Professional Documents

Culture Documents

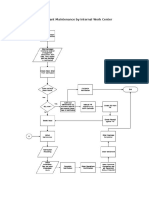

Scenario - Internal Plant Maintenance by Internal Work Center

Scenario - Internal Plant Maintenance by Internal Work Center

Uploaded by

Amit Rajput0 ratings0% found this document useful (0 votes)

23 views26 pagesThis document outlines three scenarios for internal plant maintenance: 1) Maintenance performed internally by an internal work center, which involves creating work orders from notifications, planning and scheduling work, material issue, and order completion. 2) External service hiring where a purchase requisition is created from the work order to generate a purchase order and service entry sheet. 3) Subcontracting where a subcontracting purchase requisition is created from the work order, damaged material is returned to stores, goods are issued to the subcontractor, and repaired material is received.

Original Description:

as

Original Title

Corrective Screens

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines three scenarios for internal plant maintenance: 1) Maintenance performed internally by an internal work center, which involves creating work orders from notifications, planning and scheduling work, material issue, and order completion. 2) External service hiring where a purchase requisition is created from the work order to generate a purchase order and service entry sheet. 3) Subcontracting where a subcontracting purchase requisition is created from the work order, damaged material is returned to stores, goods are issued to the subcontractor, and repaired material is received.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

23 views26 pagesScenario - Internal Plant Maintenance by Internal Work Center

Scenario - Internal Plant Maintenance by Internal Work Center

Uploaded by

Amit RajputThis document outlines three scenarios for internal plant maintenance: 1) Maintenance performed internally by an internal work center, which involves creating work orders from notifications, planning and scheduling work, material issue, and order completion. 2) External service hiring where a purchase requisition is created from the work order to generate a purchase order and service entry sheet. 3) Subcontracting where a subcontracting purchase requisition is created from the work order, damaged material is returned to stores, goods are issued to the subcontractor, and repaired material is received.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 26

Scenario Internal Plant Maintenance by Internal Work Center

Production person will run T Code IH01 for Technical System Structure

display

Locating Equipment and creating Notification

Production planner will enter his Planner Group - Operations

Maintenance Planner list out Notifications from Operations side

Maintenance Planner will convert Notification into Work Order, assigning

his Planner Group and Work Center

Planning and scheduling of Work Order

Creating Reservations into Stores for Material Issue

Material Issue - MIGO

Displaying Costs

Notification Completion entering Cause for Damage, Breakdown entry not

required

Order operation confirmation

Technical completion of Order

Order Settlement

Business completion of Order

Scenario External Service hiring at Plant

Following are Screens after raising a Notification and converting it into

Work Order.

Changing Control Key as PM03 for external operation

Planning Services

Displaying Planned Costs

On Release of Order, Purchase Requisition gets generated

PO Creation from PR and Release

Create Service Entry Sheet from PO

Service Selection and Release for Payment to Vendor

Displaying Actual Costs

Technical completion of Order

Order Settlement

Business completion of Order

Report

Scenario Subcontracting

Following are Screens after raising a Notification and converting it into

Work Order.

On Release, Subcontracting PR gets generated

Return Material to Stores into DAMAGED Batch

Goods Issue to Subcontractor

Receive Repaired Material and issue against PM Order using Transaction

MIGO

Notification Recording

Order operations confirmation

Technical completion of Order

Order Settlement

Business completion of Order

You might also like

- SCN-An Insight - SAP Toll ManufacturingDocument10 pagesSCN-An Insight - SAP Toll ManufacturingRavibabu Koduri67% (3)

- CS OverviewDocument39 pagesCS Overviewsuman7kumar7jha100% (1)

- PM Process Flow Charts PDFDocument12 pagesPM Process Flow Charts PDFMerugu Jalendhar88% (52)

- Configure IntercompanyDocument6 pagesConfigure IntercompanyaunhavcNo ratings yet

- Procedure To Change SAP Product HierarchyDocument5 pagesProcedure To Change SAP Product HierarchymkumarshahiNo ratings yet

- Scenario - Internal Plant Maintenance by Internal Work CenterDocument20 pagesScenario - Internal Plant Maintenance by Internal Work CenterAmit RajputNo ratings yet

- Introduction To CS CS Functions & Components Main Business Scenario in Customer Service Integration With Customer Service With Other ModulesDocument34 pagesIntroduction To CS CS Functions & Components Main Business Scenario in Customer Service Integration With Customer Service With Other ModulesShrinidhi Mmaatthh100% (1)

