Professional Documents

Culture Documents

Dewatering of Sludge

Dewatering of Sludge

Uploaded by

Derek ColandunoCopyright:

Available Formats

You might also like

- PEMAPSDocument9 pagesPEMAPSrodeth marquez100% (1)

- HP Presentation Herbal ProductsDocument83 pagesHP Presentation Herbal Productstaurus_vadivelNo ratings yet

- Volt Presentation PDFDocument29 pagesVolt Presentation PDFBrian Lutter100% (1)

- Flottweg Ose Thickening Centrifuges: Optimizing The Digestion Process in Waste Water Treatment PlantsDocument4 pagesFlottweg Ose Thickening Centrifuges: Optimizing The Digestion Process in Waste Water Treatment PlantsAdolfo Chaves GoyenecheaNo ratings yet

- Water-Wastewater Management of Tapioca Starch Manufacturing Using Optimization TechniqueDocument11 pagesWater-Wastewater Management of Tapioca Starch Manufacturing Using Optimization TechniqueRidwan FansuriNo ratings yet

- Comparison of Common H2S Removal Technologies For Biogas and Landfill GasDocument1 pageComparison of Common H2S Removal Technologies For Biogas and Landfill GasJess GohNo ratings yet

- Advanced Primary Treatment For Municipal WastewaterDocument4 pagesAdvanced Primary Treatment For Municipal WastewaterSrđan MaletićNo ratings yet

- Brewery - South - ZLDDocument1 pageBrewery - South - ZLDAbinash PatroNo ratings yet

- TCS WW001 MICRODYN BIO CEL MCP MBR Tuna Wastewater Treatment PlantDocument4 pagesTCS WW001 MICRODYN BIO CEL MCP MBR Tuna Wastewater Treatment PlantgulfengsolutionsNo ratings yet

- Wastewater Characterization: University Curriculum Development For Decentralized Wastewater ManagementDocument22 pagesWastewater Characterization: University Curriculum Development For Decentralized Wastewater Managementmona aminNo ratings yet

- Aerobic Sludge Digestion - Review Checklist: GeneralDocument4 pagesAerobic Sludge Digestion - Review Checklist: GeneralMagin Idelfonso TorreblancaNo ratings yet

- BEMS-MP-16 Effluent Improvement PlanDocument2 pagesBEMS-MP-16 Effluent Improvement PlanrememberNo ratings yet

- COMPREHENSIVE GUIDE Decanter Centrifuges 2021Document16 pagesCOMPREHENSIVE GUIDE Decanter Centrifuges 2021modshakNo ratings yet

- Good One Chaube ZLD Techno Economic AnalysisDocument5 pagesGood One Chaube ZLD Techno Economic AnalysisAmitNo ratings yet

- Design and Construction of LSOF - 27jan2018 - HandoutDocument10 pagesDesign and Construction of LSOF - 27jan2018 - HandoutMuvindu JayasingheNo ratings yet

- ActivateSludgeVS Membrane Reactor SLIDEDocument36 pagesActivateSludgeVS Membrane Reactor SLIDEsebascian100% (2)

- Saltworks Zero Liquid Discharge InfographicDocument2 pagesSaltworks Zero Liquid Discharge InfographicSameer HussainNo ratings yet

- Water MinimizationDocument8 pagesWater MinimizationAhmad MuzammilNo ratings yet

- SIMINE Hybrid Flot Environmental Product Declaration en PDFDocument6 pagesSIMINE Hybrid Flot Environmental Product Declaration en PDFBelen TapiaNo ratings yet

- Decentralized Wastewater Treatment Systems (Dewats) For Domestic SewageDocument41 pagesDecentralized Wastewater Treatment Systems (Dewats) For Domestic SewageSudeept MaitiNo ratings yet

- FCR WhyDontWeUseRASDocument6 pagesFCR WhyDontWeUseRASQuiLeNo ratings yet

- GE - Technologies For Industrial Water ReuseDocument131 pagesGE - Technologies For Industrial Water Reusesebascian100% (2)

