Professional Documents

Culture Documents

Uni C

Uni C

Uploaded by

Dongwon Shin0 ratings0% found this document useful (0 votes)

94 views6 pagesUni C MSDS

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUni C MSDS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

94 views6 pagesUni C

Uni C

Uploaded by

Dongwon ShinUni C MSDS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 6

iy

v4

*

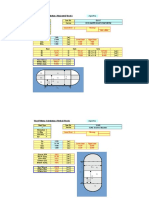

Product Sales Specification

Rev of

11/9/2004,

Unicor C

Property Specification Units Method

Appearance Clear yellow to Amber liquid N/A. Visual

Sp. Gr. at 15,6°C 0.86 -0.95 NIA ASTM D 1298

Flash Point (PMCC) >62 Per ASTM D 93

Pour Point Below -2] 1 ASTM D 97

Kinematic Viscosity at 38°C 2-6 cSt ASTM D 445

Basic Nitrogen (meq/gm) 0.62 0.72 NA UOP 751-74

Note: Where more than one test method is listed for a property, these methods are considered to be

equivaient.

Approved by:

ice President - Operations

Assistant Vice President — Works

Marketing Manager

Customer Approval

Name:

Date

Shaju Parambil 11/9/2004

Mukesh Patel 11/9/2004

Pramod Menon 11/9/2004

Position: Date:

For further information contact:

Dorf Ketal Chemicals (1) Pvt. Ltd

#1, Dorf Ketal Tower, D'Monte Lane,

Orlem, Malad (West),

Mumbai - 400064

Tel 91-22-88 13654/8828374

Fax__91-22-8813655

The information contained in this sheet is provided free of charge and ls based

‘on technical data that Dorf Ketal believes to be correct and reliable. It is

intended for use by persons having technical skill and at their own discretion

and risk. We make no warranties, express or implied, nd assume no liability in

Connection with any ofthis information asthe conditions of use are outside our

control. in addition, none of the contents ofthis publication should be taken as a

licence to operate under, or a recommendation to infringe any patent,

Page (of | Rev No. o#

‘ i maps

as Product : UNICOR C

Rev #05 Date 11/9/2004

Page of 4

MATERIAL SAFETY DATA SHEET

ODUCT IDENTIFICATION

Product Name: UOP"™ UNICOR™ ¢ Corrosion Inhibitor

ction 2, COMPOSITION

Ingredient GASNo, wee EUSymbol —-EURisk Phrase

‘Aromatic Hydrocarbons earazaas © 75-85 Xn R22

Alkyl dimer amine 68201-29-6 ©—16-28 —

4,2,4-Trimethyloenzene 95-63-6 <9 xn R-10,20,38/97138

Naphthalene 91-20:3 <6 xn R-22'36/37,40

Section 3. HAZARD IDENTIFICATION

Emergency Overview : This clear yellow to amber liquid may cause severe skin iitation. Repeated or prolonged exposure may irritate

‘eyes and the respiratory tract. The product is combustibie and toxic vapors may be given off in a fire.

Potential Health Effects

Primary Routes of Exposure : Contact with skin, eyes and product vapor inhalation. Product Ingestion is unlikely to occur if proper

‘safety/nygione procedures are followed.

‘Skin Contact : May severely iitate tho skin.

Eye Contact : Repeated or prolonged exposure may cause initation to some individuals.

Ingestion : This product is considered to have a low orcer af oral toxily

Inhalation : Inhalation of product vapors or mist may cause Iritation of the respiratory tract. Inhalation of high vapor concentrations may

cause headaches, nausea, dizziness and central nervous system depression,

Target Organ : May cause central nervous system disorder (e.g. narcosis involving a loss of co-ordination, weakness, fatigue, mental

confusion, and blurred vision) andlor damage. Overexposure may cause lung damage. Overexposure may cause kidney damage.

T AID N

Skin Contact : REMOVE FROM SKIN EMERGENCY. Apply a generous amount of walerless and hand cleaner (such as GOOP*,

GoJo”, or simiar product) to the affected area. Rub briskly on the skin, on and around the atfected area. Remove the mixture of

cleane’-product with paper towels or clean dry rags. Repeat the entire procedure, then wash the skin with @ mild sosp, rinsing with

warm water. firtation develops, obtain medial attention.

=ye contact: Flush with water for atleast 15 minutes, Hf irrtation occurs, obtain medical attention

ingestion : 00 not induce vomiting. Obtain immadiate medical attention.