- SAP CS in House Repair Order ProcessDocument36 pagesSAP CS in House Repair Order ProcessPanduNaganaboina100% (1)

- SAP Corrective MaintenanceDocument8 pagesSAP Corrective MaintenanceMoazzam Ali KhanNo ratings yet

- Sap S4hana MM-1Document45 pagesSap S4hana MM-1Cassio RegalloNo ratings yet

- Hana MM Subcontracting ProcessDocument45 pagesHana MM Subcontracting Processvenkat.dezire123No ratings yet

- Customer Service ModuleDocument4 pagesCustomer Service ModuleManoj JoshiNo ratings yet

- SAP SubcontractingDocument44 pagesSAP Subcontracting"PRISMA" Proyecto100% (1)

- Cusomer Service IssuesDocument8 pagesCusomer Service IssuesShyamNo ratings yet

- Repair Process in SAP CS - 002023Document25 pagesRepair Process in SAP CS - 002023PALURU GIRIDHARNo ratings yet

- In-House Repair Orders: IntegrationDocument18 pagesIn-House Repair Orders: IntegrationHemraj SriNo ratings yet

- Subcontracting Process in SAP MMDocument14 pagesSubcontracting Process in SAP MMPRATAP SAPMMNo ratings yet

- AMC Process in Plant MaintenanceDocument14 pagesAMC Process in Plant MaintenanceBadri PrasadNo ratings yet

- SubcontractinggDocument15 pagesSubcontractinggakshay8shinde-13No ratings yet

- Erp MM Users Guide Ver2 16052014Document72 pagesErp MM Users Guide Ver2 16052014Anonymous xdQGU5kNo ratings yet

- Subcontracting With GSTDocument3 pagesSubcontracting With GSTABHISHEK SRIVASTAVANo ratings yet

- Service Order - BusinessDocument20 pagesService Order - BusinessDon Don0% (1)

- S00.P10.11 in House Repair (Billeable)Document9 pagesS00.P10.11 in House Repair (Billeable)Rachma Respati AyuNo ratings yet

- Powder Coating Process - Subcontracting ProcessDocument3 pagesPowder Coating Process - Subcontracting ProcessBhaskar AmbikapathyNo ratings yet

- AMC Process in Plant Maintenance: Kalyan ChakravarthiDocument9 pagesAMC Process in Plant Maintenance: Kalyan Chakravarthivadiraj tanjoreNo ratings yet

- User Manual PM02 - Maintenance OrderCycleDocument40 pagesUser Manual PM02 - Maintenance OrderCycleR PrasadNo ratings yet

- SubcontractingDocument15 pagesSubcontractingPriyank Patel100% (2)

- Subcontracting Process in SAP MM After GSTDocument3 pagesSubcontracting Process in SAP MM After GSTsyedNo ratings yet

- Sub Contracting & Consignment Process in SAP MMDocument24 pagesSub Contracting & Consignment Process in SAP MMruntabNo ratings yet

- Subcontracting Process Plant o PlantDocument16 pagesSubcontracting Process Plant o PlantRP TechNo ratings yet

- 3 - K3 - Analysis and System Design of Maintenance Scheduling For The Pasteurization Machine in The Cheese Industry - TTS4Document9 pages3 - K3 - Analysis and System Design of Maintenance Scheduling For The Pasteurization Machine in The Cheese Industry - TTS4Anonymous KI0rMdNo ratings yet

- Subcontracting ProcessDocument9 pagesSubcontracting ProcesslourdumyallaNo ratings yet

- SAP Procurement - SubcontractingDocument1 pageSAP Procurement - Subcontractingvidya DeshpandeNo ratings yet

- Chap 2 Basic Cost Management Concepts and Accounting For Mass Customization OperationsDocument15 pagesChap 2 Basic Cost Management Concepts and Accounting For Mass Customization OperationsMarklorenz SumpayNo ratings yet

- Following Is The Step by Step Procedure To Create Intercompany BillingDocument7 pagesFollowing Is The Step by Step Procedure To Create Intercompany Billingiqbal1439988100% (1)

- Managed IT Services Proposal: Insert DateDocument5 pagesManaged IT Services Proposal: Insert DateRudhyNo ratings yet

- Survey of Accounting 6th Edition Warren Test BankDocument48 pagesSurvey of Accounting 6th Edition Warren Test Bankdariusarnoldvin100% (31)

- USER GUIDE - PM Module Page Wise Breakup 2.1Document49 pagesUSER GUIDE - PM Module Page Wise Breakup 2.1chandu80% (5)

