Professional Documents

Culture Documents

0%(1)0% found this document useful (1 vote)

120 viewsEPA Process Design Manual Suspended Solids Removal

EPA Process Design Manual Suspended Solids Removal

Uploaded by

kailashFiltration of particles

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stamp Duty Rates For Maharashtra in 2014Document11 pagesStamp Duty Rates For Maharashtra in 2014kailashNo ratings yet

- Osho BooksDocument10 pagesOsho Bookskailash67% (3)

- Veg LTDDocument17 pagesVeg LTDkailashNo ratings yet

- Federal ReserveDocument124 pagesFederal ReservekailashNo ratings yet

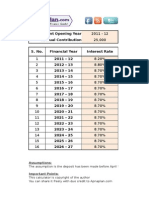

- PPF Account Opening Year Annual Contribution: AssumptionsDocument10 pagesPPF Account Opening Year Annual Contribution: AssumptionskailashNo ratings yet

- FiltrationDocument84 pagesFiltrationArun GuptaNo ratings yet

- Comparision of NDT Methods: Technical & CostsDocument11 pagesComparision of NDT Methods: Technical & Costskailash100% (1)

- Differential and Integral Calculus, IDocument143 pagesDifferential and Integral Calculus, IHarsh SharmaNo ratings yet

- Chemmolecalcsunitlabel tcm4-148466Document54 pagesChemmolecalcsunitlabel tcm4-148466Murtaza AliNo ratings yet

- Name Date of Birth Time of Birth Time Zone Location Latitude LongitudeDocument1 pageName Date of Birth Time of Birth Time Zone Location Latitude LongitudekailashNo ratings yet

- What Is Su JokDocument6 pagesWhat Is Su JokChetna Kanchan Bhagat100% (3)

- I Asked KrishnaDocument23 pagesI Asked KrishnakailashNo ratings yet

- 《童话》 Lonol Lonol Lono Oomml Lonol Lqppo Lonom Mmots Pprrqq Qqnpoono Onor LsrqpDocument9 pages《童话》 Lonol Lonol Lono Oomml Lonol Lqppo Lonom Mmots Pprrqq Qqnpoono Onor LsrqpkailashNo ratings yet

- Vedic Astrology TutorialDocument119 pagesVedic Astrology Tutorialkailash100% (7)

- The Purpose of LifeDocument1 pageThe Purpose of LifekailashNo ratings yet

- How Is Saleable Area CalculatedDocument5 pagesHow Is Saleable Area CalculatedkailashNo ratings yet

- Disease Diagnosis Through Cuspal InterlinksDocument6 pagesDisease Diagnosis Through Cuspal InterlinkskailashNo ratings yet

EPA Process Design Manual Suspended Solids Removal

EPA Process Design Manual Suspended Solids Removal

Uploaded by

kailash0%(1)0% found this document useful (1 vote)

120 views10 pagesFiltration of particles

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFiltration of particles

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0%(1)0% found this document useful (1 vote)

120 views10 pagesEPA Process Design Manual Suspended Solids Removal

EPA Process Design Manual Suspended Solids Removal

Uploaded by

kailashFiltration of particles

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 10

EPA 625/1-75-003a

PROCESS DESIGN MANUAL

FOR

SUSPENDED SOLIDS REMOVAL,

U.S. ENVIRONMENTAL PROTECTION AGENCY

Technology Transfer

@

January 1975

114329

TABLEOF CONTENTS

CHAPTER PAGE

ACKNOWLEDGMENTS ii

ABSTRACT ii

TABLE OF CONTENTS

LIST OF FIGURES

LIST OF TABLES.

