Professional Documents

Culture Documents

Variable Displacement Pump A11VO: For Open Circuits

Variable Displacement Pump A11VO: For Open Circuits

Uploaded by

HOryshorCopyright:

Available Formats

You might also like

- A11vo Rexroth Repair Manual DocumentDocument5 pagesA11vo Rexroth Repair Manual DocumentFill Jose80% (5)

- HPV02 Installation and Start-Up Instructions PDFDocument7 pagesHPV02 Installation and Start-Up Instructions PDFxxshNo ratings yet

- A11vo 130 Lrdu2Document1 pageA11vo 130 Lrdu2xxsh100% (1)

- HPV-02 Control E1P 2014-03 en PrintDocument60 pagesHPV-02 Control E1P 2014-03 en Printxxsh100% (2)

- HPV-02 Control H1P 2014-03 en PrintDocument16 pagesHPV-02 Control H1P 2014-03 en PrintxxshNo ratings yet

- D8T and D9T Track-Type Tractors Event Code ListDocument5 pagesD8T and D9T Track-Type Tractors Event Code ListEVCYNo ratings yet

- c7 Engine Electrical Renr7933renr7933 03 - SisDocument12 pagesc7 Engine Electrical Renr7933renr7933 03 - SisEVCY100% (2)

- Radiator Fan ControlDocument12 pagesRadiator Fan Controlmkisa70No ratings yet

- Workshop Manual: Training CenterDocument9 pagesWorkshop Manual: Training CenterStas100% (1)

- Hydromatik A7VODocument20 pagesHydromatik A7VOadelmomouraNo ratings yet

- A11vo 130 Lg1eDocument1 pageA11vo 130 Lg1exxsh100% (2)

- Hägglunds - Choice of Hydraulic Fluid PDFDocument2 pagesHägglunds - Choice of Hydraulic Fluid PDFAnibal RiosNo ratings yet

- LUDV Control Block of Mono and Sandwich Plate Design Type M7-22Document16 pagesLUDV Control Block of Mono and Sandwich Plate Design Type M7-22W Morales100% (2)

- 8904 Operating Instructions A4VGDocument40 pages8904 Operating Instructions A4VGEduardo Cramer100% (1)

- Axial Piston Pump Variable Displacement Bosch Rexroth A4VG 1421398966 PDFDocument60 pagesAxial Piston Pump Variable Displacement Bosch Rexroth A4VG 1421398966 PDFsssydorenko70% (10)

- Rexroth 28250 PumpandservDocument40 pagesRexroth 28250 PumpandservWillington Augusto Ariza100% (2)

- Hagglunds Viking MK 64 163000 Bo LN 0100 PDFDocument26 pagesHagglunds Viking MK 64 163000 Bo LN 0100 PDFKOSTAS100% (1)

- Re 92012Document12 pagesRe 92012Ahmed Abd Elhakeem100% (1)

- Subaru Generators Commercial Sgx3500 Sgx5000 Sgx7500e ServiceDocument46 pagesSubaru Generators Commercial Sgx3500 Sgx5000 Sgx7500e ServiceEVCY100% (2)

- Roc 442PC PDFDocument4 pagesRoc 442PC PDFEVCYNo ratings yet

- Design Procedure For Raft FoundationDocument5 pagesDesign Procedure For Raft FoundationOmkarnath YadavNo ratings yet

- 2010 Facilities Management Policies and Procedures (b4 Use)Document64 pages2010 Facilities Management Policies and Procedures (b4 Use)Bi LaiNo ratings yet

- A7volrdh163p PPB02Document19 pagesA7volrdh163p PPB02Jose Maria CuencaNo ratings yet

- A 11 VoDocument64 pagesA 11 VoJunior Enrique Yataco Ariza100% (3)

- A11vo - Re 92 500 - PDFDocument60 pagesA11vo - Re 92 500 - PDFSyed Azhar Hussain50% (2)

- Bomba Hidraulica A7VODocument52 pagesBomba Hidraulica A7VOanon_491700336100% (2)

- A11vlo 130 HD2DDocument1 pageA11vlo 130 HD2DxxshNo ratings yet

- Rexroth A11 VDocument52 pagesRexroth A11 VVikash Pandit75% (4)

- A11vlo 200-250 DRLDocument1 pageA11vlo 200-250 DRLxxsh100% (1)

- Mobile Division: Service Parts ListDocument52 pagesMobile Division: Service Parts ListSamy Sam100% (1)

- Catalogo REXROTH Serie A6VMDocument40 pagesCatalogo REXROTH Serie A6VMmiler81100% (2)

- A6V Motor PDFDocument18 pagesA6V Motor PDFTimuçin KARABULUTLAR100% (3)

- A11vo 60 LRDH2Document1 pageA11vo 60 LRDH2xxshNo ratings yet

- Assembly CBP840 PDFDocument44 pagesAssembly CBP840 PDFsean100% (2)

- Bomba Rexroth A7vo PDFDocument19 pagesBomba Rexroth A7vo PDFjose manuel barroso pantoja100% (3)

- Electro-Hydraulic Control System DFE1x For Axial Piston Variable Pumps A4VSO and A4VBO Series 1x and 3xDocument32 pagesElectro-Hydraulic Control System DFE1x For Axial Piston Variable Pumps A4VSO and A4VBO Series 1x and 3xPrasantaKumarMallika100% (2)

- Rexroth A10vso Variable Axial Piston Pump PDFDocument18 pagesRexroth A10vso Variable Axial Piston Pump PDFAkbarmoradi100% (1)

- A11v0 eDocument32 pagesA11v0 eDhanraj PatilNo ratings yet

- A11VLO260DRSDocument20 pagesA11VLO260DRSPercy TP100% (1)

- Husco PDFDocument70 pagesHusco PDFhamdaNo ratings yet

- Spares A4VG125Document37 pagesSpares A4VG125Islam Actros100% (3)

- Hight Quality Spare Parts: Bosch Rexroth (Rexroth Build) Series A4VGDocument1 pageHight Quality Spare Parts: Bosch Rexroth (Rexroth Build) Series A4VGINVESTIGACION Y DESARROLLONo ratings yet

- A8vo160la1kh1 60R1-NSG05F000 R902049223 en Zeichn R909722786Document26 pagesA8vo160la1kh1 60R1-NSG05F000 R902049223 en Zeichn R909722786xxsh100% (2)

- Book1 PDFDocument47 pagesBook1 PDFArbainn Al-RantawiNo ratings yet

- MH Parts Catalogus 2021Document112 pagesMH Parts Catalogus 2021Даниил Сторчеус100% (2)

- CMX Catalogo TecnicoDocument74 pagesCMX Catalogo TecnicoMauricio Ariel H. OrellanaNo ratings yet

- Mobile Division: Service Parts ListDocument20 pagesMobile Division: Service Parts Listlizbethdioses100% (5)

- A4vg125 GBDocument12 pagesA4vg125 GBEdgar Huiman100% (1)

- A4vsg Us-Version. Ra92100Document72 pagesA4vsg Us-Version. Ra92100Eduardo CramerNo ratings yet

- Rexroth 28250 Pump and Service ManualDocument40 pagesRexroth 28250 Pump and Service ManualRonit Manojcumar88% (8)

- Service Parts List AA4V90: Series 1Document40 pagesService Parts List AA4V90: Series 1SERgioNo ratings yet

- Variable Displacement Pump A11VO: For Open CircuitsDocument48 pagesVariable Displacement Pump A11VO: For Open Circuitsjose salvadorNo ratings yet

- Danfoss Hydraulics BasicDocument40 pagesDanfoss Hydraulics BasicMatilde Dos Santos WesselsNo ratings yet

- Secondary Control PP PDFDocument60 pagesSecondary Control PP PDFbrunosamaeian100% (1)

- Sistemas Hidrostáticos para Rodillos VibratoriosDocument12 pagesSistemas Hidrostáticos para Rodillos VibratoriosJheins Gupe100% (1)

- Rexoth A10VSO PumpDocument40 pagesRexoth A10VSO PumpAlan67% (6)

- Axial Variable Duoble PumpDocument40 pagesAxial Variable Duoble Pumpveljeg100% (1)

- Rexroth Bomba HidraulicaDocument52 pagesRexroth Bomba HidraulicaHernan LopezNo ratings yet

- Bomba Hidrailica A10VSODocument44 pagesBomba Hidrailica A10VSOkiarabenitezparejaNo ratings yet

- Re92711 2012-01Document48 pagesRe92711 2012-01Edson Huarachi FloresNo ratings yet

- Bom A4VG - REXROTHDocument44 pagesBom A4VG - REXROTHnamduong368100% (4)

- Axial Piston Pump CatalougeDocument36 pagesAxial Piston Pump Catalougemrkadu_61No ratings yet

- A10VSO18 Bomba HidraulicaDocument16 pagesA10VSO18 Bomba HidraulicaGuilherme RodriguesNo ratings yet