- Diseño Hidráulico VertederoDocument63 pagesDiseño Hidráulico VertederoFabián Alfredo Neira RuizNo ratings yet

- WR WQ Pub Design Criteria Ch12Document23 pagesWR WQ Pub Design Criteria Ch12AshokNo ratings yet

- Lact BulletinDocument2 pagesLact Bulletinmember1000No ratings yet

- Teoria de Oxidacion Avanzada Muy BuenaDocument9 pagesTeoria de Oxidacion Avanzada Muy BuenaSHERLY KIMBERLY RAMOS JESUSNo ratings yet

- Wastewater Treatment SystemsDocument7 pagesWastewater Treatment SystemsBrent SanPedroNo ratings yet

- IJETR033349Document3 pagesIJETR033349erpublicationNo ratings yet

- Symrpl 15 KLD STPDocument15 pagesSymrpl 15 KLD STPDnyaneshwar Dattatraya Phadatare100% (4)

- C) Why We Remove Solids From MudDocument25 pagesC) Why We Remove Solids From Mudiahim87No ratings yet

- NALCO - TSE in District Cooling - KM DC WokshopDocument18 pagesNALCO - TSE in District Cooling - KM DC WokshopPERICOGARCANo ratings yet

- SWCC OPEX Case StudyDocument4 pagesSWCC OPEX Case StudynssahaiNo ratings yet

- Treatment of Waste WaterDocument2 pagesTreatment of Waste WaterIvo CNo ratings yet

- Engl-210 Desalination PresentationDocument10 pagesEngl-210 Desalination Presentationapi-721749872No ratings yet

- Resource Recovery and RecyclingDocument6 pagesResource Recovery and RecyclingRishabh RajNo ratings yet

- Dowex-Marathon-A RESINA ANIÔNICADocument3 pagesDowex-Marathon-A RESINA ANIÔNICAMarcus FreitasNo ratings yet

- GEA17904 Zero Liquid Discharge Brochure PDFDocument2 pagesGEA17904 Zero Liquid Discharge Brochure PDFSolehah OmarNo ratings yet

- Desalination: Mongi Ben Ali, Lakhdar KairouaniDocument13 pagesDesalination: Mongi Ben Ali, Lakhdar KairouaniBir PremierNo ratings yet

- AST SWRO Double Pass DesalinationDocument3 pagesAST SWRO Double Pass DesalinationRashid KayumNo ratings yet

- Beverage IndustriesDocument29 pagesBeverage IndustriesIssa AdiemaNo ratings yet

- Experiment 12 Study of Dairy Effluent Plant: StructureDocument5 pagesExperiment 12 Study of Dairy Effluent Plant: StructureSrinivasa BandaloreNo ratings yet

- Desalination of Water: Filtration Chemical Sorption AssimilationDocument3 pagesDesalination of Water: Filtration Chemical Sorption AssimilationSehry SyedNo ratings yet

- Sewage Disposal With Sea Outfalls - 9march2019 - HandoutDocument10 pagesSewage Disposal With Sea Outfalls - 9march2019 - HandoutparamieNo ratings yet

- Comparative Study of Crude Oil Dehydration EquipmentsDocument8 pagesComparative Study of Crude Oil Dehydration EquipmentsSterling GordianNo ratings yet

- (EN) Reduce Waste To Landfill ProgramDocument14 pages(EN) Reduce Waste To Landfill ProgramNatasya RizkiNo ratings yet

- STP 07Document8 pagesSTP 07badelitamariusNo ratings yet

- Introduction To Wastewater Treatment: Color Odor Solids TemperatureDocument12 pagesIntroduction To Wastewater Treatment: Color Odor Solids TemperatureAaronNo ratings yet

- WT TRTMNT Plant Residuals MNGMNTDocument4 pagesWT TRTMNT Plant Residuals MNGMNTJaninaNo ratings yet

- Water Treatment Guideline - 1Document28 pagesWater Treatment Guideline - 1SofyanNo ratings yet

- Comparison Between Management System and Policies On Domestic Waste ManagementDocument21 pagesComparison Between Management System and Policies On Domestic Waste Managementthai.burmese.aidfund100% (1)