- Task Set 1 (Q)Document5 pagesTask Set 1 (Q)Bintang Di SurgaNo ratings yet

- SAP PM External Service Tutorial - Free SAP PM TrainingDocument18 pagesSAP PM External Service Tutorial - Free SAP PM TrainingHossam SaidNo ratings yet

- SAP Refurbishment Order Tutorial - Free SAP PM TrainingDocument16 pagesSAP Refurbishment Order Tutorial - Free SAP PM Trainingsurya100% (2)

- SAP PM Equipments MaintenanceDocument72 pagesSAP PM Equipments Maintenancegeekorbit100% (2)

- Cost Accaunting 2Document12 pagesCost Accaunting 2ዝምታ ተሻለNo ratings yet

- SAP MM 38 SAP Subcontracting Process Semi - Finish ProductDocument7 pagesSAP MM 38 SAP Subcontracting Process Semi - Finish ProductSujan SkNo ratings yet

- SAP Material Management (MM) - NOTESDocument54 pagesSAP Material Management (MM) - NOTESsakibssNo ratings yet

- Activity-Based Costing and Service Department Cost AllocationsDocument5 pagesActivity-Based Costing and Service Department Cost AllocationsRonnelson PascualNo ratings yet

- Equipment Master in SAP PMDocument6 pagesEquipment Master in SAP PMMarco Antônio Claret TeixeiraNo ratings yet

- Plant Maintenance Customer Service ModuleDocument6 pagesPlant Maintenance Customer Service ModuleJyotirmaya MahapatraNo ratings yet

- Hqdev Brochure: How It WorksDocument7 pagesHqdev Brochure: How It Worksmochacino68No ratings yet

- Chapter Four Accounting For MFG-1Document9 pagesChapter Four Accounting For MFG-1History and EventNo ratings yet

- Oracle Cloud Financials Invoice Imaging Release 12 ImplementationDocument6 pagesOracle Cloud Financials Invoice Imaging Release 12 ImplementationObulareddy BiyyamNo ratings yet

- Annual Maintenance Contract (English)Document9 pagesAnnual Maintenance Contract (English)Ketaki SomanNo ratings yet

- Wiley CMAexcel Learning System Exam Review 2017: Part 1, Financial Reporting, Planning, Performance, and Control (1-year access)From EverandWiley CMAexcel Learning System Exam Review 2017: Part 1, Financial Reporting, Planning, Performance, and Control (1-year access)No ratings yet

- Project HA Level - 2 Training: V Entric & Nandan: Confidential DocumentDocument71 pagesProject HA Level - 2 Training: V Entric & Nandan: Confidential DocumentAmit RajputNo ratings yet

- How To Install SQL Server 2008 R2 For SAPDocument21 pagesHow To Install SQL Server 2008 R2 For SAPAmit RajputNo ratings yet

- Sangam Bhavsar Converted CVDocument3 pagesSangam Bhavsar Converted CVAmit RajputNo ratings yet

- How To Install Sap Ides Erp 6Document10 pagesHow To Install Sap Ides Erp 6Amit RajputNo ratings yet

- How To Install SAP Dialog Instance On WindowsDocument8 pagesHow To Install SAP Dialog Instance On WindowsAmit RajputNo ratings yet

- Define CompanyDocument21 pagesDefine CompanyAmit RajputNo ratings yet

- Material Code QTY Object Type Sparelifebearingxx 1 1007 Sparelifebearing01 1 1007Document11 pagesMaterial Code QTY Object Type Sparelifebearingxx 1 1007 Sparelifebearing01 1 1007Amit RajputNo ratings yet

- Abtitude Test FormulasDocument48 pagesAbtitude Test FormulasAmit RajputNo ratings yet

- Sandip ResumeDocument1 pageSandip ResumeAmit RajputNo ratings yet

- Spare Life 28-07-2016Document11 pagesSpare Life 28-07-2016Amit RajputNo ratings yet

- First Women of The Largest DemocracyDocument1 pageFirst Women of The Largest DemocracyAmit RajputNo ratings yet

- SR - No Characteristic Counter Maintenance Plan Workcenter 1 Meas - Prod 41 48 2 Meas - Prod 41 48Document2 pagesSR - No Characteristic Counter Maintenance Plan Workcenter 1 Meas - Prod 41 48 2 Meas - Prod 41 48Amit RajputNo ratings yet

- Follow The Steps: Supervisor Supervisor H.O.D (Folding Dept.) D.G.M (I.T)Document1 pageFollow The Steps: Supervisor Supervisor H.O.D (Folding Dept.) D.G.M (I.T)Amit RajputNo ratings yet