Professional Documents

Culture Documents

Transformer Testing M G Say

Transformer Testing M G Say

Uploaded by

aayan100%(1)100% found this document useful (1 vote)

68 views8 pagestesting transformer m g say

Original Title

transformer testing m g say

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttesting transformer m g say

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(1)100% found this document useful (1 vote)

68 views8 pagesTransformer Testing M G Say

Transformer Testing M G Say

Uploaded by

aayantesting transformer m g say

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

Transformers: Theory and Performance 189

the severity and continuance of the fault, while from the colour a diagnosis

of the type of fault is possible.

If the rate of generation of gas is small, the lower float b. is unaffected.

When the fault becomes dangerous and the gas production violent, the sud-

den displacement of oil along the pipe-line tips the float bz and causes a second

contact to be closed, making the trip-coil circuit and operating the main

switches on both h.v. and Lv. sides.

Gas is not produced until the local temperature exceeds about 150 °C. Thus

momentary overloads do not affect the relay unless the transformer is already

hot. The normal to-and-fro movement of the oil produced by the cycles of

heating and cooling in service is insufficient to cause relay operation.

5.18 Testing

A transformer may be subjected to a range of tests for a variety of purposes ,

including—

(@) Routine tests after manufacture;

(6) Acceptance tests, heat runs, etc.;

(€) Specialized investigations on particular details of design, performance

or operation.

Phasing and Polarity

In manufacture, where all connections are traceable, the phases on primary and

secondary sides may readily be grouped. If not, all phases are short-circuited

Buchholz relay

Transformer

b

5.29 Buchholz protection.

190 Alternating Current Machines

except a primary and a supposedly corresponding secondary. A small direct

current is circulated in the primary and a voltmeter is connected across the

secondary. A momentary deflection of the voltmeter when the primary cur-

rent is made and broken confirms that the two windings concerned belong

to the same phase.

For this test all phase-ends should be separate. Difficulty may be experien-

ced with internally connected zigzag (interconnected star) arrangements.

Polarity has to be in accordance with B.S. 171: see Fig. 5.17.

Voltage Ratio

Most manufacturers employ bridge methods, for checking coils before

assembly.

Assembled transformers may be checked on a ratiometer, which is essenti-

ally a potential divider excited from the same supply as the transformer under

test, and subdivided so as to read the I.v. voltage in terms of the h.v. Balance

is obtained by connecting the ratiometer tapping to the l.v. winding through

an ammeter and adjusting the former until the current is zero.

D.C. Resistance

Any usual method may be used. For large low-voltage transformers alow

resistance bridge method is necessary. The d.c. resistance must be made at

known temperature, and may be used to check the design or to estimate the

eddy-current loss ratio.

Magnetizing Current and Core Loss

This test is made on a transformer complete with tank and oil, as it is per-

formed at normal rated voltage and electric stress. One winding (usually the

hw.) is left on open circuit and the other connected to a supply of normal

frequency. Readings are taken of current and power at rated voltage. The

power includes the core loss, the I7R loss (often negligible) and the dielectric

loss: the latter may be significant for transformers of extra-high voltage. The

conditions are discussed in Sect. 5.1.

If a test is made at normal frequency and variable voltage V, the active

and reactive components of the no-load current appear as in Fig. 5.30. As

the peak flux density By, is proportional to V and the core loss roughly to

Bm?, ie. to V2, the power/voltage curve is to a first approximation parabolic,

while the active current Jog is very roughly linear. The magnetizing component

Joy rises initially at low densities until the core attains its condition of maxi-

mum permeability, and thereafter rises steeply with the onset of saturation

around normal voltage. The values in Fig. 5.30, which apply to transformers

in the range 100—1 000 kVA, are expressed in per-unit terms.

Core-loss Voltmeter. Hysteresis loss (which accounts for 70-80% of the core

loss) depends upon By, but the eddy-current loss depends upon the waveform

of the flux density and therefore upon the r.m.s. density. The core loss should

be measured with a sine applied voltage, but to avoid errors due to changes in

the peak value, which can occur with negligible change in the r.m.s. voltage,

the voltage is measured as a mean value, to which the peak flux density is pro-

Transformers: Theory and Performance 191

0-025 0:05

Normal voltage

0-02 0:04

°

3

a

°

g

Power (p.u.)

Current (p.u.)