- Bomba Rexroth PDFDocument36 pagesBomba Rexroth PDFplasticos_jfm6580100% (11)

- Pump A4vgDocument68 pagesPump A4vgbiabamanbemanNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Performance Report: Cat 6050 FS and 6060 FS at La Herradura Gold Mine (Sonora, Mexico)Document24 pagesPerformance Report: Cat 6050 FS and 6060 FS at La Herradura Gold Mine (Sonora, Mexico)EVCY100% (1)

- Aehq7680 04Document4 pagesAehq7680 04EVCYNo ratings yet

- Effect of Bulk Modulus On Performance of A HydrostDocument15 pagesEffect of Bulk Modulus On Performance of A HydrostEVCYNo ratings yet

- 80HX Series: Telescopic Boom LiftsDocument2 pages80HX Series: Telescopic Boom LiftsRavi RathodNo ratings yet

- STX.8 Circuit DiagramDocument12 pagesSTX.8 Circuit DiagramEVCYNo ratings yet

- 600AJDocument1 page600AJEVCYNo ratings yet

- Pipelayer: Engine Weights Lift CapacityDocument16 pagesPipelayer: Engine Weights Lift CapacityEVCYNo ratings yet

- Kenr5710kenr5710-05 SisDocument15 pagesKenr5710kenr5710-05 SisEVCY100% (1)

- CAT Product LineDocument16 pagesCAT Product LineKas Kasanova100% (1)

- DX 700Document16 pagesDX 700EVCY100% (2)

- Trakker E4Document74 pagesTrakker E4EVCYNo ratings yet

- Capacities (Refill) : CP56B, CP68B, CP74B, CS56B, CS68B, CS74B, CS78B and CS79B Vibratory Soil CompactorsDocument2 pagesCapacities (Refill) : CP56B, CP68B, CP74B, CS56B, CS68B, CS74B, CS78B and CS79B Vibratory Soil CompactorsEVCYNo ratings yet

- Msds en Shell Spirax s4 CX 50Document9 pagesMsds en Shell Spirax s4 CX 50EVCYNo ratings yet

- t45 Atlas CopcoDocument4 pagest45 Atlas CopcoEVCYNo ratings yet

- Powershift SpecificationsDocument3 pagesPowershift SpecificationsEVCY0% (1)

- StartDocument1 pageStartEVCYNo ratings yet

- Catalogo XAS300 DDDocument2 pagesCatalogo XAS300 DDEVCY100% (1)

- ROCD5D7Document4 pagesROCD5D7EVCYNo ratings yet

- Spec ST710 - 9851 2256 01Document4 pagesSpec ST710 - 9851 2256 01EVCYNo ratings yet

- Automatic Steam Sterilization Autoclave Unit 400 LitersDocument2 pagesAutomatic Steam Sterilization Autoclave Unit 400 LitersNumanNo ratings yet

- Shimadzu System GC CatalogDocument48 pagesShimadzu System GC CatalogTerry Osenbach100% (1)

- RefractoriesDocument31 pagesRefractoriesChandra Shekar Reddy Yelety100% (2)

- Behavior of The Magnetic Abrasive Tool For Cutting Edge PDFDocument7 pagesBehavior of The Magnetic Abrasive Tool For Cutting Edge PDFKunal GuptaNo ratings yet

- Product CatalogueDocument10 pagesProduct CatalogueGuzzi VivekNo ratings yet

- Area Classification ExplainedDocument112 pagesArea Classification ExplainedNissi JimmyNo ratings yet

- Design of Masonry StructuresDocument33 pagesDesign of Masonry StructuresBhushan Raisinghani100% (2)

- 07 Askeland ChapDocument12 pages07 Askeland ChapessahhNo ratings yet

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Cooling Towers CalculationDocument4 pagesCooling Towers CalculationMuthu KumarNo ratings yet

- SEPTAGE COLLECTION CALCULATION and SEPTAGE TREATMENT PLANT DESIGN CONCEPTDocument31 pagesSEPTAGE COLLECTION CALCULATION and SEPTAGE TREATMENT PLANT DESIGN CONCEPTKladees WorldNo ratings yet

- H3-206E Shaft Arc Furnace PDFDocument8 pagesH3-206E Shaft Arc Furnace PDFRizky ArisandiNo ratings yet

- AM-00-23 Correlation of Feedstock Chemical Properties With Conversion and Coke Yield in Heavy Atmospheric Residue CrackingDocument11 pagesAM-00-23 Correlation of Feedstock Chemical Properties With Conversion and Coke Yield in Heavy Atmospheric Residue CrackingBrenan FigueroaNo ratings yet

- Geo NotesDocument7 pagesGeo NotesFaria KhanNo ratings yet

- L&T GateGlobe&CheckValves-API 600Document31 pagesL&T GateGlobe&CheckValves-API 600vsvineesh100% (1)

- About - Shri Ramm IncDocument3 pagesAbout - Shri Ramm IncbalajirajasekaranNo ratings yet

- N R B Cargo ExpressDocument3 pagesN R B Cargo Expressapi-267591894No ratings yet

- POE EOC Unit 1 - Principles of Engineering 2016Document21 pagesPOE EOC Unit 1 - Principles of Engineering 2016Y100% (2)

- KQDocument68 pagesKQKeshanNo ratings yet

- Clariant Brochure Colorants For The Paint Industry 201703 enDocument36 pagesClariant Brochure Colorants For The Paint Industry 201703 enYohanes DitoNo ratings yet

- Revised Defense EeeeDocument30 pagesRevised Defense EeeeChristine Marie BoncalesNo ratings yet

- Strength Assessment of Concrete by Replacement of CementDocument70 pagesStrength Assessment of Concrete by Replacement of CementAyon SenguptaNo ratings yet

- MXZ-2A52VA: Split-Type Air ConditionerDocument10 pagesMXZ-2A52VA: Split-Type Air Conditionersiva anandNo ratings yet

- Method StatementDocument4 pagesMethod StatementSagar ParabNo ratings yet

- Cube Compressive Strength Study-Lab ReportDocument20 pagesCube Compressive Strength Study-Lab ReportsyksamNo ratings yet

- Alimak Raise MiningDocument2 pagesAlimak Raise Miningsydneyyun100% (1)

- Vacumm With Mag EDocument8 pagesVacumm With Mag EJulen IturriozNo ratings yet

Variable Displacement Pump A11VO: For Open Circuits

Variable Displacement Pump A11VO: For Open Circuits

Uploaded by

HOryshorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Variable Displacement Pump A11VO: For Open Circuits

Variable Displacement Pump A11VO: For Open Circuits

Uploaded by

HOryshorCopyright:

Available Formats

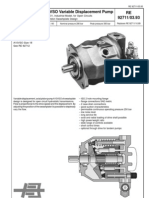

RE 92 500/07.

00

RE 92 500/07.00

Replaces: 03.97

Variable Displacement Pump A11VO

for open circuits

Sizes 40260

Series 1

Nominal pressure 350 bar

Peak pressure 400 bar

A11VO

Index

Features

Ordering Code / Standard Program

Technical Data

LR Power Control

LRD Power Control with Pressure Cut-off

LRS Power Control with Load Sensing

LR... Power Control with Stroke Limiter

LR... Power Control with Override

DR Pressure Control

HD Hydraulic Control, Pilot Pressure Dependent

EP Electric Control with Proportional Solenoid

Unit Dimensions Size 40

Unit Dimensions Size 60

Unit Dimensions Size 75

Unit Dimensions Size 95

Unit Dimensions Size 130

Unit Dimensions Size 190

Unit Dimensions Size 260

Through Drive Dimensions

Overview of A11VO Attachments

Pump Combinations A11VO + A11VO

Permissible Input or Through Drive Torque

Swivel Angle Display

Installation and Commissioning Notes

Preferred Types

A11VO

Features

1

2...3

4...6

7

8

9

10...11

12...13

14...15

16

17

18...20

21...23

24...26

27...29

30...33

34...37

38...41

42...43

44

44

45

46

47

48

Variable displacement pump with axial piston drive swashplate

design for hydrostatic drives in open circuits

Designed primarily for use in mobile applications

Pump operation either self-priming, with tank charging or charging

pump

A comprehensive range of variable units is available for different

control functions

Power can be adjusted from the outside, even when the machine

is running

The through drive is suitable for attachment of gear pumps and

axial piston pumps up to the same size, i.e. 100% through drive

The volume flow is adjustable in proportion to the drive speed

and displacement and is infinitely variable from q V max to

qV min = 0

1/48

Brueninghaus

Hydromatik

RE 92 500/07.00

Ordering Code / Standard Program

Fluid

Mineral oil (no short code)

Axial piston unit

Variable displacement, swashplate design

Charging pump (impeller)

without charging pump (no short code)

with charging pump

A11V

40 60 75 95 130 190 260

Operating mode

Pump, open circuits

L

O

Size

=^ Displacement Vg max (cm3)