- Centrifuge ThickeningDocument8 pagesCentrifuge ThickeningenviroashNo ratings yet

- 7 Solid Waste ManagementDocument41 pages7 Solid Waste ManagementEmrico Luiz PerezNo ratings yet

- Processes Design of Environmental Engineering Facilities: by Dr. Z.A. (PHD, Ass. Professor)Document61 pagesProcesses Design of Environmental Engineering Facilities: by Dr. Z.A. (PHD, Ass. Professor)Hawi EtanaNo ratings yet

- PCTWWDocument27 pagesPCTWWpakshat968No ratings yet

- Engext 27453Document8 pagesEngext 27453Yanci JhoeNo ratings yet

- Wastewater Reclamation at Industrial Parks: Confederation of Indian Industry Conference On Water ManagementDocument17 pagesWastewater Reclamation at Industrial Parks: Confederation of Indian Industry Conference On Water ManagementMohammad Jailani A JamilNo ratings yet

- Non Potable Water Reuse-Quality and Costs: Marie Marguerite Bourbigot, Bruce Durham, Tom PankratzDocument14 pagesNon Potable Water Reuse-Quality and Costs: Marie Marguerite Bourbigot, Bruce Durham, Tom PankratzNermeen AhmedNo ratings yet

- Chapter 5 Conventional Wastewater Treatment Plant Design CDocument24 pagesChapter 5 Conventional Wastewater Treatment Plant Design Ctony13touchNo ratings yet

- Cs-Coluj OnlyDocument2 pagesCs-Coluj OnlyFrialynNo ratings yet

- Primary ClarificationDocument1 pagePrimary ClarificationDerek ColandunoNo ratings yet

- Water ReuseDocument1 pageWater ReuseDerek ColandunoNo ratings yet

- Process BlowersDocument1 pageProcess BlowersDerek ColandunoNo ratings yet

- Water Testing Laboratory: Johns Creek Environmental CampusDocument1 pageWater Testing Laboratory: Johns Creek Environmental CampusDerek ColandunoNo ratings yet

- Post AerationDocument1 pagePost AerationDerek ColandunoNo ratings yet

- Odor ControlDocument1 pageOdor ControlDerek ColandunoNo ratings yet

- Electrical DistributionDocument1 pageElectrical DistributionDerek ColandunoNo ratings yet

- MonitoringDocument1 pageMonitoringDerek ColandunoNo ratings yet

- Discharge Reclaimed WaterDocument1 pageDischarge Reclaimed WaterDerek ColandunoNo ratings yet

- Fine ScreeningDocument1 pageFine ScreeningDerek ColandunoNo ratings yet

- ChemicalsDocument1 pageChemicalsDerek ColandunoNo ratings yet

- Coarse ScreeningDocument1 pageCoarse ScreeningDerek ColandunoNo ratings yet

- Publicly Funded Clinical Trials: A Route To Sustained Innovation With Affordable DrugsDocument10 pagesPublicly Funded Clinical Trials: A Route To Sustained Innovation With Affordable DrugsCenter for Economic and Policy ResearchNo ratings yet

- NCP DepressionDocument2 pagesNCP Depressionhollymadison80% (5)

- (Journal of Neurosurgery - Spine) History and Advances in Spinal NeurosurgeryDocument11 pages(Journal of Neurosurgery - Spine) History and Advances in Spinal NeurosurgerycdsaludNo ratings yet

- NCP (Fatigue)Document1 pageNCP (Fatigue)student_019100% (1)

- Case Report Guidelines GeneralDocument6 pagesCase Report Guidelines GeneralDamián VaNo ratings yet

- Drug Free Australia's Dr. Stuart Reece & Culpable Abuse of PatientsDocument6 pagesDrug Free Australia's Dr. Stuart Reece & Culpable Abuse of PatientsPaul GallagherNo ratings yet

- ENT Notes For Med StudentsDocument4 pagesENT Notes For Med Studentsnikki100% (1)

- Investigatory Project inDocument31 pagesInvestigatory Project inrchandralega2205100% (1)

