Professional Documents

Culture Documents

Six Sigma DT I Fact Sheet

Six Sigma DT I Fact Sheet

Uploaded by

Beegun DiptiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Six Sigma DT I Fact Sheet

Six Sigma DT I Fact Sheet

Uploaded by

Beegun DiptiCopyright:

Available Formats

SIX SIGMA

FACTSHEET

Six Sigma aims to maximise customer satisfaction and

minimise defects.

WHAT IS SIX SIGMA?

In statistical terms, the purpose of Six Sigma is to reduce

process variation so that virtually all the products or services

provided meet or exceed customer expectations. This is defined

as being only 3.4 defects per million occurrences.

WHAT IS SIX SIGMA?

HOW DOES SIX SIGMA WORK? 1

PROCESS IMPROVEMENT

IN DETAIL

Six Sigma was developed by Motorola in the 1980s but has its roots

in Statistical Process Control (SPC), which first appeared in 1920s.

HOW DOES SIX SIGMA WORK?

There are three basic elements to Six Sigma:

Process improvement

Process design/re-design

Process management

Each of the above three elements is examined in more detail below.

Process improvement

The purpose of process improvement is to eliminate the root

causes of performance deficiencies in processes that already

exist in the organisation. These performance deficiencies may be

causing real problems for the organisation, or may be preventing

it from working as efficiently and effectively as it could.

To eliminate these deficiencies a five-step approach is used.

DEFINE a serious problem is identified and a project team is

formed and given the responsibility and resources for solving

the problem.

MEASURE data that describes accurately how the process is

working currently is gathered and analysed in order to produce

some preliminary ideas about what might be causing the problem.

ANALYSE based upon these preliminary ideas, theories are

generated as to what might be causing the problem and, by

testing these theories, root causes are identified.

IMPROVE root causes are removed by means of designing and

implementing changes to the offending process.

CONTROL new controls are designed and implemented to

prevent the original problem from returning and to hold the

gains made by the improvement.

More details of these five steps are given later in this document.

1

SIX SIGMA

FACTSHEET

Process design/re-design

Sometimes simply improving existing processes is not enough,

and, therefore, new processes will need to be designed, or

existing processes will need to be re-designed. There are

several reasons why this could be necessary:

An organisation may choose to replace, rather than repair,

one or more of its core processes.

An organisation discovers, during an improvement project,

that simply improving an existing process will never deliver

the level of quality its customers are demanding.

An organisation identifies an opportunity to offer an entirely

new product or service.

As with process improvement, a five-step approach is used to

design/re-design a process:

DEFINE identify the goals for the new process, taking into

account the customer requirements.

MATCH develop a set of performance requirements for the

new process that match these goals.

ANALYSE carry out an analysis of these performance

requirements for the new process, and based upon this produce

an outline design for the new process.

DESIGN & IMPLEMENT work this outline design up into a

detailed design for the new process, and then implement it.

VERIFY make sure the new process performs as required and

introduce controls to ensure it keeps performing that way.

Process management

Because it requires a fundamental change in the way an

organisation is structured and managed, process management is

often the most challenging and time-consuming part of Six Sigma.

In general, process management consists of:

Defining processes, key customer requirements, and process

owners.

Measuring performance against customer requirements and

key performance indicators.

Analysing data to enhance measures and refine the process

management mechanisms.

Controlling process performance by monitoring process

inputs, process operation, and process outputs, and

responding quickly to problems and process variations.

SIX SIGMA

FACTSHEET

PROCESS IMPROVEMENT IN DETAIL

Since process improvement is the most frequently used aspect

of Six Sigma, this section looks at part one Process

Improvement in more detail.

Step 1 Define

Having identified the improvement project to be carried out, the

project needs to be established by carrying out the following

activities:

PREPARE A PROBLEM STATEMENT - this statement must

describe the problem in specific terms that identify: what is

wrong; what is the visible evidence of the problem the

symptoms; how serious is the problem, expressed in

quantifiable and measurable terms; how large is the problem

can it be addressed by a single, manageable size

improvement project or will it need to be sub-divided into

several smaller, manageable projects.

PREPARE A MISSION STATEMENT - this statement must

describe what is going to be done about the problem, ie, the

objective of the improvement project. The mission statement

should contain the same variable and unit of measure as does

the problem statement.

SELECT A PROJECT TEAM - the project team selected should

be a cross-functional team that spans all functions upon

which the improvement project will have an impact, both

direct and indirect.

Step 2 Measure

During this Measure step, symptoms of the problem that exists

are identified and a baseline measurement of current and recent

performance is established. Also, a map of how the process that

is producing the problem operates is developed.