Control devices

Power control

with override

40 60 75 95 130 190 260

40 60 75 95 130 190 260

LR

C

LR.C

LR3

LG1

LG2

LE1

LE2

with pressure cut-off

D

L. D . .

2-stage

E

L. E . .

remote controlled

G

L. . G .

with load sensing

S

L. . . S

electric override

S2

L. . . S2

hydraulic override

S5

L. . . S5

with stroke limiter negative control

p = 25 bar

H1

L. . . H1

negative control

p = 10 bar

H5

L. . . H5

positive control

p = 25 bar

H2

L. . . H2

positive control

p = 10 bar

H6

L. . . H6

positive control

U = 12 V

U1

L. . . U1

positive control

U = 24 V

U2

L. . . U2

Pressure control

DR

DR

with load sensing

DRS

DRS

remote controlled

DRG

DRG

for parallel operation

DRL

DRL

Hydraulic control,

p = 10 bar HD1

HD1

pilot pressure dependent

p = 25 bar HD2

HD2

with pressure cut-off

D

HD.D

with pressure cut-off, remote controlled

G

HD.G

Electric control,

U = 12 V

EP1

EP1

with proportional solenoid

U = 24 V

EP2

EP2

with pressure cut-off

D

EP.D

with pressure cut-off, remote controlled

G

EP.G

For controls with several additional functions, follow the order of the columns. Only one option possible in each column (e.g. LRDCH2).

Note that the following combinations are not possible with the power control:

GS, GS2, GS5, EC and the combination DG in conjunction with stroke limiters H1, H2, H5, H6, U1 and U2.

=

=

=

LR

cross-sensing

LR

high pressure dependent

LR3

pilot pressure dependent, negative LG1

pilot pressure dependent, positive LG2

with 12V solenoid, negative

LE1

with 24V solenoid, negative

LE2

available

available on request

not available

Brueninghaus Hydromatik

= preferred program (preferred types see page 48)

2/48

A11VO

RE 92 500/07.00

A11V

12

Axial piston unit

Charging pump

Operating mode

Size

Control devices

Series

1

Index

Sizes

Sizes

Direction of rotation

Viewed on shaft end

40...130

190...260

0

1

clockwise

anti-clockwise

R

L

Seals

NBR (nitrile rubber), shaft seal FKM (fluoride rubber)

Shaft end

N

40 60 75 95 130 190 260

Z

P

S

T

Splined shaft DIN 5480 for individual pumps and pump combinations

Cylindrical shaft with key DIN 6885

Splined shaft ANSI B92.1a-1976 standard for single pump

1) 1)

standard for combination pump

Mounting flange

SAE J744 2 hole

SAE J744 4 hole

C

D

Connection for service lines

Pressure port and suction port SAE

side ports (metric threads)

12

Through drive (for mounting options see page 30)

Flange SAE J744 2)

Splined shaft hub

82-2 (A)

5/8in

9T 16/32DP 3)

3/4in

11T 16/32DP 3)

101-2 (B)

7/8in

13T 16/32DP 3)

1in

15T 16/32DP 3)

W35

2x30x16x9g 4)

127-2 (C)

1 1/4in 14T 12/24DP 3)

1 1/2in 17T 12/24DP 3)

W30

2x30x14x9g 4)

W35

2x30x16x9g 4)

152-4 (D)

1 1/4in 14T 12/24DP 3)

1 3/4in 13T 8/16DP 3)

W40

2x30x18x9g 4)

W45

2x30x21x9g 4)

W50

2x30x24x9g 4)

165-4 (E)

1 3/4in 13T 8/16DP 3)

W50

2x30x24x9g 4)

W60

2x30x28x9g 4)

40 60 75 95 130 190 260

Swivel angle display

without swivel angle display (no short code)

with optical swivel angle display

with electric swivel angle display

N00

K01

K52

K02

K04

K79

K07

K24

K80

K61

K86

K17

K81

K82

K83

K72

K84

K67

V

R

1)

2) 2 =

^ 2 hole; 4 =

^ 4 hole 4) Splined shaft hub to DIN 5480

S shaft suitable for combination pump

3) Splined shaft hub to ANSI B92.1a-1976 (splined shaft allocation to SAE J744, see pages 42/43)

A11VO

3/48

Brueninghaus Hydromatik

RE 92 500/07.00

Technical Data

Hydraulic Fluid

We request that before starting a project, detailed information about

the choice of hydraulic fluids and application conditions are taken

from our catalogue sheets RE 90220 (mineral oil), RE 90221

(environmentally acceptable hydraulic oils) and RE 90223 (HF

hydraulic fluids).

The A11VO variable displacement pump is not suitable for operation

with HFA, HFB and HFC. When operating with HFD or environmentally

acceptable hydraulic fluids, restrictions in the technical data should

be noted please contact us (the hydraulic fluid used should be

stated in clear text in the order).

Operating viscosity range

We recommend that the operating viscosity (at operating

temperature), for both the efficiency and life of the unit, be chosen

within the optimum range of:

opt = opt. operating viscosity 1636 mm2/s

referred to tank temperature (open circuit).

Notes on the selection of hydraulic fluid

In order to select the correct fluid, it is necessary to know the operating

temperature in the tank (open circuit) in relation to the ambient

temperature.

The hydraulic fluid should be selected so that within the operating

temperature range, the operating viscosity lies within the optimum

range (opt) (see shaded section of the selection diagram). We

recommend that the higher viscosity grade is selected in each case.

Example: At an ambient temperature of XC, the operating

temperature in the tank is 60C. In the optimum viscosity range opt

(shaded area), this corresponds to viscosity grades VG 46 or VG 68.

VG 68 should be selected.

Important: The leakage oil temperature is influenced by pressure

and speed and is typically higher than the tank temperature. However,

maximum temperature at any point in the system must be less than

115C.

Please consult Brueninghaus Hydromatik if the above conditions

cannot be kept at extreme operating parameters or because of high

ambient temperature.

Viscosity limits

The limiting values for viscosity are as follows:

min = 5 mm2/s

short term, at a max. permissible leakage oil temperature tmax = 115C

max = 1600 mm2/s short term, on cold start (tmin = -40C)

Please note that the max. fluid temperature is also not exceeded in

certain areas (for instance bearing area).

At temperatures of 25C to 40C special measures may be required.

Please contact us for further information.

Selection diagram

2500-40

1600

1000

600

400

-20

20

40

60

80

100

1600

0

10

VG 68

VG 46

VG 32

VG 2

2

VG

200

Viscosity in mm2/s

100

60

40

36

opt.

20

16

10

5

-40

-25

tmin = -40C

Brueninghaus Hydromatik

-10 0 10

30

50

Fluid temperature range

4/48

70

5

90

115

Temperature t in C

tmax = +115C

A11VO

RE 92 500/07.00

Technical Data

Maximum permissible speed (speed limit)

Permissible speed due to increasing the input pressure pabs at suction

port S or if Vg < Vg max

1,2

Speed nmax / nmax1

Filtration

The finer the filtration, the better the achieved purity grade of the

hydraulic fluid and the longer the life of the axial piston unit.

To ensure the functioning of the axial piston unit, a minimum purity

grade of

9 to NAS 1638

18/15 to ISO/DIS 4406 is necessary.

At very high hydraulic fluid temperatures, a minimum purity grade of

8 to NAS 1638

17/14 to ISO/DIS 4406 is necessary.

If the above mentioned grades cannot be maintained, please consult

us.

pabs = 1,5 bar

1,1

pabs = 1 bar

1,0

0,9

0,8

Input operating pressure range

Absolute pressure at port S (suction port)

Version without charging pump

pabs min _____________________________________________________ 0,8 bar

pabs max ______________________________________________________ 30 bar

Please consult us if the pressure is > 5 bar.

Version with charging pump

pabs min _____________________________________________________ 0,6 bar

pabs max _______________________________________________________ 2 bar

Output operating pressure range

Pressure at port A or B

Nominal pressure pN ______________________________________ 350 bar

Peak pressure pmax ________________________________________ 400 bar

1,0

0,9

Displacement Vg / Vg max

Shaft seal temperature range

The FPM shaft seal is suitable for housing temperatures of 25C to

+115C.

Note:

An NBR shaft seal is required for applications below 25C

(permissible temperature range: -40C to +90C).

Please state NBR shaft seal in clear text when ordering.

Charging pump

The charging pump is a centrifugal pump. Its role is to charge the

A11VO, enabling it to run at higher speeds. It also makes cold starting

easier at low temperatures and high hydraulic fluid viscosity.

Tank charging is never required.

Case drain pressure

Maximum permissible pressure of the leakage fluid at ports T1 and T2

pL _______________________________________________________ 2 bar abs.

A drain oil line to the tank is necessary.

Flushing the housing

If a variable displacement pump with variable displacement units EP,

HD, DR or with stroke limiter (H., U.) is operated for an extended

period (t > 10 min) with zero volume flow or operating pressure <

15 bar, the housing should be flushed via one of the ports T1, T2 or R

to avoid overheating.

