Professional Documents

Culture Documents

EDMS 38894488 Title V Permit Modification Dec 5 2008 Murphy Oil

EDMS 38894488 Title V Permit Modification Dec 5 2008 Murphy Oil

Uploaded by

GeauxGreenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EDMS 38894488 Title V Permit Modification Dec 5 2008 Murphy Oil

EDMS 38894488 Title V Permit Modification Dec 5 2008 Murphy Oil

Uploaded by

GeauxGreenCopyright:

Available Formats

RECEIPT OF CHECK

0103832

12/5/2008

Date o~ Check

!:

12/3/2008

Check Number ~-:----~~--------

Amount Received $2,332.50

RECEIP1i GENERATED BY:

Sunshine McManus

COMMENTS modification

Media: AIR QUALITYI

Rcporc Dltelfime I I 12I5f2008 2:2647 PM '

1

•

MAIN F~LE

i

OIL USA, INC.

MERAUX REFINERY P. O. BOX 100 MERAUX LA 70075-0100

iUOO DEC

PrJ 1 06

·.i

LDE{J F'<ECEI~T

MURPHY

5

HAND-DELIVERED

December 5, 2008

,

original to IDa

~8Py to iLi(o"tttll J~:u .:~

, f fl(tg;', '1

Ms. Cheryl Nolan

II

Assistant Secretary

Office of Envifbnmental Services

Louisiana Depsrtment of Environmental Quality P.O. Box 431311

Baton Rouge, eA 70821-4313

RE: MurpJl Oil USA, Inc. -Meraux Refinery Merau~ SL Bernard Parish, Louisiana

II ".

Part 70 Operatbig Permit Minor Modification Application

II •

Title ~,Pe,.mit No.: 2500-00001-V3

Agen£J! Interest No.: 1238 v' '

II . . '

Dear Ms. Nolan: '

II

Murphy Oil USA, Inc. (MOUSA) is submitting this minor modification application to the Title

VlPart 70 Perihit No. 2S00-00001-V3, issued May 8, 2008. MOUA is submitting this minor modification application to reinstate Tank 80-9 and to replace three tanks by constructing and operating Tanks 1-3A, 80-SA, and 80-IOA at the Meraux Refinery, As MOUSA is not requesting an increase in CAP emission limits in this application, the application qualifies to receive minor lhodification procedures. 1

MOUSA is Jldertaking this project to replace previously existing tanks and to address postKatrina storag~ capacity shortages. The use of domed internal floating roofs on Tanks 80-9 and 80-IOA, as well as an internal floating roof on Tank 1-3A, will result in significant reductions in VOC emission~ versus the previously existing tanks. The construction of Tank 80-SA will enable tank farm changes to accommodate the future BenFree Unit, which must be built and operational by January, 2010 to satisfy the Mobile Source Air Toxics rule. The tanks will be constructed within the current boundaries of the Meraux Refinery and will be located at sites of previously existing tanks.!

.... Tank 1-3~ will replace Tank 1-3 at its existing location. (Tank 1-3 was built prior to 1958.) Tank 1.3A! will have a capacity of 1,000 barrels and will be in slop oil return service for oily waters recbvered from the onsite Wastewater Treatment Plant. Tank 1-3A will be equipped with an intl~rnal floating roof, whereas Tank 1-3 was a fixed roof tank. ,

LDEQ

1 Per paone conversation between Bryan Johnston (LDEQ) and Cheri Kwast on November 6, 2008, minor mo~ificalion procedures are appropriate if tanks are being added to an emissions CAP if the emissions CAP ~oes not increase. Public notice is not required for a minor modification, which includes an addition ofa ~our.~e 10 an emissions CM~J1jJmns do not change.

(504) 271-4141 USA. FAX (504) 278-5201

•

•

•

Ms. Cheryl Nolan- Page 2

II

December 5, 2008

... Tank 80·5A will replace Tank 80·5 at its previous location. (Tank 80·5 was demolished in 2001.) Ta~ 80·5A will have a capacity of 80,000 barrels and will be in heavy oil service.

II

... Tank 80-9 is an existing tank that will be restored to the permit. Tank 80·9A has a capacity

of 80,000 ~rrels and will be permitted for gasoline, middle distillate, and naphtha service. MOUSA Jill' replace the external floating roof with a domed internal floating roof, which will reduc~!emissions. MOUSA allowed the tank to be removed from Title V Permit No. 2500.000011. V2, as the strategic plan at that time was to remove the tank.

II

... Tank 80-10A will replace Tank 80·10 at its previous location. (Tank 80-10 was demolished

in 2006.).iiTank 80·10A will have a capacity of 80,000 barrels and will be permitted for gasoline, middle distillate, sour water, naphtha, and heavy oil service. Tank 80-1 OA will have a doJed internal floating roof.

MOUSA plans Ito begin construction of the new tanks immediately upon approval and, therefore, respectfully requests that the LDEQ process this application in the most expeditious manner possible. Purkuant to LAC 33:I.Chapter 18, MOUSA is submitting a certified "Request for Expedited Perkt Processing" form with this application. Pursuant to Louisiana Administrative

II

Code (LAC) 33:III.223, Fee Number 0720, the applicable permit processing fee in the amount of

$2,332.50 is al~o being provided with this submittal. MOUSA has authorized the expenditure of the funds necJ!ssary to cover the additional cost incurred by LDEQ in association with this

d· d I' •

expe ite pernut request.

·11

Please contact Mr. Matthew Dobbins with MOUSA at (504) 271-4141 if you have any questions

II di hi 1"

or comments regar mg t IS app ication.

Attachments

Refinery Manager Meraux Refinery

Sincerely,

MURPHY OIL USA, INC.

cc: Mr. Syed Quadri - LDEQ

I,

Mr. Jeff Robinson - EPA

•

•

•

Ms. Cheryl Nolan - Page 3

II

December 5,2008

Title V Permit Minor Modification Application

bee: Mr. Kent Veron - MOUSA Mr. Mfttt Dobbins - MOUSA

Ms. V~lerie Barth - Trinity Consultants

G;IAIRITITLE ¥\PERMIT APPLICATIONSIPERMIT V4\08120S.DEQ LETTER..DOC

)

.~

•

•

STATE OF LOUISIANA

DE~ARTMENT OF ENVIRONMENTAL QUALITY

Office of Environmental Services' Environmental Assistance Division

Post!Office Box 4313 • Baton Rouge, LA 70821-4313 .

Custdmer Service: 225-219-LDEQ (5337) or Toll Free 1-866-896-LDEQ (5337)

II

REQUEST FOR EXPEDITED PERMIT PROCESSING

This form is to bellsubmitted when an applicant requests consideration for expedited processing of permits, mocltications. licenses, registrations, or variances in accordance with LAC 33:I.Chapter 18. Submission of this form shall in no way constitute approval of the expedited permit request. The Office will notify the applicant in writing of the decision to expedite processing of the requested permit application. ALL n·J'FORMATION MUST BE PROVIDED. Please submit one form for each activity for which expeditf;!'d processing is requested.

II

;~-.; .. : ..... ': ,',' ... ,' . ·jlL:~:· · .. ~<-;:;~~cr"~9:N}I-- F *;~!LiTvt~f.8~~~1[.IQN::.~~~:,:~:::~:::: '::,;~ .. :.' :-.;:'.)'. ··::::·~·.:.'n~'·;~!;··.;,:,~:~

Agepc}Arii~rEls't (AI)~#' :11238 ~;p.er~i~ ~:(ii'pe~~{~~4L . j~:!~.;:.~;; 2S00-00001-V3

:" ;',: X Ai(:' lI' \.': S~I)~vVast~:::',<~<· ;-;" ;N'~vV.Facllit\t{· .'. ~;'y~,' x~O·d,i~,e9iF~9.U!tY,

,t:{···, :.,Water 1[,: :.:~ :Ha~ardous·~\.yaste. }Typeof /Gener~L~e-rmit·.:·:) (:".:' :., _.Vi:irianb~;ri~;~p·>::);:

~r.JIedia . . .. "

;~)' ··'Other: 'IV:::~;ermlt ~·Lice!1se.:,::: ..... :~~:U ~ .. :, . Registt#.!'iqX,··(l\;.:

. 'Ii . ", ' ,''-:: '. .. Ren'~V;;ai w/~o~mcation.·:.. ·\:.\t,:·: ... ::.':"'>.:

II

Matl_Dobbins@murphyoilcorp.com

" r , ~.~ :.

Meraux Refinery

Street P.O. Box 100

Cf~y Meraux I State I LA

Name Matt Dobbins

Phone .. ( S04 ) 271-4141

Cell Phone. ( 504) 278-5268 Mailing Address

Zlp .. ::1 70075

Technical Contact Avaitable

. 11

After Normal Work Hours

I

Fax

( 504) 278-5201

II

~ .... ~

SECTION II - EXPEDITED PER~IT INFORMATION

~. ' .. , ".

1, How many new ~ermanentjobs will result from this permit aCtion?

"

o

.2. Date requested f8r final permit decision I January 13, 2009

"

',',

X Yes' :'No·

Yes X No'<

3. Is construction a~tivity proposed in permit application? ..

"

4. Does the applica~t' owe any outstanding fees to LDEQ?

If you answered ijYes" to No.4, above, attach explanation to this form.

'.

••• I,~

'5. Is there a limit tol~he amount you are willing to pay to expedite the permit?

. Yes .. :: X:No.:<

form_7172_r01 12/13/06

Expedited Permit Request Page 1 of 2

t ' , , ,

I

i

I

I ,

I

i I

I

I'

i

I

!

