Professional Documents

Culture Documents

44 Timbang, Frances Patricia D. 2A - PH Name of Defect Definition of Defect Illustration of Defect Reason of The Defect Remedy of The Defect

44 Timbang, Frances Patricia D. 2A - PH Name of Defect Definition of Defect Illustration of Defect Reason of The Defect Remedy of The Defect

Uploaded by

Frances Patricia TimbangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

44 Timbang, Frances Patricia D. 2A - PH Name of Defect Definition of Defect Illustration of Defect Reason of The Defect Remedy of The Defect

44 Timbang, Frances Patricia D. 2A - PH Name of Defect Definition of Defect Illustration of Defect Reason of The Defect Remedy of The Defect

Uploaded by

Frances Patricia TimbangCopyright:

Available Formats

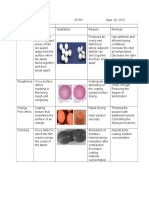

44 TIMBANG, FRANCES PATRICIA D.

2A PH

NAME OF DEFECT

DEFINITION OF

DEFECT

ILLUSTRATION OF DEFECT

REASON OF

THE DEFECT

REMEDY OF

THE DEFECT

1. Chipping/Erosio

n

Increased

brittleness in the

tablet

High degree of

attrition

associated with

the coating

process like

excessive use of

fillers and

pigments

Increase

hardness of the

film by

increasing the

molecular weight

grade of

polymer.

2. Sticking

Involves sticking

of tablets with

each other and

with pan walls.

Higher rate of

application of

coating solution

and inefficient

drying

3. Roughness

Involves presence

of previously

dried sprayed

coating solution

droplets into the

core.

Drying of coating

solution before

reaching surface

of tablet during

spraying

Use optimum

and efficient

drying

conditions.

Increase the inlet

air temperature.

Moving the

nozzle closer

enough;

Reducing the

degree of

atomization.

4. Cracking

Cracking occurs

when the internal

stress exceeds

the tensile

strength of

tablets.

Absorption of

moisture

Adjusting the

coating solution

concentration

5. Capping

Complete/partial

separation of the

upper/lower

surface of the

tablet horizontally

Air is entrapped

in between the

two punches;

improperly dried

granules

Compress the

tablet material at

higher

temperature

6. Bridging/Hazing

Occurs in tablets

consisting in

monogram or

bisection

Too much filling

and thereby

narrowing;

Improper

application of the

tablet

solution/poor

design of the

tablet embossing

Control of

spraying of

normal solution,

concentration of

coating material

7. Blistering

Contains an unsmooth coated

surface with a

number of

uneven spots

called blisters.

Effect of

temperature on

the strength,

elasticity and

adhesion of the

coat

Use mild drying

solution

8. Soft Tablets

The condition

where tablets are

susceptible to

hydrolysis

Lack of drying

time, Improper

storage

Application of

low compaction

nature

9. Lamination

Air entrapment

between layers of

tablet

Low levels of

binding agent

Change in the

method of

granulation

10.Print defect

Letters are

designed in

uneven surface or

layer

Punches having

rough surface

Proper blending

of tablet powder

You might also like

- Problems Associated in Tablet ManufacturingDocument12 pagesProblems Associated in Tablet ManufacturingRajib Chowdhury100% (1)

- Name of DefectDocument3 pagesName of DefectJana EncaboNo ratings yet

- Problems and Remedies For Tablet CoatingDocument7 pagesProblems and Remedies For Tablet CoatingAnowar HossainNo ratings yet

- Processing Problems, Pharmaceutical Dosage FormsDocument3 pagesProcessing Problems, Pharmaceutical Dosage FormsFleur Jeizl Perez100% (1)

- Tablet DefectsDocument3 pagesTablet Defectsjeniccax17No ratings yet

- Industrial Pharmacy - CoatingDocument16 pagesIndustrial Pharmacy - CoatingSolomonNo ratings yet

- Tablet ManufactureDocument10 pagesTablet ManufactureAdemola OgundiwinNo ratings yet

- Tablet Coating 12Document44 pagesTablet Coating 12abraham debebeNo ratings yet

- Problems Causes and Remedies in Tablet Manufacturing & CoatingDocument28 pagesProblems Causes and Remedies in Tablet Manufacturing & CoatingPhArMaCyGrAdUaTeS100% (1)

- CoatingDocument19 pagesCoatingWond WossenNo ratings yet

- Paint FailureDocument4 pagesPaint Failurerajiv_quantumNo ratings yet

- Common Tablet DefectsDocument2 pagesCommon Tablet DefectsMaiah Dinglasan0% (1)

- PHARDOSE Tablet DefectsDocument2 pagesPHARDOSE Tablet DefectskarenNo ratings yet

- Final CoatingDocument21 pagesFinal CoatingEman Rizq NaeemNo ratings yet

- Tablet Coating Process: Made byDocument25 pagesTablet Coating Process: Made byYuppie RajNo ratings yet

- Pharmaceutical Manufacturing Lecture HWDocument2 pagesPharmaceutical Manufacturing Lecture HWKimberly Mae MesinaNo ratings yet

- Problems Causes and Remedies in Tablet Manufacturing: Nadanasabapathi.P., M.Pharm JR - Research.asst Apex Labs, ChennaiDocument28 pagesProblems Causes and Remedies in Tablet Manufacturing: Nadanasabapathi.P., M.Pharm JR - Research.asst Apex Labs, Chennaiabhi8554No ratings yet

- CappingDocument9 pagesCappingmmsmahmudNo ratings yet

- Tablet Defects and Coating Defects and Others PDFDocument3 pagesTablet Defects and Coating Defects and Others PDFZinc YuloNo ratings yet