- Narayana Hrudalaya Heart HospitalDocument17 pagesNarayana Hrudalaya Heart HospitalWaibhav Krishna100% (1)

- Pharmacoepidemiology Pharmacoepidemiology At3: Studies Using Automated Databases GDocument27 pagesPharmacoepidemiology Pharmacoepidemiology At3: Studies Using Automated Databases GRuth Vargas GonzalesNo ratings yet

- Off Label Drug - Bu SintaDocument18 pagesOff Label Drug - Bu SintaChandra NiansariNo ratings yet

- Comparative+Efficacy+of+570 581Document12 pagesComparative+Efficacy+of+570 581Mansour ZamaniNo ratings yet

- Word File Dr.Document13 pagesWord File Dr.Pankaj HatwarNo ratings yet

- Communication: Communication Is A Process of Sharing Information and Meaning, of Sending and Receiving MessagesDocument5 pagesCommunication: Communication Is A Process of Sharing Information and Meaning, of Sending and Receiving MessagesNina OaipNo ratings yet

- Bio FoldersDocument11 pagesBio Foldersgoksel3173No ratings yet

- Laminitis - Prevention, Diagnosis and Treatment PDFDocument10 pagesLaminitis - Prevention, Diagnosis and Treatment PDFfrankyNo ratings yet

- Providing Post Advice and Post Services To Hilot ClientsDocument15 pagesProviding Post Advice and Post Services To Hilot Clientsjazzy mallariNo ratings yet

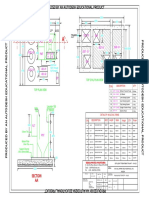

- Plan Layout For ETP - 10 KLD-ModelDocument1 pagePlan Layout For ETP - 10 KLD-Modellionisback100% (1)

- Anger Management:: UNIT - I (Lesson: 3)Document5 pagesAnger Management:: UNIT - I (Lesson: 3)harshitha reddyNo ratings yet

- Q&A401Document10 pagesQ&A401Yasmin LopezNo ratings yet

- In The Dental Implant Era, Why Do We Still Bother Saving Teeth?Document8 pagesIn The Dental Implant Era, Why Do We Still Bother Saving Teeth?Gabriela ArgeseanuNo ratings yet

- Canadian Journal of Occupational TherapyDocument9 pagesCanadian Journal of Occupational TherapyFrancesca GozmanNo ratings yet

- Pharma LectureDocument153 pagesPharma LectureMike OngNo ratings yet

- Activity 1: Science or Not Science?Document3 pagesActivity 1: Science or Not Science?Rivera MaeNo ratings yet

- The Earliest Years: 1. Research On The History or Evolution of Mental Health-Psychiatric Nursing (10 Points)Document3 pagesThe Earliest Years: 1. Research On The History or Evolution of Mental Health-Psychiatric Nursing (10 Points)Kristian Karl Bautista Kiw-isNo ratings yet

- Toronto Western Spasmodic Torticollis Rating Scale TWSTRSDocument3 pagesToronto Western Spasmodic Torticollis Rating Scale TWSTRSVioleta López Neciosup0% (1)

- Final Hospital Bill Format PDFDocument2 pagesFinal Hospital Bill Format PDFIbrar ShaikhNo ratings yet

- Reading The Holter ECG ReportDocument50 pagesReading The Holter ECG ReportOpptimuss Prime100% (2)

Dewatering of Sludge

Dewatering of Sludge

Uploaded by

Derek ColandunoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dewatering of Sludge

Dewatering of Sludge

Uploaded by

Derek ColandunoCopyright:

Available Formats

Dewatering of Sludge

J o h n s C r e e k E n v i r on m e n t a l C a m p u s

Dewatering of residuals is the physical process of removing the water content of the “sludge.” Sludge is dewatered

to reduce the cost associated with transporting the waste residuals to a disposal site and taking up space in a

landfill, because there is simply less volume. Dewatered residuals are also easier to handle.