•

•

•

i I·

I

I I

I

. II

'Ifyou answered "Yes" to No.5, above, please read and complete the following:

II .'.

I understand that i~ such a maximum amount is requested, the number of overtime hours a department employee or contractor works processing the permit, modification, license, registration, or variance shall be · .,Iimited accordingly.I'/f further processing of the document is required, the department's continued review will .' . not be in accordance with 'the provisions of this Chapter, and the request will no longer be handled on an

: expedited basis. I Jnderstand tha/the department will charge'a fee for the expedited processing which was ..

performed. (LAC 33:1.1805). .

. II . '

· l wish to limit the ex'pedited permit fee to:

No limit

I

1

Maintaining tank capacity availability by replacement of existing tanks tha are no longer in service with tanks with mora stringent emission controls.

.. ' ... ~

.

'SECTION IV ":CERTIFiOATlo.~S.·.·

.i; .... -,. ".:.

'. " :",.' :,:" II' . .0' ...... : ',' . .-:. " . ., .' _- :,' ,.",_- .;;{.;:. ::.' '.

: Check:'th~~~J)propriate box regarding,pendlng.enforcement actions and-lawsuits. .•... ;.. . ...

"0 l~e~ify.{hat~ am' not subject to ~n;:'ki,~~i~9_:.~t~~e or fe~e"fJl enforcem~n~'ac~jo~sj ·i~cIUding.citi~e·n .. suitS -.

. broughtunderst(jle or federallaw. t ": .. '" .. .' . .: -:.'~ .

1/": . or" .... "'11' .. '.: ' •. ',' '. . ... , . ":'~:':, ;:'.-.~:;

( .':" 0 I am currimqy ~ubject. tO,pending state or federal e;iforceriient,actions, including citizen suits brought>

· :',' ,,'. <.' under state gr federal law. .' .' , ':' . .-. . " '::

• Ple'iia'se read and complete the following: , . , . :-"' ..

.'. " "~'.' II ' .- .

· I, as the duly authorized responsible official, certify in accordance with LAC 33:1.1B03.C, that should additional information be requ~fed to complete the permit process, all requested information will be provided . within the

timeframes specified I by the department. ' .

I ut?dersta'nd that: 1 .

•. . If the requested information is not provided within the fimeframes specified, or if the limit I have indicated _as a maximudl amount to be paid for expedited processing is reached, the Department reserves the 'right to cease processing the permit, modification, license, registration, or variance 8S Em expeqitedpermit. .

. • If the depart~~nt ceases expediteipe'rmit processing, I will be billed (or·the expedjte:ci.pi~·c.essing that

occurred in accordance with LA C 33: I. 1805, B. . . '

• Failure to pay::the expedited permit processing fee by the due date specified on the invoice will constitut~,; a violation of these regulations and shall subject the applicant to relevant enforcement action under the' Louisiana En~!ronmental Quality Act including, but not limited to, revocation or suspension of the .permit, ,

modification, license, registration, or variance. .

• There is no gJlarantee that a final permit decision will be issued by the date I have requested.

• The submitta/lbf this request does not release me from liability for any vio/a/ions relaled to ihis activity or the Environmdntal Quality Act.

• A permit ma~l be required prior to any construction at the site, operation of the proposed' activity or commencement of discharges from this proposed activity, and I should refer to media-specific

regulations fO~1 t~ ipformation. /l .

Signature II./;t~ x:J1i17A~ Title Refinery Manager

IjLy~n G. Bourgeois (J

Printed Name

It? ~ 3 -0&

Date

form_7172_r01 12/13/06

Expedited Permit Request Page 2 of 2

'.

TITLE V MINOR MODIFICATION ApPLICATION MURPHY OIL USA, INC. • MERAUX REFINERY

Prepared by:

Valerie Barth • Principal Consultant Cheri Kwast • Consultant Carol Waszkowski • Technical Assistant

TRINITY CONSULT ANTS 4000 S, Sherwood Forest Boulevard Suite 503 Baton Rouge, Louisiana 70816 (225) 292-2661

December 2008

Project 081901.0063

•

•

TriuityA CGnsultants

•

'e

•

TABLE OF CONTENTS

1. INTRODUCTION ,.. , 1

II

1.1 REGULATORY CONSIDERATIONS 2

II

1.1.1 REGULATORY ANAL YS[S 2

II

1.2 . EMISSION RATE CALCULA TrONS 3

, II

2. ApPLICATION FOR ApPROVAL OF EMISSIONS

ApPENDlxA I

AREA MA~ & PLOT PLAN

ApPENDlXB

INSIGNIFICANT ACTIVITES AND GCXVIl ACTIVITIES

ApPENDIX c II

EMISSION CALCULATIONS

ApPENDIXD I

CERTIFICNfE OF GOOD STANDING

ApPENDIX E II

COMPLIANCE SCHEDULE AND ENFORCEMENT ACTION DOCUMENTATION

II Murphy Oil USA, lnc.

Trinity Consultants

1-- ~---- .. - -------------..-------------------------------------

•

••

•

1. INTRODUCTION

Murphy Oil ust Inc. (MOUSA) own' and operates a petroleum refinery in Meraux, Louisiana. MOUSA is subihiuing this minor modification application in order to modify the facility's Title V permit accordin~ to the provisions in the Code of Federal Regulations (40 CFR Part 70) and as required by the Louisiana Department of Environmental Quality (LDEQ) Operating Permits Program, Chapter 5 of th~1 Administrative Code. Required data, certifications, and application forms are included in this ~pplication.

MOUSA receivL Title V Permit No. 2500-00001-V3 on May 8, 2008. MOUSA is submitting this minor modific~tion application to replace three tanks by constructing and operating Tanks 1-3A, 80-

II

5A, and 80-lOt at the Meraux Refinery. MOUSA is also requesting to reinstate Tank 80-9 in this

permit modifidtion. As there is no increase in CAP emission limits requested in this application, the

II

application qualifies to be processed using minor modification procedures. I

II

MOUSA is undertaking this project to replace existing tanks. The tanks will be constructed within

the current bou~daries of the Meraux Refinery and will be located at sites of existing tanks. Coverage under a Title ~I permit is required before construction can commence on these tanks. The tanks that

will be replaced are described more specifically below: .

... Tank 1-3AI~ilI replace Tank 1-3 at its existing location. (Tank 1-3 was built prior to 1958.) Tank 1-3A will have a capacity of 1,000 barrels and will be in slop oil return service for oily waters

II

recovered from the onsite Wastewater Treatment Plant. Tank 1-3A will be equipped with an

internal flo~ting roof, whereas Tank 1-3 was a fixed roof tank. Therefore, MOUSA will realize a significant I~eduction in VOC emissions at this tank. Tank 1-3A will be subject to, and meet the emission cgntrol standards, ofNSPS Kb and MACT CC.

11

.... Tank SO-SA will replace Tank 80-5 at its previous location. (Tank 80-5 was demolished in 2001.)

II

Tank 80-SA will have a capacity of 80,000 barrels and will be in heavy oil service. Due to the

low vapor ~ressure of this material, Tank 80-5 will not be subject to NSPS Kb control standards, so it will o~ly be required to have a fixed roof.

[I .

.... Tank 80-9 is an existing tank that will be incorporated into the permit. Tank 80-9 has a capacity

of 80,000 tiarrels and will be permitted for gasoline, middle distillate, and naphtha service. MOUSA J!ill replace the external floating roof with a domed internal floating roof. Tank 80-9 will be sutiject to, and meet the emission control standards, of MACT CC. MOUSA previously requested that the tank be removed in Title V Permit No. 2500-00001- V2, as the strategic plan at that time Jlas to remove the tank. The plans for this tank have now changed.

II

.... Tank 80-1 OA will replace Tank 80- IO at its previous location. (Tank 80-10 was demolished in

2006.) Ta~ 80-1 OA will have a capacity of 80,000 barrels a1td will be permitted for gasoline, middle didlillate, sour water, naphtha, and heavy oil service .. Tank 80-1 OA will be subject to, and

- IJ .

I Per p~one conversation between Bryan Johnston (LDEQ) and Cheri Kwast on November 6,2008, minor modification proJkdures are appropriate if tanks are being added to an emissions CAP if the emissions CAP does not

increase. Public Hotice is not required lor a minor modification, which includes an addition of II source to an emissions CAP I if the capped emi~sions do not change.

II

II Murphy Oil USA, Inc.

Trinity Consultants '

•

meet the control standards of, NSPS Kb and MAC[ CC. Tank 80-IOA will have a domed . I fl II. f

mterna oatmg roo .

There is no increase proposed to the annual throughputs of the new tanks. Each lank will continue to have the same 11nnual throughput as the tank it will replace. Also, the tanks will comply with all federal and statg Spill Prevention, Control and Countermeasures (SPCC) rules.

1.1 REGULATORY CONSIDERATIONS

•

1.1.1 REGULATORY ANALYSIS

Tabl~s I through 4 of Section 23 of the AAE contain the regulatory applicability analysis forT1nks 1-3A, 80-SA, 80-9, and 80-IOA. Federally applicable requirements as well as state!~egulations affecting the tanks are identified. This application only contains the regulatory applicability for the new equipment, as required.l

II

The following list outlines the changes made to the regulatory applicability tables as they

are fgund in the facility's current Title V permit.

II

... Tank 1-3 is being tom down and replaced with a new internal floating roof tank that

~ill be called Tank 1-3A. Tank J-3A must comply with NSPS Kb and MACT CC.