- Processing ProblemDocument3 pagesProcessing ProblemMeah PachecoNo ratings yet

- Pante, Jaselle A. 2F-PH: Name Illustration Reason RemedyDocument2 pagesPante, Jaselle A. 2F-PH: Name Illustration Reason RemedyJasellePanteNo ratings yet

- Pharmaceutical Dosage (Lec) HWDocument3 pagesPharmaceutical Dosage (Lec) HWKimberly Mae MesinaNo ratings yet

- Problems in Tablet ManufacturingDocument12 pagesProblems in Tablet ManufacturingftthanuNo ratings yet

- Tablet DefectDocument4 pagesTablet DefectVielka AdapNo ratings yet

- 3 PDF Original PDFDocument30 pages3 PDF Original PDFDevang GondaliyaNo ratings yet

- Tablet SalutDocument9 pagesTablet SalutRiaaNo ratings yet

- Defects in TabletsDocument36 pagesDefects in TabletsSunil DarjiNo ratings yet

- Solid Dosage Form Part 3Document24 pagesSolid Dosage Form Part 3Claire Marie AlvaranNo ratings yet

- Processing ProblemDocument3 pagesProcessing ProblemMeah PachecoNo ratings yet

- Problems of Tablet Manufacturing: 1. Tableting Process 2. Excipient MachineDocument7 pagesProblems of Tablet Manufacturing: 1. Tableting Process 2. Excipient Machinemonoj5859No ratings yet

- Tablet CoatingDocument13 pagesTablet CoatingMaryam NoorNo ratings yet

- 10 Defects of TabletsDocument3 pages10 Defects of TabletsHolihuaChua100% (2)

- An Overview On Tablet CoatingDocument4 pagesAn Overview On Tablet Coatingronahaniifah11No ratings yet

- Problems in Tablet ManufacturingDocument22 pagesProblems in Tablet ManufacturingJOSUA DONRIO SIMANJUNTAK 2022No ratings yet

- Problem Illustration Remidies 1. CappingDocument4 pagesProblem Illustration Remidies 1. CappingMikee MeladNo ratings yet

- 8.uploads Downloads DOWN 00F7784227428513Brygram8 PowdercoatDocument1 page8.uploads Downloads DOWN 00F7784227428513Brygram8 PowdercoatPhanhai KakaNo ratings yet

- Tablet CoatingDocument51 pagesTablet CoatingsuminderNo ratings yet

- Plastics Molded ProblemsDocument11 pagesPlastics Molded ProblemsJaynie Lee VillaranNo ratings yet

- Spray Coating and Drying ProcessesDocument15 pagesSpray Coating and Drying Processesshadysamy05No ratings yet

- Tablet CoatingDocument50 pagesTablet CoatingNaufal HanifNo ratings yet

- Tablet:Problems in Tablet Manufacturing: From PharmpediaDocument15 pagesTablet:Problems in Tablet Manufacturing: From PharmpediaMuhammad AyubNo ratings yet

- ThePlasticTroubleshooter BlistersDocument4 pagesThePlasticTroubleshooter BlistersAnurag SrivastavaNo ratings yet

- Various Polymer in PharmacyDocument23 pagesVarious Polymer in PharmacyMohamed AbdeshafeeNo ratings yet

- Tablet Processing Problems and Its RemediesDocument39 pagesTablet Processing Problems and Its RemediesAnaliza Kitongan LantayanNo ratings yet

- Tableting Problem & RemedyDocument26 pagesTableting Problem & RemedyJannat NewajNo ratings yet

- Paint DefectsDocument45 pagesPaint Defectsningsarinya73No ratings yet

- Name of Defect Description Illustration Reason Remedy 1. ChippingDocument2 pagesName of Defect Description Illustration Reason Remedy 1. ChippingLea Pesigan100% (1)

- Tablet Coating BasicsDocument4 pagesTablet Coating BasicsTahir KhanNo ratings yet

- Toz Boya Saklama KoşullariDocument2 pagesToz Boya Saklama Koşullariparadoxid78No ratings yet

- Plastic Design ConsiderationsDocument16 pagesPlastic Design ConsiderationsAlok MallickNo ratings yet

- TDS - Pilot II - English (Uk) - Issued.12.03.2012 PDFDocument4 pagesTDS - Pilot II - English (Uk) - Issued.12.03.2012 PDFNPTNo ratings yet

- Compaction and CompressionDocument6 pagesCompaction and CompressionHaroon Rahim100% (1)

- Defects in Injection MouldingDocument44 pagesDefects in Injection Mouldingsatish100% (1)

- Nylon 6 Resins Correcting Molding Problems A Trouble Shooting GuideDocument12 pagesNylon 6 Resins Correcting Molding Problems A Trouble Shooting Guidebala sivakasanNo ratings yet

- LORD JMC700K Coating Application RecommendationsDocument2 pagesLORD JMC700K Coating Application Recommendationsg.cuachaNo ratings yet

- Powder Caoting Defects and ActionsDocument8 pagesPowder Caoting Defects and ActionsManoharar RNo ratings yet

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- Organization Info Sheet RACDocument3 pagesOrganization Info Sheet RACFrances Patricia TimbangNo ratings yet

- Theology and FaithDocument19 pagesTheology and FaithFrances Patricia TimbangNo ratings yet

- NSTPDocument3 pagesNSTPFrances Patricia TimbangNo ratings yet

- El CapoDocument2 pagesEl CapoFrances Patricia TimbangNo ratings yet

- Reflection Number 1 SCL 3Document1 pageReflection Number 1 SCL 3Frances Patricia Timbang100% (1)