Professional Documents

Culture Documents

Corrective and Preventive Action On High Rejection Rate

Corrective and Preventive Action On High Rejection Rate

Uploaded by

Rakesh0 ratings0% found this document useful (0 votes)

141 views1 pageThe document summarizes weld testing results that identified issues with weld quality. Twenty-five welders took the test and several failed certain requirements. Common defects identified were porosity and incomplete fusion. The root causes were determined to be weather conditions allowing impurities and overconfidence in welders' abilities. Corrective actions included retraining welders on techniques and monitoring performance, while preventative actions focused on continual training and stricter welder assessment and monitoring procedures.

Original Description:

Welding

Original Title

Corrective and Preventive Action on High Rejection Rate

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes weld testing results that identified issues with weld quality. Twenty-five welders took the test and several failed certain requirements. Common defects identified were porosity and incomplete fusion. The root causes were determined to be weather conditions allowing impurities and overconfidence in welders' abilities. Corrective actions included retraining welders on techniques and monitoring performance, while preventative actions focused on continual training and stricter welder assessment and monitoring procedures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

141 views1 pageCorrective and Preventive Action On High Rejection Rate

Corrective and Preventive Action On High Rejection Rate

Uploaded by

RakeshThe document summarizes weld testing results that identified issues with weld quality. Twenty-five welders took the test and several failed certain requirements. Common defects identified were porosity and incomplete fusion. The root causes were determined to be weather conditions allowing impurities and overconfidence in welders' abilities. Corrective actions included retraining welders on techniques and monitoring performance, while preventative actions focused on continual training and stricter welder assessment and monitoring procedures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

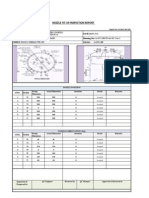

Al Rushaid

Construction Co., Ltd.

FINDINGS

ROOT CAUSED

CORRECTIVE ACTION

PREVENTIVE ACTION

1

Based on the result of radiographic testing of our

welders the from 15 Sept 2015 to 03 Nov 2015

following are noted:

a. Twenty five (25) welders take the First

Three Production Joints requirement.

i. One (1) welder failed all First Three Production

Joints.

ii. Three (3) welders failed two (2) First Three

Production Joints.

iii. Four (4) welders failed one (1) First Three

Production Joints.

iv. One (1) welder on-going for First Three

Production Joints.

v. Two (2) welders for RT First Three Production

Joints.

2

3

b. Out of six (6) joints examined in Normal

Production Joints, two (2) joints failed.

i. First Three Production Joint which is equivalent to 20% rejection rate.

ii. Normal Production joints equivalent to 33.33%

rejection rate.

c. Common Causes

i. First Three Production Joints

Common defects found on First Three Production are Porosity (POR) and Incomplete Fusion

(IF)

iii. Normal Production Joints

All Incomplete Fusion (IF) found defect for

two joints failed in Normal Production.

1 Change of season. Weather condition(s) during those

days have been unpredictable. Heavy sandstorms have

always been encountered at site.

2 Overconfidence of Supervisor/In-Charge Person with the

welders who had passed the WPQT. They should properly

assess the capabilities these welders based on the skills

categorization, rate of rejection from previous project.

1 Re-train the welder on proper welding techniques

to minimize/eliminate common weld defects.

1 Conduct continuous training/seminar on welding techniques

and weld defects.

2 Supervisor/In-Charge of welders should check and

monitor sufficiency of wind barrier/tents to minimize

the entry of foreign particles that could affect the

result of weld process.

2 Monitor the Daily Welders Performance.

3 Assess welders previous qualification/background and

performance record to determine the type of monitoring to

be implemented before their First Three Production Joints.

3 Demobilized welder(s) that did not pass the First

Three Production Joint.

4 Closely monitor welder(s) who have minimal failures in the First Three Production Joint.

4 Welders who have minimal failures in the First Three

Production Joint and completed / passed penalty joints shall

be utilized as assist welder upon qualification. This to retrain them in adopting new techniques in minimizing the

defects that they have acquired.

5 Implement Welders Checklist to minimize common weld

defects by checking the equipment, gases and welding

consumables.

You might also like

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- Control of Welding Rejection Rate and NDT Backlog in MEGA ProjectDocument10 pagesControl of Welding Rejection Rate and NDT Backlog in MEGA ProjectMubeenNo ratings yet

- Mohammed Diab. Inspection Supervisor - Saudi AramcoDocument1 pageMohammed Diab. Inspection Supervisor - Saudi AramcoSenakeNo ratings yet

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- O - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlDocument8 pagesO - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlMDhana SekarNo ratings yet

- Attachment 22 - (SECL-PIP026) Welding Consumable Issue SlipDocument5 pagesAttachment 22 - (SECL-PIP026) Welding Consumable Issue SlipRjeb mohamedNo ratings yet

- Nozzle Fit-Up Inspection Report: Inspected & Prepared byDocument9 pagesNozzle Fit-Up Inspection Report: Inspected & Prepared byDaison PaulNo ratings yet

- Weld Matrix Format 1Document7 pagesWeld Matrix Format 1Arslan WaheedNo ratings yet