11

Tank I -3A complies with MACT CC by complying with NSPS Kb as allowed.

II

4 ~ank 80-5 was tom down and is being replaced with a new fixed roof tank that will be

JaIled Tank 80-SA. Tank SO-SA must comply with MACT CC as a Group 2 Tank.

11

~ank SO-SA is exempt from NSPS Kb due to the low vapor pressure of the heavy oil it

J,ill store. Tank 80-SA will be subject to MACT cc.

11

... ~ank 80-9 is being repaired and converted to a domed external floating roof tank. As

the costs associated with the repair of Tank 80-9 does not cause it to be considered r~constructed and the modification to the tank will not cause an increase in emissions

11

(pnk 80-9 is being converted from an EFR to a DEFRlIFR), the modification to Tank

80-9 will not trigger NSPS Kb, but the tank must comply with MACT Cc.

~. .

4 ~ank SO-10 was tom down and is being replaced a new domed external floating roof t~nk called Tank SO-IDA. Tank SO-IDA is subject to NSPS Kb and MACT CC.· Tank

11

80-1 OA complies with MACT CC by complying with NSPS Kb as allowed.

2 Per phJ~e conversation between Syed Quadri (LDEQ) and Cheri Kwast (Trinity) on November 12,2008, only

'I

the regulatory applf,cability for the sources with changes in regulatory applicability need to be included in the application,

• ;;:.::'::<;J;'Y.Wl ""'''0"" ",I;"b;I;" "O~ '0' ,,'" '0 be ;"1 •• ",, m ,Ii, '1'1'''''';0' ; f '0 <h,"g~ 're bci'g

I) Murphy Oil USA, lnc.

2

Trinity Consultants

•

1.2 EMISSION RATE CALCULATIONS

Emission rate calculations for Tanks 1-3A, 80-SA, 80-9, and 80-1 OA have been included in Appendix C of this applicMtion. Since no changes are being requested for the tank emission CAPs, calculations

II

of the CAP limits have not been included in this application.' To maintain consistency with the

current Title V ~ennil, calculation of the maximum emission rates have been included in Appendix C. Tank 80-10A is1lbeing added to the gasoline, middle distillate, naphtha, and heavy oil CAPs. Tank 80-1 OA will alsb operate in sour water service. Tank 80-9 is being added to the gasoline, middle distillate, and nMphtha CAPs. Tank 1-3A is being added to the slop oil CAP, and Tank 80-SA is being added to the he~vy oil CAP.

•

3 Per pho~~ conversation between Syed Quadri (LDEQ) and Cheri Kwast (Trinity) on November 12,2008, calculations should ~Iot be included if CAP emissions are not changing.

•

II .

Murphy Oil US~, Inc.

3

Trinity Consultants

•

2. ApPLICATION FOR ApPROVAL OF EMISSIONS 1

II .

l__~~~~ __ M_urphY Oil ]' Inc.

•

e·

Trinity Consultants

•

Department of Envnonmental Quality Office of Envirorllnental Services Air Permit~ Division

P.O. Bo~ 4313

Baton Rouge, L~ 70821-4313

"

(225) 219-3181

"

LOUISIANA

Application for Approval of Emissions of Air Pollutants from Part 70 Sources

1. II . PLEASE TYPE OR PRINT

Facility Informatien [LAC 33: 111.517 .D_1]

Facility Name or Process Unit Name (if any) I

Meraux Refinery II

Agency Interest Number (A.I. Number) Currently Effective Per

1238 II 2500-00001- V3

Company - Name Of Owner

"

Murphy Oil U.S.A,I!nc.

Company - Name or Operator (if different from Owner)

II

Parent Company (if Company - Name of Owner given above is a division)

Murphy Oil Corpo4tion

Ownership: 11

Check the appropriate box.

I8l . II h' 1 . hi o regulated utility Om

corporation, partners ip, or so e propnetors ip

11 Dot

o state govenunent 0 federal govenunent

• 2 . Physical LoJltion and Process Description

"

ILAC 33: 111.51 ':1.0.18, unless otherwise stated]

II

What does this facility produce? Add more rows as necessary.

See introduction. II

II

What modification)/changes are proposed in this application? Add more rows as necessa

See introduction. II .

"

II

Nearest town (in the same parish as the facility): Parish(es) where facilit

Meraux, LA· 11 SI. Bernard

Distance To (mi): II - 239.4 Texas - 236.2 Arkansas - 31.9 M

Latitude of Facility Front Gate: 290eg 55 Min 48 Sec

II

Longitude of Facility Front Gate: 890eg 2§Min ±lSec

Distance from neJ}est Class I Area 91.8 kilometers

Add physical addrJL and description of location of (he facility belo~. If the facility has n

directions. Add mJ~e rows as necessary.

MU!Ehy Oil U.S.A!~ Inc., Meraux Refinery

2500 E. SI. Bernard Hi~hwax

Meraux, LA 70075J

!8J Map attached (~equired per LAC 33:II1.517.D.I)

• [8] Description of ~rocesses and products attached (required per LAC 33: II1.517.0 .2)

[8] lntroduction/Description of the proposed project attached (required per LAC 33 :1II.517.

form_7195_rOO

06/06/07 [8J All Process Units

o Pro~ess Unit-specific Permit

mit Number(s)

unicipal government

her, specify

ry.

Y is located:

ississippi

-101.2 Alabama 80 Hundredths 70 Hundredths

o address, provide driving

0.5)

3. Confidentiality (LAC 33.I.Chapter 5]

• Are you requesting dbnfidentiality for any information except air· pollutant emission rates? 0 Yes [8J No

If 'yes, " list the se~tions for which confidentiality is requested below. Add rows as necessary. Confidentiality requests

require a submittal that is separate from this application. Information for which confidentiality is requested should not be

submitted with this Jpplication. Consult instructions.

II

II

4. Type of APpJbation (LAC 33:III.517.D)

Complete the appropriate column (lor 2) that corresponds to the type of permit being sought. Check all that apply within

the appropriate colufun. I

Column 1 [I Column 2

o Part 70 General 11 [8J Part 70 Regular

o Renewal II o Renewal I

Select one, if applicable: Select one, if applicable: I

"

o Entirely new facility o Entirely new facility

o Modification or ~Ixpansion of existing facility (may also o Significant modification or expansion of existing facility

include reconciliations) (may also include reconciliations) [LAC 33:11I.527]

OR T' III

econci iation on y [8J Minor modification or expansion of existing facility (may

o Individual emiss~bns unites) addition also include reconciliations) [LAC 33:111.525]

o Reconciliation only

NSR Analysis:

I

,

psoD NNSRD

• Does this submittal tdate or replace an application currently under review? 0 Yes [8] No I

. II

If yes, provide date that the prior application was submitted:

Select one if this apJ~ication is for an existing facility that does not have an air quality permit

o Previously Grandfathered (LAC 33:III.50 I.B.6)

o Previously Exempted (e.g., Small Source Exemption; Act 918)

o Previously Unpermitted

I

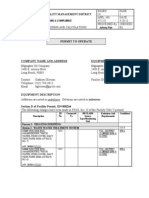

5. Fee Information (LAC 33:III.517.D.17J

Fee Parameter: If the fee code is based on an operational parameter (such as number of employees or capital cost), enter that

q I

parameter here. Refinery crude throughput.

Industrial Category: Enter the Standard Industrial Classification (SIC) Codes that apply to the facility.

Primary SICC: 11 2911

Secondary SICC(s): N/A

Project Fee calculLion: Enter fee code, permit type, production capacity/throughput, and fee amount pursuant to LAC

33:III.Chapter 2. Add rows to this table as needed. Include with the application the amount in the Grand Total blank as the

permit application f~e.

FEE EXISTING INCREMENTAL SURCHARGES

CODE TYPE CAPACITY CAPACITY MULTIPLIER NSPS PSD AIR TOTAL

INCREASE TOXICS AMOUNT

0720 Minorll 125,000 N/A NJA [8J 0 0 $2,332.50

BBUday

• GRAND TOTAL $2,332.50

form 7195 rOO :

- -

06/06/07 more than 25 IOns/year of all nonattainment [!ollutants, change emissions by more than 10 tons/year of an individual toxic

• air [!ollutant, or change emissions by more than 100 tons/year of all other criteria (attainment) Qollutants, then the Qennit

fee is egual to the minimum minor modification fee for each fee [!rocess catego[Y involved. Per LAC 33:IIl.211.A, the

25% NSPS fee has been assessed.

Electronic Fund T~anSfer (EFT): If paying the penn it application fee using an Electronic Fund Transfer (EFT), ple~s

include the EIT Tra!nsaction Number, the Date that the EFT was made, and the total dollar amount submitted in the E

If not paying the perlhit application fee using EFT, leave blank.

EFT Transactirin Number Date of Submittal Total Dollar Amount

N/A II N/A s N/A

6. Key Dates

Estimat~d date construction will commence: 112009 Estimated date operation will commence: 512009

7. Pending per!it Applications - For Process Unit-Specific Permits Only

II .