NG

40

60

75

95

130 190 260

qV flush (L/min)

Vg max

Vg min

M1

R T1 T2

It is not necessary to flush the housing on the version with

charging pump (A11VLO).

A11VO

5/48

Brueninghaus Hydromatik

RE 92 500/07.00

Technical Data

Table of values, (theoretical values, regardless of mh and v; approximate values)

Size

A11VO

40

60

75

95

130

A11VLO (with charging pump)

Displacement

Vg max

cm3

42

58,3

74

93,8

130

Vg min

cm3

0

0

0

0

0

1

Max. speed )

nmax

min1

3000 2700 2550 2350 2100

at Vg max

Max. speed 3)

nmax

min-1

3500 3250 3000 2780 2500

at Vg Vg max

Flow 4)

qV max

L/min

122

153

183

214

265

at nmax und Vg max

Power at qV max

Pmax

kW

73

92

110

129

159

and p = 350 bar

Torque at Vg max

Tmax

Nm

234

324

412

522

724

and p = 350 bar

Moment of inertia

J

kgm2

0,0048 0,0082 0,0115 0,0173 0,0318

about the drive axis

Weight (approx.)

m

kg

28

36

45

53

66

190

260

130

130

0

190

192,7

0

260

260

0

192,7

0

260

0

2100

1800 2500 2) 2500 2) 2300 2)

2500

2300

2500

2500

2300

393

454

315

467

580

236

273

190

281

349

1073

1448

724

1073

1448

0,055 0,0878 0,0337 0,0577 0,0895

95

125

69

100

130

1) The

values are quoted for an absolute pressure (pabs) of 1 bar at suction port S and mineral fluid.

values are quoted for an absolute pressure (pabs) of at least 0.8 bar at suction port S and mineral operating fluid.

3) The values are quoted for V < V

g

g max or increase of the input pressure pabs at suction port S (see graph on page 5).

4) Allows for 3% displacement loss.

2) The

Determination of size

Flow

qV=

Drive torque

T =

Drive power

P=

Vg n v

in L/min

1000

Vg p

1,59 Vg p

20 mh

2 T n

60000

100 mh

Tn

9549

Drive

Permissible radial and axial loading of drive

Size

Distance of Fq

a

Fq

(from shaft collar)

b

c

a, b, c

Max. permissible radial force

a

at

b

c

+

Max. permissible axial force Fax

Brueninghaus Hydromatik

qV p

600 t

Fq max

Fq max

Fq max

Fax max

in Nm

in kW

Vg =

p =

n =

v =

mh =

t =

in cm3

in bar

in rpm

geometric displacement per revolution

differential pressure

speed

volumetric efficiency

mechanical-hydraulic efficiency

total efficiency (t = v mh)

mm

mm

mm

N

N

N

40

17,5

30

42,5

3600

2891

2416

60

17,5

30

42,5

5000

4046

3398

75

20

35

50

6300

4950

4077

95

20

35

50

8000

6334

5242

130

22,5

40

57,5

11 000

8594

7051

190

26

46

66

16 925

13 225

10 850

260

29

50

71

22 000

16 809

13 600

1500

2200

2750

3500

4800

6000

4150

6/48

A11VO

RE 92 500/07.00

Power Control

Power control regulates the pump displacement as a function of

operating pressure so that a preset drive output is not exceeded at

constant drive speed.

pB Vg = constant

320 bar

pB = operating pressure

Vg = displacement

Precise adjustment according to the hyperbolic characteristic ensures

optimum power utilisation.

The operating pressure acts, via a piston, on a fulcrum. This is

countered by an externally adjustable spring force which determines

the power setting.

If the operating pressure exceeds the set spring force, the pilot valve

is actuated via the fulcrum and the pump swivels back (direction Vg

min). This shortens the lever length at the fulcrum and the operating

pressure can increase in the same proportion as the displacement

decreases (pBVg = constant).

The output power (characteristic) is influenced by the efficiency of

the pump.

When ordering, please state in clear text:

Drive power P in kW

Drive speed n in rpm

Max. flow qv max in L/min

Once the details have been clarified, a power graph can be produced

on our computers.

A11VO

Characteristic: LR

Operating pressure pB in bar

LR

Setting range

Start of control

50 bar

Vg min

Displacement

Vg max

Circuit diagram: LR

7/48

Vg max

Vg min

M1

R T1 T2

Brueninghaus Hydromatik

RE 92 500/07.00

LRD

Power Control with Pressure Cut-off

LRE Power control with 2-stage pressure cut-off

Pressure cut-off corresponds to a pressure control which adjusts the

pump displacement back to Vg min when the set pressure signal value

is reached.

This function overrides power control, i.e. below the pressure signal

value, the power control function is performed.

The valve is integrated into the control housing and is permanently

set to a pressure signal value at the factory.

Setting range 50 to 350 bar.

Sequencing an external pilot pressure at port Y allows the basic

pressure cut-off value to be increased by 50+20 bar and a second

pressure setting to be implemented. This value is higher than the

setting value of the primary pressure relief valve and thus switches

off pressure cut-off. The pressure signal at port Y must be between

20 and 50 bar.

Characteristic: LRD

Characteristic: LRE

350

max

Setting range

50

min

Vg min

Displacement

Circuit diagram: LRD

Increased pressure cut-off

=^ Pressure cut-off switched off

Primary pressure relief valve

390

Operating pressure pB in bar

Operating pressure pB in bar

LRD Power control with pressure cut-off

370

350

320

Vg max

Basic pressure cut-off value

Vg min

Displacement

Vg max

Circuit diagram: LRE

Y

Vg max

Brueninghaus Hydromatik

Vg min

M1

Vg max

R T1 T2

8/48

Vg min

M1

R T1 T2

A11VO

RE 92 500/07.00

LRS Power Control with Load Sensing

LRDS Power control with pressure cut-off

Circuit diagram: LRDS

and load sensing

The load sensing control works as a flow controller controlled by

load pressure and co-ordinates the pump displacement to the quantity

required by the actuator.

The pump flow depends on the external orifice (control block, throttle

valve) switched between the pump and the actuator, but is not affected

by the load pressure over the whole range below the pressure signal

value.

The valve compares the pressure upstream of the orifice with the

downstream pressure and keeps the pressure drop (differential

pressure p) occurring here, and hence the flow, constant.

If the differential pressure rises, the pump is swivelled back (direction

Vg min). If the differential pressure p drops, the pump is swivelled

out (direction Vg max) until balance is restored in the valve.

(1)

porifice = ppump pactuator

Vg max

The setting range for p is between 14 bar and 25 bar.

The standard setting is 18 bar (please state in clear text).

The stand-by pressure in zero stroke mode (orifice closed) is slightly

higher than the p-setting.

Power control and pressure cut-off override the load sensing control,

i.e. the load sensing function is performed below the set hyperbolic

characteristic and below the set pressure signal value.

In a standard LS system, pressure cut-off is integrated into the pump

control. In an LUDV system, pressure cut-off is integrated into the

LUDV valve block.

(1) The orifice (throttle valve) is not included in the supply.

M1

R T1 T2

LRS5

Power control with load sensing,

with hydraulic override

By sequencing an external pilot pressure at port Z, the differential

pressure p of the load sensing control can be proportionally

overridden.

An example of this is shown in the characteristic below. Please consult

us when planning your system.

Characteristic: LRS5

25

Operating pressure pB in bar

pLS in bar

Characteristic: LRS

18

14

10

5

13

6

2

10

15

20

25

Pilot pressure pz in bar

30

Circuit diagram: LRS5

X

Vg min

Displacement

Z4

(1)

Vg max

Vg max

A11VO

Vg min

9/48

Vg min

M1

R T1 T2

Brueninghaus Hydromatik

RE 92 500/07.00

LR...

Power Control with Stroke Limiter

LR... Power control with stroke limiter

LRU1/2 Power control with electric stroke

The stroke limiter enables the pump displacement to be infinitely

varied or limited across the whole setting range. The displacement is

set once proportionally by the pilot current applied at the proportional solenoid or the pilot pressure applied at port Y (max. 40 bar).

Direct current at 12V (U1) or 24V (U2) respectively is required to

trigger the proportional solenoid (insulation IP 54).

The stroke limiter is overridden by the power control, i.e. below the

power control characteristic (hyperbolic characteristic) the

displacement is set according to the pilot current or pilot pressure. If

the power control characteristic is exceeded by the flow set or the

operating pressure, the power control overrides and readjusts the

displacement according to the hyperbolic characteristic.

To swivel the pump out of its initial position Vg max towards Vg min, a

positioning pressure of 30 bar is needed with the electric stroke limiter

LRU1/2 and the hydraulic stroke limiter LRH2/6.

The necessary positioning oil is taken from the high pressure or from

the external positioning pressure available at port G (> 30 bar).