At the Johns Creek Environmental Campus, sludge is dewatered using centrifugation. Sludge is fed into three

centrifuges that spin at high speeds. The sludge is separated into a dense cake of residuals and a waste liquid

stream (centrate). The centrate is recycled back into the plant for treatment while the dewatered residuals (cake)

are discharged directly to a container located below each centrifuge. These dewatered residuals are then sent

to the landfill for disposal. A chemical polymer is added to the sludge feed line to improve solids capture and

centrate quality.

Dewatered residuals are collected

High Speed Centrifuge separate water from the residuals and trucked to a landfill

Centrifuges are used to

Dewatering / Chemical Storage

Process Design Parameters

separate solids (residuals)

Number of Centrifuges

and liquid (centrate) 3 (2 duty/1 standby)

for Solids Dewatering

Capacity of Centrifuge (each) 425 gpm / 2,700 lb/hr

Design Feed Total Solids

1 to 2.5 percent

Concentration

Dewatered Residuals Total

20 percent

Solids Concentration

Design Solids Capture 95 percent

Number of Centrifuge Pumps 3 (2 duty and 1 standby)

You might also like

- PEMAPSDocument9 pagesPEMAPSrodeth marquez100% (1)

- HP Presentation Herbal ProductsDocument83 pagesHP Presentation Herbal Productstaurus_vadivelNo ratings yet

- Volt Presentation PDFDocument29 pagesVolt Presentation PDFBrian Lutter100% (1)

- Flottweg Ose Thickening Centrifuges: Optimizing The Digestion Process in Waste Water Treatment PlantsDocument4 pagesFlottweg Ose Thickening Centrifuges: Optimizing The Digestion Process in Waste Water Treatment PlantsAdolfo Chaves GoyenecheaNo ratings yet

- Water-Wastewater Management of Tapioca Starch Manufacturing Using Optimization TechniqueDocument11 pagesWater-Wastewater Management of Tapioca Starch Manufacturing Using Optimization TechniqueRidwan FansuriNo ratings yet

- Comparison of Common H2S Removal Technologies For Biogas and Landfill GasDocument1 pageComparison of Common H2S Removal Technologies For Biogas and Landfill GasJess GohNo ratings yet

- Advanced Primary Treatment For Municipal WastewaterDocument4 pagesAdvanced Primary Treatment For Municipal WastewaterSrđan MaletićNo ratings yet

- Brewery - South - ZLDDocument1 pageBrewery - South - ZLDAbinash PatroNo ratings yet

- TCS WW001 MICRODYN BIO CEL MCP MBR Tuna Wastewater Treatment PlantDocument4 pagesTCS WW001 MICRODYN BIO CEL MCP MBR Tuna Wastewater Treatment PlantgulfengsolutionsNo ratings yet

- Wastewater Characterization: University Curriculum Development For Decentralized Wastewater ManagementDocument22 pagesWastewater Characterization: University Curriculum Development For Decentralized Wastewater Managementmona aminNo ratings yet

- Aerobic Sludge Digestion - Review Checklist: GeneralDocument4 pagesAerobic Sludge Digestion - Review Checklist: GeneralMagin Idelfonso TorreblancaNo ratings yet

- BEMS-MP-16 Effluent Improvement PlanDocument2 pagesBEMS-MP-16 Effluent Improvement PlanrememberNo ratings yet

- COMPREHENSIVE GUIDE Decanter Centrifuges 2021Document16 pagesCOMPREHENSIVE GUIDE Decanter Centrifuges 2021modshakNo ratings yet

- Good One Chaube ZLD Techno Economic AnalysisDocument5 pagesGood One Chaube ZLD Techno Economic AnalysisAmitNo ratings yet

- Design and Construction of LSOF - 27jan2018 - HandoutDocument10 pagesDesign and Construction of LSOF - 27jan2018 - HandoutMuvindu JayasingheNo ratings yet

- ActivateSludgeVS Membrane Reactor SLIDEDocument36 pagesActivateSludgeVS Membrane Reactor SLIDEsebascian100% (2)

- Saltworks Zero Liquid Discharge InfographicDocument2 pagesSaltworks Zero Liquid Discharge InfographicSameer HussainNo ratings yet