[LAC 33:III.517·.D.18]'·

List all other proceJ~ units at this facility for which Part 70 permit applications have been submitted, but have not be

acted upon by LDE<ti as of the dale of submittal of this application. If none, state "none" in the table. **It is not necessa

to update this table tJuring the permit review process, unless requested by LDEQ. **

Process l!~it Name Permit Number Date Submitted

II

11

II

II

II

• 8. LAC 33:1.1701 Requirements - Answer all below for new sources and permit renewals -

DYes [8J No II

Does the company or owner have federal or state environmental permits identical to, or of a similar nature to, the perm

for which you are aflplying in Louisiana or other states? (This requirement applies to all individuals, partnerships,

corporations. or othler entities who own a controlling interest of 50% or more in your company. or who participate in th

environmental manJgement of the facility for an entity applying for the permit or an ownership interest in the permit.)

DYes [8J No

If yes, list Sta tes: N/A

--

Do you owe any outstanding fees or final penalties to the Department? DYes DNo

If yes. explain beloJ/ Add rows if necessary.

II

II

II

1 II. limi d li bili ? DYes DNo

s your company a corporation or 1m lie IQ I uy company.

If yes, attach a cop~ of your company's Certificate of Registration and/or Certificate of Good Standing from the

Secretary of State. liThe appropriate certificate(s) should be attached to the end of this application as an appendi

Note: *Please refer. to Appendix D for the Certificate of Good Standing .

•

form _7195 _rOO

06/06/07 UO'Ptional** Fee Explanation: Use the space provided 10 give an explanation of the fee determination displayed above.

II

In accordance with LAC 33:1IJ.21I.B.l3.d. since this pennit modification does not increase caoacity. chan~e emissions bv

e FT.

en

ry

it

e

x.

9. Permit Shield Request ILAC 33:III.517.E.7) - 0 Yes [8J No

• If yes, check the a~propriate boxes to indicate the type of permit shield being sought. Include the specific regulatory

citation(s) for which the shield is being requested. Give an explanation of the circumstances that will justify the permit

shield request. Att~bh additional pages if necessary. If additional pages are used, attach them directly behind this page and

enter "See Attache1lpages" into the Explanation field. ;

Type of Permit Shield request (check all that apply):

II

Non-applicability determination for: Specific Citation(s) Explanation

0 40 CFR 60

o 40 CFR 61

,

o 40 CFR63 I

D II

Prevention of Significant Deterioration ,

II

0 II

Nonattainment New Source Review I

II

II

Interpretation of monitoring, recordkeeping,

and/or reporting ~~quirements, and/or means

of cri'mpliance for: Specific Citation(s) Explanation •

•

o 40 CFR60

o 40 CFR61

o 40 CFR 63

II

o Prevention of Significant Deterioration

. II .

II

o NonattainmentNew Source Review

II

o

State Implementation Plan (SIP) Regulation(s) r'6ferenced in 40 CFR 52

Subpart T II

form_7195 _rOO 06/06/07

•

•

•

10. Certification of Compliance With Applicable Requirements

Statement for AP~licable Requirements for Which the Company and Facility Referenced In This Application Is In

Compliance II

Based on information and belief, formed after reasonable inquiry, the company and facility referenced in this application is in compliance with and will continue to comply with all applicable requirements pertaining to the sources covered by the

permit 8PPlic8tionlias outlined in Tables 1 and 2 in the permit application. \

For requirements kromulgated as of the date of this certification with compliance dates effective during the permit term, I further certify that;:the company and facility referenced in this application will comply with such requirements on a timely basis and wiJl continue 10 comply with such requirements.

. II

CERTIFICATION: I certify, under provisions in Louisiana and United States law which provide criminal penalties for falsell statements, that based on information and belief formediafter reasonable inquiry, the statements and information I contained in this Application for

Approval of Emissions of Air Pollutants from Part 70

Sources, includirig all attachments thereto and the

compliance state&ent above, are true, accurate, and

complete. II

a. Responsible Of~cial

Name II

Lynn G. Bourgeois

Title II

Refinery Manager]

Company . II

Murphy Oil U.S.1\;, Inc.

Suite, mail drop, or division

II

Street or P.O. Box

P .0.Bolt 100 II

City II I ~tate I Zip

Meraux LA 70075

Business phone II

(504) 271-4141

Email Address II

Lynn _iourgeois@p1urphYOilcorp.com form_7195_rOO 06/06/07

CERTIFICATION: I certify that the engineering calculations, drawings, and design are true and accurate to the best of my knowledge.

b. Professional Engineer

Name

Mr. Paul Greywall, P.E.

Title

Director, Business Development

Company

Trinity Consultants, Inc.

Suite, mail drop, or division

Street or P.O. Box

12770 Merit Dr.

City I State I Zip

Dallas TX 75251

Business phone

(972) 661-8100

Email Address

Paul_ G reywa Il@trinityconsultants.com Louisiana Registration No.

29270

-------------- ----

11. Personnel rUr.4.C 33:11I.517.D.11

"

II

• a. Manager of Facility who is located at plant site b. On-site contact regardin ~ air pollution control

Name III DPrimary contact Name [2]Primary contact

Lynn G. Bourgeois 1 Mr. Mati Dobbins

Title II Title

Refinery Manager Environmental Engineer

Company IJ Company

Murphy Oil U.S.A., ~.nc. Murphy Oil U.S.A., Inc.

Suite, mail drop, 01ldiviSion Suite, mail drop, or division

Street or P.O. Box II Street or P.O. Box

P.O. Box 100 P.O. Box 100

City II State I Zip City State I Zip

Meraux LA 70075 Meraux LA 70075 ,

Business phone II Business phone !

(504) 271-4141 (504) 271-4141

Email address IJ Email address

Lynn _ Bourgeois@ll},urphyoilcorp.com Matt_ Dobbins@murphyoilcorp.com

II ;

c. Person to contac~lwith written correspondence d. Person who prepared this report !

Name II I Name I DPrimary contact

Mr. Matt Dobbins [2]Primary contact Ms. Valerie Barth

,

• Title II Title .

Environmental Engineer Principal Consultant

Company II Company

Murphy Oil U.S.A., Inc, Trinity Consultants

Suite, mail ~rop, 01idivision Suite, mail drop, or division

Suite 503

Street or P.O. Box 11 Street or P.O. Box

P.O. Box 100 4000 S. Sherwood Forest Blvd.

City " I State I ~~~75 City State I Zip

Meraux LA Baton Rouge LA 70816.

Business phone II Business phone I

(504) 271-4141 (225) 292-2661

Email address II Email address i

Matt~ Dobbins@mu,whyoilcorp.com vbarth@trinityconsultants.com

II

e. Person to contact'about Annual Maintenance Fees Oa [8]b Dc Dd D other (specify below) .

Name If Suite, mail drop, or division I

DPrimary contact

Title I) Street or P.O. Box ;

Company " City State Zip

I

• Business Phone II Email Address

form_7195_rOO

06/06/07

,

-~ --- • 12. Proposed Project Emissions [LAC 33:111.517.0.3]

II

List the total emissions following the proposed project for this facility or process unit (for process unit-specific

permits). Speciatelall criteria pollutants, TAP, and HAP for the proposed project.

II Pollutant Proposed Emission Rate (tons/year)

II 1,3-Butadiene 0.04

2~2,4-Trimethylpentane 4.271

II

II Ammonia 45.64

II Benzene 8.23

II Carbon Monoxide 1960.70

II Cumene 0.07

II Ethyl Benzene 1.48

II Formaldehyde 2.91

II Hydrochloric Acid 0.D3

II Hydrofluoric acid 0.50

II Hydrogen Sulfide 6.22

Methyl Tertiary Butyl Ether 10.43

II.

Naphthalene (and Methyl Naphthalenes) 0.53

II

11 N-hexane 7.91

• II Nitrogen Oxides 1220.06

II Particulate Matter (PM 1 0) 206.40

Polynuclear Aromatic Hydrocarbons 0:111

II

II . Sulfur Dioxide 684.49

II Toluene 8.25

II Total voe 600.30

Xylene (mixed Isomers) 8.11

I ~

• 13. History of Permitted Emissions (LAC 33:IlI.517.D.18]

• List each of the folloJing in chronological order:

"

• The Penni! Number and Date Action Issued for each air quality permit that has been issued to this facility or

I,

process unit (for process unit-specific permits) within the last ten (10) years.

• All small soJ~ce exemptions, authorizations to construct, administrative amendments, case-by-case insignificant

activities, and changes of tank service that have been approved since the currently effective Title V Operating

Permit or St~ie Operating Permit was issued to this facility or process unit (for process unit-specific permits). It

is not necess~ to list any such activities issued prior to the issuance of the currently effective Title V Operating

Permit or Sffite Operating_ Permit, if one exists.

Ji~rmit Number Date Action Issued

~pOO-OOOO 1- VO 04117/01

~pOO-OOOO 1- VI 02/08/02

30~.9-VO (rescinded) 03/31/06

304.6- VO (rescinded) 11109/06

2500-0000 J - V2 (incorporates 3029- VO and 3046- VO 11120107

11 items)

~.500-0000 1- V3 05/08/08

II

II

II

II

II

II

II

II

• JI

JI ,

II

II

II

II ,

II

II .

II

II

11

II

11

II

II

II

II ,

II ,

II

II

II

II

• II

U

11

torm_7195_rOO

06/06/07 14. Facility-wide Permitted Emissions - For Process Unit-Specific Permits Only [LAC

• 33:III.517.D.3J II

List each of the following:

• All currentl~leffective air quality permits for this facility. All process units located at this facility should be

represented ih this section. This includes any Acid Rain or PSD permits.

For each listed currently effective air quality permit:

• Show each J,brmitting action's grand total for each permitted pollutant. These rates should be those shown in

the pennittin~ action as issued by LDEQ and not those shown in the application for the permitting action.· For

administrative amendments, it is only necessary to state the emission rates that were amended.