If the operating pressure is > 30 bar and Vg min > 0, no external

positioning pressure is required. In this case the change-over valve

should be removed from the pump before commissioning (see note

in repair instructions RDE 92500-R) and port G should be closed.

limiter (positive control)

Control from Vg min to Vg max

As the pilot current increases, the pump swivels to a higher

displacement.

Start of control at approx.:

400 mA (12 V) 200 mA (24 V)

End of control at approx.:

1200 mA (12 V) 600 mA (24 V)

Starting position in unpressurised state: Vg max

At operating pressure > 30 bar the pump swivels from Vg max towards

Vg min (pilot current < start of control)

The following are available to trigger the proportional solenoid:

Proportional amplifier PV ________________ (see RE 95023)

Proportional amplifier VT 2000 ___________ (see RE 29904)

Chopper amplifier CV ___________________ (see RE 95029)

Microcontroller MC ____________________ (see RE 95050)

Characteristic: LRU2

Pilot current I in mA

800

600

400

200

0

Vg min

0,5

Displacement

1,0

Vg max

Circuit diagram: LRU1/2

Vg max

Brueninghaus Hydromatik

10/48

Vg min

M1

R T1 T2

A11VO

RE 92 500/07.00

LR...

Power Control with Stroke Limiter

LRH1/5 Hydraulic stroke limiter (negative control)

LRH2/6 Hydraulic stroke limiter (positive control)

Control from Vg max to Vg min

As the pilot pressure rises, the pump swivels to a smaller displacement.

Start of control (at Vg max) adjustable _________ from 4 10 bar

Please state start of control in clear text when ordering.

Starting position in unpressurised state: Vg max

Control from Vg min to Vg max

As the pilot pressure rises, the pump swivels to a higher displacement.

Start of control (at Vg min) adjustable _________ from 4 10 bar

Please state start of control in clear text when ordering.

Starting position in unpressurised state: Vg max

At operating pressure > 30 bar the pump swivels from Vg max towards

Vg min (pilot pressure < start of control)

Characteristic: H1

Pilot pressure rise (Vg max Vg min) ___________ p = 25 bar

Characteristic: H2

Pilot pressure rise (Vg min Vg max) ___________ p= 25 bar

4

1,0

Vg max

0

Vg min

0,5

Displacement

1,0

Vg max

Characteristic: H5

Pilot pressure rise (Vg max Vg min) ___________ p = 10 bar

Characteristic: H6

Pilot pressure rise (Vg min Vg max) ___________ p = 10 bar

Pilot pressure pSt in bar

Setting range

0,5

Displacement

Pilot pressure pSt in bar

Setting range

0

Vg min

35

30

25

20

15

10

4

Pilot pressure pSt in bar

Setting range

Pilot pressure pSt in bar

Setting range

35

30

25

20

15

10

20

15

10

4

0

Vg min

0,5

1,0

Displacement

Circuit diagram: LRH1, LRH5

Vg max

20

15

10

4

0

Vg min

Vg max

A11VO

1,0

Vg max

Circuit diagram: LRH2, LRH6

Y

0,5

Displacement

Vg max

Vg min

M1

R T 1 T2

11/48

Vg min

M1

R T1 T2

Brueninghaus Hydromatik

RE 92 500/07.00

LR...

Power Control with Override

LRC Override with cross-sensing

Circuit diagram: LRC

pHD

Cross-sensing is a total power control (high pressure dependent)

which links two A11VO pumps of equal size with LRC control in

power control.

If one pump is running at operating pressures below the set start of

control, the drive power not drawn, in a limit case up to 100%, is

available to the other pump. Total drive power is thus distributed

between two actuators as required.

Power released by pressure cut-off or other overrides is disregarded.

Semi cross-sensing function

If LRC control is used on the first pump (A11VO) and another pump

mounted on the through drive also with power control without crosssensing, the power required for the second pump is subtracted from

the first pump in its setting. The second pump has priority in the

total power setting.

LR3 High pressure dependent override

Vg max

R T1 T2

M1

Circuit diagram: LR3

High pressure dependent power override is a total power control

where the power setting is loaded by the operating pressure of an

attached fixed displacement pump (port Z).

The A11VO can thus be set to 100% of the total drive power. The

power setting of the A11VO is reduced in proportion to the loaddependent rise in the operating pressure of the fixed displacement

pump. The fixed displacement pump has priority in the total power

setting.

The measuring area for the power reduction is adapted to the

displacement of the fixed displacement pump.

LE1/2 Electric override (negative)

pHD

Vg max

Vg min

M1

R T1 T2

Circuit diagram: LE1, LE2

In this case, in contrast to hydraulic power override, the power setting

is loaded by a pilot current. This pilot current acts, via a proportional

solenoid, against the power control setting spring.

^ power decrease.

Higher pilot current =

Direct current at 12V (E1) or 24V (E2) respectively is required to

trigger the proportional solenoid.

The mechanically set basic power setting can be varied by means of

different pilot currents.

If the pilot current signal is variably readjusted via a load limit sensing control, the power decrease of all the actuators is adapted to

the possible power output of the diesel engine.

Vg max

Brueninghaus Hydromatik

LR

Vg min

12/48

Vg min

M1

R T 1 T2

A11VO

RE 92 500/07.00

LR...

Power Control with Override

LG1/2 Pilot pressure dependent override

Circuit diagram: LG1

An external pilot pressure acts via port Z on the power control setting

spring.

The mechanically set basic power setting can be varied by means of

different pilot pressure settings.

If the pilot pressure signal is variably readjusted via a load limit sensing control, the power decrease of all the actuators is adapted to

the possible power output of the diesel engine.

The pilot pressure used for power control is generated by an external

controller which is not part of the A11VO (see also sheet RE 95072,

Electronic load limit sensing control for excavators, GLB).

Vg max

LG1 Negative power override

With negative power override LG1, the force resulting from the pilot

pressure acts against the power control setting spring, i.e. higher

^ power decrease.

pilot pressure =

LG2 Positive power override

With positive power override LG2, the force resulting from the pilot

pressure supports the power control setting spring, i.e. higher pilot

^ power increase.

pressure =

Vg min

M1

R T1 T2

Circuit diagram: LG2

Z

Vg max

Vg min

M1

R T1 T2

Operating pressure pB (bar)

Controlling the power setting

A11VO

13/48

pSt

LG2

pHD

LRC

Vg min

Displacement

LR3 LE1/2 LG1

Vg max

Brueninghaus Hydromatik

RE 92 500/07.00

DR

Pressure Control

DR

Pressure control

DRS

The pressure control maintains constant pressure in a hydraulic system

within its control range despite fluctuations in the flow required. The

variable displacement pump delivers only the amount of hydraulic

fluid needed by the actuators. If the operating pressure exceeds the

pressure signal value set at the integral valve, the pump is

automatically swivelled back and the closed loop error reduced.

Starting position in unpressurised state: Vg max

Setting range 50 to 350 bar.

pmax

max. 10 bar

Characteristic: DR

350

Setting range

Operating pressure

pB in bar

300

250

200

150

100

50

0

Flow qv in L/min

Circuit diagram: DR

The load sensing control works as a flow controller controlled by

load pressure and co-ordinates the pump displacement to the quantity

required by the actuator.

The pump flow depends on the external orifice (control block, throttle

valve) switched between the pump and the actuator, but is not affected

by the load pressure over the whole range below the pressure signal

value.

The valve compares the pressure upstream of the orifice with the

downstream pressure and keeps the pressure drop (differential

pressure p) occurring here, and hence the flow, constant.

If the differential pressure rises, the pump is swivelled back (direction

Vg min). If the differential pressure p drops, the pump is swivelled

out (direction Vg max) until balance is restored in the valve.

porifice = ppump - pactuator

The setting range for p is between 14 bar and 25 bar.

The standard setting is 18 bar (please state in clear text).

The stand-by pressure in zero stroke mode (orifice closed) is slightly

higher than the p setting.

Pressure control overrides the load sensing control, i.e. the load sensing function is performed below the set pressure signal value.

(1) The orifice (throttle valve) is not included in the supply.

Characteristic: DRS

Operating pressure pB in bar

Pressure control with load sensing

A G

Vg max

Vg min

Flow qv in L/min

S

M1

R T1 T2

Circuit diagram: DRS

X

(1)

Vg max

Brueninghaus Hydromatik

14/48

Vg min

M1

R T1 T2

A11VO

RE 92 500/07.00

DR

Pressure Control

DRG

DRL Pressure control for parallel operation

Pressure remote control

Pressure control DRL is designed for pressure control of several A11VO

axial piston pumps arranged in parallel.

The pressure signal valve for all the pumps connected to the system

can be preset by means of an external pressure relief valve (1).

Setting range 50 to 350 bar.

Each pump can be disconnected from the system via a 3-2 way valve

(2), also separately mounted.

Check valves (3) should as a rule be provided in the main conduit

(port A) or control line (port X).

The external valves are not included in the supply.