However, the real purpose of this step is to analyse the symptoms

and then to confirm, or modify, the mission statement based

upon the results of this analysis. In Six Sigma a symptom is

defined as the outward, observable evidence of a problem. It is

an output of the process that is producing the problem.

If a symptom like this occurs on an ongoing basis, it signals a

chronic, underlying quality problem that needs to be addressed.

To address such a problem, first of all, the symptom needs to be

analysed in the following manner:

SIX SIGMA

FACTSHEET

Develop operational definitions

Measure the symptom

Define the boundaries that is, the scope of the improvement

project

Concentrate on the vital few those sources of error thought

to be largely responsible for the problem. It is time

consuming to attempt to tackle all possible sources, and the

result may not justify the effort.

Once the above analysis of the symptoms has been completed,

the mission statement should be revisited to confirm that it is

still applicable, or to modify it to make it applicable. The results

of the analysis may reveal that the problem is somewhat

different from the one that was originally described; or that the

improvement project is too large and needs to be broken down

into more manageable parts.

Step 3 Analyse

During this Analyse step, theories about the causes of the

problem are formulated, these theories are tested, and, finally

the root causes of the problem are identified.

FORMULATING THE THEORIES the project team

brainstorms possible theories, documents them, and then

organises them in the form of a cause-and-effect diagram.

TESTING THE THEORIES before any theory can be accepted as

true, it must be systematically tested. Any data required to test

a particular theory, that is not available, must first be collected.

If the data collected demonstrates that a particular theory is

clearly not important, then that theory can be eliminated.

IDENTIFYING THE ROOT CAUSE(S) once testing has been

completed, the root cause(s) of the problem should be able to

be determined.

Once found, the removal of the real root cause(s) will sharply

reduce or eliminate the problem/deficiency.

Step 4 Improve

During this Improve step, several sequential activities are

performed and these are described below.

EVALUATION OF ALTERNATIVES alternative improvement

methods are evaluated to determine which method will best

remove, or reduce the effect of, the root cause(s) of the

SIX SIGMA

FACTSHEET

problem. This evaluation is carried out using a set of

evaluation criteria such as cost, impact, cost/benefit ratio,

cultural impact etc

DESIGN OF THE IMPROVEMENT an improvement method

has been selected, the improvement process is designed by

confirm that the improvement achieves the project goals;

determining the required resources; specify the procedures

and the other changes required; assessing human resource

requirements to determine whether any training/re-training is

required.

PLAN FOR CULTURAL RESISTANCE by their very nature,

improvement efforts create change in an organisation and

cultural resistance is a natural consequence of change.

Therefore, dealing with this potential cultural resistance needs

to be factored into the improvement project plan.

PROVE EFFECTIVENESS before an improvement is finally

adopted, it must be proven effective under operating

conditions. This could be done with a pilot test; a dry run,

which doesnt involve delivery to the customer; an acceptance

test; a simulation

IMPLEMENT this involves introducing the proposed change

to the people that will make it work. This demands: a clear

plan; a description of the change; an explanation indicating

why the change is necessary; involvement of those affected;

the change.

The most important parts of implementation, though, are good

planning, good preparation, and good cooperation between all

of the individuals concerned.

Step 5 Control

During this Control step, controls are put in place to ensure that

the gains that have been achieved will continue and the

problem will not recur. To do this the following activities need to

be carried out.

Design effective quality controls

Foolproof the improvement

Audit the controls.

For more information on Achieving best practice in your business:

Visit our website at www.dti.gov.uk/bestpractice

Call us on 0870 150 2500 to order from our range of free

best practice publications or visit www.dti.gov.uk/publications

Contact your local Business Link adviser by visiting the website at

www.businesslink.gov.uk or calling 0845 600 9 006

Published by the Department of Trade and Industry. www.dti.gov.uk

Crown Copyright. 04/04

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- D3NET-Modbus Communication Adaptor - Functional SpecificationsDocument34 pagesD3NET-Modbus Communication Adaptor - Functional SpecificationsJoão Carlos AlmeidaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Time Management QuizDocument3 pagesTime Management QuizfarazvehvariaNo ratings yet

- Chapter 3 Retail in India - Retail ManagementDocument16 pagesChapter 3 Retail in India - Retail ManagementRahul Pratap Singh KauravNo ratings yet

- BPCL Prject Front PageDocument1 pageBPCL Prject Front PagefarazvehvariaNo ratings yet

- Marketing Ethics at The Millennium: Review, Reflections and RecommendationsDocument33 pagesMarketing Ethics at The Millennium: Review, Reflections and RecommendationsfarazvehvariaNo ratings yet