• Group the pJmitted emission rates by permit action. Consult instructions.

As the last entry, sho~ the facility-wide grand total for each pollutant.

Permit Actions , Date Action Issued Pollutant Permitted Emission Rate

II (tonstyr)

N/A II

II

II

II

II I

II

II

II

II

II

II

'. II

II

II ,

II

II

II

II

II

II i

II

II

II ,

II ,

,

II

II

II

11

II

II

II

II

II

• II ;

II

.

form 7195 rOO

- -

06/06/07 •

•

•

15.a. Enforcement Actions (LAC 33:1I1.517.D.18] - [8J Yes 0 No

If yes, list all federallhd state air quality enforcement actions, seltleme~t agreements, and consent decrees received for this facility and/or pr&ess unit (for process unit-specific permits) since 'the issuance of the currently effective Title V

"

Operating Permit or State Operating Permit. For each action, list the type of action (or its tracking number), the

regulatory authority o~ authorities that issued the action, and the date that the action was issued. Summarize the conditions imposed b~ the enforcement action, settlement agreement, and consent decree in Section 23, Table 2. It is not necessary to submit a 'bopy of the referenced action. Add rows to table as necessary.

II

Type of Actloh Issuing Authority Date Action Issued Summary of Conditions'

or Tracking NuJ,ber I

Included? ,

AE-CN-08-0l22 !I Louisiana Department of August 29,2008 ~Yes DNo

Environmental Quality Note: The ongoing Jrrespondence related to enforcement action AE-CN-08-0122 including the compliance order, compliance plan, and!~equest for adjudicatory hearing have been included in Appendix E.

. II .

15.b. Schedule for Compliance [LAC 33:III.517.E.4] l'8l Yes 0 No

If the facility or pro~less unit for which application is being made is not in full compliance with all applicable regulations, give a dbscription of how compliance will be achieved, including a schedule for compliance below. Add rows as necessary, See instructions.

The compliance plaJ~ for Enforcement Tracking Nos. MM-CN-02-00 15 and AE-CN-08-0122 submitted by Murphy Oil USA, Inc. to thell.ouisiana Department of Envirorunental Quality on October 26, 2006 and October 8,2008,

respectively, are included in Appendix E of this application.

16. Letters of AI~proval for Alternate Methods of Compliance - 0 Yes l'8l No

If yes, list all corresp1bndence with LDEQ, EPA, or other regulatory bodies that provides for or supports a request for alternate methods of1bompliance with any applicable regulations for this facility or process unit (for process unitspecific. permits). Li~t the date of issuance of the letter and the regulation referenced by the letter, Attach as an appendix a copy of ~11 documents referenced in this table. Letters that are not included may not be incorporated into a final permit. ~dd rows to table as necessary.

Note: No alternate JLhOdS of compliance are being requested in this permit application that have not been

incorporated into lhel:current Title V Permit No. 2500-00001- V3. .

Date Letter Issued] Issuing Authority I

Referenced Regulationts) Copy of Letter Attached?

N/A II DYes DNo

II D Yes UNo

II DYes DNo

II DYes 0 No II

17. Initial Notifications and Performance Tests (LAC 33:111.517.E.l( - [8J Yes 0 No

If yes, list any initiailinotifications that have been submitted or one-time performance tests that have been performed for this facility or prdcess unit (for process unit-specific permits) since the issuance of the currently effective Title V Operating Permit or State Operating Permit in order to satisfy regulatory requirements. Any initial notification or one-time performance test requirements that have not been satisfied should be listed in Section 23, Table 2 of this

"

application. Any notifications or performance tests that recur periodically should also be properly noted in Section

23, Table 2 of this aplplication. Add rows to table as necessary .

form_7195_rOO 06/06/07

• Initial Notification or

One-time perform~nce Test'! Regulatory Citation Satisfied Date Completed/Approved

NSPS Notification of 40 CFR 60.7(a)(I) Submittal dated July 29, 2008

Construction Comm~ncement 40 CFR 63.9(b)(2)

(300-4) IJ

NESHAP Initial Notification

(300-4) II

NSPS Notification of 40 CFR 60.7(a)(I) Submittal dated August 8,2008

Construction Comm~ncement 40 CFR 63.9(b)(2)

(300-6A) II

NESHAP Initial Notification

(300-6A) II

NSPS Notification of 40 CFR 60.7(a)(I) Submittal dated September 19,2008

Construction Comm~ncement 40 CFR 63.9(b)(2)

(250-8) II

NESHAP Initial Notification

(250-8) II ••

18. Existing pJvention er Significant Deterioration or Nonattainment New Source Review Limitations ILA!C 33:III.517.D.18]

Do one or more emi~sions sources represented in this permit application currently operate under one or more NSR permits? C8] Yes D No I

If"yes," summarize the limitations from such permit(s) in the following table. Add rows to table as necessary. Be sure to

I .1. lirni fi h ' ( )' S 13 d 14 f h' r

note any annua emissions mutations rom sue permit s m ecuons an ot trns apphcatron,

Permit Date Emission Pollutant BACTILAER Averaging Description of Control

Number Issued Point ID Limit 1 Period Technology/Work

No. Practice Standards

PSD-LA-566 II CO 197.81b/hr Hourly High temperature

06/14/1991 2-77

II regeneration

PSD-LA-566 II High temperature

06/14/1991 2-77 CO 866.4 tpy Yearly

II regeneration

PSD-LA-566 II

06/14/1991 2-77 PMw 26.01b/hr Hourly ESP

II

PSD-LA-566 II

06/14/1991 2-77 PMIO 113.9 tpy Yearly ESP

II

..

PSD-LA-19 qp/07/1977 1-76 S02 5761bs/day Daily Emission limit

PSD-LA-19 ~~/071l977 1-76 TSP 105lbs/day Daily Emission limit 1 "

For example, Ib/MM Btu, ppmvd @ 15% O2, Ib/ton, Ib/hr

form_7195_rOO 06/06/07

•

•

•

'.

19. Air Quality Dispersion Modeling ILAC 33:111.517.D.15]

Was Air Quality Dis}ersion Modeling as required by LAC 33:11I performed in support of this permit application? (Air Quality Dispersion Modelin~ is only required when applying/or PSD permits and as requested by LDEQ.)

~asY~: Q~a~~ D~l,,;on Modeling completed in accordance with LA C 33.111 ever been performed for this facility in support of a air perJlil application previously submitted for this facility or process unit (for process unit-specific permits) or as required by otherllregu{ations AND approved by LDEQ?

I8l Yes D No I .

If yes, enter the date the most recent Air Quality Dispersion Modeling results as required by LAC 33:III were submitted:

May 31, 2007 I

If the answer to eith~r question above is "yes," enter a summary of the most recent results in the following table. If the answer to both questions is 'I'tno," enter "none" in the table. Add rows to table as necessary.

I .

Calculated Maximum Louisiana Toxic Air Pollutant

Ambient Air Standard or

Pollutant Time Period Ground Level (National Ambient Air QualitY

Concentration Standard {NAAQS})

Visibility 24-hr 0.442 tldv 0.5 L'ldv Best Available Retrofit

Technology (BARD Exemption

Threshold

Formaldehyde II Annual 0.004 7.69

II .

Ammonia 8-hr 0.2 640

II ,

1,3-Butadiene Annual 0.35 0.92

Naphthalene II 8-hr 199.7 1,190

Polynuclear Annual 0.03 0.06

Aromatic

Hydrocarbons

Xylene II 8-hr 1485.6 10,300

n-Hexane II 8-hr 759.3 4,190

Hydrogen II 8-hr 36.00 61.90

Fluoride

Hydrogen II 8-lrr 50.5 330

Sulfide

Toluene II 8-hr 1211.6 8,900

Benzene II Annual 9.6 12 Note: The toxics Inodehng results listed above were submitted III March 2002 and are the only facility-wide modeling submitted since the issuance of Title V Permit No. 2500-00001- VO.

form _7195 _rOO 06/06/07

•

•

•

20. General Condition XVII Activities- ~ Yes 0 No

Enter all activities that qualify as Louisiana Air Emissions Permit General Condition XVII Activities.

• Expand thik table as necessary to include all such activities.

• See instructions to determine what qualifies as a General Condition XVII Activity.

• Do not incl~de emissions from General Condition XVII Activities in the proposed emissions totals for the permit li . 'I

apJ'ilcatlOn.

II Emission Rates - TPY

II

Work Activity Schedule PM10 S02 NO. CO VOC Other'

Carbon ReplacemeMtI Recharging 8 timeslyr - 3.5 2.5 - 0.14 0.04 (H2S)

II 0.02 (NHJ)

Changing Filters II 300 times/yr - - - - 0.07 -

Cleaning of Equipn:!ent 96 timeslyr - - - - 0.02 -

Clearing of Pipelin~s 240 times/yr - - - - . 0.47 -

C M' II 24 times/yr 0.02

ompressor amtenance - - - - -

Draining Compressor Bottles 7200 tirnes/yr - - - - 2.7 -

Instrument Maintenance 240 times/yr - - - - 0.43 -

" -

Miscellaneous Equipment 21 times/yr - - - - 4.4 -

Preparation II

Nitrogen Blowing q:fPipelines 240 times/yr - - - - 0.06 - :

Pump Maintenancej 1000 times/yr - - - - 3.6 -

Sampling II 360 times/yr - - - - 0.15 -

Sludge Removal II Twicelyr 1.95 ,

- - - - -

Solids Removal fro~ Sumps S nmes/yr - - - - 0.24 -

Solids Loading/Unloading 58 times/yr 1.45 - - - - -

Tank Gauging II 390 times/yr - - - - 0.076 -

Valve Maintenancej 960 times/yr - - - - 1.30 - !

Portable Waste Tanks (for storage As Required 0.06

II - - - - -

of samples to be recycled)

Painting Operations' 2,200 gallyr - - - - 2.9 -

"

Welding operalioJ (welding rod) 75lb/week,

100lb/week 0.04

during - - - - -

II

turnarounds

Parts Washers OpePations 400 gal/yr - - - - 1.3 -

" .

Taking Floating Roof Tanks Out 5 times/yr - 1.9

of Service II - - - , -

Taking Fixed ROofllfankS Out of 4 times/yr - 0.30

Service j - - - -

" Note: *No changes were made as part of this application. Calculations have been included III Appendix B of this application. I

21. Insignificant Activities [LAC 33:11I.501.B.5] - [8] Yes 0 No

Enter all activities lliat qualify as Insignificant Activities.

"

• Expand this table as necessary to include all such activities.

• For sourc~~ claimed to be insignificant based on size or emission rate (LAC 33:HI.501.B.5.A), information must be supplied to verify each claim. This may include but is not limited to operating hours, volumes, and heat input

form_}195 rOO 06/06/07

•

•

•

ratings.

If aggregateemissions from all similar pieces of equipment (i.e. all LAC 33:1II.501.B.5.A.1 activities) claimed to be insignificant are greater than 5 tons per year for any pollutant, then the activities can not be claimed as insignificant' and must be represented as permitted emission sources. Consult instructions.

II

•

Emission Point ID No.

Citation

- EJpty Drum Washing See Appendix B LAC 33:III.501.B.5.A.7

- A~ine and Diesel Storage Tanks See Appendix B LAC 33:I11.501.B.5.A.3·

I~ See Appendix B LAC 33:III.50I.B.5.A.6

- Laboratory Equipment Vents

- Di~sel Storage Tank Y - V -310 See Appendix B LAC 33:III.501.B.5.A.3

StJrage and Use of Water Treating See Appendix B LAC 33:1II.501.B.5.B.8

- C~~micals

- A('6eous Caustic Storage Tanks See Appendix B LAC 33:1I1.50I.B.5.B.40 Description

Physical/Operating Data

form _7195 _rOO 06/06/07

•

••

•

22. Regulatory 'Applicability for Commonly Applicable Regulations - Answer all below

,

[LAC 33:III.511.D.101 .

Does thisfacility co~tain asbestos or asbestos containing materials? [8J Yes 0 No

If"yes," the facilityipr any portion thereof may be subject to 40 CFR 61, Subpart M, LAC 33:IlI.Chapter 27, and/or LAC 33:II1.5151 and this application must address compliance as stated in Section 23 of this application

Is the facility or prJhess unit represented in this permit subject to 40 CFR 68, or is any otherprocess unit located at the same facility as ~he process unit represented in this application subject to 40 CFR 68? [8J Yes 0 No

If "yes," the entire :facility is subject to 40 CFR 68 and LAC 33:IILChapter 59 and this application must address compliance as stated in Section 23 of this application;

II

Is the facility listed in LAC 33:111.5611

I

Table 5 [8J Yes 0 No

I

Table 6 [8J Yes 0 No

I .

Table 7 [8J Yes 0 No

Does the applicant bwn or operate commercial refrigeration equipment normally containing more than 50 pounds of refrigerant at thi~/acility or process unit? [8J Yes 0 No

If"yes," the entire facility is subject to 40 CFR 82, Subpart F and this application must address compliance as stated

in Section 23 ofthi~ application. .

form _7195 _rOO 06/06/07

•

•

••

23. Applicable Regulations, Air Pollution Control Measures, Monitoring, and Recordkeeping Important points for Table I [LAC 33:III.517 .D.I 0]:

• List in Tabl~1 I, by Emission Point ID Number and Descriptive Name of the Equipment, state and federal pollution ab~tement programs and note the applicability or non-applicability of the regulations to each

• ~~~s~· the JadingS for the columns in Table I as necessary to reflect all applicable regulations, in addition to any regul~bons that do not apply but need an applicability determination to verify this fact.

• For each piJe of equipment, enter "I" for each regulation that applies. Enter "2" for each regulation that applies to thl~ type of source, but from which this source of emissions is exempt. Enter "3" for equipment that is subj~t to a regulation, but does not have any applicable requirements. Also, enter "3" for each regulation that have applicable requirements that apply to the particular emission source but the regulations ~tirrentlY do not apply due to meeting a specific criterion, such as it has not been constructed, modified or ~econstructed since the regulations have been in place.

• Leave the sJ'aces blank when the regulations clearly would not apply under any circumstances to the source.

For examplet LAC 33:111.2103 - Storage of Volatile Organic Compounds would never apply to a steam generating b8iler, no matter the circumstances.

C I· /I .

• onsu t mstructions.

II

Important points for Table 2 [LAC 33:III.517.D.4; LAC 33:III.5l7.D.7; LAC 33:111.517.0.10]:

• For each pi~he of equipment listed in Table 2, include all applicable limitation, recordkeeping, reporting, monitoring, ~nd testing requirements. Also include anyone-time notification or one-time tests performance test requirements that have not been fulfilled.

• Each of the~~ regulatory aspects (limitation, recordkeeping, reporting, etc.) should be addressed for each regulation tHJt is applicable to each emissions source or emissions point.

• For each re~ulation that provides a choice regarding the method of compliance, indicate the method of compliance that will be employed. It is not sufficient to state that all compliance options will be employed, though multiple compliance options may be approved as alternative operating scenarios.

• Consult instructions .

11

Important points for "Fable 3 [LAC 33:IIl.517.D.16]:

"

• Each time a 2 or a 3 is used to describe applicability of a SOUTce in Table I t an entry should be made in Table

3 that explaias the exemption or non-applicability status of the regulation to that source.

• Fill in all reqhested information in the table.

• The exact n~lgulatory citation that provides for the specific exemption or non-applicability determination

'"

should be entered into the Citation Providing for Exemption or Non-applicability column.

• Consult InstJ!uctions.

Important points for \fable 4 [LAC 33:IlI.517 .D.18]

• List any siri~le emission source that routes its emissions to another point where these emISSIOns are commingled;lwith the emissions of other sources before being released to the atmosphere. Do not list any single emission source in this table that does not route its emissions in this manner.

• List any andl1all emission sources that are routed as described above. This includes emission sources that do not otherwisJ appear in this permit application.

• Consult instiLctions .

form _7195 _rOO 06/06/07

•

•

•

e..

! f-:::-t-I~I-H

:::: I

~ ~ I

I

=

~ ~I

- ~ - -

~ II

•

•

•

.

~ t-"f---t-I-I--l

~ :-

t - - - -

.

,Jl - .. ~. -

•

<

z

<

§

~

0

0 ..J

>- z :i

~ '"

t.J .j_ C2

z

G: '" -e

~ c..

t.J ..J ~

• 0:: 00::

X

:;, ;;..":

< XZ

0:: c..~

'" 0::'"

~ ~~

:;t;;

x

;.>

-e

0::

'"

::;: •

c Z

.. ..

Ui

o Z

c .9

f U

..

15

N

.. tJ

;

'§

E

"

u

e Z

o Z

..

15

N

g e:

u o ...

g e:

u o ...

o Z

o Z

e:

u o ...

o Z

..

15

N

.... 00 ,,0 _ 0

~~

....

o Z

•

a

Z

c Z

c

Z

a Z

a Z

" ..

<0 s:

C '"

~ 0

E

:b- N

C ...

:: V c

"" ,. ...

9 ,.

...

... ...

a ~

:f 0

x §;

'" .,

"$ ']5

~ ...,

g 0

'"

e: It

U U

<:> C>

.. .. ._

-= 'S:

~=-

.,-

-~

- ..

U']5

UN

'" -

c

., d

'9 '"

~ , E f::

z; 8 u

~ <:>

...

-< W

Z ~

-< 5

Vi QI .. -

.5 J!!

S ~ 'P.:

0 ;:- E ~

(,,) -l !- .. 0

~ ...

>- z :i ::::i o L>

~ ·c

- '" -e ~.<>

W -iC2 ::> e.-=

z '" -< QI

ti: ::> ~ c ::::J:'=

Q.. c.'"

W e ..

..J C. -e . _ "

• ~ .~ -= ..

:0 ~ -l ;. ,.

X " ... .,

-< ;2 e:~~

::> >- z

-< :t: '" '-'l 'C a "

0:: Q.. C. " 0'<:

W .c 10.0 II) •

W 0:: ell W t ~~ ~

...

::;: ::> ,_; :::;: 'r; :s '"

::;: Q

rn Z .. g " It

X ...: ~ ~ ~.~

'-'l

::> I- '§.E~t:

-< -< E ~ ru 0

0:: !- 8= ~:'"

w Of) " . ..

::;: ,..; .<:=[

- u

W '-0 s :

-l " .. 0

0::0 .~ ~~

-e

1- ~ ~ ~

" ,,-

f;.I U IA

f:~ Ig

ee -" 0

UJ .. u ';; 4

..

:0

" " ~

:0 :0

'" N d

-o

g g .:.:

"-

It e: o

0

u u ..

'" '"

.. .. ,,; z;

e

•

--~--- -----

•

'"

I-

Z

W

~

<I: w

Z 0::

<I: ;5

~ 0'

::l ~

° >-

0 .....l I-

>- z :i :i

IX en <I:

w .{ C2 ::l

Z OIl <I: 0'

~ :l .... :.::

w .....l 0 -e

• a:

>o:0IX ...l

:l ;.. <I: ~

<I: :I: Z W

c:: e, :.:: 0

WIX~ W

~;:J ~

z ,_;: Q

OIl Z

X «

w

;:J I-

<I: -e

c:: i-

w '"

~ N

W

...l

~

«

I- oj

Z

Q

i:

·0

• ""

"

.~ -c

..,

·e -'"

w "

.,

I- '" ....

... o

•

a Z

a Z

a Z

a Z

o Z

o

Z

II ~

,I,. ..

'" -c

<Il ::>

'0 ::i!

-

-

ci

'"

c:

u o ..

-

'" '0

o

-=

..

E

o ....

9

•

f'

d

z

e

"

0

• "-

c

,2 -c

t::'(

's ::

W.J c

..

I- •

•

••

c o -.:

S G

-c

Z

-c

Z

o Z

o 0 a Z Z Z

e Z

-c

Z

~ "

,:g

f,.

~

-c

.~

o ,::;

f-t

" ....

.r. ~

.. ... '-I>. .. _

,. ..,

-e ·5

'"

- f-

-

-

........: -

-

.. u

.3 9

E

.,

u

I--

¢ Z Q

•

•

•

c

c ....

. ~ ff

.. ..

.. "" " - ~ ...

<~

" ...

-

-

-

I--

E

..

E ~

.~

~

~

"2 o

..

;;

Vi

v ...; <::>

o Z

a

Z

o Z

o Z

o Z

I

(Il .., <::>

" o

.~

U

~

.., ,..,

u

:5

o Z

-

-

•

•

•

"

.S!

~ o

co Z

o 0 0 z z z

~

z

-

-

-

o Z

-

"

~

.:

" ao(

.. _

~z

,; Z Q

-

-

-

~ c ..

~

.!:

" <Too:(

.. _

~z

-

.. "

a

'§

e

o u

-<> .... .... o

•

•

•

o Z

a Z

c Z

o Z

-c

:z.

s Z

o Z

000 Z Z Z

c

Z

-c

:z.

e Z

c Z

o Z

-

'" .8

...

a

s

z;

~

z

s

z

.. "

;

'§.

e

8

-

.; Z Q

•

•

•

..

E

'"

e z

o Z

a ;Z

a ;Z

o z

e ;Z

a Z

a ;z.

a ;Z

o ;Z

.s Z

s

Z

-c

Z

$

Z

-

s

;Z

s

Z

I-

c

.2

E o e :;

'§

E

"

u

ci Z Q

\

\

•

•

•

It

o o ~

o Z

a Z

o Z

c Z

a Z

c Z

c Z

o Z

.. ... C co

]

E

d

:<i It

u o ~

o Z

o

Z

o Z

-

c

" .. "

~~

.. ... '-10- v_

>'0 <.5!

... .. Q.

-

i:

..

E

-~

• ~ a a s

~~ Z Z Z

~

-=

0

~

!

'" •

::;

z.

e

i:

·0

• "-

=

·S a-

~

·il ..,.

~ e

~ I-

-c N .... o

•

•

•

c

~

...

. ~

a:

1:

"

o

a Z

c Z

~

" ,. ..

~ff

" .. ... "" v_

,. ..,

4( .~

.. e,

«

~

«

Z

~

Z

o Z

a Z

-

-

" e

'3 o

~ Z

-c

Z

s Z

.. " c

"

e

E

"

u

" Z

Q

-

o Z

3 8

~ ~

.;.;

""

~

-

~ Z

-

-

s Z

;:'l

... o

o Z

•

-e

Z

-e

1!i

;l

0

:.-W ..J

:i

j;(Z Vl

~ <=

z

ii: Vl«

;lll.

~ ..JQ

• j;( -~

x 0«

;l >z

« :I:~

" II.~

~ I!t:.Q:l

:;;: ;l .

:t !-

<Il

X

;l

-e

~

~

:t •

e

c

.. "

.~ S

" ... "'W. ,,_

'" .,. « 0

...

~

o z

e z

c Z

o Z

!:

c

"

]

E

8

c Z

c z

o Z

.,;

-o

1:.:

u o

"

.s ~<

"" .:

o z

e'

•

•

" "

E

e

.~

" 0 C::z

>

'E o

a Z

c Z

a Z

c z

o z

" 2

...

e E

~ c

E

"'_ ",

c "

:: ~ t:>

<= "

" ..

E e

- u

0 u

'i "

0

~

.. .!!.

~ ~

.,; .,;

'" '"

e: e:

u u

0 0

v .,. ;; Z o

•

•

•

c ..

E 1::

"

~ 0

"z ...

C o

..

E

til

•

•

•

o Z

c Z

~ "

._ a

o .;:;

~'O

" " -e a

o u '" ,.., " " e ... . _ a

J:. -;::;:

~ii .~

-

'" ..

22 it:' ~'!!:

.....

.

.."

,0

::;: .:;

'~

a Z

c Z

-

o Z

-

.~

c

c .S

~ o

.. " " "

~

E

d

-

~

c

~ '" " " _ .[;

a u a.. "

.~ ~

•

•

•

;. " I:

.. "

~ff

" '" '"10-

" - ~ ."

«.S!

'" " 0..

-,.....

;-

-= o

c Z

c Z

" z

c Z

c c c Z Z Z

c Z

-

c Z

-

..

of

~ c ..

e

~

'S

~~

"z

o Z

c Z

-

5 ,5

~

;E:

... o

•

•

•

c z

" "

E

" ...

. ~

a: ~

"

o

o Z

c Z

I-

I---

I-

o

Z

Cl

•

•

•

o Z

o Z

c Z

o Z

c Z

o Z

c Z

o Z

-

~ z

o Z

o Z

o Z

-

.;

Z

Q c

c .g

"0; »

~ )

:"l

- o

•

•

•

c

€

..

':;

~ c C::z

,.

" o

:: ,50

::<

-

'--+-- .. '-, f-

I-

z

I

•

•

•

o -D

ct:

U.

U o ...

..,00 uO _0 -" r... ~

!-~ r- ,

J

:::1 :;-1

~

o

'"

~I

(..,1 ~I

'" o

.. a

<C> '" '-

c .., N .

•

•

•

CD .-;

a

;; z o

•

•

U

>-z Q::-

•

-'

o

"',

c.:

LL.'

Li

0' .;-,

" o

'"

Z

Q

,« o

,.,

o 00 ,"'=

," ,"

!-

------------------------------~------------------------------------------------

'.

•

~oo " 0 -0 .£;N

'" -

1-::1:

N

-c -c

« 0

'" 0- -

'7 0 0 0

- 00 QO 00

"'" "'" "'" "'"

C '" C C

'" " OJ '"

l- I- l- I-

- 11.

e

'0

Q.. 0 -c -c

ez « '" o- 0 I

• '( 0 -

o " 0 0

.;;; Q - 00

'" - 00 00

's II

L>J g

'" .,

;

o ~

0- o o N

•

•

•

24. Emissions Inventory Questionnaire (EIQ) Forms [LAC 33:111.517.0.3; 517.D.61 Complete one (I) EIQ for: .

• Each emissiog source. If two emission sources have a common stack, the applicant may submit one EIQ sheet for the dhmmon emissions point. Note any emissions sources that route to this conunon point in Table 4 of the application.

• Each emissioris CAP that is proposed. In general, this applies to each source that is part of the CAP.

• Each altematJloperating scenario that a source may operate under. Some common scenarios are:

I. Souftes that combust multiple fuels

2. Sou~es that have Startup/Shutdown max lb/hr emission rates higher than the max Ib/hr for normal operMting conditions would need an EIQ for the Startup/Shutdown emission rates for those sources

• Fugitive emissions releases. One (I) ElQ should be completed for each of the following types of fugitive

.• II .. .

emISSIOns sources or emissions points:

E .11

I. quipment leaks.

2. Non11equiPment leaks (i.e. road dust, settling ponds, etc).

For each EIQ: I

• Fill in all requested information.

• Speciate all T~xic 'Air Pollutants and Hazardous Air Pollutants emitted by the source.

• Use appropridte significant figures.

C I· n .

• onsu t instructions.

II

The EIQ is in Microsoft Word Excel. Click on this link to get to the EIQ form,

http://www . deg.louisi a~a.gov/portallLinkClick.aspx?link=pennits%2 fai~102 [6-6-07 EIQ.x Is&tabi d=27 58

form 7195 rOO

- -

06/06/07

z E

•

c:

.2 1i.<: ';: Z :::

.. Q

"

E

;>

'0 >

<: <:

Z Z

.( .( .( .( <: <: .(

-'i:' ~~

c ~. • • • * * * c: c:

<';

~1:

. -

" Z

N ...

o 0

o <:>

ci ci

•

~ s

..

z

.. ~ ....

"'<::

~] 4 • •

<:<:.

..;

~

II

~

;> o <,f)

.. c:

.~ ·s

'-l ..

-s

... o IJ

E

" c:

.~ .~

:::

.. Q

- ~ ,. M ~ r-;-

j; ~ ;r ~ : ~

o - 0 0 cO 0

~ f"o. 0 - 0 t"o""'I

V') 0 - - - r""l

o 0 000

o 0 0 0- 0 0

.-. '" C

o ;::

u·

2

...

