Professional Documents

Culture Documents

273 Structure 2001 07 Parking

273 Structure 2001 07 Parking

Uploaded by

brianmanson78Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

273 Structure 2001 07 Parking

273 Structure 2001 07 Parking

Uploaded by

brianmanson78Copyright:

Available Formats

John Cross, P.E.

fter decades of minimal activity, steel-framed parking

structures are gaining popularity with designers and developers, according to Dale

Denda, an industry analyst with the Parking

Market Research Company. Exposed steelframe construction is back as a recognized

option for multi-story parking structures, he

insists.

Steel has long been recognized for its obvious advantages: lower construction costs (in

addition to reduced structure weight which

reduces foundation costs), rapid construction

time, and longer clear-spans. Some designers

have also touted steels security benefits

fewer and smaller columns mean fewer places

for predators to hide.

In the past however, some designers have

shied away from steel because of structural

fire protection requirements and perceived

failings of standard coatings. Fortunately, the

steel industry has addressed both of these

concerns.

In 1972, the steel industry sponsored the

full-scale Scranton Fire Test, the results of

which put the fire safety issue to rest. The test

showed that a car fire in an open parking

garage does not spread to fully involve adjacent vehicles, and temperatures of unprotected steel during this exposure are well

below those at which the strength of structural steel begins to diminish. Today, under

the International Building Code, open, detached parking garages up to 75-high can be

framed with unprotected steel in most jurisdictions. In fact, a study of more than 400

AT&T-Lucent, Warren, NJ

STRUCTURE July/August 2001

37

parking garage fires during the past decade by

the Parking Market Research Corporation

reveals less than a total of $50,000 in structural damage.

The coatings industry has also played

their part in increasing the viability of steel

for parking structures. Today, coating technology exists that can effectively protect steel

framing systems with limited touch up for

significant periods. Hot dip galvanizing,

which utilizes the cathodic process of introducing zinc to the corrosion circuit as the

sacrificial anode, has a projected protection

Steel has made the fastest inroads into the

airport, health-care and university markets.

These three markets share the need for fast

erection on tight sites, and also often are involved with the expansion of existing structures.

Portland International Airport,

Portland, OR

A notable recent project is the expansion

of a parking garage at Portland International

Airport. The project involved adding 3,300

spaces to an existing three story, pre-cast con-

Portland International Airport, Portland, OR

The expansion of the garage required

7,500 tons of structural steel. Typical interior

floor framing for the expansion consisted of

3 composite G90 galvanized metal decking

with a 3-1/2 concrete topping. Reinforcing

steel was added to the low flutes of the deck

as a backup system in event of deck corrosion.

W16x26 floor beams span 30 to W30x116

girders with columns in a 30 x 60 bay system. Two levels of the expansion were supported directly on top of existing pre-cast

concrete columns. New pin piles were installed inside the garage and supported approximately half the weight of the existing

structure and the upper two levels of the expansion.

The west expansion of the garage was column free to allow buses and commercial vehicles unimpeded access. To create this

column free space, W33x118 beams at 10 on

center span 95 between column lines. To accomplish this span large cambers were required that varied from beam to beam to

provide slope for storm water runoff.

Structural engineer for this award-winning project was KPFF Consulting Engineers. Project architect was Zimmer Gunsul

Frasca. Baugh Construction served as general

contractor with Fought & Company and

Canron Steel as steel fabricators.

Jefferson at Lenox Park,

Atlanta, GA

Jefferson at Lenox Park, Atlanta, GA

life (less than 5% surface corrosion) in excess

of 40 years.

Likewise, new high-performance paint

systems are now available at an economic

price. Todays high performance paint systems, which utilize zinc rich primers and one

or two topcoats of epoxy, have an expected

life-span (with minimal touch-up) that exceeds 25 years.

38

crete framed parking structure. Steel was chosen as the framing material for the garage

expansion to minimize structure weight and

allow the existing garage to remain open during the construction process. The design of

the expanded structure called for a four-story

addition to the top of the existing garage and

a 95 widening of the existing structure with

a seven-story steel framed addition.