0 0-25 0-5 075 10 125

Voltage (p.u)

5.30 No-load test values.

portional. The mean voltage is adjusted to 2 \/ 2/7 = 0.90 times the rated r.m.s.

voltage. A rectifier type of voltmeter is suitable.

Magnetizing Current Unbalance. The magnetic path length associated with

the central phase of a 3-ph 3-limbed core-type transformer is significantly

shorter than that of either of the outer phases. The configuration [1] shows

that the outer path lengths include two half-yokes additional to the limb. As

a consequence, the magnetizing current and core loss values are asymmetric,

to an extent depending on the path-length ratio. If the centre path length is

one-half that of either outer, then its magnetizing current is likely to be about

30% less, and this is independent of the peak flux density level. The measure-

ment of the total core loss by 2-wattmeter method is made difficult by the

fact that it is the small difference between two large readings on account of

the very low power factor: the measurement also depends upon which phase

currents pass through the wattmeter current-circuits, and even on the phase

sequence if the wattmeter volt-circuits have inductance errors. The most satis-

factory way of measuring the core loss is to use one wattmeter for each phase.

Leakage Impedance and Load Loss

One winding is short-circuited, and the other (usually the h.v. to reduce the

current and increase the voltage to be measured) is connected through volt-

meters, ammeters and wattmeters to a supply of normal frequency but of a

fraction (510%) of normal voltage. With rated full-load current circulated,

the load loss is measured and adjusted to standard reference temperature, i.e. to

75 °C for insulation classes AEB, and to 115 °C for FHC. The power measure-

ment includes a very small core loss (which is generally neglected) and the

eddy and stray losses. The terminal short-circuit connections must be carefully

192 Alternating Current Machines

arranged, as l.v. winding resistances may be very low. In adjusting the measured

loss to reference temperature it may be necessary to take account of the

fact that while the ohmic I7R loss increases with temperature, the eddy-loss

ratio, eq.(3.1), actually falls.

The leakage impedance voltage is given by the voltage Veo required to cir-

culate rated current at reference temperature. The ratio Vsc/Isc gives the leak-

age impedance Z, (if the measurements are made on the primary), from which

the leakage reactance can be calculated.

Total Loss

This is the sum of the no-load loss at rated voltage, and the load loss at rated

current adjusted to reference temperature. In the case of multiwinding trans-

formers it is stated for one pair of windings.

EXAMPLE 5.6: An 11/0.44 kV 50 Hz 300 kVA 3-ph mesh/star transformer

gave the following test results at rated voltage and current: No-load: 440 V

21.1 A, 1.30 kW (Lv. side). Short-circuit: 630 V, 15.7 A, 3.08 kW (h.v. side,

winding temperature 30 °C). Evaluate the rated loss, impedance voltage, per-

unit resistance and leakage reactance, and the efficiency and regulation on

full load at p.f. 0.8 lagging.

The no-load loss is Py = 1.30 kW (0.043 p.u.); the no-load current is Ih=

21.1 A (0.053 p.u.)

The s.c. test impedance voltage is 630/11 000 = 0.057 p.u. and the resis-

tance is 3.08/300 = 0.010 p.u., giving the leakage impedance €y = (0.057? —

0.010) = 0.057 p.u. The adjusted load loss is 3.08 (235 + 75)/(235 + 30) =

3.60 kW, whence €, = 0.012 p.u. and €; = 0.057 p.u.

The total adjusted loss is 1.30 + 3.60 = 4.90 kW. At full load and p.f. 0.8

lagging the efficiency and regulation are

=1-——42___

0* 1" 300x 0.8449

€= 0.012 x 0.8 + 0.057 x 0.6 = 0.043 pu.

= 0.980 p.u.

With large transformers it is necessary to treat the ohmic and eddy-loss I7R

effects separately in determining the load loss.

Temperature-rise

This is measured during the performance of a heat-run intended to reproduce

as far as is practicable the conditions of rated continuous load. The methods

include (a) Back-to-back connection; (6) Delta/delta connection; (c) Equiva-

lent open- or short-circuit run.

Back-to-back Connection. Two identical transformers A and B, Fig. 5.31 (a),

are connected in parallel on one side to a supply of normal voltage and fre-

quency. Disregarding the effect of the auxiliary transformer C, wattmeter

W, reads the core loss of the two transformers together. The other sides are

now properly paralleled, and a circulating voltage introduced by C to circu-

late full-load current in the primaries, and therefore also in the secondaries.