'" c

..:-.a:~

,,~

.. .. -'0 <,f) .. ... ..

Ol!)

:<: II .. " .- 0

".&>

:I: <

t-

o ....

= <Iol

..

= ....

Q e .;;:;

III

...

E ~

" Co

c:

.. ..

~

... ::> 0. c

-

...

..

:c

:£1

C! 0: ~ ~ q ~ ~

000'0000

0000000 0000000 o 0 0 0 0- 0 0

•

•

•

•

z E

-

';;

~ .€

.. '"

l?,g

.>: .. ... > ..

Vi

" Q.

=

.. "

s

'0 >

;;; E

u

]

00 o o N .... (l)

..0

a

(l) o (l)

c

.!:: <

...

,£

~ E

.. z

--~----------------------------~------- _--

o o q o o q -o V>

«:

N

~I

.. 1--f-4-4--1

..

:r: 't:I c os

't:I

~ ~

o

.. ..

g ~ -=

" .. 0

= ,~ .c

- ...

".= Q. QJ

; ~ ~

Uu

: :

: :

E < ~

0./')

, "

o .~ 00 ~ ,.

<J> o Q.

E

..

I-

* •

*

:5g:5ogggg

o o· 0 '0 0 0

•

•

•

z E

o

00 o o N ..... IU

"E

IU o 4)

Q

ere> o N

OJ) <=

.~

u 0.. o

6

"

6

.;:;

d

z

.... o o 0::

"E

"

u::

... o ~ u

~

... o

~

"

E

'" o

.. Co Co <'(

.... o ..

6

" <=

..

.~

Co .;::

~

.. Q

-c

<n I

o 00

<5 Z' Q~

-!::

..

E

::l

"0 ;>

<'( ..:

Z Z

-;;; E

v

]

o z

Q

... .,

.. <

~ Z

..

" Po.

..

w ... "- -"= = "

(,;)~

"t>

"

ti'i

E -< ~

...... 'C

o .. 00 :c

::l

'" o

0..

E

.. I-

< < z z

..:

e~ .. ...

e.c 8 g ';;] 6 6 ~;::. v v

... p.. ... <'(.Q f- e

..

;;:Z

..:'" :c<

u

'7 .... 00 0 O? ~

00 <:> o .....

- ....

o -

o 0

o 0

o <:>

o 0

"

c: " ... c:

" "

rf. I~ ~

•

•

•

z =

00 o o N ....

<!,) .D

5

u I!J

c

~ E

.. Z

< <

z z

:$

.,

'" ..

= o

IF)

C .s

~

'"

"s

I"l ..

-=

....

o ..

E

'" I':

"

of

0. "~

~

OJ Q

0:>

Z

Q~

-9

u 1=

..2

o

>

"

E

]

o z Q

.= ~

o ~ Q.. ~

..

" ... 0= " .. ~

"'~

"s

w

E 0\ ~

,

o u 00 "

?

::> IF)

o ~

E

~

« <

~ < < z Z Z

< < < «

Z Z Z Z

~ <II

= o

"C u ;::l

!::

<II C

... ...

~

:;

Q. C

.. ..

=

;

~

.5

< < < « ...:;

q q c> coo 0 o 0 0 0: 6 -6 0

-1::

~I

~I

s

z

~I

o 0 0 0 0- 0- 0

g g g g g g g

•

•

•

z f

q-

o DO

~ Z -c I-

.,; z Q

-

o Co

E

.,

1-

~I

--'" I':

.g

u

= ..

.... ...,

.S

.. OJ

~

....

::J Q..

=

- ::l

Co C

..

.. :r:

;.., 10.

E = <l.I

> C

- C

Q

._

'" '"

..... o .,

E

'" =

.. ,.

Q. .;:

~

OJ

C

-c

Z

-~

.. >,

::l';)j C C r:: 0 <::,

C! 000 o 0 0 ci

goo 0

o g g g

o

Z

cO'

•

•

•

00 o o N

.... <l)

S

<l) u Il,)

Q

z ::

~I ~I

« «

~ ..

E

..

z,

~ .0::: o ';;;

..

'S

w ..

.;

.... o ..

E

'" '" .. :.

ii ';: 1;:

.. Q

" .. ",

", '" '" ,:

_I bD

"':: e

.:3, j

"

E

'" "0

>

« «

Z Z

.. ..

~ « '" Z

..

.. 0..

«

Z

-

= o

'0;;

ell

~I

~I

~I

L_ ~ ~ _

~::

"'~ .. ... -",

'" .. ... ..

or_;)

.E ... OIl:'

,- 0

".0

::c:«

~~ ",'"

'" - - ... ia >«

.. "

o ..

..

2<

~ ... .. 011 .. ..

- .. .. ..c:

E '" ~ .~

CO

« « « « « « « z z z z z z z

D

'a . ..... .. 0 011

:ggota

... " .. ..c: ~..c - u

U .. I':

Q~

«

« «

«

...

8

Q:!

bD I': '::: .. o

Ii:

-

'"

.~ ~

.. '"

,- ..

e .. Ii) ; 'aU

.. ~

t: ..

's 'OJ

... ~ ..

0..

D

o o o v

.. "" .. <.0

!- e

'" ..... z

""", «< ::C:u

o 0 0 000 0

000 0 0 0 ci

o 0 0 a a 0 0

g g g :5 g g g

•

•

•

z ::

~.:::

u-

.. " -"1:1

v; .. ... ....

~()

.c ... ~"

.- 0

".&:J

=~

~ - UN

.. - - ._ V;-

.... ..

o ...

..

2<

-"

... C><>

" .. - ..

".c

E ~

... -

C;Q

~I ~I

.... "

0;

E ~ ~ E Z Z

~

o

E

::I

-0 >

~I

~ z

]

.5

-c

00 o o N ... Q) .D

6

11.1 U 11.1

c

c ..

"

... Q

~ u .. ;;

... Q

I:

. ~

.. ..

~

:!

'"

E

... (;j

e u

~ .~

.( 0::1

U

-

... Q ..

E

or c ...

"

Q. '': ~

OIl

Q

o

.... o o I>: 011 I:

.~

li:

I--

o

2>

00

« « « « Z Z Z Z

« «

o Z

-.:-

.. >.

'"I: ..

I: I:

<.;.

.,

:!

.. g:;

I:

"e 's

~ "1:1 .. ..

8.

o .. C.

~'i:: - - -

~.cMOOO

"'Ii!; ~ 0 0 0 ~ .0 6 0v' 0v' <::.0 v

..

c. .. ~.D

f- ;

-z c.", <.( :tV

C! 0 C! C! o 0 0 0

000 0

o 0 0 0

o 0 0 0

z =

•

"

E

:;;I

'0 >

0; E

u

.5

« « z z

o

0, 0 0, 0

0, 0, 0

--.:'

Of >.

"'.: '"

c "

<!

E~ " ...

eoE

.- '"

.. ~

"'.. ~

<!::.

•

.. " ...

:::J o

'"

...

Q. '" <~

!- g

.... z Q.", « ::Cu

,. ~ ~ ~ =t ~ ~ ~

o 0 CQ a

a - 0 M - - - .,......

o 0 0

o 00,0

-;c

.g

... ::l ...

- '"

.s

... ...

~ ;

!:L c

.....l

6

0..

:3

C/)

I"'"l

,

... o

"

E

'" c

" ;-

.~

. .: :;:

.. Q

~I

~ ~--+--t--~~

..

::c 'Q c ~

'Q

..

'"

;::l

Ql = "'" ._

C)

.% ~ "N

~.::

"'~ '- '"

o ..

...

2<

-" ... bb

" ... - " " -

e~

d.":

CiQ

'" ...

o z

OJ

:::J

"" ._

o

" CI.

>. !-

o z

Q

" -;;,...,

c ' ... -

~

~

o

5

w

" "

:c

:;;I

'" o

CI.

E

...

!-

•

'i:

oj

:;

~

•

•

•

z E

iii .E E

.0 ::I VI

'o

"

8

00 o o N ... <l) .J::;

E

<I)

~ o

t!

~ ]

--~

--,::

o U

< •

I'

IJ.I -o ~I a

~I ..

II

~ ~I

~I

-c Z

u

a

::I

~

... ...

o z;

I-1.l

6

....I o

(fJ

<C o o

- I

o 00

o

z,

Cc

- -

e .2

.~ ~ ~

;: z z

..

C

...

J!l

.. « «

~ Z Z

... .. 110

'iii'

c

~

u ::I .. ...

.5 t ~

;

c.

.s

0; 1--~-1-~-I

... :r "0 c ..

"0

...

:5

'il ::I t.l.. ... o OJ c. ;...

!-

o

-;~

,,e .,

c e

<!

;::

"

-= '0

110

•

•

•

00 o o N ... o .0

5

u o

c

<{

z

-e

z

" C

a

"8 N .co ::E

~ :;

0;S

..

z,

"

a

::I

"0 >

'" ..

'5 z

<{ <{

z z

o

000

-

~

..

~

::I o en

'" =

.~

'E

w ..

.;:

.... o ..

S

'" = ...

.~ 0.

... ..

t Q

UJ

~

.....l o

U'l

< o o

- .

o 00

~ ...... ... 0 tlD

~ ~ t;

""' .... .c ~...I:::-u

U .. c Q;:J

s __ ::r ...

S:E

._ '"

.. ~

"'-

:;_-

~::

.. ~ .. .. -'1:1 ." .. ... ..