STRUCTURE July/August 2001

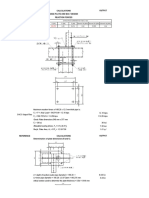

A different approach to steelframed,

conventionally reinforced cast-in-place deck

system was utilized for an apartment complex

parking deck at Jefferson at Lenox Park in

Atlanta, GA. A clear span, 62 parking bay

was constructed using a castellated steel beam

in a composite system with the slab and the

deck. The system included the use of a 30

castellated beam fabricated from W21x44

and W21x50 wide flange beams. The typical

beam weighed only 47 lbs. per lineal foot, reducing the overall weight of the parking

structure. The smaller top cord section had

welded stud shear connectors applied in the

field and is composite with the corrugated

metal deck and concrete. The deck consists of

a 3 deep, 20-gage composite galvanized deck

with 3 of normal weight, reinforced concrete

over the high corrugation.

Principal exterior girders are regular

W24x62 wide flange beams on 30 spans. The

largest column section is a W8x67. The low

weight of the steel in the structure allowed

significant savings in the foundation costs for

the project resulting in a total per space cost

of $4,500 and a differential cost savings of

$600,000 compared to a concrete alternative.

A vibration study of the finished project was

conducted by Dr. Thomas M. Murray, P.E.,

who concluded that the performance of the

beam-deck system was excellent with barely

perceivable vibrations.

The project was developed by JPI, Inc.

with JPI Construction serving as the general

contractor. Structural design was completed

by Alliance Structural Engineers. SMI Steel

Products supplied the castellated beams.

Winthrop University Hospital,

Mineola, NY

The parking requirements of the

Winthrop University Hospital were addressed through the recent construction of a

630 space, three-story steel framed parking

structure with a 6 nominal composite, post

tensioned deck. Ten feet floor-to-floor height

is typical with a minimum clearance of 72.

Architectural pre-cast panels are used as a

faade treatment for the structure. The posttensioned deck was chosen based on the hospitals desire to avoid joints and maintain a

large expanse of crack free space typical with

this style deck. This minimizes the probability of leakage and/or chloride contamination

of the slab, which in turn reduces maintenance and future repair expense. Also, by utilizing post-tensioning, the amount of steel

required to reinforce the slab was reduced. A

40% solids penetrating silane sealer was applied to the deck surface to act as additional

protection against moisture and chloride absorption.

The structure utilized 750 tons of steel.

Typical members were 30 deep spanning 60

across drive lanes and parking bays. By utilizing the composite action of the steel frame

running in a single plane across the drive

aisles and parking bays and the concrete deck,

the weight of the steel frame was reduced to

about 9 lbs. per square foot. The concrete

faade panels were erected at the same time as

the structural components to add stability to

the structure during erection.

The steel was protected by shop blasting

to bare metal (SSPC-SP6) and shop applying

3 mils of an epoxy/zinc based primer. A 4 to

Winthrop University Hospital, Mineola, NY

6 mil epoxy topcoat applied in the field completed the protective coating system.

The project was constructed as a design/build project by Carl Walker Construction and Carl Walker, Inc. Sydney Brown and

Son served as the architect and Axis Construction was the construction manager. The

design/build contracting approach was chosen in order to facilitate faster project delivery and resulted in significant time savings

through the simultaneous structural design,

foundation work, steel fabrication and mill

orders.

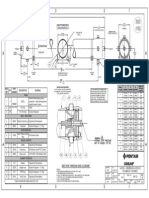

AT&T-Lucent, Warren, NJ

The benefits of combining a steel-framing

system and pre-cast double tee decks are very

apparent in four parking structures constructed at AT&Ts office complex in Warren, NJ. The four garages contain a total of

3,600 spaces on three levels.