- By FarazDocument88 pagesBy FarazfarazvehvariaNo ratings yet

- Encrypt Your Data AssetsDocument353 pagesEncrypt Your Data AssetsSHAHID FAROOQNo ratings yet

- Physics Practical For Class 10.Document16 pagesPhysics Practical For Class 10.uzayerrahman06No ratings yet

- LCM: Lightweight Communications and Marshalling: Albert S. Huang, Edwin Olson, David C. MooreDocument6 pagesLCM: Lightweight Communications and Marshalling: Albert S. Huang, Edwin Olson, David C. Mooreinher1tanceNo ratings yet

- System Resources On PC (IRQ, DMA, I-OAddress)Document4 pagesSystem Resources On PC (IRQ, DMA, I-OAddress)guilhangNo ratings yet

- Jupiter ObservationDocument16 pagesJupiter ObservationbufzclericNo ratings yet

- 2020 Ignite K3 Set Up GuideDocument30 pages2020 Ignite K3 Set Up GuidedjeisnerNo ratings yet

- C ++ YuktDocument7 pagesC ++ YuktVicky SinghNo ratings yet

- Service ManualDocument429 pagesService ManualChris CoulsonNo ratings yet

- Bilimeter OP ManualDocument16 pagesBilimeter OP ManualargonaiseNo ratings yet

- Electric Guitar GuideDocument26 pagesElectric Guitar GuideGerardo Delgado100% (1)

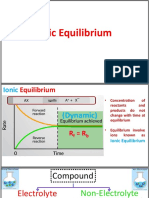

- Ionic EquilibriumDocument14 pagesIonic Equilibrium8842 AnuragNo ratings yet

- Hysteretic Response of RC Infilled Frames - Altin 1992Document18 pagesHysteretic Response of RC Infilled Frames - Altin 1992Nefeli ChatzatoglouNo ratings yet

- Geometry Basics VocabularyDocument39 pagesGeometry Basics VocabularyIsrael Jimenez FelixNo ratings yet

- Time Value of MoneyDocument10 pagesTime Value of MoneyRandy ManzanoNo ratings yet

- Ionic Compounds (With Matchmaker Game)Document3 pagesIonic Compounds (With Matchmaker Game)paydaklevent00No ratings yet

- RLV's Re-Entry Trajectory Optimization Based On B-Spline TheoryDocument5 pagesRLV's Re-Entry Trajectory Optimization Based On B-Spline TheoryShubham KaduNo ratings yet

- Grade 4 DLL Quarter 2 Week 4 (Sir Bien Cruz)Document42 pagesGrade 4 DLL Quarter 2 Week 4 (Sir Bien Cruz)FayeNo ratings yet

- BIDM RegDocument2 pagesBIDM RegSagar DamaniNo ratings yet

- DataDog EBookMonitoringModernInfrastructureDocument86 pagesDataDog EBookMonitoringModernInfrastructurezangui mehdiNo ratings yet

- Osiloskop Analog PDFDocument4 pagesOsiloskop Analog PDFSauqia MufidamuyassarNo ratings yet

- Theoritical FrameworkDocument4 pagesTheoritical FrameworkBryan Clareza0% (1)

- Practical Research 2 Module - Week 1-1Document8 pagesPractical Research 2 Module - Week 1-1Cherabel Gomez75% (4)

- Finite Element Analysis in DesignDocument3 pagesFinite Element Analysis in DesignShivangAggarwalNo ratings yet

- 3.5 ArchimedesDocument13 pages3.5 ArchimedesNURUL FAEZAH BINTI MUSTAPA MoeNo ratings yet

- ERIKS - Simrit Merkel Omegat Stangafdichtingen (OMS-SPR)Document6 pagesERIKS - Simrit Merkel Omegat Stangafdichtingen (OMS-SPR)Sérgio GomesNo ratings yet

- Site ExplorationDocument17 pagesSite ExplorationLEPARIYO SAMUELNo ratings yet

- Petroleum Engineering Programme HandbookDocument79 pagesPetroleum Engineering Programme HandbookMohammed Shoaib50% (2)

- C Programming - Notes-1Document40 pagesC Programming - Notes-1Sumit NirmalNo ratings yet

- - Thời gian thi: 60 phút. Trong đó thời gian quy định, sinh viên làm bài và sao chép đáp án vào tờ làm bài. - Nội dung kiểm tra: liên quan đến các nội dung trong 5 bài học đã họcDocument4 pages- Thời gian thi: 60 phút. Trong đó thời gian quy định, sinh viên làm bài và sao chép đáp án vào tờ làm bài. - Nội dung kiểm tra: liên quan đến các nội dung trong 5 bài học đã họcTuyet Nhi100% (1)