- Water MinimizationDocument8 pagesWater MinimizationAhmad MuzammilNo ratings yet

- SIMINE Hybrid Flot Environmental Product Declaration en PDFDocument6 pagesSIMINE Hybrid Flot Environmental Product Declaration en PDFBelen TapiaNo ratings yet

- Decentralized Wastewater Treatment Systems (Dewats) For Domestic SewageDocument41 pagesDecentralized Wastewater Treatment Systems (Dewats) For Domestic SewageSudeept MaitiNo ratings yet

- FCR WhyDontWeUseRASDocument6 pagesFCR WhyDontWeUseRASQuiLeNo ratings yet

- GE - Technologies For Industrial Water ReuseDocument131 pagesGE - Technologies For Industrial Water Reusesebascian100% (2)

- Diseño Hidráulico VertederoDocument63 pagesDiseño Hidráulico VertederoFabián Alfredo Neira RuizNo ratings yet

- WR WQ Pub Design Criteria Ch12Document23 pagesWR WQ Pub Design Criteria Ch12AshokNo ratings yet

- Lact BulletinDocument2 pagesLact Bulletinmember1000No ratings yet

- Teoria de Oxidacion Avanzada Muy BuenaDocument9 pagesTeoria de Oxidacion Avanzada Muy BuenaSHERLY KIMBERLY RAMOS JESUSNo ratings yet

- Wastewater Treatment SystemsDocument7 pagesWastewater Treatment SystemsBrent SanPedroNo ratings yet

- IJETR033349Document3 pagesIJETR033349erpublicationNo ratings yet

- Symrpl 15 KLD STPDocument15 pagesSymrpl 15 KLD STPDnyaneshwar Dattatraya Phadatare100% (4)

- C) Why We Remove Solids From MudDocument25 pagesC) Why We Remove Solids From Mudiahim87No ratings yet

- NALCO - TSE in District Cooling - KM DC WokshopDocument18 pagesNALCO - TSE in District Cooling - KM DC WokshopPERICOGARCANo ratings yet

- SWCC OPEX Case StudyDocument4 pagesSWCC OPEX Case StudynssahaiNo ratings yet

- Treatment of Waste WaterDocument2 pagesTreatment of Waste WaterIvo CNo ratings yet

- Engl-210 Desalination PresentationDocument10 pagesEngl-210 Desalination Presentationapi-721749872No ratings yet

- Resource Recovery and RecyclingDocument6 pagesResource Recovery and RecyclingRishabh RajNo ratings yet

- Dowex-Marathon-A RESINA ANIÔNICADocument3 pagesDowex-Marathon-A RESINA ANIÔNICAMarcus FreitasNo ratings yet

- GEA17904 Zero Liquid Discharge Brochure PDFDocument2 pagesGEA17904 Zero Liquid Discharge Brochure PDFSolehah OmarNo ratings yet

- Desalination: Mongi Ben Ali, Lakhdar KairouaniDocument13 pagesDesalination: Mongi Ben Ali, Lakhdar KairouaniBir PremierNo ratings yet

- AST SWRO Double Pass DesalinationDocument3 pagesAST SWRO Double Pass DesalinationRashid KayumNo ratings yet

- Beverage IndustriesDocument29 pagesBeverage IndustriesIssa AdiemaNo ratings yet

- Experiment 12 Study of Dairy Effluent Plant: StructureDocument5 pagesExperiment 12 Study of Dairy Effluent Plant: StructureSrinivasa BandaloreNo ratings yet

- Desalination of Water: Filtration Chemical Sorption AssimilationDocument3 pagesDesalination of Water: Filtration Chemical Sorption AssimilationSehry SyedNo ratings yet

- Sewage Disposal With Sea Outfalls - 9march2019 - HandoutDocument10 pagesSewage Disposal With Sea Outfalls - 9march2019 - HandoutparamieNo ratings yet

- Comparative Study of Crude Oil Dehydration EquipmentsDocument8 pagesComparative Study of Crude Oil Dehydration EquipmentsSterling GordianNo ratings yet