We recommend that the following is used as the separate pressure

relief valve (1):

DBDH 6 (manual), see RE 25402.

Characteristic: DRG

Circuit diagram : DRL

pmax

max. 10 bar

The pressure remote control enables the pressure control setting to

be overridden by means of a separate pressure relief valve (1) and a

lower pressure signal value can thus be set.

Setting range 50 to 350 bar.

Alternatively, the system can be started at low operating pressures

(stand-by pressure) by actuating a 2-2 way valve (2), also separately

mounted.

Both functions can be carried out separately or in conjunction (see

circuit diagram).

The external valves are not included in the supply.

We recommend that the following is used as the separate pressure

relief valve (1):

DBDH 6 (manual), see RE 25402.

Setting range

Operating pressure

pB in bar

350

300

(2)

(1)

250

(3)

200

(3)

150

X

100

50

0

Flow qv in L/min

M

Circuit diagram: DRG

(1)

Vg max

Vg min

max. 5m

(2)

M1

R T1 T2

A G

Vg max

A11VO

Vg min

M1

R T1 T2

15/48

Brueninghaus Hydromatik

RE 92 500/07.00

HD

Hydraulic Control, Pilot Pressure Dependent

Pilot pressure dependent control allows the pump displacement to

be infinitely adjusted in proportion to the pilot pressure applied to

port Y (max. 40 bar).

Control from Vg min to Vg max.

As the pilot pressure rises, the pump swivels to a higher displacement.

Start of control (at Vg min), adjustable _____ from 4 10 bar.

Start of control should be stated in clear text when ordering.

Pump starting position in unpressurised state: Vg max

To swivel the pump from its starting position Vg max towards Vg min, a

positioning pressure of 30 bar is needed (pilot pressure < start of

control).

The necessary positioning oil is taken from the operating pressure if

this is > 30 bar. If the operating pressure is < 30 bar, the positioning

oil has to be taken from the external positioning pressure available

at port G (> 30 bar).

If the operating pressure is > 30 bar and Vg min > 0, no external

positioning pressure is required. In this case the change-over valve

should be removed from the pump before commissioning (see note

in repair instructions RDE 92500-R) and port G should be closed.

HD

HD.D Hydraulic control with pressure cut-off

Hydraulic control, pilot pressure dependent

Pilot pressure pSt in bar

Setting range

Characteristic: HD1

Pilot pressure rise Vg min to Vg max _________________ p = 10 bar

20

15

10

4

0

Vg min

0,5

Displacement

1,0

Vg max

Characteristic: HD2

Pilot pressure rise Vg min to Vg max _________________ p = 25 bar

Pressure cut-off corresponds to a pressure control which adjusts the

pump displacement back to Vg min when the set pressure signal value

is reached.

This function overrides HD control, i.e. below the pressure signal value,

the pilot pressure dependent function is performed.

The valve is integrated into the control housing and is permanently

set to a pressure signal value at the factory.

Setting range 50 to 350 bar.

Characteristic: HD1D, HD2D

Integral pressure cut-off

Setting range

Operating pressure pB in bar

Pilot pressure pSt in bar

Setting range

35

30

25

20

15

10

4

0

Vg min

0,5

Displacement

1,0

Vg max

max

350

50

min

Vg min

Displacement

Vg max

Circuit diagram: HD1D, HD2D

Circuit diagram: HD1, HD2

Vg max

Brueninghaus Hydromatik

M1

Vg min

Vg max

R T1 T2

16/48

M1

Vg min

R T1 T2

A11VO

RE 92 500/07.00

EP

Electric Control with Proportional Solenoid

Electric control with proportional solenoid allows the pump

displacement to be infinitely set and programmed in proportion to

the solenoid force or current strength. The control force at the control

spool is applied by a proportional solenoid.

Direct current at 12V (EP1) or 24V (EP2) respectively is required to

trigger the proportional solenoid (insulation IP 54).

Control from Vg min to Vg max

As the pilot current increases, the pump swivels to a higher

displacement.

Start of control at approx.:

400 mA (12 V) 200 mA (24 V)

End of control at approx.:

1200 mA (12 V) 600 mA (24 V)

Starting position in unpressurised state: Vg max

To swivel the pump from its starting position Vg max towards Vg min, a

positioning pressure of 30 bar is needed (pilot current < start of

control).

The necessary positioning oil is taken from the operating pressure if

this is > 30 bar. If the operating pressure is < 30 bar, the positioning

oil has to be taken from the external positioning pressure available

at port G (> 30 bar).

If the operating pressure is > 30 bar and Vg min > 0, no external

positioning pressure is required. In this case the change-over valve

should be removed from the pump before commissioning (see note

in repair instructions RDE 92500-R) and port G should be closed.

Important:

Pump with EP control should be fitted in the tank only if mineral

hydraulic fluid is used and the oil temperature in the tank does not

exceed 80C.

The following are available to trigger the proportional solenoid:

Proportional amplifier PV ________________ (see RE 95023)

Proportional amplifier VT 2000 ___________ (see RE 29904)

Chopper amplifier CV ___________________ (see RE 95029)

Microcontroller MC ____________________ (see RE 95050)

EP.D

Electric control with pressure cut-off

Pressure cut-off corresponds to a pressure control which adjusts the

pump displacement back to Vg min when the set pressure signal value

is reached.

This function overrides EP control, i.e. below the pressure signal value,

the pilot current dependent function is performed.

The valve is integrated into the control housing and is permanently

set to a pressure signal value at the factory.

Setting range 50 to 350 bar.

Characteristic: EP2D

Integral pressure cut-off

Setting range

Characteristic: EP2

0

Vg min

0,5

Displacement

50

min

Vg min

Vg max

A11VO

1,0

Vg max

max

350

Displacement

Vg max

Circuit diagram: EP2D

Circuit diagram: EP

Operating pressure pB in bar

Pilot current I in mA

800

700

600

500

400

300

200

100

M1

Vg min

Vg max

R T1 T2

17/48

M1

Vg min

R T1 T2

Brueninghaus Hydromatik

RE 92 500/07.00

Unit Dimensions Size 40

Prior to finalising your design, please request certified installation drawing.

LRDCS:

Power control LR with pressure cut-off D, cross-sensing control C and load sensing control S

T1 M

Z

View Y

Clockwise rotation

(Anti-clockwise rotation)

Z

Vg min

M10; 17 deep

T1

B

(S)

S

(A)

T2

R

Flange SAE J744

101-2 (B)

Detail V

T2

Vg max

M1

W

T2

Detail W

S

D

C

M12; 20 deep

LR

T1

M G

Shaft ends

Splined shaft DIN 5480

W35x2x30x16x9g

Cyl. shaft with key

DIN 6885 AS10x8x56

Ports

A, B Service port

SAE 3/4; 420 bar

(6000 psi) High pressure series

Suction port

SAE 2; 210 bar

(3000 psi) Standard series

T1, T2

R

M1

M

X

Air bleed, tank

Air bleed, oil drain

Measuring point, regulating chamber

Measuring point, service port

Pilot port

M22x1,5; 14 deep

M22x1,5; 14 deep

M12x1,5; 12 deep

M12x1,5; 12 deep

M14x1,5; 12 deep

for version with load sensing (S) and

remote pressure ct-off control (G)

Splined shaft ANSI B92.1a-1976 Splined shaft ANSI B92.1a-1976

1in 15T 16/32DP 1)

1 1/4in 14T 12/24DP 1)

(SAE J744 25-4 (B-B))

(SAE J744 32-4 (C))

Pilot port

M14x1,5; 12 deep

for version with stroke limiter (H...),

2-stage pressure cut-off (E) and HD

Pilot port

M14x1,5; 12 deep

for version with cross-sensing (C) and

power override (LR3, LG1)

Port for positioning pressure (controller) M14x1,5; 12 deep

for version with stroke limiter (H.., U2),

HD and EP with screwed fitting GE10 - PLM

(otherwise port G closed)

1)

30 pressure angle, flat root, side fit, tolerance class 5

Brueninghaus Hydromatik

18/48

A11VO

RE 92 500/07.00

Unit Dimensions Size 40

Prior to finalising your design, please request certified installation drawing.

LRDH1/LRDH5:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg max to Vg min)

LRDH2/LRDH6:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg min to Vg max)

D

H1/5

D

H2/6

LR

LRDU1/LRDU2:

Power control with pressure cut-off and electric stroke

limiter (function: Vg min to Vg max)

LR

LR3DS:

Power control with high pressure dependent override,

pressure cut-off and load sensing control

S

D

D

U1/2

LR3

LR

LG1E:

Power control with pilot pressure dependent override

(negative) and 2-stage pressure cut-off

LG2E:

Power control with pilot pressure dependent override

(positive) and 2-stage pressure cut-off

Z

Y

E

LG1

A11VO

19/48

Brueninghaus Hydromatik

RE 92 500/07.00

Unit Dimensions Size 40

Prior to finalising your design, please request certified installation drawing.