FOREWARD

1 INTRODUCTION

1.1 Purpose Ll

1.2 Wastewater Solids tl

13 References 13

2 GENERAL DESIGN CONSIDERATIONS

2.1 Applications of Suspended 21

Solids Separation Processes

2.2 Process Selection 21

3 FLOW VARIATIONS AND EQUALIZATION

3.1 Flow Variation 31

3.2 Performance vs. Flow Variation 3-1

3.3 Flow Equalization 3.2

3.4 References 3.2

4 PRINCIPLES OF CHEMICAL TREATMENT

4.1 Introduction 4-1

4.2 Destabilization Mechanisms 4

43 Selection of Chemical Coagulants 42

44 Coagulation Control 4-6

45 References 4-16

5 STORAGE AND FEEDING OF CHEMICALS

SL General Sl

5.2. Aluminum Compounds SL

5.3 fron Compounds 5-16

54 Lime 5-24

5.5 Other Inorganic Chemicals 5-34

5.6 Polymers 5-50

5.7 Chemical Feeders 5-59

58 References 5-66

6 CHEMICAL MIXING, FLOCCULATION AND.

SOLIDS-CONTACT PROCESSES

6.1 Introduction 61

6.2 Chemical Mixing 63

63 Flocculation 65

64 Solids-Contact Processes 68

65 References 612

TABLE OF CONTENTS - Continued

CHAPTER

7 GRAVITY SEPARATION

7.1 Introduction

7.2 Configuration of Sedimentation units

7.3 Basic Factors Affecting Settling Tank Design

74 Clarifier Design Considerations

7.5 Primary Sedimentation

7.6 Secondary Sedimentation

7.7 Chemical Sedimentation

7.8 Flotation

7.9 Shallow Settling Devices

7.10 Wedge-Wire Settlers

7.1L References

8 PHYSICAL STRAINING PROCESSES

8.1 General

8.2 Wedge-Wire Screens

83 Microscreening

8.4 Other Screening Devices

8.5 Diatomaceous Earth Filters

8.6 Ultrafiltration

8.7 References

9 GRANULAR MEDIA FILTRATION

9.1 Introduction

9.2 Process Alternatives

9.3 Process Variables

9.4 Selection of Filtration Rate

and Terminal Headloss

9.5 Filtration Media

9.6 Filter Controi Systems

9.7 Filter Cleaning Systems

98 Filter Structures and General

Arrangement

9.9 Pilot Studies

9.10 Special Designs

9.11 Slow Sand Filters

9.12 References

10 COST ESTIMATES,

10.1 Introduction

10.2 Curve Content

10.3 Operation and Maintenance Costs

10.4 Freight

10.5 Howto Use Cost Curves

10.6 Curve Descriptions

10.7 References

vi

PAGE

Tt

Tl

72

7-14

715

7-2

723

720

7-32

735

8-1

8-1

831

8-33

8-36

8-43

ot

9-3

99

9-20

9-26

9-31

9-35,

9-45

9-46

9-48,

9-52

9-54

10-1

10-1

10-1

10-2

10-2

10-2

10-16

Figure No.

41

42

43

44

45

46

5-1

5-2

5-3

5-4.

5-5

5-6

5-7

58

5-9

5-10

5-H

5-12

LIST OF FIGURES

Jar Test Units With Mechanical (Top)

and Magnetic (Bottom) Stirrers

Six-Position Sampler

Settling Curves Frequently Obtained

Jar Test Results

Zeta Potential Apparatus

Coagulation of Raw Sewage With Alum

Typical Dry Feéd System

Crystallization of Alum Solutions

Viscosity of Alum Solutions

Alternative Liquid Feed Systems

For Overhead Storage

Alternative Liquid Feed-Systems

For Ground Storage

Freezing Point Curves For Commercial

Ferric Chloride Solutions

Viscosity vs. Composition of Ferric

Chloride Solutions at Various Temperatures

Typical Lime Feed System

Lime Requirement For pH 211.0 asa

Function of the Wastewater Alkalinity

Viscosity of Soda Solutions

Viscosity of Caustic Soda Solutions

Typical Caustic Soda Feed System

vit

Page

48

4-12

4:13

4-15

5-7

SIL

5-12

S14

514

5-17

5-18,

5-31

5-35

537

5-45

Figure No.