- Astm A335 p91 PipeDocument1 pageAstm A335 p91 PipeBhagwati SteelageNo ratings yet

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- Visual Inspection Report - During WeldingDocument1 pageVisual Inspection Report - During WeldingsurwaneNo ratings yet

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- Welding Practice For Duplex-1 PDFDocument18 pagesWelding Practice For Duplex-1 PDFBipin Rohit100% (1)

- Electrode SelectionDocument1 pageElectrode SelectionMel gibsonNo ratings yet

- Stage 1 - Welding Inspection Prior To Welding WorkDocument7 pagesStage 1 - Welding Inspection Prior To Welding WorkIrvansyah RazadinNo ratings yet

- Paint Coating Stainless SteelsDocument2 pagesPaint Coating Stainless SteelsSilva NumaNo ratings yet

- ADOR Booklet F Web FDocument132 pagesADOR Booklet F Web FbadesharamkNo ratings yet

- Metrode Welding Duplex & Superduplex Stainless SteelsDocument18 pagesMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- PBI-CCP-QA-0001 QA Welding Consumable Control ProcedureDocument15 pagesPBI-CCP-QA-0001 QA Welding Consumable Control ProcedureTadaya KasaharaNo ratings yet

- Silo-1 Fit-Up Inspection ReportDocument3 pagesSilo-1 Fit-Up Inspection ReportsivaNo ratings yet

- WPSDocument25 pagesWPSWaqas WaqasNo ratings yet

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 pagesOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNo ratings yet

- Weekly Weld Repair AnalysisDocument1 pageWeekly Weld Repair AnalysisknocknocknockNo ratings yet

- Welding Procedure For PVCDocument4 pagesWelding Procedure For PVCVince Tuyulab0% (1)

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- Cswip 3.1Document2 pagesCswip 3.1Anna PariniNo ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- Paint Code Standard ListDocument1 pagePaint Code Standard Listravi00098No ratings yet

- Safe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallDocument1 pageSafe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallHarun Akkaya100% (1)

- Sfa-5 28Document32 pagesSfa-5 28Bruno FDNo ratings yet

- Geometric Unsharpness FormulaDocument2 pagesGeometric Unsharpness FormulaJayaneela Prawin0% (1)

- PFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFDocument8 pagesPFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFfatapia74No ratings yet

- Welding Control Procedure (Project Standards and Specifications)Document4 pagesWelding Control Procedure (Project Standards and Specifications)Axtella Global for Information Technology CompanyqNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- 6-12-0002 Rev 8 Supplementary Specification For Carbon Steel VesselsDocument7 pages6-12-0002 Rev 8 Supplementary Specification For Carbon Steel Vesselsravi2007No ratings yet

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- TK®-236 Physical Properties: 1. HardnessDocument2 pagesTK®-236 Physical Properties: 1. HardnessSaradhi MedapureddyNo ratings yet

- MOTS-12 Welding and NDE of WeldsDocument1 pageMOTS-12 Welding and NDE of Weldsryan.sNo ratings yet

- Saes W 011Document2 pagesSaes W 011hendraox3996No ratings yet

- AKP Storage TanksDocument51 pagesAKP Storage Tankscris_2010No ratings yet

- Auditing Oof Welding Under ASME Section IXDocument21 pagesAuditing Oof Welding Under ASME Section IXsabahiraqNo ratings yet

- Norma CWB Cambios en W47.1-2009Document6 pagesNorma CWB Cambios en W47.1-2009Jose ManuelNo ratings yet

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- How To Write A Welding Procedure SpecificationDocument10 pagesHow To Write A Welding Procedure SpecificationHoang LamNo ratings yet

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument1 pagePiping Daily Fit Up Quality Control and Inspection Report FormKo Lin Tun0% (1)

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportgst ajah100% (1)

- Application Form For CSWIP 5 Year Renewal (Overseas) No LogbookDocument8 pagesApplication Form For CSWIP 5 Year Renewal (Overseas) No Logbook04352No ratings yet

- Pickling and Passivation ProcedureDocument3 pagesPickling and Passivation Procedurearun sNo ratings yet

- Fiberglass Reinforced Plastics (FRP) FabricationsDocument8 pagesFiberglass Reinforced Plastics (FRP) FabricationsEngr Qaisar NazeerNo ratings yet

- Essential and Non-Essential Variables For WPS - PQRDocument4 pagesEssential and Non-Essential Variables For WPS - PQRNatarajan MurugesanNo ratings yet

- Welder Operator TrainingDocument22 pagesWelder Operator TrainingsniperiNo ratings yet

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- Verticality Report.Document2 pagesVerticality Report.Gajanan R Ghatage100% (1)

- GMAW Welding Gas SelectionDocument4 pagesGMAW Welding Gas SelectionkapsarcNo ratings yet

- Non-Destructive Testing Requirements: Welding Procedures ManualDocument4 pagesNon-Destructive Testing Requirements: Welding Procedures ManualcarlosNo ratings yet

- Site Inspection ManualDocument196 pagesSite Inspection ManualMahmoudNo ratings yet