Transformers: Theory and Performance 193

The circulating power is measured by wattmeter W2, which records the load

loss. If the two transformers have suitable tappings it may be possible to dis-

pense with C by deliberate unbalance. The arrangement for 3-ph transformers

is shown in (6). Because of the phasing of the magnetizing and circulating

currents, there is a slight difference in the load loss of the pair; this may be

averaged out if the auxiliary supply frequency is lower than normal.

Delta-delta Connection. The primary side is excited normally: the secondaries,

in open delta, are joined to the auxiliary supply to circulate full-load current,

achieving the same result as the back-to-back connection.

Equivalent Run. Where the I’R loss is several times the core loss, a heat-run

may be made by a short-circuit test at a current sufficiently greater than full-

load value to cover the (absent) core loss. With high-frequency transformers

it may be possible to approximate to normal loss by an open-circuit test at

overvoltage. A normal heat-run at low power factor may require a large syn-

chronous compensator, possibly backed with a static capacitor bank. A 500

MVA transformer with 0.2 p.u. reactance would require a test equipment

capable of 100 Mvar for the temperature-rise test.

Insulation

The integrity of the insulation to earth and between turns, coils, tappings,

windings and phases is tested (i) by power-frequency induced voltage, (ii)

by power-frequency applied voltage, and (iii) by impulse applied voltage.

Induced voltages are generated by the transformer itself by open-circuit test

Auxiliary Main Auxiliary Main

b

5.31 Back-to-back tests.

194 Alternating Current Machines

at a frequency up to twice normal in order to limit the level of core saturation.

The peak induced voltage v;, of a given winding is measured, and vj/-/2 is

taken as the r.m.s. voltage that must match the specified B.S. value for the

system rated voltage level. Although the test voltage is greater than normal,

its distribution is the same as in service.

Applied voltages are derived from test transformers. The whole of a tested

winding is raised to terminal level, unlike the effect of induced voltage.

Impulse voltages are applied to the h.v. windings of a transformer by means

of a surge or impulse generator. The test voltage wave takes the forms shown

@ Full wave b Chopped wave

Applied

voltage

Timing

wave

/ \ J iitiate Current in

neutral

c connection

5.32 Impulse tests.

in Fig. 5.32: (a) is a full wave, and (b) a chopped wave obtained by parallel-

ing the impulse generator by a rod spark-gap, which has a delayed breakdown.

The standard full wave is designated 1.2/50 us, indicating that the initial rise

time is 1.2 ys, and that it decays to one-half peak value in 50 ps. A test

sequence might be as follows: one full wave at reduced voltage; one full wave

at test level; two chopped waves in succession; one final full wave at test

level. For each test simultaneous oscillographic records are made of the ap-

plied impulse voltage and of the neutral current, the latter from the drop

across a non-reactive resistor connected between the tank and earth. If an

initial test is made at a voltage substantially below the expected impulse

strength of the transformer, any failure that occurs during the normal test

routine will show an anomaly in the current record. With modern techniques

and considerable experience, failures can be detected with near certainty even

when there are no other signs (e.g. noise or smoke). Fig. 5.32(c) shows typi-

cal oscillographic records.

Transformers: Theory and Performance 195

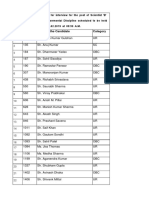

Test Voltages

These are based on the highest r.m.s. system voltage V,. Test voltage levels V;

(in t.m.s. for power-frequency tests and in peak for impulse tests) are given

in BS 171. They approximate to the following:

Test Voltages, kV

A: Air-insulated windings, and oil-immersed windings not

subject to impulse testing.

O: Oil-insulated windings designed for impulse testing.

System voltage Power-frequency test Impulse test

Vs A ° °

Less than 1.1 2.5 ~ 7

3-36 21 Vy - -

17.5-72.5 — 7418V, 204424,

100-245 (Std. 1)* - 1.9 Vs 4.5 Vs

100~420 (Std.2)* 9 — 15 Vy 3.5 Vs

* Standard 1 for non-effectively-earthed windings; Standard 2

for effectively-earthed windings.

Overcurrent

System short-circuit currents have immediate mechanical effects, and rapidly

developing thermal effects, on transformers. The most severe case is that ofa

terminal short circuit, for which the result for a transformer of leakage impe-

dance z per-unit is a current comprising the components

@) a symmetrical alternating current of r.m.s, value 1 /z per-unit, and

i) an exponentially decaying direct current with an initial value that may

reach almost the peak of the a.c. component, as a result of the ‘doubling

effect’.