- (EN) Reduce Waste To Landfill ProgramDocument14 pages(EN) Reduce Waste To Landfill ProgramNatasya RizkiNo ratings yet

- STP 07Document8 pagesSTP 07badelitamariusNo ratings yet

- Introduction To Wastewater Treatment: Color Odor Solids TemperatureDocument12 pagesIntroduction To Wastewater Treatment: Color Odor Solids TemperatureAaronNo ratings yet

- WT TRTMNT Plant Residuals MNGMNTDocument4 pagesWT TRTMNT Plant Residuals MNGMNTJaninaNo ratings yet

- Water Treatment Guideline - 1Document28 pagesWater Treatment Guideline - 1SofyanNo ratings yet

- Comparison Between Management System and Policies On Domestic Waste ManagementDocument21 pagesComparison Between Management System and Policies On Domestic Waste Managementthai.burmese.aidfund100% (1)

- Centrifuge ThickeningDocument8 pagesCentrifuge ThickeningenviroashNo ratings yet

- 7 Solid Waste ManagementDocument41 pages7 Solid Waste ManagementEmrico Luiz PerezNo ratings yet

- Processes Design of Environmental Engineering Facilities: by Dr. Z.A. (PHD, Ass. Professor)Document61 pagesProcesses Design of Environmental Engineering Facilities: by Dr. Z.A. (PHD, Ass. Professor)Hawi EtanaNo ratings yet

- PCTWWDocument27 pagesPCTWWpakshat968No ratings yet

- Engext 27453Document8 pagesEngext 27453Yanci JhoeNo ratings yet

- Wastewater Reclamation at Industrial Parks: Confederation of Indian Industry Conference On Water ManagementDocument17 pagesWastewater Reclamation at Industrial Parks: Confederation of Indian Industry Conference On Water ManagementMohammad Jailani A JamilNo ratings yet

- Non Potable Water Reuse-Quality and Costs: Marie Marguerite Bourbigot, Bruce Durham, Tom PankratzDocument14 pagesNon Potable Water Reuse-Quality and Costs: Marie Marguerite Bourbigot, Bruce Durham, Tom PankratzNermeen AhmedNo ratings yet

- Chapter 5 Conventional Wastewater Treatment Plant Design CDocument24 pagesChapter 5 Conventional Wastewater Treatment Plant Design Ctony13touchNo ratings yet

- Cs-Coluj OnlyDocument2 pagesCs-Coluj OnlyFrialynNo ratings yet

- Primary ClarificationDocument1 pagePrimary ClarificationDerek ColandunoNo ratings yet

- Water ReuseDocument1 pageWater ReuseDerek ColandunoNo ratings yet

- Process BlowersDocument1 pageProcess BlowersDerek ColandunoNo ratings yet

- Water Testing Laboratory: Johns Creek Environmental CampusDocument1 pageWater Testing Laboratory: Johns Creek Environmental CampusDerek ColandunoNo ratings yet

- Post AerationDocument1 pagePost AerationDerek ColandunoNo ratings yet

- Odor ControlDocument1 pageOdor ControlDerek ColandunoNo ratings yet

- Electrical DistributionDocument1 pageElectrical DistributionDerek ColandunoNo ratings yet

- MonitoringDocument1 pageMonitoringDerek ColandunoNo ratings yet

- Discharge Reclaimed WaterDocument1 pageDischarge Reclaimed WaterDerek ColandunoNo ratings yet

- Fine ScreeningDocument1 pageFine ScreeningDerek ColandunoNo ratings yet

- ChemicalsDocument1 pageChemicalsDerek ColandunoNo ratings yet

- Coarse ScreeningDocument1 pageCoarse ScreeningDerek ColandunoNo ratings yet

- Publicly Funded Clinical Trials: A Route To Sustained Innovation With Affordable DrugsDocument10 pagesPublicly Funded Clinical Trials: A Route To Sustained Innovation With Affordable DrugsCenter for Economic and Policy ResearchNo ratings yet

- NCP DepressionDocument2 pagesNCP Depressionhollymadison80% (5)

