Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

20 viewsCV Satria Power038

CV Satria Power038

Uploaded by

Andry Priyantotroubleshooting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Detroit Diesel Engine Series 60 Parts CatalogueDocument16 pagesDetroit Diesel Engine Series 60 Parts CatalogueAndry Priyanto100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Module, Engine Control PDFDocument6 pagesModule, Engine Control PDFAndry PriyantoNo ratings yet

- Afa BeltsDocument20 pagesAfa BeltsAndry Priyanto67% (3)

- Rev-023. Penawaran Harga Pandaros Perkins 4006 SeriesDocument1 pageRev-023. Penawaran Harga Pandaros Perkins 4006 SeriesAndry PriyantoNo ratings yet

- Cummins QSB 6.7 MonitoringDocument2 pagesCummins QSB 6.7 MonitoringAndry Priyanto100% (1)

- Oil FilterDocument2 pagesOil FilterAndry PriyantoNo ratings yet

- Jobs Report KP Singa LautDocument3 pagesJobs Report KP Singa LautAndry PriyantoNo ratings yet

- 0 515 010 444 - Tachometer Installation and Operations Instructions Ducati&RotaxDocument4 pages0 515 010 444 - Tachometer Installation and Operations Instructions Ducati&RotaxAndry PriyantoNo ratings yet

- Troubleshooting Report Genset MAN D2862 LE 223Document4 pagesTroubleshooting Report Genset MAN D2862 LE 223Andry PriyantoNo ratings yet

- Print Nama BayiDocument1 pagePrint Nama BayiAndry PriyantoNo ratings yet

- Caterpillar Vr3 Vr4 ConnectionsDocument80 pagesCaterpillar Vr3 Vr4 ConnectionsJercy Sanchez100% (6)

- Engine Number Guide: Engines 2 Litre/cylinderDocument4 pagesEngine Number Guide: Engines 2 Litre/cylinderaney2002100% (4)

- Step by Step OverhaulDocument1 pageStep by Step OverhaulAndry PriyantoNo ratings yet

CV Satria Power038

CV Satria Power038

Uploaded by

Andry Priyanto0 ratings0% found this document useful (0 votes)

20 views2 pagestroubleshooting

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttroubleshooting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

20 views2 pagesCV Satria Power038

CV Satria Power038

Uploaded by

Andry Priyantotroubleshooting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

GF} ov son coun

PER BU RGAUTABA PERI nae Bh 9 ra sh Bean Ty 6-nA omacnis

TROUBLESHOOTING REPORT

CUSTOMER =: PT. WASKITA BETON PRECAST DATE + 8 DEC, 2015,

site KUALA TANJUNG Hf 6036

ENGINE PERKINS TECHNICIAN: DWIANDRI

TPE 2206C-TAG2 SERIES PRIVANTO

sv. + TGBF5031010307V.

Type of fobs

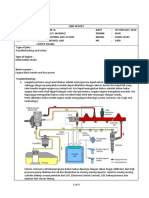

* Troubleshooting Engine Perkins 2206C-TAG2

Work reasons :

‘© Engine cranks but will nt start

Analisys :

Probable Causes

Fuel Supply Visually check the fuel level ‘OK

2. Purge the air from the fuel system ok

3. Checking fuel lines for the following faults OK

restriction, collapsed lines, and pinches lines

4. Replacement of the fuel filters oK

5. Service on the low pressure fuel supply circuit | OK

6. Checking fuel pressure during engine cranking

with ET software OK

7. Checking fuel transfer pump, fuel transfer

ump coupling oK

8 Checking pressure regulating valve ‘Not Goop

Troubleshooting with 1. Connect the software and checking for active | OK

ET/software tool. codes and logged codes. No anything is present

Diagnostic codes and Event | 2._Perform injector solenoid test ok

codes.

Electrical power supply to 1. Checking and contenity cable of voltage battery | OK

the ECM (engine control (+) to ECM pin number 48,52,53

module) 2. Checking and contenity cable of Voltage battery | OK

(-)to ECM pin number 61,63,65

3. Checking and contenity cable for ignition (+)to | OK

ECM pin number 70

Position sensor 1. Cranking engine and observe the engine speed | OK

On status screen of the software is present

2. Checking crankshaft position sensor

~ Resistance 75-230 ohm, result 126 ohm | OK

Page 1 of 2

CV. SATRIA POWER

cvsaTaA Power

PERUM BUM IRGANTARA PERMA nan Wale lok CD-2 no:10 Jats ath eas Tip 071 8430634 fav 021-84306348

= Checking voltage during engine cranking

0,6 -2 VAC, result 0,9 VAC

3. Checking camshaft position sensor

~ Resistance 600-1800 ohm, result 1025

ohm

~ Checking voltage during engine cranking

0,6~2 VAC, result 1 VAC

OK

oK

ok

Electronic Unit injector 1. Checking visual injector for dirty on head nozzle

2. Perform service and calibration electronic unit

injector

NOT GOOD

NOT YET

Conclusion and Recommendation :

1. Replacement of pressure regulating valve

2. Service and calibration of electronic unit injector

Technician

Page 2 of 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Detroit Diesel Engine Series 60 Parts CatalogueDocument16 pagesDetroit Diesel Engine Series 60 Parts CatalogueAndry Priyanto100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Module, Engine Control PDFDocument6 pagesModule, Engine Control PDFAndry PriyantoNo ratings yet

- Afa BeltsDocument20 pagesAfa BeltsAndry Priyanto67% (3)

- Rev-023. Penawaran Harga Pandaros Perkins 4006 SeriesDocument1 pageRev-023. Penawaran Harga Pandaros Perkins 4006 SeriesAndry PriyantoNo ratings yet

- Cummins QSB 6.7 MonitoringDocument2 pagesCummins QSB 6.7 MonitoringAndry Priyanto100% (1)

- Oil FilterDocument2 pagesOil FilterAndry PriyantoNo ratings yet

- Jobs Report KP Singa LautDocument3 pagesJobs Report KP Singa LautAndry PriyantoNo ratings yet

- 0 515 010 444 - Tachometer Installation and Operations Instructions Ducati&RotaxDocument4 pages0 515 010 444 - Tachometer Installation and Operations Instructions Ducati&RotaxAndry PriyantoNo ratings yet

- Troubleshooting Report Genset MAN D2862 LE 223Document4 pagesTroubleshooting Report Genset MAN D2862 LE 223Andry PriyantoNo ratings yet

- Print Nama BayiDocument1 pagePrint Nama BayiAndry PriyantoNo ratings yet

- Caterpillar Vr3 Vr4 ConnectionsDocument80 pagesCaterpillar Vr3 Vr4 ConnectionsJercy Sanchez100% (6)

- Engine Number Guide: Engines 2 Litre/cylinderDocument4 pagesEngine Number Guide: Engines 2 Litre/cylinderaney2002100% (4)

- Step by Step OverhaulDocument1 pageStep by Step OverhaulAndry PriyantoNo ratings yet