The garages were designed by Zaldastani

Associates and fabricated by Interstate Steel

utilizing the Hybrid System approach. The

Hybrid System consists of paired steel

columns and girders designed to support the

pre-cast floor deck and provide lateral stability during and after construction. Paired

plates at 5 -on-center interconnect the paired

columns vertically. The columns were erected

to full height, interconnected at each floor

with steel girders at each of the two column

lines. This arrangement provides vertical stability in the transverse direction by the ladder

STRUCTURE July/August 2001

frame cantilevering from the ground and in

the longitudinal direction by conventional

frame action.

Special attention was given to connection

details in order to create a moment resisting

frame that enabled the steel supported structure to readily resist lateral forces without the

introduction of unsightly shear walls or bracing.

The floor consists of pre-cast double tees

that were attached to the top flange of the

frames steel girders. The flanges of the double tees were welded together in the manner

normally provided for pre-topped tees and a

connection was made between the tees in a

shaped cast-in-place infill that incorporates

floor and roof drains into the deck system.

The Hybrid System has been optimized

to reduce the number of pieces in construction and to simplify erection. The advantage

of the approach was evident in the design and

construction of the project in a ten-month

period, matching the demand for parking

spaces from the adjacent office buildings. The

total cost savings of the Hybrid System over

the concrete alternative exceeded one million

dollars.

John Cross, P.E., is National Project Director

with AISC Marketing, LLC in Chicago.

39

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- EM 1110-2-2901 Tunnels and Shafts in RockDocument236 pagesEM 1110-2-2901 Tunnels and Shafts in Rockxhifrah100% (3)

- Software Testing and Quality Assurance Power Point PresentationDocument24 pagesSoftware Testing and Quality Assurance Power Point PresentationsripriyavinothNo ratings yet

- An Introduction To Rigid Pavement DesignDocument24 pagesAn Introduction To Rigid Pavement DesignSheikh Nouman Mohsin Ramzi100% (1)

- Cable Sizing CalculationDocument15 pagesCable Sizing Calculationrajinipre-1No ratings yet

- Ecological Engineering and Civil Works in NetherlandsDocument369 pagesEcological Engineering and Civil Works in NetherlandsSantiago mosquera guerreroNo ratings yet

- M-Llwas: Low Level Windshear Alert SystemDocument7 pagesM-Llwas: Low Level Windshear Alert SystemJose Luis Velasco CadavidNo ratings yet

- StaadPro FAQDocument250 pagesStaadPro FAQJose Luis Velasco CadavidNo ratings yet

- The LFM FamilyDocument1 pageThe LFM FamilyJose Luis Velasco CadavidNo ratings yet

- Performance Criteria For 12-Inch Concrete Substantial Dividing WallsDocument20 pagesPerformance Criteria For 12-Inch Concrete Substantial Dividing WallsJose Luis Velasco CadavidNo ratings yet

- STAAD (1) .Ect HelpDocument419 pagesSTAAD (1) .Ect HelpJose Luis Velasco CadavidNo ratings yet

- Visualising Leed ElementalDocument1 pageVisualising Leed ElementalJose Luis Velasco CadavidNo ratings yet

- IP - 040302 (Blast Resistant Buildings)Document8 pagesIP - 040302 (Blast Resistant Buildings)Jose Luis Velasco CadavidNo ratings yet

- Hardy Frame "STK" Washers Are Required in The Top of Panels WhenDocument1 pageHardy Frame "STK" Washers Are Required in The Top of Panels WhenJose Luis Velasco CadavidNo ratings yet

- ASTM D6938-15 Nuclear DensitometerDocument9 pagesASTM D6938-15 Nuclear DensitometerJose Luis Velasco Cadavid100% (2)

- Section A: Notes: 4 5 1 4 3 NotesDocument1 pageSection A: Notes: 4 5 1 4 3 NotesJose Luis Velasco CadavidNo ratings yet

- M 251 96 PDFDocument5 pagesM 251 96 PDFJose Luis Velasco CadavidNo ratings yet

- Net Explosive WeightDocument1 pageNet Explosive WeightJose Luis Velasco CadavidNo ratings yet