Inhalation : Remove effected area to fresh ai. I respiratory problems develop, obtain medical attention,

Notes to physician : 1oxicty of amount of material ingested should be weighed against the risk f chemical pneumonia when emptying

the stomach is considered

‘Section 5, FIRE FIGHTING MEASURES

Flash Point : > 62°C PMCC

Extinguishing Media: Use wator fog, foam dry chemical or COs

Fire and Explosion Hazards: Toxic vapors may be given off In @ fre (See section 10). Wear protective clathing and self-contained

breathing apparatus.

eoSEts is Ny

Rev #05 Date: 11/9/2004

Page 2 of

‘Section 6, ACCIDENTAL RELEASE MEASURES

Large Spill : Standard hydrocarbon spit procedures apply to this product. Remove all sources of ignition, Isolate the affected areas,

CConfina entry into the affected area to those persons property protected. Stop leak at the source. Cut off and redirect surtace runoft by

trenching or diking. Spills should be contained through the use of commercial ol adsorbent, but other materials such earth, sand or

sawdust may be more expedient to limit the extent of the spi, Prevent the release of this product into the waterway or sewer. To

prevent further losses, reposition, plug or place the leaking container into an oversized recovery drumfcontainer.

‘Small Spill: VVear protective equipment. Absorb spilled product using 2 commercial all absorbent soaking up as much product as

possible. Product should be disposed af in accordance with all applicable government regulations,

‘Seotion 7, HANDLING AND STORAGE

Store in tightly closed, propery labeled containers in a cool, well ventilated area away from alt ignition sources. Store out of direct

sunlight. Wear appropriate personal protective equipment. Avoid inhalation of product vapors or mist. Never use @ weiding or cutting

torch on of near a drum (even empty) because vapors from the materal (even residue) can ignite explosively. Follow all MSDS/label

precautions even after container is emptied because it may retain product residue.

Section 8. EXPOSURE CONTROLS AND PERSONAL PROTECTION

Respiratory Protection : Where natural ventilation is inadequate, use mechanical ventiation, other engineering controls, or an organic

‘absorption respirator (in USA — NIOSH/ MSHA approved) io prevent inhalation of product vapor.

‘Skin protection : Gloves, foctwear, coveralls andior apron as necessary to prevent repeated oF prolonged skin contact. Any clothing,

which becomes wet with product should be removed immediately and laundered before reuse.

Eye Protection

Chemical goggles or face shield as necessary to prevent eye contact

Exposure Limits

Ingredient MAK OEL-TWA(EH40/98) "ACGIH TLV-TWA(1997)

Aromatic Hydrocarbons Ne ‘s0mgim NE

‘Alkyl dimmer amine NE NE

1,2.4-tvimethyibenzene NE ‘2emaing, 25 ppp 128mg/m*, 25 ppm

Naphihelene 10 ppm, SOmgim® 10 ppm, 50 mg/m? 10 ppm,62mgim?

STEL 15pm. 78mgim*

‘Section 9. PHYSICAL AND CHEMICAL PROPERTIES

‘These data do not represent technical or sales specifications.

Appearance Clear yellow to Amber Liquid

‘Sp. Gr 086-095 @ 156°C

Oder Hydrocarbon Apparent Bulk Density NA

pH NA, ‘Solubility in water Insoluble

% Volatile >75@16°C Boiling Point 300 °F (149°C)

Pour Point Below -21°C Freezing Point NA

Kinematic Viscosity @ 38°C: 2-6 cSt Melting Point NA,

Vapor Density > (Air= 1) Vapor Pressure < 10 mmHg @ 60°F

‘Section 10, STABILITY

Stability : Stable,

Condition to avoid : Thermal decomposition. Exposure to heat, ight sparks and open flame,

Hazardous Decomposition Products : The product itself does not readily decompose unless subject to extreme temperature or

chemical concitions, CO, CO:, NOx may be generated in the event of incomplete burning.

Hazardous Polymerization : Will not occur.

Incompatible Materials : Reactive with mineral acids and bases,

Msps

Product : UNICOR C

Rev # 05 Date : 11/9/2004

Page 3 of

11. TOXICOLOGICAL MATT

Acute Oral Toxicity =

Mixture of approximately 20% Alkyl dimer amine and 80% Aromat hydrocarbon: Oral LDsy > 5 g/kg (rat)

‘Acomate Solvent: Oral LDsy of 11.97 gfkg (rat) (includes 1.2.4-rimethylbenzene and naphthalene)

Trimethylbenzene = Acute Oral LDzs: 8970 malig (rat)

Naphthalene : Oral LDsa: 490 mg/kg (rat)

Acute Dermal Toxicity :

Mixture of approximately 20% Alky! dimer amine and 80% Aromatic hydrocarbon : Dermal LDzo > 2 glkg (rabbit)

‘Aromatic Selvent: Dermat LOw4 8 g/kg (rabbit) includes 1,2,4-rimethylbenzene and naphthalene)

Acute Inhalation Toxicit

‘An inhalation LCzo's not available for this product

‘Aromatic Solvent: Inhalation LCap > 580 pprn/4H (rat) (Includes 1,2,4-rimethyloenzene and naphthalene)

4,24-timethyloerzene : Inhalation LCza" 18/m'/4H (rat)

‘ertation =

vyin: Mixture of approximately 20% Alky| clmer amine and 80% Aromatic hydrocarbon had a primary irntation index = 3.5/8 maximum

(jebbit. Material is a primary skin trtant but is not corrosive. Moderate imtation persisted longer than 72 hours.