5-13

5-14

5-15

5-16

5-17

6-1

6-2

63

6-5

TA

12

13

15

16

77

18

LIST OF FIGURES (continued)

Typical Schematic of a Dry Polymer Feed System

Typical Automatic Polymer Feed

System for Large Plants

Positive Displacement Pumps

Screw Feeder

Positive Displacement Solid Feeder-Rotary

Impeller Mixer

Mechanical Flocculation Basin

Horizontal Shaft-Reel Type

Mechanical Flocculator Vertical

Shait-Paddle Type

Solids Contact Clarifier Without

Sludge Blanket Filtration

Solids Contact Clarifier With Sludge

Blanket Filtration

Rectangular Settling Tanks

Typical Clarifier Configurations

Results of Salt-Injection Tests With

Different Types of Sedimentation Tanks

Schematic Representation of Settling Zones

Sedimentation In a Secondary Settling Tank

Dependence of MLSS Concentration on Secondary

Settling Tank Underflow Concentration

Typical Flotation Unit

Module of Steeply Inclined Tubes

viii

Page

5-51

5-58

5-61

5-63

5-63

64

6-7

6-7

69

6-10

7-3

14

146

7-10

7-10

TAT

7-25

7B

Figure No.

19

7-10

7

Tl

7-13

Bd

8-3

8-4

8-5

8-6

8-7

8-8

8-9

LIST OF FIGURES (continued)

Tube Settlers in Existing Clarifier

Plan View of Modified Clarifier

Tube Settler-Flow Pattern

Simple Wedge Wire Clarifier

Installation of Wedge Wire Panels in a Clarifier

Hydrasieve Unit

‘Schematic

Screen Detail

Curved Screen Bars

Rotating Wedge Wire Screen at North

Chicago S.T.P.

Typical Microscreen Unit

Micro-Matic® Strainer

Microscreen Capacity Chart

Microscreen Removal at Various Flow Rates

Microscreening of Trickling Filter Plant Effluent

Microscreen Unit With Pleated Outer Surface

The Sweco Concentrator

Vertical Leaf Vacuum Filter

Vertical Leaf Pressure Filter

‘Schematic Flow Diagram of the Pikes Peak

Treatment & Reuse System

Page

7-29

7-29

84

8-8

8-10

BIL

8-16

8-23

8.24

8-27

8-35

8-37

Figure No.

8-16

9-1

9-2

9-3

94

9-5

9-6

9-7

9-8

9-9

9-10

OL

9-12

9-13

9-14

9-15

10-1

10-2

10-3

LIST OF FIGURES (continued)

“Storage Battery” Membrane Modules

Typical Rapid Sand Filter

Filter Configurations

Cross Section of Upflow Filter

Typical Pressure Filter

Run Length vs. Filter Rate for Various

Terminal Headlosses

Net Production Rate vs. Filter Rate

for Various Run Lengths

Grain Size Curve

Flow Control Systems

Automatic Gravity Filter, Single Compartment

Minimum Fluidization Velocity, Vmf, to Achieve

10 Percent Bed Expansion at 25°C

Effect of Temperature on Vmf for Sand and Coal

and on Absolute Viscosity of Water

Underdrains

Simater Filter

Hydromation In-Depth Filter

Hardinge Travelling Backwash Filter

Flocculators-Flash Mixers

Chemical Feed Systems

Sedimentation

Page

8-41

9-5

9-6

9-8

9-21

9-24

9-27

9-33

9-36

9.37

9-38

9-40

9-49

9-50

9-51

10-3

10-5

10-7

Figure No.

10-4

10-5

10-6

10-7

10-8

10-9

LIST OF FIGURES (continued)

Solids Contact

Flotation

Wire Septums and Settling Tubes

Wedge Wire Screens: Rotating and Stationary

Microscreens

Media Filters

xi

Page

10-8

10-10

10-11

10-13

10-14

10-15

Table No,

2-1

41

Sl

5-2

5-3

5-4

5-5

5-6

5-7

58

5-12

S-

Tl

12

7-3

74

LIST OF TABLES

Selected SS Separation Process Applications

SS Removal Performance For Chemical Coagulation

Applications To Phosphate Removal

Partial List of Alum Manufacturing Plants

Reactions of Aluminum Sulfate

Reactions of Ferric Sulfate

Reactions of Ferrous Sulfate

Partial List of Lime Manufacturing Plants

Reactions of Lime

Partial List of Caustic Soda Manufacturing Plants

CO2Yields of Common Fuels

Partial List of Carbon Dioxide Manufacturing Plants

Partial List of Polymer Sources and Trade Names

Types of Chemical Feeders

Performance of Special Settling Tank Inlets

Typical Design Parameters For Primary Clarifiers

Typical Design Parameters For Secondary Clarifiers

Dissolved-Air Flotation Applications

Tube Settler Installations

xiii

Page

S15

5-23

5-24

5-28

5-34

5-39

5-46

S47

5-51

5-65

7.14

7-16

7-26

731

Table No.