- (Journal of Neurosurgery - Spine) History and Advances in Spinal NeurosurgeryDocument11 pages(Journal of Neurosurgery - Spine) History and Advances in Spinal NeurosurgerycdsaludNo ratings yet

- NCP (Fatigue)Document1 pageNCP (Fatigue)student_019100% (1)

- Case Report Guidelines GeneralDocument6 pagesCase Report Guidelines GeneralDamián VaNo ratings yet

- Drug Free Australia's Dr. Stuart Reece & Culpable Abuse of PatientsDocument6 pagesDrug Free Australia's Dr. Stuart Reece & Culpable Abuse of PatientsPaul GallagherNo ratings yet

- ENT Notes For Med StudentsDocument4 pagesENT Notes For Med Studentsnikki100% (1)

- Investigatory Project inDocument31 pagesInvestigatory Project inrchandralega2205100% (1)

- Narayana Hrudalaya Heart HospitalDocument17 pagesNarayana Hrudalaya Heart HospitalWaibhav Krishna100% (1)

- Pharmacoepidemiology Pharmacoepidemiology At3: Studies Using Automated Databases GDocument27 pagesPharmacoepidemiology Pharmacoepidemiology At3: Studies Using Automated Databases GRuth Vargas GonzalesNo ratings yet

- Off Label Drug - Bu SintaDocument18 pagesOff Label Drug - Bu SintaChandra NiansariNo ratings yet

- Comparative+Efficacy+of+570 581Document12 pagesComparative+Efficacy+of+570 581Mansour ZamaniNo ratings yet

- Word File Dr.Document13 pagesWord File Dr.Pankaj HatwarNo ratings yet

- Communication: Communication Is A Process of Sharing Information and Meaning, of Sending and Receiving MessagesDocument5 pagesCommunication: Communication Is A Process of Sharing Information and Meaning, of Sending and Receiving MessagesNina OaipNo ratings yet

- Bio FoldersDocument11 pagesBio Foldersgoksel3173No ratings yet

- Laminitis - Prevention, Diagnosis and Treatment PDFDocument10 pagesLaminitis - Prevention, Diagnosis and Treatment PDFfrankyNo ratings yet

- Providing Post Advice and Post Services To Hilot ClientsDocument15 pagesProviding Post Advice and Post Services To Hilot Clientsjazzy mallariNo ratings yet

- Plan Layout For ETP - 10 KLD-ModelDocument1 pagePlan Layout For ETP - 10 KLD-Modellionisback100% (1)

- Anger Management:: UNIT - I (Lesson: 3)Document5 pagesAnger Management:: UNIT - I (Lesson: 3)harshitha reddyNo ratings yet

- Q&A401Document10 pagesQ&A401Yasmin LopezNo ratings yet

- In The Dental Implant Era, Why Do We Still Bother Saving Teeth?Document8 pagesIn The Dental Implant Era, Why Do We Still Bother Saving Teeth?Gabriela ArgeseanuNo ratings yet

- Canadian Journal of Occupational TherapyDocument9 pagesCanadian Journal of Occupational TherapyFrancesca GozmanNo ratings yet

- Pharma LectureDocument153 pagesPharma LectureMike OngNo ratings yet

- Activity 1: Science or Not Science?Document3 pagesActivity 1: Science or Not Science?Rivera MaeNo ratings yet

- The Earliest Years: 1. Research On The History or Evolution of Mental Health-Psychiatric Nursing (10 Points)Document3 pagesThe Earliest Years: 1. Research On The History or Evolution of Mental Health-Psychiatric Nursing (10 Points)Kristian Karl Bautista Kiw-isNo ratings yet

- Toronto Western Spasmodic Torticollis Rating Scale TWSTRSDocument3 pagesToronto Western Spasmodic Torticollis Rating Scale TWSTRSVioleta López Neciosup0% (1)

- Final Hospital Bill Format PDFDocument2 pagesFinal Hospital Bill Format PDFIbrar ShaikhNo ratings yet

- Reading The Holter ECG ReportDocument50 pagesReading The Holter ECG ReportOpptimuss Prime100% (2)