HD1D/HD2D:

Hydraulic, pilot pressure dependent control with pressure

cut-off

EP1D/EP2D:

Electric control (proportional solenoid) with pressure cutoff

D

EP1/2

D

HD1/2

DRS/DRG:

Pressure control with load sensing

Pressure remote control

S/G

DR

Brueninghaus Hydromatik

20/48

A11VO

RE 92 500/07.00

Unit Dimensions Size 60

Prior to finalising your design, please request certified installation drawing.

LRDCS:

Power control LR with pressure cut-off D, cross-sensing control C and load sensing control S

View Y

Clockwise rotation

(Anti-clockwise rotation)

T1 M

Z

Vg min

M10; 17 deep

B

T2

T1

B

(S)

S

(A)

T2

Flange SAE J744

127-2 (C)

M1

Vg max

W

T2

S

D

C

Detail W

LR

M12; 20 deep

T1

M G

Shaft ends

Splined shaft DIN 5480

W35x2x30x16x9g

Cyl. shaft with key

DIN 6885 AS10x8x56

Ports

A, B Service port

SAE 3/4; 420 bar

(6000 psi) High pressure series

Suction port

SAE 2; 210 bar

(3000 psi) Standard series

T1, T2

R

M1

M

X

Air bleed, tank

Air bleed, oil drain

Measuring point, regulating chamber

Measuring point, service port

Pilot port

M22x1,5; 14 deep

M22x1,5; 14 deep

M12x1,5; 12 deep

M12x1,5; 12 deep

M14x1,5; 12 deep

for version with load sensing (S) and

remote presure cut-off control (G)

Splined shaft ANSI B92.1a-1976 Splined shaft ANSI B92.1a-1976

1 1/4in 14T 12/24DP 1)

1 3/8in 21T 16/32DP 1)

(SAE J744 32-4 (C))

Pilot port

M14x1,5; 12 deep

for version with stroke limiter (H...),

2-stage pressure cut-off (E) and HD

Pilot port

M14x1,5; 12 deep

for version with cross-sensing (C) and

power override (LR3, LG1)

Port for positioning pressure (controller) M14x1,5; 12 deep

for version with stroke limiter (H.., U2),

HD and EP with screwed fitting GE10 - PLM

(otherwise port G closed)

1)

30 pressure angle, flat root, side fit, tolerance class 5

A11VO

21/48

Brueninghaus Hydromatik

RE 92 500/07.00

Unit Dimensions Size 60

Prior to finalising your design, please request certified installation drawing.

LRDH1/LRDH5:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg max to Vg min)

LRDH2/LRDH6:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg min to Vg max)

D

H1/5

D

H2/6

LR

LRDU1/LRDU2:

Power control with pressure cut-off and electric stroke

limiter (function: Vg min to Vg max)

LR

LR3DS:

Power control with high pressure dependent override,

pressure cut-off and load sensing control

S

D

D

U1/2

LR

LG1E:

Power control with pilot pressure dependent override

(negative) and 2-stage pressure cut-off

LR3

LG2E:

Power control with pilot pressure dependent override

(positive) and 2-stage pressure cut-off

Z

Y

E

LG1

Brueninghaus Hydromatik

22/48

A11VO

RE 92 500/07.00

Unit Dimensions Size 60

Prior to finalising your design, please request certified installation drawing.

HD1D/HD2D:

Hydraulic, pilot pressure dependent control with pressure

cut-off

EP1D/EP2D:

Electric control (proportional solenoid) with pressure cutoff

D

HD1/2

D

EP1/2

DRS/DRG:

Pressure control with load sensing

Pressure remote control

S/G

DR

A11VO

23/48

Brueninghaus Hydromatik

RE 92 500/07.00

Unit Dimensions Size 75

Prior to finalising your design, please request certified installation drawing.

LRDCS:

Power control LR with pressure cut-off D, cross-sensing control C and load sensing control S

View Y

Clockwise rotation

(Anti-clockwise rotation)

T1 M

Z

Z

X

Vg min

M12; 17 deep

T1

B

(S)

S

(A)

T2

T2

Flange SAE J744

152-4 (D)

M1

Vg max

W

T2

S

D

C

Detail W

LR

M12; 17 deep

T1

M G

Shaft ends

Splined shaft DIN 5480

W40x2x30x18x9g

Cyl. shaft with key

DIN 6885 AS12x8x80

Ports

A, B Service port

SAE 1; 420 bar

(6000 psi) High pressure series

Suction port

SAE 2 1/2; 210 bar

(3000 psi) Standard series

T1, T2

R

M1

M

X

Air bleed, tank

Air bleed, oil drain

Measuring point, regulating chamber

Measuring point, service port

Pilot port

M22x1,5; 14 deep

M22x1,5; 14 deep

M12x1,5; 12 deep

M12x1,5; 12 deep

M14x1,5; 12 deep

for version with load sensing (S) and

remote presure cut-off control (G)

Splined shaft ANSI B92.1a-1976 Splined shaft ANSI B92.1a-1976

1 1/4in 14T 12/24DP 1)

1 3/8in 21T 16/32DP 1)

(SAE J744 32-4 (C))

Pilot port

M14x1,5; 12 deep

for version with stroke limiter (H...),

2-stage pressure cut-off (E) and HD

Pilot port

M14x1,5; 12 deep

for version with cross-sensing (C) and

power override (LR3, LG1)

Port for positioning pressure (controller) M14x1,5; 12 deep

for version with stroke limiter (H.., U2),

HD and EP with screwed fitting GE10 - PLM

(otherwise port G closed)

1)

30 pressure angle, flat root, side fit, tolerance class 5

Brueninghaus Hydromatik

24/48

A11VO

RE 92 500/07.00

Unit Dimensions Size 75

Prior to finalising your design, please request certified installation drawing.

LRDH1/LRDH5:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg max to Vg min)

LRDH2/LRDH6:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg min to Vg max)

D

H1/5

D

H2/6

LR

LRDU1/LRDU2:

Power control with pressure cut-off and electric stroke

limiter (function: Vg min to Vg max)

LR

LR3DS:

Power control with high pressure dependent override,

pressure cut-off and load sensing control

S

D

D

U1/2

LR3

LR

LG1E:

Power control with pilot pressure dependent override

(negative) and 2-stage pressure cut-off

LG2E:

Power control with pilot pressure dependent override

(positive) and 2-stage pressure cut-off

Z

Y

E

LG1

A11VO

25/48

Brueninghaus Hydromatik

RE 92 500/07.00

Unit Dimensions Size 75

Prior to finalising your design, please request certified installation drawing.

HD1D/HD2D:

Hydraulic, pilot pressure dependent control with pressure

cut-off

EP1D/EP2D:

Electric control (proportional solenoid) with pressure cutoff

G

G

D

EP1/2

D

HD1/2

DRS/DRG:

Pressure control with load sensing

Pressure remote control

S/G

DR

Brueninghaus Hydromatik

26/48

A11VO

RE 92 500/07.00

Unit Dimensions Size 95

Prior to finalising your design, please request certified installation drawing.

LRDCS:

Power control LR with pressure cut-off D, cross-sensing control C and load sensing control S

View Y

Clockwise rotation

(Anti-clockwise rotation)

T1 M

Z

Vg min

M12; 17 deep

T1

Y

T2

R

Flange SAE J744

152-4 (D)

B

(S)

S

(A)

T2

M1

Vg max

W

X

T2

Detail W

S

D

C

LR

M16; 24 deep

M G

Z

T1

Shaft ends

Splined shaft DIN 5480

W45x2x30x21x9g

Cyl. shaft with key

DIN 6885 AS14x9x80

B

Ports

A, B Service ports

SAE 1; 420 bar

(6000 psi) High pressure series

Suction port

SAE 3; 140 bar

(2000 psi) Standard series

T1, T2

R

M1

M

X

Air bleed, tank

Air bleed, oil drain

Measuring point, regulating chamber

Measuring point, service port

Pilot port

M26x1,5; 16 deep

M26x1,5; 16 deep

M12x1,5; 12 deep

M12x1,5; 12 deep

M14x1,5; 12 deep

for version with load sensing (S), DRL and

remote pressure cut-off control (G)

S

Splined shaft ANSI B92.1a-1976

1 3/4in 13T 8/16DP 1)

(SAE J744 44-4 (D))

Pilot port

M14x1,5; 12 deep

for version with stroke limiter (H...),

2-stage pressure cut-off (E) and HD

Pilot port

M14x1,5; 12 deep

for version with cross-sensing (C) and

power override (LR3, LG1)

Port for positioning pressure (controller) M14x1,5; 12 deep

for version with stroke limiter (H.., U2),

HD and EP with screwed fitting GE10 - PLM

(otherwise port G closed)

1)

30 pressure angle, flat root, side fit, tolerance class 5

A11VO

27/48

Brueninghaus Hydromatik

RE 92 500/07.00

Unit Dimensions Size 95

Prior to finalising your design, please request certified installation drawing.

