Professional Documents

Culture Documents

Detailed Engineering Drawings, Codes and Standards: Piping & Instrumentation Diagram - Designer Checklist

Detailed Engineering Drawings, Codes and Standards: Piping & Instrumentation Diagram - Designer Checklist

Uploaded by

Suresh RamakrishnanCopyright:

Available Formats

You might also like

- Process Plant Start Up Commissioning & Troubleshooting Outline NewDocument2 pagesProcess Plant Start Up Commissioning & Troubleshooting Outline Newtahri99100% (1)

- Engineering Calculation ProcessDocument3 pagesEngineering Calculation ProcessMafe SalazarNo ratings yet

- PSM Workbook CanadaDocument56 pagesPSM Workbook CanadaSPIDERMAB33100% (1)

- Synergi Pipeline Simulator Brochure - tcm8 59286 PDFDocument4 pagesSynergi Pipeline Simulator Brochure - tcm8 59286 PDFAlexanderNo ratings yet

- PSSR FormDocument16 pagesPSSR Formmythee100% (6)

- Chapter 1Document7 pagesChapter 1Gustavo AgudeloNo ratings yet

- Bulletin 627 Bureau of Mines Flammability of Combustible GAs and VaporsDocument130 pagesBulletin 627 Bureau of Mines Flammability of Combustible GAs and Vaporsedgardiaz5519No ratings yet

- AutoCAD 2016 Tutorials For Chemical Engineering BasicDocument2 pagesAutoCAD 2016 Tutorials For Chemical Engineering BasicLi ChNo ratings yet

- Beginner 'S Errors To Avoid: The Rev E.B. EvansDocument10 pagesBeginner 'S Errors To Avoid: The Rev E.B. EvansAnonymous NwnJNONo ratings yet

- A Simple Simulation With ASPEN EDRDocument9 pagesA Simple Simulation With ASPEN EDRgaming jafarNo ratings yet

- Process Safety Engineer ResponsibilitiesDocument23 pagesProcess Safety Engineer ResponsibilitiesTFattahNo ratings yet

- Flare BloDocument14 pagesFlare BloKalyana AyyaswamyNo ratings yet

- Double Block and BleedDocument1 pageDouble Block and BleedRMG0512No ratings yet

- A Review On CFD Analysis of Control ValvesDocument4 pagesA Review On CFD Analysis of Control ValvesGRD JournalsNo ratings yet

- Eight Tips For Addressing OSHA RAGAGEPDocument17 pagesEight Tips For Addressing OSHA RAGAGEPjoesuhreNo ratings yet

- Hysys TascDocument10 pagesHysys TascMariano PodestáNo ratings yet

- Valve Glossary A To CDocument80 pagesValve Glossary A To Cguailo100% (13)

- M004 & E004 Basic Safety in Process DesignDocument66 pagesM004 & E004 Basic Safety in Process DesignebsmsartNo ratings yet

- DynamicModel7 3 PDFDocument224 pagesDynamicModel7 3 PDFArcangelo Di TanoNo ratings yet

- Auto Drain 70APADH4000Document3 pagesAuto Drain 70APADH4000thomasoburNo ratings yet

- A554 K PRG Pu Lis Doc Am Supply PlanDocument107 pagesA554 K PRG Pu Lis Doc Am Supply PlanNon Etabas GadnatamNo ratings yet

- Engineering 003-Civil Structural Design Criteria On ShoreDocument22 pagesEngineering 003-Civil Structural Design Criteria On Shoremarin cristian100% (1)

- AspenAerogel - Handling GuidelinesDocument7 pagesAspenAerogel - Handling GuidelineskflimNo ratings yet

- Waste Treatment and Disposal - R. Hester, R. Harrison (1995) WWDocument161 pagesWaste Treatment and Disposal - R. Hester, R. Harrison (1995) WWr_alhamesNo ratings yet

- Waste Heat RecoveryDocument37 pagesWaste Heat RecoveryShelty Juliavionni100% (1)

- Risk Based Process Safety DesignDocument13 pagesRisk Based Process Safety DesignVan SotNo ratings yet

- 150 Chemical Engineering Interview Question With Answers - Chemical Engineering Questions - Chemical EngineeringDocument32 pages150 Chemical Engineering Interview Question With Answers - Chemical Engineering Questions - Chemical EngineeringSafril Kartika WardanaNo ratings yet

- Ethylene c2 Splitter Tower Selection SizDocument27 pagesEthylene c2 Splitter Tower Selection Sizmsn1981No ratings yet

- Sihi 105Document8 pagesSihi 105Sandi AslanNo ratings yet

- Manual de Vaporizadores AmbientalesDocument9 pagesManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoNo ratings yet

- Jump Start Aspen HYSYS V8Document29 pagesJump Start Aspen HYSYS V8hayfronbsterNo ratings yet

- Engineeringpracticejan2016 PDFDocument17 pagesEngineeringpracticejan2016 PDFChemkhiNo ratings yet

- Korf Tutorial PDFDocument17 pagesKorf Tutorial PDFAadi Khan100% (1)

- Distillation Column Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDocument24 pagesDistillation Column Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignGilles DakouriNo ratings yet

- How To Seek The Commodity CodesDocument15 pagesHow To Seek The Commodity CodesMahmoud A. SalemNo ratings yet

- Check List InglesDocument6 pagesCheck List InglesManuel Perez MendezNo ratings yet

- Icarus Reference Guide PDFDocument966 pagesIcarus Reference Guide PDFPrashantGauravNo ratings yet

- Vess FireDocument21 pagesVess FirecsNo ratings yet

- 4.323-Pre Start Up Safety Review (PSUSR)Document3 pages4.323-Pre Start Up Safety Review (PSUSR)kirandevi1981No ratings yet

- Cause and Effect AnalysisDocument13 pagesCause and Effect AnalysisAadi KhanNo ratings yet

- Sweetening Technologies - A Look at The Whole Picture 1Document1 pageSweetening Technologies - A Look at The Whole Picture 1hrbinaNo ratings yet

- 11-3644 Aspen EDR Webinar 5-22 FINALDocument3 pages11-3644 Aspen EDR Webinar 5-22 FINALsidiq16No ratings yet

- 01) Pressure Vessels and Piping-NewDocument242 pages01) Pressure Vessels and Piping-NewHaytham Mohamed0% (1)

- Process Industry Practices Vessels: PIP VEFV6100 Vessels/S&T Heat Exchangers Internals DetailsDocument4 pagesProcess Industry Practices Vessels: PIP VEFV6100 Vessels/S&T Heat Exchangers Internals Detailsmsaldivar177No ratings yet

- '11 CCPScatalogDocument12 pages'11 CCPScatalogpemburu bukuNo ratings yet

- Process Safety Check List 1Document2 pagesProcess Safety Check List 1renjithv_4No ratings yet

- Retrofitting The Existing Flare / Burnery For Smoke Less OperationsDocument31 pagesRetrofitting The Existing Flare / Burnery For Smoke Less Operationsmehul10941No ratings yet

- Safety in OverpressureDocument27 pagesSafety in OverpressurevrajakisoriDasiNo ratings yet

- Checklist For Line-By-Line ReviewDocument3 pagesChecklist For Line-By-Line ReviewSusanna Paul100% (1)

- Reciprocating Compressors For Oxygen ServiceDocument35 pagesReciprocating Compressors For Oxygen Servicedaimon_pNo ratings yet

- Flow Diagrams For Chemical Processes: Chemical Project Engineering and EconomicsDocument31 pagesFlow Diagrams For Chemical Processes: Chemical Project Engineering and EconomicsSandipSingNo ratings yet

- Design & Simulation (Assign 4)Document11 pagesDesign & Simulation (Assign 4)Saad AhmedNo ratings yet

- Techno-Economic Assessment About Propylene OxideDocument5 pagesTechno-Economic Assessment About Propylene OxideIntratec SolutionsNo ratings yet

- Plant Engineering and Design The Ultimate Step-By-Step GuideFrom EverandPlant Engineering and Design The Ultimate Step-By-Step GuideNo ratings yet

- Essential Practices for Managing Chemical Reactivity HazardsFrom EverandEssential Practices for Managing Chemical Reactivity HazardsNo ratings yet

- RMP HP SD in Nov 16Document2 pagesRMP HP SD in Nov 16Suresh RamakrishnanNo ratings yet

- Tef - 2016 Sports & GamesDocument4 pagesTef - 2016 Sports & GamesSuresh RamakrishnanNo ratings yet

- H2 Postion Laro S - DDocument1 pageH2 Postion Laro S - DSuresh RamakrishnanNo ratings yet

- 3247tef-2016 Sports Registration SureshDocument4 pages3247tef-2016 Sports Registration SureshSuresh RamakrishnanNo ratings yet

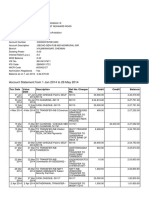

- Account Statement From 1 Jan 2014 To 26 May 2014: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument2 pagesAccount Statement From 1 Jan 2014 To 26 May 2014: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceSuresh RamakrishnanNo ratings yet

- TEFDocument12 pagesTEFSuresh RamakrishnanNo ratings yet

- PaymentDocument1 pagePaymentSuresh RamakrishnanNo ratings yet

- PIP Accepted IdeasDocument9 pagesPIP Accepted IdeasSuresh RamakrishnanNo ratings yet

- TEF Sports Day Suresh RegiterDocument1 pageTEF Sports Day Suresh RegiterSuresh RamakrishnanNo ratings yet

- Convection Section CleaningDocument10 pagesConvection Section CleaningSuresh RamakrishnanNo ratings yet

- Qualitynet InvoiceDocument1 pageQualitynet InvoiceSuresh RamakrishnanNo ratings yet

- Start Up PlanDocument5 pagesStart Up PlanSuresh RamakrishnanNo ratings yet

- Synthesis Gas - Co - H - MethanolDocument18 pagesSynthesis Gas - Co - H - MethanolSuresh RamakrishnanNo ratings yet

- Steam To Carbon Ratio Calculations: InstructionsDocument8 pagesSteam To Carbon Ratio Calculations: InstructionsSuresh Ramakrishnan100% (1)

- Format Loop Description-BlankDocument1 pageFormat Loop Description-BlankSuresh RamakrishnanNo ratings yet

- On Stage Programs (Will Be Conducted On 8 May) : Event CodeDocument4 pagesOn Stage Programs (Will Be Conducted On 8 May) : Event CodeSuresh RamakrishnanNo ratings yet

- Convert Ammonia To MethanolDocument16 pagesConvert Ammonia To MethanolSuresh RamakrishnanNo ratings yet

- RMP and Fup H Balance Report: H Production H ConsumptionDocument1 pageRMP and Fup H Balance Report: H Production H ConsumptionSuresh RamakrishnanNo ratings yet

- Reformer Convection SectionDocument7 pagesReformer Convection SectionSuresh RamakrishnanNo ratings yet

- Air PreheaterDocument11 pagesAir PreheaterSuresh Ramakrishnan100% (1)

- House Chart: Truth Faith Peace HarmonyDocument1 pageHouse Chart: Truth Faith Peace HarmonySuresh RamakrishnanNo ratings yet

Detailed Engineering Drawings, Codes and Standards: Piping & Instrumentation Diagram - Designer Checklist

Detailed Engineering Drawings, Codes and Standards: Piping & Instrumentation Diagram - Designer Checklist

Uploaded by

Suresh RamakrishnanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detailed Engineering Drawings, Codes and Standards: Piping & Instrumentation Diagram - Designer Checklist

Detailed Engineering Drawings, Codes and Standards: Piping & Instrumentation Diagram - Designer Checklist

Uploaded by

Suresh RamakrishnanCopyright:

Available Formats

Detailed Engineering Drawings, Codes and Standards

PIPING & INSTRUMENTATION DIAGRAM DESIGNER

CHECKLIST

S/N

CHECK

2

3

4

5

6

7

ITEM DESCRIPTION

My companys document/drawing #

Client document #

Licensor/Vendor document #

Title block: including the By/Approved/Checked blocks filled and

signed, Date, Rev. all company logos, client signoff block?

All equipment tagged, title above equip, spelling of names

correct?

Not crowded: Normally have about 4 pieces of equipment per

drawing

Where feasible, streams come in the left side and go out the

right side fo the drawing. Battery limits are marked. Stream

tags include the fluid, drawing #, note the equipment name and

8

9

10

11

12

13

14

15

16

17

18

19

tag the stream is from/going to

Line arrows are on each turn of a line, in the correct direction?

Vessels Size, design temperature/design pressure, full

vacuum, internals/levels, skirt height to grade

Heat exchangers Area, design temp/pressure, duty, motor

horsepower (air coolers), condenser/reboilers have elevation,

motors have controls

Heater size, duty, design T/P, coil arrangement, utilities on a

separate page

Boiler size, design T/P, superheater outlet T, utilities own page

Tank size, capacity, type, heaters/agitators shown

Pump rated flow, horsepower, differential head. Showing

temporary strainers, drains, motor w/ controls

Turbines in/out temp/pressure, horsepower, strainers

Compressor Actual Cubic Feet per Minute inlet, discharge

pressure, driver type, horsepower, strainer, lube/seal oil

Instruments are right type, local/transmitted, control type,

block/bypass valves shown

Instrumentation signal lines are correct line type, local/DCS

code correct

Control valve type, failure mode shown, block/bypass valves,

GE200 Course

Handout P&ID Designers Checklist

Detailed Engineering Drawings, Codes and Standards

20

reducers, the sizes used are the latest from controls department

Pressure Relief Valves: set pressure, PSV size is latest,

inlet/discharge size and pipe spec. match latest calculations,

outlet lines are Car Sealed Open or have no valves (if to

21

atmosphere), the relief outlet goes to drain/flare/atmosphere

Lines connecting to a main flare line connect to that line from

above, even making a detour if necessary. (This is an old

drafters trick to remind pipers that flare lines need to slope

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

downward to drain properly)

Block valves: show if they are normally open or closed, car

sealed open or closed?

Drain valves present, use smaller gate valve symbol, they are

between checks/gates/etc.

Minor valves are placed logically (check valve near pump

discharge, swing blind near a gate valve)

Spectacle blinds are correctly shown normally open/closed and

they are on the side of the valve facing the danger (i.e.

pressure source, contamination source)

Steam-outs/steam connections where required? Full vacuum

rating on equipment when required

Pipe specs. are all shown and are correct, spec. breaks over

valves/PSVs, steam and electrical tracing is shown

Double-block valves (with 3/4 drain between) where

procedures say there are needed (normally 600 psig+ or

dangerous fluids like acid)

Insulation is shown on equipment and pipes?

Tie Points are at all old/new line interfaces

Lines connect to each other according to projects branch table

(e.g. do I need to show an expander before tee?)

Show slopes, elevations,

Note whenever any items must be within sight of each other

(e.g. ensure level gauge can be seen by someone operating this

manual globe valve)

Utility P&IDs tie in correctly to main drawings, and show

connect to utility stations & analyzers

Header line numbers include all header block valves (so that

when the header is built the block valves are installed with the

header, not any branch lines)

Any items rotated for easy access, such as handwheels on

valves, are rotated to an angle that is possible considering the

GE200 Course

Handout P&ID Designers Checklist

Detailed Engineering Drawings, Codes and Standards

number of bolt holes on the lines. (Ex: per ASME B16.5 I see

that for 150# carbon steel, 0.5 to 3 lines can rotated 90

degrees , 4 to 8 lines can rotate 45 degrees , 10 to 14 can

37

38

39

40

41

42

43

rotate 30 degrees)

Neat DWG, no dog-legs/bad-connections

When lines cross, vertical lines break for horizontal lines except

that instrumentation lines break for process lines. (This rule

varies by company)

Matches Process Flow Diagram (PFD) connectivity,

Equipment names match other documents like the PFD,

equipment list, datasheet, etc.

All Notes/Holds are ok? Is it clear what they refer to? Spelling?

Are the general project notes and holds, that must be added to

each drawing, in place?

All the mark-ups were applied by the drafters correctly, spelling

is correct

Check the drafting process did not introduce any random new

errors or mistakes. (Sometimes during a revision, a drafters

template will be set wrong, or a line type will change for no

apparent reason, causing a little mistake. And no one will be

looking for it, because everyone just focuses on the areas that

44

45

were marked up!)

Are revision triangles, clouds, and other markings in the revision

process added or deleted as required?

Do your own mini-HAZOP of the process: can any deviation in

normal temperature, pressure, flowrate, operator mistakes,

utility failures, etc. cause a safety problem? Are any remaining

46

47

safety issues going to be properly documented for the operators

Similarly, can you think of any operability problems? Any

common maintenance tasks that cannot be done here? Or any

practical problems building or installing what youve planned?

Taking a look at the set of P&IDs as a whole, the stream

connections between the drawings are correct (all inlet streams

match to outlet streams somewhere, or at least has an

adequate explanation)

GE200 Course

Handout P&ID Designers Checklist

You might also like

- Process Plant Start Up Commissioning & Troubleshooting Outline NewDocument2 pagesProcess Plant Start Up Commissioning & Troubleshooting Outline Newtahri99100% (1)

- Engineering Calculation ProcessDocument3 pagesEngineering Calculation ProcessMafe SalazarNo ratings yet

- PSM Workbook CanadaDocument56 pagesPSM Workbook CanadaSPIDERMAB33100% (1)

- Synergi Pipeline Simulator Brochure - tcm8 59286 PDFDocument4 pagesSynergi Pipeline Simulator Brochure - tcm8 59286 PDFAlexanderNo ratings yet

- PSSR FormDocument16 pagesPSSR Formmythee100% (6)

- Chapter 1Document7 pagesChapter 1Gustavo AgudeloNo ratings yet

- Bulletin 627 Bureau of Mines Flammability of Combustible GAs and VaporsDocument130 pagesBulletin 627 Bureau of Mines Flammability of Combustible GAs and Vaporsedgardiaz5519No ratings yet

- AutoCAD 2016 Tutorials For Chemical Engineering BasicDocument2 pagesAutoCAD 2016 Tutorials For Chemical Engineering BasicLi ChNo ratings yet

- Beginner 'S Errors To Avoid: The Rev E.B. EvansDocument10 pagesBeginner 'S Errors To Avoid: The Rev E.B. EvansAnonymous NwnJNONo ratings yet

- A Simple Simulation With ASPEN EDRDocument9 pagesA Simple Simulation With ASPEN EDRgaming jafarNo ratings yet

- Process Safety Engineer ResponsibilitiesDocument23 pagesProcess Safety Engineer ResponsibilitiesTFattahNo ratings yet

- Flare BloDocument14 pagesFlare BloKalyana AyyaswamyNo ratings yet

- Double Block and BleedDocument1 pageDouble Block and BleedRMG0512No ratings yet

- A Review On CFD Analysis of Control ValvesDocument4 pagesA Review On CFD Analysis of Control ValvesGRD JournalsNo ratings yet

- Eight Tips For Addressing OSHA RAGAGEPDocument17 pagesEight Tips For Addressing OSHA RAGAGEPjoesuhreNo ratings yet

- Hysys TascDocument10 pagesHysys TascMariano PodestáNo ratings yet

- Valve Glossary A To CDocument80 pagesValve Glossary A To Cguailo100% (13)

- M004 & E004 Basic Safety in Process DesignDocument66 pagesM004 & E004 Basic Safety in Process DesignebsmsartNo ratings yet

- DynamicModel7 3 PDFDocument224 pagesDynamicModel7 3 PDFArcangelo Di TanoNo ratings yet

- Auto Drain 70APADH4000Document3 pagesAuto Drain 70APADH4000thomasoburNo ratings yet

- A554 K PRG Pu Lis Doc Am Supply PlanDocument107 pagesA554 K PRG Pu Lis Doc Am Supply PlanNon Etabas GadnatamNo ratings yet

- Engineering 003-Civil Structural Design Criteria On ShoreDocument22 pagesEngineering 003-Civil Structural Design Criteria On Shoremarin cristian100% (1)

- AspenAerogel - Handling GuidelinesDocument7 pagesAspenAerogel - Handling GuidelineskflimNo ratings yet

- Waste Treatment and Disposal - R. Hester, R. Harrison (1995) WWDocument161 pagesWaste Treatment and Disposal - R. Hester, R. Harrison (1995) WWr_alhamesNo ratings yet

- Waste Heat RecoveryDocument37 pagesWaste Heat RecoveryShelty Juliavionni100% (1)

- Risk Based Process Safety DesignDocument13 pagesRisk Based Process Safety DesignVan SotNo ratings yet

- 150 Chemical Engineering Interview Question With Answers - Chemical Engineering Questions - Chemical EngineeringDocument32 pages150 Chemical Engineering Interview Question With Answers - Chemical Engineering Questions - Chemical EngineeringSafril Kartika WardanaNo ratings yet

- Ethylene c2 Splitter Tower Selection SizDocument27 pagesEthylene c2 Splitter Tower Selection Sizmsn1981No ratings yet

- Sihi 105Document8 pagesSihi 105Sandi AslanNo ratings yet

- Manual de Vaporizadores AmbientalesDocument9 pagesManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoNo ratings yet

- Jump Start Aspen HYSYS V8Document29 pagesJump Start Aspen HYSYS V8hayfronbsterNo ratings yet

- Engineeringpracticejan2016 PDFDocument17 pagesEngineeringpracticejan2016 PDFChemkhiNo ratings yet

- Korf Tutorial PDFDocument17 pagesKorf Tutorial PDFAadi Khan100% (1)

- Distillation Column Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDocument24 pagesDistillation Column Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignGilles DakouriNo ratings yet

- How To Seek The Commodity CodesDocument15 pagesHow To Seek The Commodity CodesMahmoud A. SalemNo ratings yet

- Check List InglesDocument6 pagesCheck List InglesManuel Perez MendezNo ratings yet

- Icarus Reference Guide PDFDocument966 pagesIcarus Reference Guide PDFPrashantGauravNo ratings yet

- Vess FireDocument21 pagesVess FirecsNo ratings yet

- 4.323-Pre Start Up Safety Review (PSUSR)Document3 pages4.323-Pre Start Up Safety Review (PSUSR)kirandevi1981No ratings yet

- Cause and Effect AnalysisDocument13 pagesCause and Effect AnalysisAadi KhanNo ratings yet

- Sweetening Technologies - A Look at The Whole Picture 1Document1 pageSweetening Technologies - A Look at The Whole Picture 1hrbinaNo ratings yet

- 11-3644 Aspen EDR Webinar 5-22 FINALDocument3 pages11-3644 Aspen EDR Webinar 5-22 FINALsidiq16No ratings yet

- 01) Pressure Vessels and Piping-NewDocument242 pages01) Pressure Vessels and Piping-NewHaytham Mohamed0% (1)

- Process Industry Practices Vessels: PIP VEFV6100 Vessels/S&T Heat Exchangers Internals DetailsDocument4 pagesProcess Industry Practices Vessels: PIP VEFV6100 Vessels/S&T Heat Exchangers Internals Detailsmsaldivar177No ratings yet

- '11 CCPScatalogDocument12 pages'11 CCPScatalogpemburu bukuNo ratings yet

- Process Safety Check List 1Document2 pagesProcess Safety Check List 1renjithv_4No ratings yet

- Retrofitting The Existing Flare / Burnery For Smoke Less OperationsDocument31 pagesRetrofitting The Existing Flare / Burnery For Smoke Less Operationsmehul10941No ratings yet

- Safety in OverpressureDocument27 pagesSafety in OverpressurevrajakisoriDasiNo ratings yet

- Checklist For Line-By-Line ReviewDocument3 pagesChecklist For Line-By-Line ReviewSusanna Paul100% (1)

- Reciprocating Compressors For Oxygen ServiceDocument35 pagesReciprocating Compressors For Oxygen Servicedaimon_pNo ratings yet

- Flow Diagrams For Chemical Processes: Chemical Project Engineering and EconomicsDocument31 pagesFlow Diagrams For Chemical Processes: Chemical Project Engineering and EconomicsSandipSingNo ratings yet

- Design & Simulation (Assign 4)Document11 pagesDesign & Simulation (Assign 4)Saad AhmedNo ratings yet

- Techno-Economic Assessment About Propylene OxideDocument5 pagesTechno-Economic Assessment About Propylene OxideIntratec SolutionsNo ratings yet

- Plant Engineering and Design The Ultimate Step-By-Step GuideFrom EverandPlant Engineering and Design The Ultimate Step-By-Step GuideNo ratings yet

- Essential Practices for Managing Chemical Reactivity HazardsFrom EverandEssential Practices for Managing Chemical Reactivity HazardsNo ratings yet

- RMP HP SD in Nov 16Document2 pagesRMP HP SD in Nov 16Suresh RamakrishnanNo ratings yet

- Tef - 2016 Sports & GamesDocument4 pagesTef - 2016 Sports & GamesSuresh RamakrishnanNo ratings yet

- H2 Postion Laro S - DDocument1 pageH2 Postion Laro S - DSuresh RamakrishnanNo ratings yet

- 3247tef-2016 Sports Registration SureshDocument4 pages3247tef-2016 Sports Registration SureshSuresh RamakrishnanNo ratings yet

- Account Statement From 1 Jan 2014 To 26 May 2014: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument2 pagesAccount Statement From 1 Jan 2014 To 26 May 2014: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceSuresh RamakrishnanNo ratings yet

- TEFDocument12 pagesTEFSuresh RamakrishnanNo ratings yet

- PaymentDocument1 pagePaymentSuresh RamakrishnanNo ratings yet

- PIP Accepted IdeasDocument9 pagesPIP Accepted IdeasSuresh RamakrishnanNo ratings yet

- TEF Sports Day Suresh RegiterDocument1 pageTEF Sports Day Suresh RegiterSuresh RamakrishnanNo ratings yet

- Convection Section CleaningDocument10 pagesConvection Section CleaningSuresh RamakrishnanNo ratings yet

- Qualitynet InvoiceDocument1 pageQualitynet InvoiceSuresh RamakrishnanNo ratings yet

- Start Up PlanDocument5 pagesStart Up PlanSuresh RamakrishnanNo ratings yet

- Synthesis Gas - Co - H - MethanolDocument18 pagesSynthesis Gas - Co - H - MethanolSuresh RamakrishnanNo ratings yet

- Steam To Carbon Ratio Calculations: InstructionsDocument8 pagesSteam To Carbon Ratio Calculations: InstructionsSuresh Ramakrishnan100% (1)

- Format Loop Description-BlankDocument1 pageFormat Loop Description-BlankSuresh RamakrishnanNo ratings yet

- On Stage Programs (Will Be Conducted On 8 May) : Event CodeDocument4 pagesOn Stage Programs (Will Be Conducted On 8 May) : Event CodeSuresh RamakrishnanNo ratings yet

- Convert Ammonia To MethanolDocument16 pagesConvert Ammonia To MethanolSuresh RamakrishnanNo ratings yet

- RMP and Fup H Balance Report: H Production H ConsumptionDocument1 pageRMP and Fup H Balance Report: H Production H ConsumptionSuresh RamakrishnanNo ratings yet

- Reformer Convection SectionDocument7 pagesReformer Convection SectionSuresh RamakrishnanNo ratings yet

- Air PreheaterDocument11 pagesAir PreheaterSuresh Ramakrishnan100% (1)

- House Chart: Truth Faith Peace HarmonyDocument1 pageHouse Chart: Truth Faith Peace HarmonySuresh RamakrishnanNo ratings yet