- AASHTO Pedestrian BridgesDocument21 pagesAASHTO Pedestrian BridgesJose Luis Velasco CadavidNo ratings yet

- Winter Safety: Snowstorms, Low TemperaturesDocument2 pagesWinter Safety: Snowstorms, Low TemperaturesJose Luis Velasco CadavidNo ratings yet

- Bridge Inspection, Maintenance, and RepairDocument186 pagesBridge Inspection, Maintenance, and Repairapi-3741340No ratings yet

- Manual de Sap2000 1Document94 pagesManual de Sap2000 1miguelaseNo ratings yet

- MK6e Control System ChecksDocument4 pagesMK6e Control System ChecksAugustine Owo Ukpong100% (1)

- Technical Specification of Control CableDocument5 pagesTechnical Specification of Control CableBknboy PaliNo ratings yet

- Analysis and Design of Multi-Storied Building (Main Project) Sita GowriDocument114 pagesAnalysis and Design of Multi-Storied Building (Main Project) Sita Gowridskumar49100% (5)

- BetonDocument2 pagesBetonEmily StaffordNo ratings yet

- Technical Specifications For Voltage StabiliserDocument5 pagesTechnical Specifications For Voltage StabiliserFrancis MainaNo ratings yet

- Boiler Life Assessment: L. V. Rama RaoDocument21 pagesBoiler Life Assessment: L. V. Rama RaoArunNo ratings yet

- Astm A192 Asme Sa192Document4 pagesAstm A192 Asme Sa192Mingo EvaNo ratings yet

- NEHRP SeismicDesignofMaso PDFDocument73 pagesNEHRP SeismicDesignofMaso PDFB JNo ratings yet

- Apr48-Apu48 B7053088Document2 pagesApr48-Apu48 B7053088jcguillenNo ratings yet

- Jurnal Dinding Penahan TanahDocument11 pagesJurnal Dinding Penahan TanahAnonymous 7npIQ1kYDNo ratings yet

- 2 WSDDocument30 pages2 WSDlemi celemenNo ratings yet

- Sigma CatalogDocument174 pagesSigma Catalogoguz gurzNo ratings yet

- Apple IPR Instituted Against Immersion '710 Patent Claims.Document40 pagesApple IPR Instituted Against Immersion '710 Patent Claims.TradeHawkNo ratings yet

- 3RN10101CG00 Datasheet enDocument3 pages3RN10101CG00 Datasheet entompagryNo ratings yet

- IV Year CSE 2022 23Document53 pagesIV Year CSE 2022 23811 Anusha RaibagiNo ratings yet

- Base Plate & Bolt DesignDocument2 pagesBase Plate & Bolt DesigndovermanNo ratings yet

- ASIC Verification CalibreDocument33 pagesASIC Verification CalibremaniroopNo ratings yet

- 2ND and 3RD Yrs Practical ScheduleDocument5 pages2ND and 3RD Yrs Practical ScheduleKenny nwangiNo ratings yet

- Journal-Analysis of Semi Circular-Arch Truses Using I-DeasDocument7 pagesJournal-Analysis of Semi Circular-Arch Truses Using I-DeascurrjekNo ratings yet

- DWG REF QTY Number Description Material Shell: Order SectionDocument2 pagesDWG REF QTY Number Description Material Shell: Order SectionRamanNegiNo ratings yet

- 01 - Corporate Piping-Mechanical ProceduresDocument2 pages01 - Corporate Piping-Mechanical Proceduresmostafa aliNo ratings yet

- 05 - Tubing SelectionDocument26 pages05 - Tubing SelectionNisar KhanNo ratings yet

- Practicum Grade FormDocument3 pagesPracticum Grade Formchan parkNo ratings yet

- Wight FdbsDocument3 pagesWight FdbsClarenz BragaNo ratings yet

- 09 Naskah PublikasiDocument9 pages09 Naskah Publikasiwidnu wirasetiaNo ratings yet

- 1 Certificat ISO 9001Document3 pages1 Certificat ISO 9001CARMEN DIMITRIUNo ratings yet