LRDH1/LRDH5:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg max to Vg min)

LRDH2/LRDH6:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg min to Vg max)

D

H1/5

D

H2/6

LR

LRDU1/LRDU2:

Power control with pressure cut-off and electric stroke

limiter (function: Vg min to Vg max)

LR

LR3DS:

Power control with high pressure dependent override,

pressure cut-off and load sensing control

S

D

D

U1/2

LR3

LR

LG1E:

Power control with pilot pressure dependent override

(negative) and 2-stage pressure cut-off

LG2E:

Power control with pilot pressure dependent override

(positive) and 2-stage pressure cut-off

Z

Y

E

LG1

Brueninghaus Hydromatik

28/48

A11VO

RE 92 500/07.00

Unit Dimensions Size 95

Prior to finalising your design, please request certified installation drawing.

LE1S/LE2S:

Power control with electric override (negative) and load

sensing control

S

LE2

HD1D/HD2D:

Hydraulic, pilot pressure dependent control with pressure

cut-off

EP1D/EP2D:

Electric control (proportional solenoid) with pressure cutoff

D

HD1/2

D

EP1/2

DRS/DRG:

Pressure control with load sensing

Pressure remote control

DRL:

Pressure control for parallel operation

S/G

DR

DR

A11VO

29/48

Brueninghaus Hydromatik

RE 92 500/07.00

Unit Dimensions Size 130

Prior to finalising your design, please request certified installation drawing.

LRDCS:

Power control LR with pressure cut-off D, cross-sensing control C and load sensing control S

View Y

Clockwise rotation

(Anti-clockwise rotation)

T1 M

Vg min

M12; 17 deep

T1

B

(S)

S

(A)

T2

T2

Flange SAE J744 R

152-4 (D)

M1

Vg max

W

X

T2

S

D

C

Detail W

LR

M16; 24 deep

T1

Shaft ends

M G

Ports

A, B Service port (without charging pump)

Splined shaft DIN 5480

W50x2x30x24x9g

Cyl. shaft with key

DIN 6885 AS14x9x80

SAE 1; 420 bar

(6000 psi) High pressure series

Suction port (without charging pump)

SAE 3; 140 bar

(2000 psi) Standard series

T1, T2

R

M1

M

X

Air bleed, tank

Air bleed, oil drain

Measuring point, regulating chamber

Measuring point, service port

Pilot port

M26x1,5; 16 deep

M26x1,5; 16 deep

M12x1,5; 12 deep

M12x1,5; 12 deep

M14x1,5; 12 deep

for version with load sensing (S), DRL and

remote pressure cut-off control (G)

S

Splined shaft ANSI B92.1a-1976

1 3/4in 13T 8/16DP 1)

(SAE J744 44-4 (D))

Pilot port

M14x1,5; 12 deep

for version with stroke limiter (H...),

2-stage pressure cut-off (E) and HD

Pilot port

M14x1,5; 12 deep

or version with cross-sensing (C) and

power override (LR3, LG1)

Port for positioning pressure (controller) M14x1,5; 12 deep

for version with stroke limiter (H.., U2),

HD and EP with screwed fitting GE10 - PLM

(otherwise port G closed)

1)

30 pressure angle, flat root, side fit, tolerance class 5

Brueninghaus Hydromatik

30/48

A11VO

RE 92 500/07.00

Unit Dimensions Size 130

Prior to finalising your design, please request certified installation drawing.

LRDH1/LRDH5:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg max to Vg min)

LRDH2/LRDH6:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg min to Vg max)

D

H1/5

D

H2/6

LR

LRDU1/LRDU2:

Power control with pressure cut-off and electric stroke

limiter (function: Vg min to Vg max)

LR

LR3DS:

Power control with high pressure dependent override,

pressure cut-off and load sensing control

Z

G

S

D

D

U1/2

LR3

LR

LG1E:

Power control with pilot pressure dependent override

(negative) and 2-stage pressure cut-off

LG2E:

Power control with pilot pressure dependent override

(positive) and 2-stage pressure cut-off

Z

Y

E

LG1

A11VO

31/48

Brueninghaus Hydromatik

RE 92 500/07.00

Unit Dimensions Size 130

Prior to finalising your design, please request certified installation drawing.

LE1S/LE2S:

Power control with electric override (negative) and load

sensing control

S

LE2

HD1D/HD2D:

Hydraulic, pilot pressure dependent control with pressure

cut-off

EP1D/EP2D:

Electric control (proportional solenoid) with pressure cutoff

D

EP1/2

D

HD1/2

DRS/DRG:

Pressure control with load sensing

Pressure remote control

DRL:

Pressure control for parallel operation

S/G

DR

Brueninghaus Hydromatik

DR

32/48

A11VO

RE 92 500/07.00

Unit Dimensions Size 130

Prior to finalising your design, please request certified installation drawing.

Version with charging pump A11VLO130LRDS:

Power control LR with pressure cut-off D and load sensing control S

T1

View Y

Clockwise rotation

(Anti-clockwise rotation)

Vg min

M14; 19 deep

T1

Y

B

(S)

S

(A)

T2

T2

Flange SAE J744 R

152-4 (D)

M1

Vg max

W

X

T2

Detail W

S

D

LR

M16; 24 deep

M G

T1

Ports

A, B Service port (with charging pump)

SAE 1 1/4; 420 bar

(6000 psi) High pressure series

Suction port (with charging pump)

T1, T2

R

M1

M

X

Air bleed, tank

Air bleed, oil drain

Measuring point, regulating chamber

Measuring point, service port

Pilot port

SAE 3; 140 bar

(2000 psi) Standard series

M26x1,5; 16 deep

M26x1,5; 16 deep

M12x1,5; 12 deep

M12x1,5; 12 deep

M14x1,5; 12 deep

for version with load sensing (S), DRL and

remote pressure cut-off control (G)

Pilot port

M14x1,5; 12 deep

for version with stroke limiter (H...),

2-stage pressure cut-off (E) and HD

Pilot port

M14x1,5; 12 deep

or version with cross-sensing (C) and

power override (LR3, LG1)

Port for positioning pressure (controller) M14x1,5; 12 deep

for version with stroke limiter (H.., U2),

HD and EP with screwed fitting GE10 - PLM

(otherwise port G closed)

A11VO

33/48

Brueninghaus Hydromatik

RE 92 500/07.00

Unit Dimensions Size 190

Prior to finalising your design, please request certified installation drawing.

LRDCS:

Power control LR with pressure cut-off D, cross-sensing control C and load sensing control S

View Y

Clockwise rotation

(Anti-clockwise rotation)

T1 M

Vg min

M16; 21 deep

T1

B

(S)

S

(A)

T2

T2

R

Flange SAE J744

165-4 (E)

M1

Vg max

W

T2

S X

Detail W

S

D

LR

M16; 24 deep

M G

Z

T1

Shaft ends

Ports

A, B Service port (without charging pump)

Splined shaft DIN 5480

W50x2x30x24x9g

Cyl. shaft with key

DIN 6885 AS16x10x100

SAE 1 1/2; 420 bar

(6000 psi) High pressure series

Suction port (without charging pump)

SAE 3 1/2; 35 bar

(500 psi) Standard series

T1, T2

R

M1

M

X

Air bleed, tank

Air bleed, oil drain

Measuring point, regulating chamber

Measuring point, service port

Pilot port

M33x2; 16 deep

M33x2; 16 deep

M12x1,5; 12 deep

M12x1,5; 12 deep

M14x1,5; 12 deep

for version with load sensing (S), DRL and

remote pressure cut-off control (G)

Splined shaft ANSI B92.1a-1976 Splined shaft ANSI B92.1a-1976

1 3/4in 13T 8/16DP 1)

2in 15T 8/16DP 1)

(SAE J744 44-4 (D))

(SAE J744 50-4 (F))

Pilot port

M14x1,5; 12 deep

for version with stroke limiter (H...),

2-stage pressure cut-off (E) and HD

Pilot port

M14x1,5; 12 deep

or version with cross-sensing (C) and

power override (LR3, LG1)

Port for positioning pressure (controller) M14x1,5; 12 deep

for version with stroke limiter (H.., U2),

HD and EP with screwed fitting GE10 - PLM

(otherwise port G closed)

1)

30 pressure angle, flat root, side fit, tolerance class 5

Brueninghaus Hydromatik

34/48

A11VO

RE 92 500/07.00

Unit Dimensions Size 190

Prior to finalising your design, please request certified installation drawing.

LRDH1/LRDH5:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg max to Vg min)

LRDH2/LRDH6:

Power control with pressure cut-off and hydraulic stroke

limiter (function: Vg min to Vg max)

Y

G

D

LR

H1/5

LRDU1/LRDU2:

Power control with pressure cut-off and electric stroke

limiter (function: Vg min to Vg max)

D

LR

H2/6

LR3DS: