Professional Documents

Culture Documents

UG 45 Sample Calculation

UG 45 Sample Calculation

Uploaded by

Aris PurniawanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UG 45 Sample Calculation

UG 45 Sample Calculation

Uploaded by

Aris PurniawanCopyright:

Available Formats

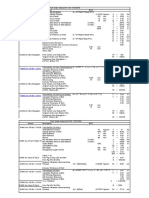

THICKNESS OF NOZZLE AS PER UG-45

11.75

Nozzle Size :

in

Inputs

UG-45 b(1) for Internal Pressure

Internal Design Pressure

Diameter of Shell/Head

Design Temperature

Allowable Stress of Shell

Joint Efficiency

Corrosion Allowance

Formula used

t=

Inputs

UG-45 b(2) for External Pressure

P

D

Temp

S

E

CA

400.00

60.00

250.00

14300.00

1.00

0.00

psi

in

F

psi

External Design Pressure

Diameter of Shell/Head

Design Temperature

Allowable Stress of Shell

Joint Efficiency

Corrosion Allowance

in

Formula used

PD

2( SE 0.6 P )

Result

t=

P

D

Temp

S

E

CA

15.00

60.00

250.00

14300.00

1.00

0.00

psi

in

F

psi

in

0.0315

in

t

t

CA

8.3738

0.00

mm

mm

mm

t

t

8.3738

0.3297

mm

in

P

D

Temp

S

E

CA

400.00

PD

2( SE 0.6 P )

Result

Thickness

0.8535

in

Thickness

Inputs

UG-16(b)

Inputs

UG-45 b(4)

Minimum thickness

Minimum thickness

Corrosion Allowance

Result

LATER

ASME Section VIII Index L-7.2 Example 2

Thickness

Thickness

t

t

CA

1/16

1.59

3.00

in

mm

mm

t

t

4.5875

0.1806

mm

in

Final Result

Standard Wall Thk of pipe

Minimum thickness

Corrosion Allowance

Result

Thickness

Thickness

9.57

Inputs

UG-45 a for Internal Pressure

Step 1:

Max ( UG 45b(1) , UG 16b)

0.8535

mm

Step 2:

Max ( UG 45b(2) , UG 16b)

0.1806

mm

Step 3:

Max ( Step1 , Step 2)

0.8535

mm

Step 4:

Min ( Step3 , UG-45 b(4))

0.3297

mm

Step 5:

Max ( Step4 , UG-45 (a))

0.3297

mm

Min Required thickness of

Nozzle

0.3297

mm

Internal Design Pressure

Diameter of Pipe

Design Temperature

Allowable Stress

Joint Efficiency

Corrosion Allowance

Formula used

t=

psi

in

250.00 F

16600.00 psi

11.75

1.00

0.00

in

0.14

in

PD

2( SE 0.6 P )

Result

Actual Thickness of Pipe

Actual Thickness of Pipe

Thickness

Sch

Pipe Schedule Thickness x 0.875 (12.5% Undertolerance )

should be greater than

Minimum Required Thickness

You might also like

- PV External Pressure Spreadsheet ASME VIII Div 1Document1 pagePV External Pressure Spreadsheet ASME VIII Div 1Gohar ZamanNo ratings yet

- Horizontal Pressure Vessel Calculation (Eng)Document59 pagesHorizontal Pressure Vessel Calculation (Eng)Chamseddine MerdasNo ratings yet

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNo ratings yet

- Pressure Vessel Design ManualDocument32 pagesPressure Vessel Design ManualAris Purniawan100% (1)

- Part 10-L - 1 Shell (Semi) (ASME)Document17 pagesPart 10-L - 1 Shell (Semi) (ASME)ammarmpNo ratings yet

- Design Calculations For Pressure VesselsDocument24 pagesDesign Calculations For Pressure VesselsMichael Lageman94% (16)

- API CalculationsDocument11 pagesAPI CalculationsMohammed Illiasuddin100% (1)

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNo ratings yet

- Design Calculations For Pressure VesselsDocument28 pagesDesign Calculations For Pressure VesselsUmair AwanNo ratings yet

- WRC For NozzleDocument43 pagesWRC For NozzleSachin55860% (1)

- Pressure Vessel Assessment SpreadsheetDocument3 pagesPressure Vessel Assessment SpreadsheetrawirabbatNo ratings yet

- 31barg CalculationDocument10 pages31barg Calculationshani5573No ratings yet

- Sight Glass Selection Guide PDFDocument7 pagesSight Glass Selection Guide PDFani_datNo ratings yet

- Pressure Vessel Calculations ASME SectioDocument11 pagesPressure Vessel Calculations ASME Sectioivan chirinosNo ratings yet

- ThicknessDocument53 pagesThicknessRajul MuraliNo ratings yet

- Pipe Thickness Calculations - : ClassDocument1 pagePipe Thickness Calculations - : ClassOluwachidiNo ratings yet

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- Nozzle Calcs Rev ADocument6 pagesNozzle Calcs Rev AbolivarNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument17 pagesThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- Pressure Vessel Design Calculations - by Abdel Halim Galala PDFDocument127 pagesPressure Vessel Design Calculations - by Abdel Halim Galala PDFsizmaru100% (1)

- Pressure Vessel Design CalculationsDocument2 pagesPressure Vessel Design CalculationsMohan VarkeyNo ratings yet

- Pressure Vessel Design 2018 VER BDocument61 pagesPressure Vessel Design 2018 VER BBob FitcherNo ratings yet

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- Pressure Vessel Design Training - Course ContentDocument13 pagesPressure Vessel Design Training - Course Contentamol shindeNo ratings yet

- Pressure Vessel FormulaDocument9 pagesPressure Vessel FormulaNasir Khan JadoonNo ratings yet

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocument1 pageRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNo ratings yet

- Pipe Wall Thickness Under External PressureDocument1 pagePipe Wall Thickness Under External PressureAnonymous DJrec2No ratings yet

- PV Elite WebinarDocument24 pagesPV Elite WebinarAndrea Hank LattanzioNo ratings yet

- Rectangular TankDocument4 pagesRectangular Tankknsaravana0% (1)

- Pressure Vessel Design (Faiz Zelin)Document1 pagePressure Vessel Design (Faiz Zelin)arcelitasNo ratings yet

- PV EliteDocument6 pagesPV ElitevikrantgulhaneNo ratings yet

- Pressure Vessel Design Excel Sheet Basic Designing Non Critical PDocument1 pagePressure Vessel Design Excel Sheet Basic Designing Non Critical PKaramYassNo ratings yet

- ASME VIII CalculationDocument15 pagesASME VIII CalculationJoao Osmar Correa100% (1)

- ASME Impact Test RequirementDocument7 pagesASME Impact Test RequirementkasimshaikhNo ratings yet

- External PressureDocument22 pagesExternal PressureAbhijeet SahuNo ratings yet

- Cast - Basket Strainers - 2nd EditionDocument27 pagesCast - Basket Strainers - 2nd EditionmartinnovelNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- VESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedDocument6 pagesVESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedMuhammad Farukh ManzoorNo ratings yet

- Manual Design Validation CalculationDocument21 pagesManual Design Validation CalculationToniNo ratings yet

- Combined Shell-Ring InertiaDocument13 pagesCombined Shell-Ring Inertianeurolepsia3790No ratings yet

- External Pressure - Pressure Vessel EngineeringDocument15 pagesExternal Pressure - Pressure Vessel Engineeringarjun100% (1)

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNo ratings yet

- Project of Pressure VesselDocument25 pagesProject of Pressure VesselKalkidan DanielNo ratings yet

- Training Manual For PVelite Basic LevelDocument41 pagesTraining Manual For PVelite Basic LevelRajaram100% (1)

- FRP RF CalcDocument1 pageFRP RF CalcmukeshNo ratings yet

- Design For External Pressure-13022018Document14 pagesDesign For External Pressure-13022018ToniNo ratings yet

- Asme A-2 Reverse Flange CalculationDocument1 pageAsme A-2 Reverse Flange CalculationpastylNo ratings yet

- External Pressure ToleranceDocument4 pagesExternal Pressure ToleranceAKSHAY BHATKAR100% (1)

- Pressure Vessel Calculation Report PDFDocument12 pagesPressure Vessel Calculation Report PDFVictor Fakoya50% (2)

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George Racz100% (1)

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Design Calculations For Pressure ShellDocument33 pagesDesign Calculations For Pressure ShellGeorge GeorgianNo ratings yet

- Design Calculations For Pressure VesselsDocument73 pagesDesign Calculations For Pressure Vesselsshani5573No ratings yet

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsPeña Eepesa100% (2)

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Weight Estimation of Vessels AppsDocument39 pagesWeight Estimation of Vessels Appsmacwan23No ratings yet

- Mud Gas Separator CalculationDocument16 pagesMud Gas Separator CalculationErwin Gomop-asNo ratings yet

- PDMS CommandDocument51 pagesPDMS CommandAris PurniawanNo ratings yet

- R3642-Shwe Spool Numbering (New Format) - R3Document1 pageR3642-Shwe Spool Numbering (New Format) - R3Aris PurniawanNo ratings yet

- Floating Dock M.burhan REV.01 PDFDocument2 pagesFloating Dock M.burhan REV.01 PDFAris PurniawanNo ratings yet

- Rubbish Bin PDFDocument1 pageRubbish Bin PDFAris PurniawanNo ratings yet

- Smartplant Spoolgen: Automatic Isometrics For Fabrication & Erection Kim, Kyung Deck - Intergraph KoreaDocument31 pagesSmartplant Spoolgen: Automatic Isometrics For Fabrication & Erection Kim, Kyung Deck - Intergraph KoreaAris PurniawanNo ratings yet

- Curriculum VitaeDocument1 pageCurriculum VitaeAris PurniawanNo ratings yet

- Profile: Basic SkillsDocument2 pagesProfile: Basic SkillsAris PurniawanNo ratings yet

- Fabrication Daily Progress: No DescriptionDocument4 pagesFabrication Daily Progress: No DescriptionAris PurniawanNo ratings yet

- Pipe (Parametric Fittings) : Pronest 2015 Optional ModuleDocument1 pagePipe (Parametric Fittings) : Pronest 2015 Optional ModuleAris PurniawanNo ratings yet

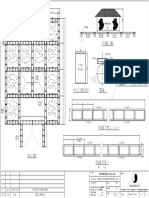

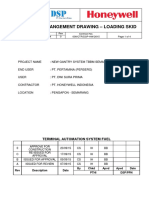

- TBBM 09 2 MEC DWG 001 A4 Rev 0 - General Arrangement Drawing Loading SkidDocument9 pagesTBBM 09 2 MEC DWG 001 A4 Rev 0 - General Arrangement Drawing Loading SkidAris PurniawanNo ratings yet