inven-

tion and in what manner the sume is to

be performed, to be particularly described

and ascertained in-and by the following

statement :

In a British Patent, No. 24,001 of

1910, L have described a bladeless turbine

having a rotor

consisting of dises with

openings in the central portions, and

separating star-washers, these parts when

assembled. being riveted together into a

single solid structure anid keyed to the

t. This form of rotor uperates: satis-

factorily but in long esperienee certain

improvements in ifs construction

heen found desirable and these constitute

my present invention

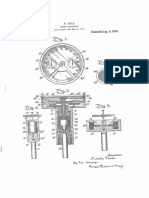

Tn the new design, illustrated inthe

accompanying drawings Fig

2, respectively showing a section through

the rotor ou line TT and a side view partly

broken away exposing a portion of # star=

washer, I preferably employ two heavier

end-plates 1, 1 of suitable material made

tapering on ‘the outside toward the pori-

phery, as shown, for the purpose of redue=

ing the maximum centrifugal stress ax

much as practicable, ‘The inside dises

2.2 are relatively thin and may be

tapered on both sides in the peripheral

part bevond th with the

same object in view, but plates of substan-

tially uniform thickness, as fnrnished by

the mills, can also be employed. Each of

the plates-—thiek as well as thin—is pro-

vided with exhaust openings 3, 3.

leaving a solid central portion 4. 4...

like the hub and spokes of a wheel. Tf

there is an odd number of thin plates the

centyal one may be plain, if desired, Star-

washers 5, 5 _ of similar configur

tion, and projecting with their arms co:

siderably beyond the exhaust openings,

serve the purpose of keeping the dises

apart in the central region and for the

peripheral spacing the thin plates have

sinall holes drilled in them preferably on

a citele, or circles, of suitable diameter,

and in’ these are driven tight-fitting

spacers or studs 6, 6... . which may be

have

Tand Fig

star-washers

upset at the ends so that they will project

on cach side w trifle more than the thick-

ness of the star-washers 5, 5 When

the plates are put together the separating

studs do not come in line but are

straddled, as indicated in Fig. 1 and in

the broken away part of Fig. 2 by the

plain and dotted small eiveles, in order to

give opportunity for slight yielding,

theeky eliminating constructional

dittieulties which might be caused by

unevenness or other mechanical impertec-

tinus, Sced a rotor can be finished closely

iv predetermined overall dimensions and

will run true on the outside even if the

thin inside plates should vary a little in

thickness or be stightly warped. ‘To

simplify the construction L provide only

every second plate with studs, using plain

hefween. Furthermore, with the

object of cheapening the manufacture, I

tay dispense with the studs altogether,

vcromplishing the peripheral spacing b:

Ineans of other spacers such as small

tosses or raised in’ the

plates, thus reducing: the machine work

on the thin ones to a single operation in a

stumping press. ‘The star-washers, while

preterable, are not indispensable and may

he replaced by round separating washers

of a diameter about equal to that of the

hub part of the dises.

MII the plates and washers are fitted om

and keyed to q sleeve 7, threaded at the

ends and equipped with nuts 8, § for

drawine the thick end-plates together or,

if desired, the nuts and threads on the

sleeve may be omitted, collars fareed on

its ends and the-xame upset. ‘The sleeve

fils snugly on the shaft 9 and is fastened

to it as usual

This construction enables the use of

thinner inside plates then practicable in

the earlier form, thus affording a greater

ctive surface and increasing correspond-

ingly the output, while the smaller clear-

ances are instrumental in reducing the

leakage losses,

Having now particularly described and

ascertained the nature of my said inven-

fion and in what manner the same is to

he performed, I declare that what T

claim is:—

1. A rotor for steam and gas turbines

protuberances

10

65

80

90

100

105,

110

M5

10

20

composed of plane spaced discs and two

rigid end-plates holding them in fixed

position Jaterally but permitting their

independent expansion or contraction in

the radial direction, said dises and plates

being provided with exhaust openings in

their central portions, substantially as

described.

20 A turbine yotor comprising plane

dises with spacers allowing radial dis.

placement, central separating washers and

two rigid tapering end-plates for holding

the structure firmly near the shaft, said

dises and end-plates having exhaust open=

ings in their central portions. substanti-

ally as described.

3. In a rotor for highspeed turbines

plane spaced dises with exhaust openings

in their centyal and tapering

towards the periphery as, and forthe pur

pose, deseribed.

portions

J. A turbine rotor consisting of a sys-

tem of dises held apart by spacers in frie~

tional contact with them and alternately

straddled and for the purpose,

described

5. A invbine rotor composed of plane

parallel dises having exhaust openings in

their contral portions and projections for

5

holdine thenr avart near the periphery, 30

substantialiy as deseribed

6. In a turbine rotor composed of flat

discs with exhasst open

{ral portions, star washers of similar con-

figwration atl projecting with their arms

considerably bevond the openings in the

ises, substantially uy described

es in their cons

Dated Che 23rd day of August, 1921.

NIKOLA TESLA.

Redhill: Printed for His Majesty's Stationery Office, by Love & Malcomson, Ttd.—1922

epreductton of the Original J

[This Drawing tsa full-sizer

Seo

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Patented Jan. 3, 1922.,: Frequency MeterDocument4 pagesPatented Jan. 3, 1922.,: Frequency MeterNemanja StojanovicNo ratings yet

- Patented A110". 6, 19181..: LilllllliDocument5 pagesPatented A110". 6, 19181..: LilllllliNemanja StojanovicNo ratings yet

- Guitarrrr PDFDocument39 pagesGuitarrrr PDFNemanja StojanovicNo ratings yet

- Tommy Emmanuel Amazing GraceDocument6 pagesTommy Emmanuel Amazing GraceJennifer Johnson50% (4)

- Us 20020182054Document12 pagesUs 20020182054Nemanja StojanovicNo ratings yet

- UserGuide SimpoeWorksDocument1 pageUserGuide SimpoeWorksNemanja StojanovicNo ratings yet