The overcurrent limits in BS 171 specify the symmetrical r.m.s. current Jee in

(i) for a range of ratings S:

S MVA: 0.63 1.25 3.15 6.3 12.5 25 +100

Tog P-u. = 25 20 16 14 12 10 8

Zz pu.: 0.04 0,05 0.0625 0.0715 0.0835 0.10 0.125

A transformer will in general be designed to have leakage impedance correspon-

ding to z.

Thermal Effects. If Ig is not greater than 20 p.u. the transformer must with

stand the heating effect for 3 sec without exceeding a specified temperature

limit. For /g, greater than 20 p.u. the time is reduced to 2 sec. Taking the

initial winding temperature 4 to be the maximum coolant temperature

(40 °C) plus the permissible temperature-rise given in Sect. 4.7, then the maxi-

mum winding temperature 0,, reached must not exceed the following values

{in °C) corresponding to the insulation class and conductor material indicated:

196 Alternating Current Machines

Type and insulation class: | Dry A E B FHC OA

Windings: copper 180 250 350 350 250

aluminium 180 200 200 — 200

The calculation is made on the basis of eq.(4.3) in the form

Om = Oo + aJ7t x 1073

for a short-circuit current of duration ¢ (in sec) producing in the windings the

current density J (in A/mm?). The factor a takes account of the resistivity,

temperature coefficient, density and thermal capacity of the conductor

material and is expressed as a function of the average temperature 4 (9; + 8):

4m + 99),°C 140 160 180 200 220 240

Factor a, copper 7.41 7.80 820 859 8.99 9.38

aluminum 165 17.4 183 - — —

The conditions imposed settle the maximum short-circuit current densities,

which range from 40 A/mm? for a 3-sec short circuit in a dry transformer

with aluminium windings up to 100 A/mm? for an oil-immersed water-cooled

transformer with copper windings and a 2-sec duration.

Mechanical Forces. The transformer must withstand the mechanical forces

on short-circuit. The value of F = Ni in eqs.(2.19) and (2.20) is found with

i= 1.8(/2 ig), the asymmetrical initial peak current assuming a small decre-

ment.

5.19 Special types

Some types of transformer outwith those for normal electrical systems include

the following.

Miniature Transformers

The open air-cooled construction has largely been superseded by hermetically

sealed arrangements in air- or oil-filled containers, the connections being

brought out through metal/glass or metal/ceramic seals. Transformers for

mobile equipments and working at frequencies in the range 400—1 600 Hz

employ cores of relatively costly materials and high loadings for reduction

of mass. Very thin c.r.0.s. or nickel-iron cores are wound with coils insulated

by high-temperature dielectrics such as fibreglass and silicones. A fully sealed

30 VA 1 600 Hz unit may have a mass as low as 0.1 kg.

Mining Transformers

These work under particularly onerous conditions, with restricted headroom

and a potentially explosive ambient atmosphere. The modern underground

unit is ‘dry’, has a class C insulant, and is enclosed in a flameproof casing.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On-Line WB State Quota & PVT Management Quota UG Medical & Dental Counseling Process-2018Document10 pagesOn-Line WB State Quota & PVT Management Quota UG Medical & Dental Counseling Process-2018aayanNo ratings yet

- Sample Duty RosterDocument1 pageSample Duty RosteraayanNo ratings yet

- Public Service Commission, West Bengal Advertisement No. 9/2019Document5 pagesPublic Service Commission, West Bengal Advertisement No. 9/2019aayanNo ratings yet

- Rotary Cam SwitchDocument16 pagesRotary Cam Switchkvp0107100% (1)

- Chemical Civil Environmental 09.01.19Document3 pagesChemical Civil Environmental 09.01.19aayanNo ratings yet

- Principal: Scheme of Examination For The Post of Principal, Vice-Principal, PGTS, TGTS, Librarian and Prts Are As UnderDocument10 pagesPrincipal: Scheme of Examination For The Post of Principal, Vice-Principal, PGTS, TGTS, Librarian and Prts Are As UnderaayanNo ratings yet

- Smart Grid Security: Threats, Vulnerabilities and SolutionsDocument6 pagesSmart Grid Security: Threats, Vulnerabilities and SolutionsaayanNo ratings yet