Eye. Mixture of approximately 20% Alkyl dimer amine and 80% Aromatic hydrocarbon had @_ maximum draize score of 18/110 (rabbit).

‘Mig conjunctivitis with complete clearing within 7 days. Not 2 primary eye irtant

‘Additional Toxicological Information : No other data shown.

‘Section 12, ECOLOGICAL INFORMATION,

No data is available for the product.

13. DISPOSAL INFORM.

Waste material, including liquids, contaminated absorbent and material from spill clean-up procedures, must be handled in accordance

with all applicable government regulations. It ig up-to the user of this product to determine the hazards associated with any waste

material generated. Recommended cisposal methods include incineration for contaminated liquids and solid,

jon 14. ORT INFORM)

ADR / RID : Not Regulated.

International Maritime Organization (IMO) : Not requiated.

‘Section 15, REGULATORY INFORMATION,

Council of European Communities Directive on Classification, Packing and Labeling of Dangerous Substences/Preparation

(GTIS43IEEC 8 88/379IEEC)

38 Iritating to skin

£28 After contact with skin, wash immediately with plenty of wateriess handcleaner. $36/37/39 Wear suitable protective

clothing, gloves end eyeltace protection.

Xi Iitant

European Inventory of existing Commercial Chemical Substances :

|All components of this preparation are included in EINECSIELINCS.

ie we

Product : UNICOR

Rev #05 Date: 11/9/2004

Page 4 of 4

‘Section 16. OTHER INFORMATION

NA, Not applicable.

NO. Not determined

NE None established.

MAK | Maximale Arbeitsplatzkonzentrationen, German exposure limits

ore ‘Occupational Exposure Limits EH40, U.K.

o - Total dust

pa Fine dust.

ACGIM - ‘American Conference of Governmental Industrial Hygienists

mW ‘Threshold Limit Value.

For additional information conceming this product. contact the folowing

PRODUGT EMERGENCIES

Dorf Ketal Chemicals (I) Pvt. Ltd. Dorf Ketal LLC

‘#1 DORF KETAL TOWERS 3727 Greenbriar

D Mone street, Marve Road Suite 114,

Malad (W), dombay 64 Staffors, TX 77477.

Tet +91-22-8819656 / =91-22-8628374 Tel No, 281-497-3700

Fax: +01-22-6813655 Fax No, 281-491-373

“The data and recommendations presented inthis date sheet concerting the use of our preduct and the materials contain there in are believed to be

accurate and are based on information which is consteced reliable as of the date hereof However, the customer should determine the suitability of such

‘material er his purpose befave adopting therm on a commercial scale, Since the use our products by ches i beyond our contol, no quarartee, express

OF implied. Is made and no responsiblity assumed for the use of this material or the results to te oblaned thre from. Information on tis form is

furnished fer the purpose ot compliance with Goverment Health and Safety Regulations and shall not be used for any otver purposes. Moreover, the

recommendations contained in tis dale sheet ave not lo be constructed as a icense to operate under, or@ recommendation to infiinge, any existing

Patents, nor should they be confused with state, municipal or insurance requirements, or wih national safety codes

END OF MSDS

DORF KETAL CHEMICALS INDIA PVT LTD

W-165/B, MIDC Teloja,

Raigad Dist, India

Telefax : +91-22-741-0466

Report No +

Dated :

CERTIFICATE OF ANALYSIS

cCERIEKA_a Ser oe

Product

Batch Number

mecca wast [em

— a

a

Specific Gravity @ 15.6°C ASTM D 1298

Kinenacie Wiscosity @ 36°C Gaaipcaas _

Flash Point °C(PMCC) ‘ASTM D 93

‘Pour Point °C ‘ASTM D 97 )

For Dorf Ketal Chemicals India Pvt. Ltd.

Authorized Signatory

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Unicor Type J Corrosion Inhibitor: MSDS NumberDocument3 pagesUnicor Type J Corrosion Inhibitor: MSDS NumberDongwon Shin100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design of Vacuum SystemDocument5 pagesDesign of Vacuum SystemDongwon ShinNo ratings yet

- Choked FlowDocument4 pagesChoked Flowroberto_man5003No ratings yet

- Vessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDocument4 pagesVessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDongwon ShinNo ratings yet

- Material Safety Data Sheet - Perchloroethylene: Colonial Chemical Solutions, IncDocument3 pagesMaterial Safety Data Sheet - Perchloroethylene: Colonial Chemical Solutions, IncDongwon ShinNo ratings yet