84

8-2

8-3

8-4

8-5

8-6

87

8-8

8-9

8-10

811

8-12

o1

9-2

9-3

9-4

9-5

9-6

LIST OF TABLES (continued)

Physical Straining Processes

Specifications of Hydrasieves

Wed ge-Wire Screens: Municipal Treatment Installations

Data Sheet-Wedge Wire Screens

Microscreen Design Parameters

Microscreen Installations

Municipal Microscreen Installations

Typical Microscreen Power and Space Requirements

Diatomaceous Earth Filtration of Secondary Effluent

Results of Ultrafiltration Installations

Summary of Pikes Peak Data

Typical Membrane Specifications

Results of Studies of Filtration of Effluents From

Secondary Biological Treatment

Results of Studies of Filtration of Chemically

Treated Secondary Effluent

Results of Studies of Filtration Following Chemical

Treatment of Primary or Raw Wastewater

Expected Effluent Suspended Solids From Multimedia

Filtration of Secondary Effluent

Typical Media Designs For Filters

Filter Gravel Design

xiv

Page

8.2

8-5

8-9

8-13

8-17

8-18

8-28

8-36

8-38

8-39

8-42

9-12

9-15

9-16

9.17

9-30

9-43

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stamp Duty Rates For Maharashtra in 2014Document11 pagesStamp Duty Rates For Maharashtra in 2014kailashNo ratings yet

- Osho BooksDocument10 pagesOsho Bookskailash67% (3)

- Veg LTDDocument17 pagesVeg LTDkailashNo ratings yet

- Federal ReserveDocument124 pagesFederal ReservekailashNo ratings yet

- PPF Account Opening Year Annual Contribution: AssumptionsDocument10 pagesPPF Account Opening Year Annual Contribution: AssumptionskailashNo ratings yet

- FiltrationDocument84 pagesFiltrationArun GuptaNo ratings yet

- Comparision of NDT Methods: Technical & CostsDocument11 pagesComparision of NDT Methods: Technical & Costskailash100% (1)

- Differential and Integral Calculus, IDocument143 pagesDifferential and Integral Calculus, IHarsh SharmaNo ratings yet

- Chemmolecalcsunitlabel tcm4-148466Document54 pagesChemmolecalcsunitlabel tcm4-148466Murtaza AliNo ratings yet

- Name Date of Birth Time of Birth Time Zone Location Latitude LongitudeDocument1 pageName Date of Birth Time of Birth Time Zone Location Latitude LongitudekailashNo ratings yet

- What Is Su JokDocument6 pagesWhat Is Su JokChetna Kanchan Bhagat100% (3)

- I Asked KrishnaDocument23 pagesI Asked KrishnakailashNo ratings yet

- 《童话》 Lonol Lonol Lono Oomml Lonol Lqppo Lonom Mmots Pprrqq Qqnpoono Onor LsrqpDocument9 pages《童话》 Lonol Lonol Lono Oomml Lonol Lqppo Lonom Mmots Pprrqq Qqnpoono Onor LsrqpkailashNo ratings yet

- Vedic Astrology TutorialDocument119 pagesVedic Astrology Tutorialkailash100% (7)

- The Purpose of LifeDocument1 pageThe Purpose of LifekailashNo ratings yet

- How Is Saleable Area CalculatedDocument5 pagesHow Is Saleable Area CalculatedkailashNo ratings yet

- Disease Diagnosis Through Cuspal InterlinksDocument6 pagesDisease Diagnosis Through Cuspal InterlinkskailashNo ratings yet